A predictable water supply is something many take for granted. But the mechanism to deliver water where it’s needed is anything but basic. Maintaining consistent water flow and pressure is a by-product of many components working in tandem, including pipes and pumps of different capacities, and the ability to predict, analyze, and satisfy water needs.

A pipe break or loss of water pressure can have profound effects on a city’s residents and businesses by putting a halt to operations and undermining productivity and profitability. For the utility charged with delivering the water supply, a deviation in the level of service or an interruption can have negative social, economic, or financial impacts.

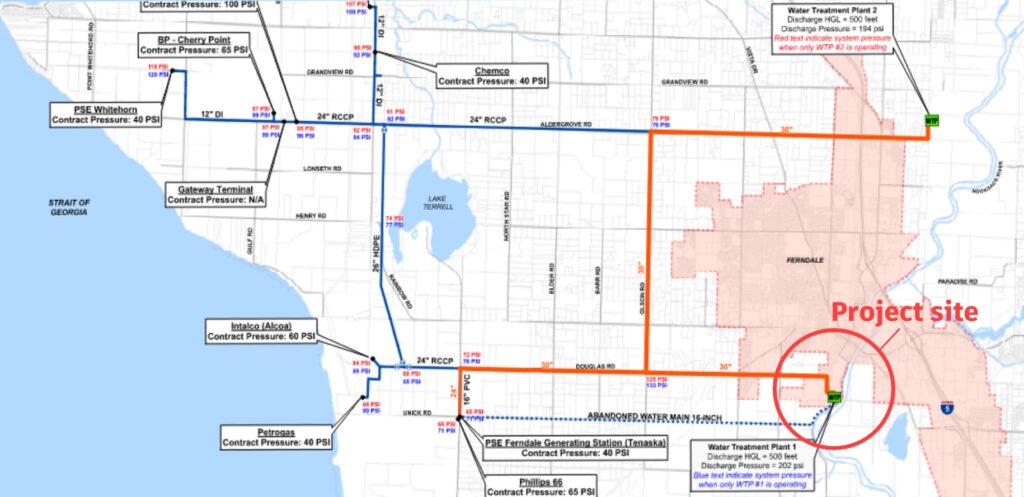

To provide reliable water delivery for the industrial and irrigation customers in Ferndale, WA, 100 miles north of Seattle, the Public Utility District No. 1 of Whatcom County (PUD) tasked Consor Engineers, a water and transportation infrastructure consulting firm, with conducting hydraulic modeling simulations to assess its current industrial water system and select new high head service pumps for a proposed new water treatment plant.

A closed system requires sophisticated analysis

The PUD water system is a closed system, meaning that it has no system storage to act as buffers to respond to demand variations. Consequently, the PUD team relies heavily on a series of high head service pumps to maintain water availability at appropriate pressure.

More specifically, the system consists of two water treatment plants with two 200 psi pump stations and more than 20 miles of 24-inch-diameter transmission mains. The PUD is planning to upgrade their oldest water treatment plant to deliver up to 21 MGD of flow with delivery pressures ranging from 40 to 100 psi. Importantly, pump and water main redundancy is not currently part of the system, increasing the risk that a pump failure or line break will result in major service disruption. This is especially crucial because of their industrial customer base, who require water 24/7.

“We wanted to use hydraulic modeling tools to assist with pump selection by simulating flow and pressure under multiple operating scenarios and a changing set of existing and future conditions,” says Professional Engineer Chadwick Johnson, summing up the challenge facing his Consor Engineers team in helping the PUD with its long-term CIP process.

Consor first had to gather credible, comprehensive information about the system’s current capabilities and limitations and forecast longer-term needs. While the PUD had some of this data, it couldn’t manipulate it to run multiple scenarios that showed system performance under anticipated conditions.

Prior to retaining Consor, the district had primarily relied upon Microsoft Excel-based models to monitor water flow and capacity. Consor used InfoWater Pro software to develop a model that could identify network constraints and generate system curves that informed the design of a new pump station in the network. The Scenario Manager application in InfoWater Pro enabled Consor to set varied hydraulic parameters to simulate different operating conditions in the Whatcom PUD’s closed system.

Flexibility to generate optimal system configuration

InfoWater Pro made all the difference in understanding how the current system performs, while helping them anticipate project performance under future scenarios. The user-friendly GIS interface helped the Consor team create a digital twin of the Whatcom PUD system that they employed to model different configurations that used both current and new pump and pipe capacity.

