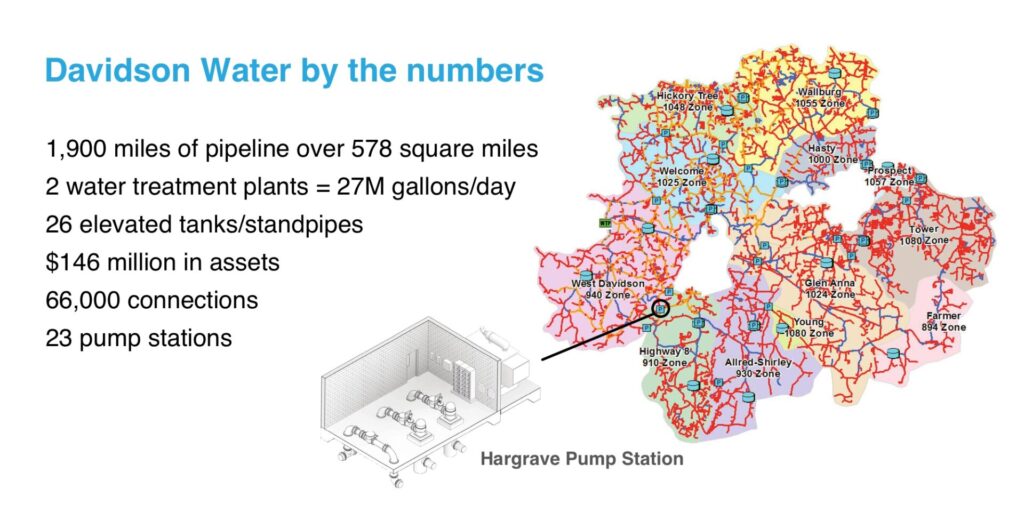

As a nonprofit membership-based organization, Davidson Water is entirely supported by the rates and fees paid by its member customers – no county taxes involved. Created over 50 years ago by enterprising businessmen who realized that this part of the popular Piedmont corridor of commerce and trade would not be able to host more business without reliable access to clean water, Davidson Water provides a stellar example of both water stewardship and a commitment to innovation, going far beyond in their customer service to ensure they have as few outages as possible.

50+ years of smart stewardship

You can trace the history of North Carolina’s Davidson Water on the office walls of its Vice President of Construction & Engineering Robert Walters. Framed plaques, awards, and historic photos hang in neatly organized rows on this friendly Southern gentleman’s walls, marking the utility’s milestones and proudest moments. Whereas some water utilities struggle to maintain and build out their basic infrastructure, Walters’ membership-based utility has racked up yet another win, recently completing the utility’s latest 50-year water master plan.

Walters has worked for Davidson Water for much of its history. He knows this system inside and out, having also originally worked for the engineering firm that designed it. Under his stewardship, the utility has continually stepped up its technological prowess, staying ahead of the curve and continuing to explore new innovations, from high-tech to low-tech.

Cleaning up the downside of aging PVC

Which is not to say that they don’t face challenges. With 70% of Davidson Water’s water distribution system comprised of PVC piping that they’ve been slowly replacing over time, they’ve experienced a significant number of water main breaks, many of which they’ve attributed to water hammer or transient events.

“Our specifications changed to Ductile Iron (Dl) nearly 20 years ago, partly because we were having so many failures with PVC,” says Walters, “but a lot of utilities, particularly rural utilities, will still install PVC if they have active, corrosive soils within their coverage area. They may prefer it simply because of the amount of mileage they can get for their money.”

“Some of our original PVC pipe marginally met the manufacturing specs, but we have some areas of very high pressure,” he continues. “You throw high pressure in with transients and pipe that’s just barely meeting the code as far as manufacturing standards… you mix all that together and you’ve got a recipe for pipe failure.”

To keep moving forward on their replacement of PVC, they regularly turn to Hazen and Sawyer Senior Associate Crystal Broadbent to perform systemwide transient analyses to mitigate the risk of leaks and breaks.

“Hazen and Sawyer have dug in really deep,” says Walters. “Not a lot of engineering firms have people dedicated like Crystal, with the depth of knowledge and practice to understand the finer points of hydraulic modeling,” he says. “She is known as a guru for transients. Not only in my world, but in the greater water industry. She understands it completely.”

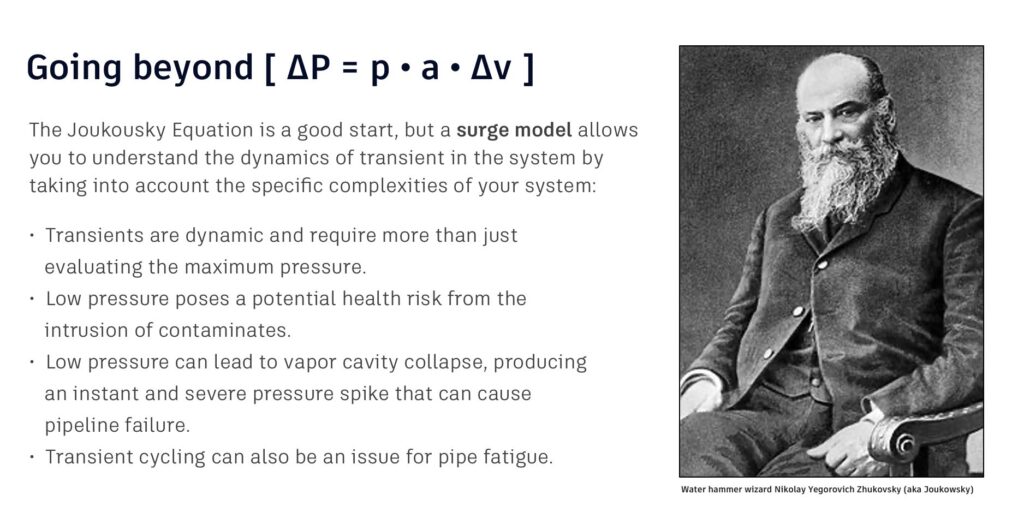

Models that begin – but don’t end – with Joukouwsky

“Full distribution surge models are important in identifying issues not just at pump stations but throughout the system,” says Broadbent. “Creating an accurate transient model allows us to understand the dynamics of the entire system. It can also help you perform ‘what if’ scenarios without actually going into the field to try things with experimentation.”

“In the past, as hydraulic modelers, we often performed simple hand calculations like the Joukouwsky Equation, but transients are really dynamic and require more than just evaluating the maximum pressure.”

“For example, we have a lot of concerns about low pressure, and that’s becoming more evident in the research, as well as with what I’ve seen with clients.” If pressure is too low – or even negative – it can lead to potential health contamination when things infiltrate into the pipe that weren’t meant to be there.

“You also have to watch for vapor cavities,” she continues, “which can create very severe pressure spikes when they collapse. Not all modeling software can pick up the instantaneous pressure spikes from a vapor cavity collapse. Therefore, if cavitation pressures are predicted by the software, we just solve for it.”

But perhaps most important for working with Davidson Water is the issue of pipe replacement. “Transient cycling is also an issue if you have a lot of PVC pipe, but good modeling can even help us understand the cycling behavior that comes from normal operations.”

Upgrading pumps with extreme attention to detail

One example of the kind of project she regularly tackles using InfoWater Pro is pump replacement. To understand every detail, Crystal leverages the transient analysis capabilities inside the app to simulate extreme surge events. Originally an add-on app called InfoSurge, this critical functionality was folded into the app earlier this year and is now standard issue for all InfoWater Pro subscribers.