Specifically, InfoWater Pro helped Consor Engineers:

- Analyze system-wide capacity under various scenarios

- Assess fire flow needs for anticipated developments

- Plot a system development curve over a 20-year timeline

- Select appropriate pumps to match growth projections

InfoWater Pro significantly simplified this work, and the Scenario Manager enabled the team to easily toggle between results of the different operating scenarios to arrive at an optimal configuration. At key points, Consor validated the hydraulic model results in relation to field SCADA data from the Whatcom PUD.

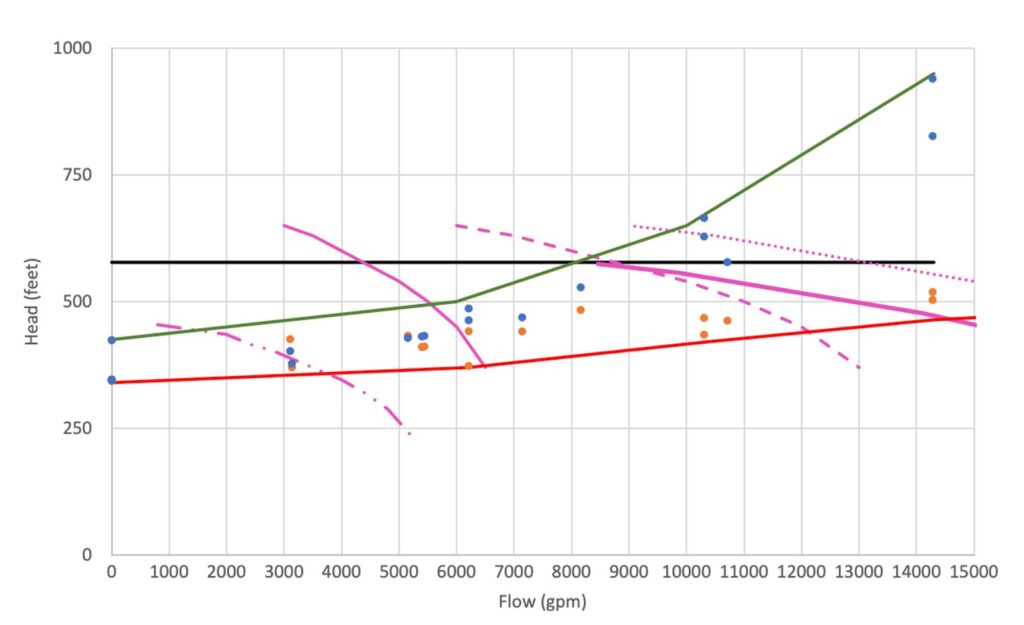

With the hydraulic model built and validated, Consor used the InfoWater Pro System Curve feature to develop and analyze existing and future system curves. This enabled the selection of appropriate pumps to cover anticipated operating needs without compromising pump performance or efficiency. The InfoWater Pro hydraulic model also helped Consor confirm that the proposed pumps would not drive the system’s operating pressures higher than the pipe pressure ratings, which could have catastrophic consequences.

With credible system curves, Whatcom PUD and Consor were able to verify their proposed pump design against the existing capital improvement plan that called for:

- Various pump replacements

- Various water main extensions

- Built-in pump redundancy to ensure supply continuity

For its part, Consor was very satisfied with InfoWater Pro, noting that the model enabled its team to optimize pump selection while accounting for operational constraints, including variations in present and future demand projections and possible pipe breaks in Whatcom’s closed water system. Finally, because Infowater Pro uses the EPANET engine, it could easily be exported to other modeling platforms, which was useful in helping Consor share the model with a surge analysis specialist.

Finding a balance with hard data

Whatcom PUD leaders knew that any request for capital funding had to be grounded in hard data and reflect a measured approach to investment, one demonstrating that proposed improvements would maintain service through a variety of conditions and respond to increased future demand but not result in unnecessary overspending. Whatcom PUD integrated the output of the hydraulic model to prioritize the spending of capital funds and, ultimately, to support the goals outlined in its capital improvement plan.

Using powerful tools like InfoWater Pro to gain deeper insight into current and future operating capacity has helped increase the Whatcom PUD’s confidence in its ability to deliver water supply when and where it’s needed throughout its jurisdiction.