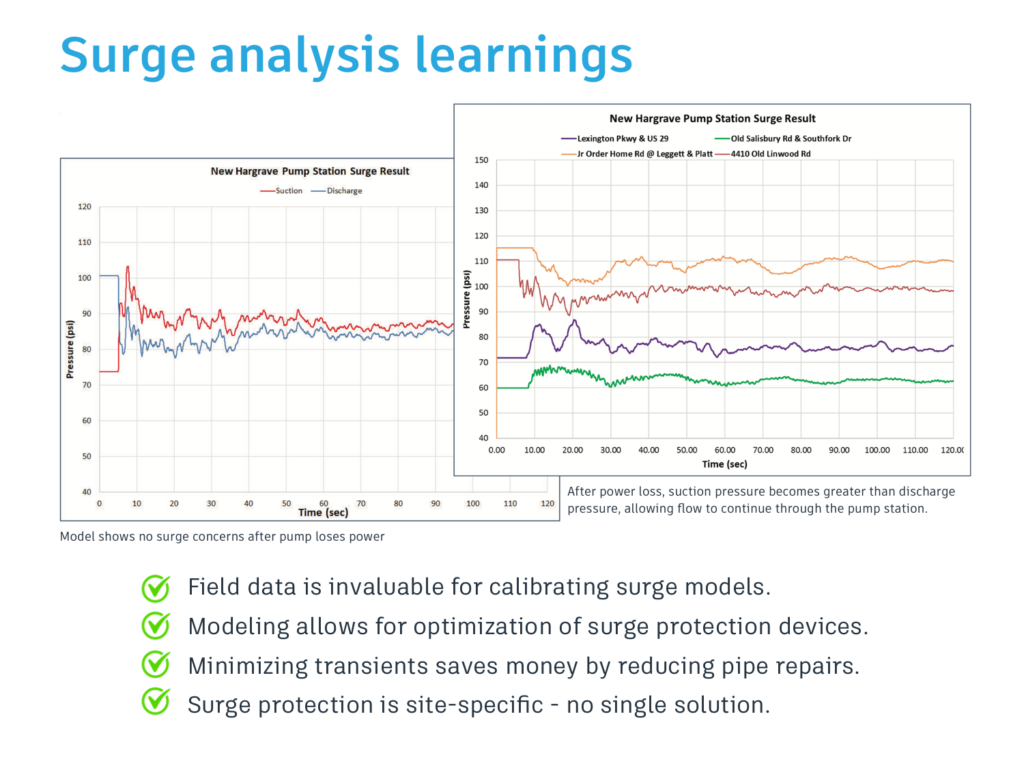

Their goal for this particular pump replacement project was to help Davidson upgrade their 0.6 MGD Hargrave Pump Station to 2.1 MGD to meet increasing water demands in this pressure zone. They knew that upgrading Hargrave would correlate to higher flows and velocities downstream, potentially increasing the risk of extreme transient pressures in the event of a pump trip or even during routine operations such throttling valves, operating hydrants, or activating pumps. They needed to carefully assess how Hargrave draws suction from a higher-pressure zone (940 ft HGL) to a lower pressure zone (910 ft HGL) to identify the water hammer potential in either pressure zones and mitigate the risk of transients.

The transient model was calibrated to field tests and used to recommend and implement a comprehensive transient mitigation strategy, without the need to skeletonize or reduce the size of Davidson Water’s hydraulic model.

To skeletonize… or not to skeletonize?

While it’s tempting to rely on skeletonization to reduce your model size and make your analysis more simplified when computing transients like this, Autodesk Technical Marketing Manager and professional hydraulic modeler Youssef Al Fahham, PE suggests rethinking skeletonization. “Model skeletonization overlooks the complex interactions and attenuations of transient pressure waves in dead-ends and low-flow pipes, which are typical targets for skeletonization and model size reduction.”

Perhaps more worrisome, it can introduce significant error in estimating extreme pressure transients. “Research has shown us that skeletonization techniques and demand reallocation strategies, if not addressed with extreme caution, can lead to poorly designed and inadequate transient mitigation strategies, or in some cases, overdesign. That’s where this whole concept of systemwide transient analysis, without the need to skeletonize, becomes critical.”

Choosing the right surge control device

They modeled the water distribution network in InfoWater Pro, including the new Hargrave Pump Station and several new water lines on both the suction and discharge sides. “During a power loss, the pump will slow down depending on the inertia. That’s why the inertial value is really important to understand,” explains Broadbent. “When there’s enough pressure on the suction side and it’s higher than the discharge side, the flow never wants to stop because the energy is always greater on the suction side than the downstream side. It always wants to keep flow going through the station.”

Broadbent’s model suggested that the risk of damaging transient pressures during a power outage was small, but water hammer effects can be mitigated even further by thoroughly testing your model with different types of surge control devices.

InfoWater Pro’s Surge Analysis feature can accommodate a wide range of commonly employed devices, including open surge tanks, closed surge tanks, discharge tanks, pressure relief valves, surge anticipation valves, air release/vacuum valves, and pump bypass lines. By considering and testing all of your options, you can choose the most reliable device and pinpoint exactly where it should be located.

“We decided to take advantage of that in our design and add a bypass check valve at the pump station so that the water would go through the check valve instead of through the pump, so the pump can come to a complete shutdown.”

By trying out a bypass check valve in InfoWater Pro to mimic the behavior of water as it continues to pass through the station, she gained a few additional benefits:

- Provide reduction in pressure fluctuations, which can help to reduce long-term cyclical pressure stress on distribution piping

- Help to attenuate unforeseen transient surges that may develop in the future

- Allow a substantial volume of water (0.8 MGD) to pass through the pump station when not in operation – and without spinning the pumps

The result? With attention to detail like this, Davidson can always handle the pressure.

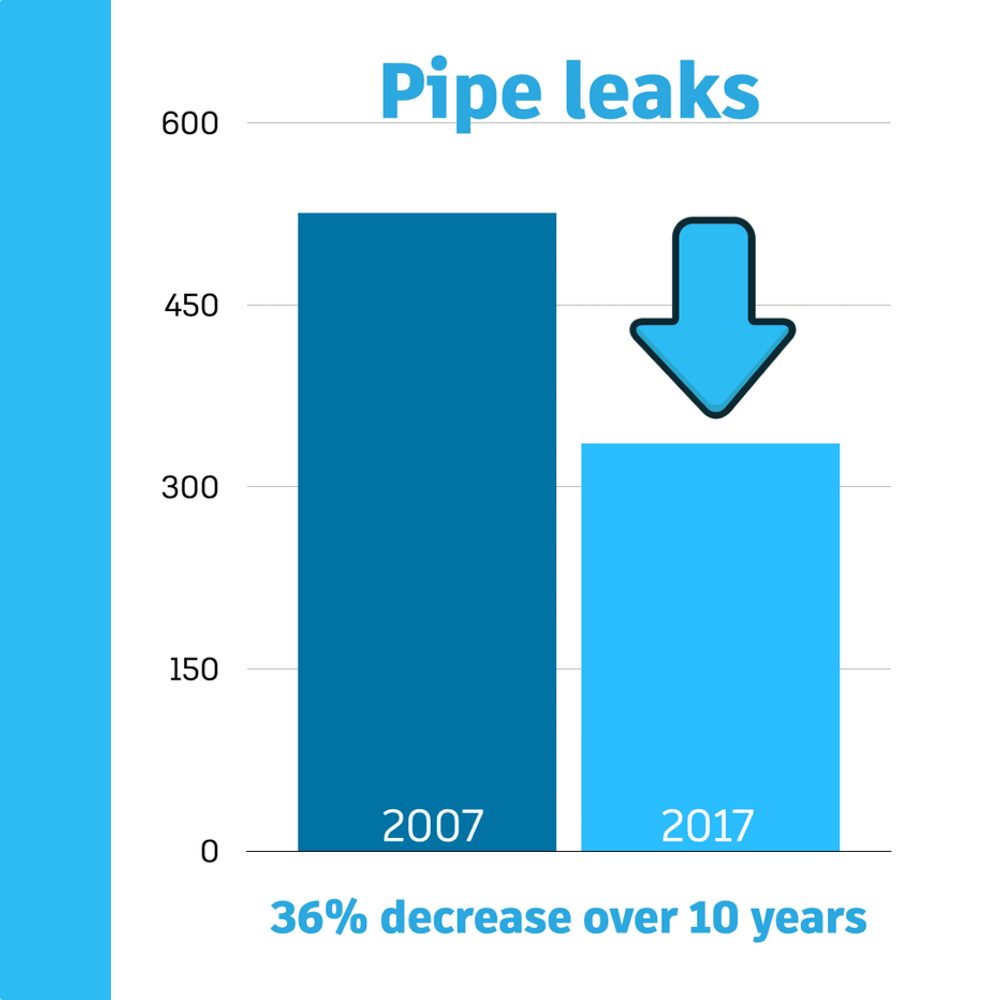

This PVC pipe replacement strategy incorporating the finer points of hydraulic modeling has already paid off big, with a 36% decrease in leaks over 10 years after replacing PVC with DI pipe. Broadbent’s focus on water hammer effects has given Davidson the clearest and most accurate view they can get into the inner workings of their pipes.

Staying ahead of high-tech (and low-tech) trends

Davidson’s embrace of transient analysis is just one in an ongoing evolution of innovations in the 43 years that Walters has been working at Davidson. A lot has changed since he began working in the water industry.

“In the late 80s and early 90s, we had hand-drawn as-builts – 8 ½ x 11 papers in a 3-ring binder. All of our crew chiefs had one,” explains Walters. “But we wanted to pursue digitalization, so we used AutoCAD to digitize our as-built drawings. And then around 12 years ago, we took those digitized drawings and put them into GIS and started building databases around them to track our assets.” They went even further, employing a firm to perform a sub-centimeter GPS grade survey, so they will always have the most accurate GIS picture possible of their system and its assets.

“I think the knowledge of hydraulic modeling was, at the beginning, pretty much nonexistent,” Walters muses. “Even now, engineers who don’t deal in hydraulic modeling – plus transients to go along with that – I’d say many of them don’t really know the impacts that can happen, or how they can be avoided.”

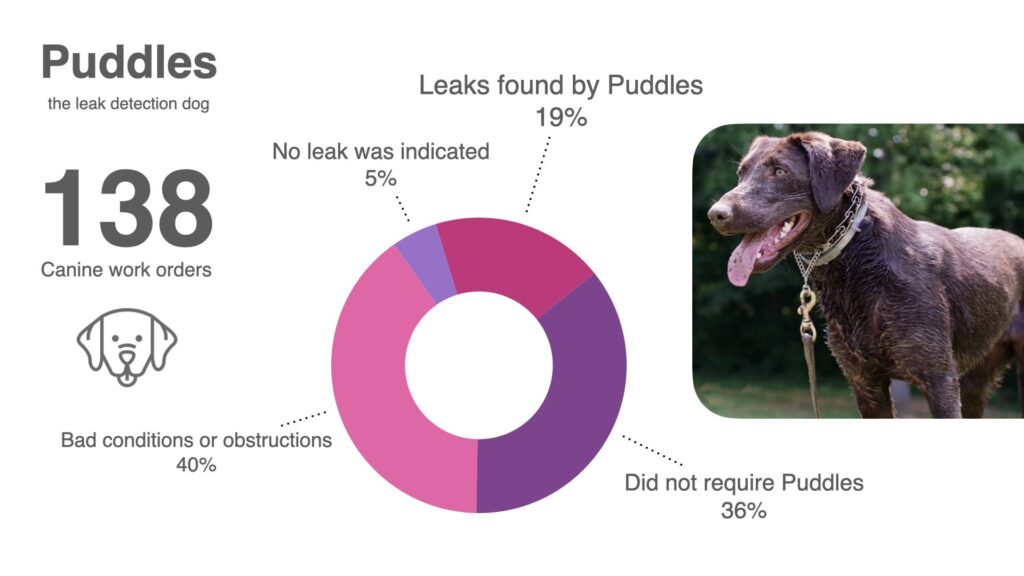

Of course, not all pipe breaks and leaks can be avoided, even with every high-tech tool. It always helps to attack the problem from different angles, which is why last year Davidson Water added a new tool to their toolbox: Puddles the leak detection dog.

This three-year-old chocolate Labrador retriever has been trained to sniff out off-gassing chlorine in treated water, sometimes from up to four feet underground. Ever the innovator, Walters is in talks with a satellite imagery provider to potentially utilize their mapping technology to identify leakage points of interest in the area, new technology that would also help make Puddles’ job more efficient – beyond the excellent work Puddles is already doing in her down time with school visits and community events.

Not every water utility out there has a leak-sniffing dog (yet?), and it sure is refreshing to see this kind of openness to experimentation. It’s also, of course, an excellent strategy for community outreach – and Davidson makes the most of it. They added Puddles’ work orders to their system, so they can track her progress and transparently report on it. They made sure to include a report of her work orders in the 2022 newsletter that they send to customers. Adorable and effective.

Building community with integrity

Davidson’s dedication to community and integrity goes far beyond Puddles:

- They’ve bumped up security beyond what is required for both their water plants and source waters.

- They completed a disinfectant conversion project from chlorine gas to sodium hyperchlorite (liquid bleach), which makes both customer and employee lives safer.

- Every year, they award four $2,000 scholarships to local university-bound high school seniors.

- They also award four $1,000 scholarships to the local community college.

- Last year, their employees gave almost $10,000 in donations to local charities and food banks.

Best of all, they’ve realized an important metric that every water utility strives for but that some simply cannot reach: a big fat zero. In 2022, Davidson Water recorded no violations of any permit conditions, environmental regulations, or environmental laws, which may have also helped them earn a North Carolina AWOP (Area Wide Optimization Program) award given by the NC Department of Environmental Quality. The award recognizes water systems that meet much more stringent regulations and achieve higher levels of water quality than is required by the EPA.

Simply put, Davidson Water goes farther and cares more than they have to because they believe in their mission and in their community. They’re rock-solid-ready for the next 50 years. And that’s as refreshing as a tall glass of cold water on a scorching hot Southern day.

Go deeper into InfoWater Pro

- Do you currently use InfoWater Pro? Skill up with InfoWater Pro’s free training courses and advanced learning modules

- Who else uses InfoWater Pro? CHA Consulting is helping Florida utilities meet ambitious reclaimed water effluent regulations

- Simulating pumps is a strength of this software. Read about Consor Engineers: Simulating sophisticated pump flows in a closed system