Tasked with strict drainage compliance requirements for a solar panel farm in the UK countryside, Project Centre used their brand-new drainage software to streamline design workflows and achieve the results they needed.

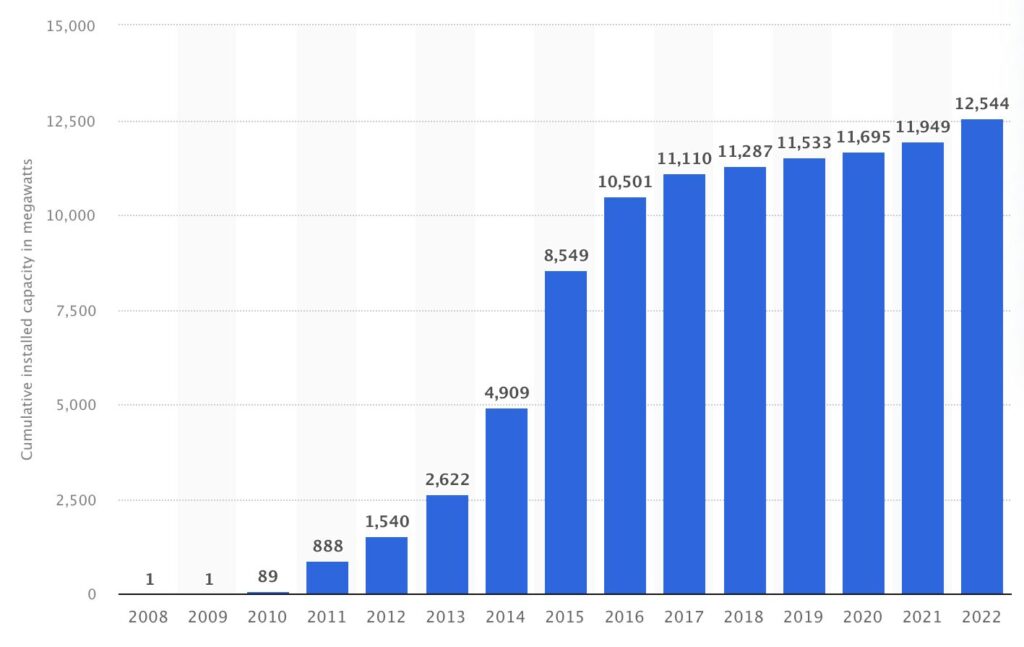

Solar farms are sprouting up all across the UK, and this green transition trend has become a bright spot in the UK’s economy. Converting greenfields into solar farms is a big change in how the land has traditionally been used, which means both regulators and everyday citizens are watching closely at how these new developments are implemented. This means drainage designers must follow every environmental rule and best practice and be at the top of their game to show how their nature-friendly implementations are backed by solid science.

Adopting InfoDrainage for nature-friendly design

Because Project Centre’s team of engineers long relied on the capabilities of MicroDrainage, they had been hesitant to switch to the next-generation InfoDrainage app. This is not uncommon. Engineers naturally become attached to their ways of working, particularly if they feel that they’ve locked down their workflows as a group, relying on trusted software to always spit out reliable results. This hesitance to begin anew is often bolstered by the argument that onboarding and learning new software tools could mean potential billable time lost, which is a legitimate fear. Or, as Principal Civil Engineer F. Javier Soto puts it, “Time is money.”

Ultimately, they wanted more power than MicroDrainage could provide, so their teams took the leap and collectively upgraded to InfoDrainage, which went more smoothly than expected. “A designer was new to this software as a whole, and in just two weeks, he was able to onboard with InfoDrainage to a surprising level,” says Soto. He credits the “extremely user-friendly” interface for the quick uptake. “It just makes sense when you get into it.”’

They weren’t alone in the transition. Soto gives a tip of the hat to Autodesk support staff and their availability to meet with Project Centre’s IT and engineering teams. “The Autodesk support team walked them through everything they needed to know.” With their teams up to speed, they put InfoDrainage to the test by tackling a project with strict drainage compliance requirements.

Designing with strict requirements

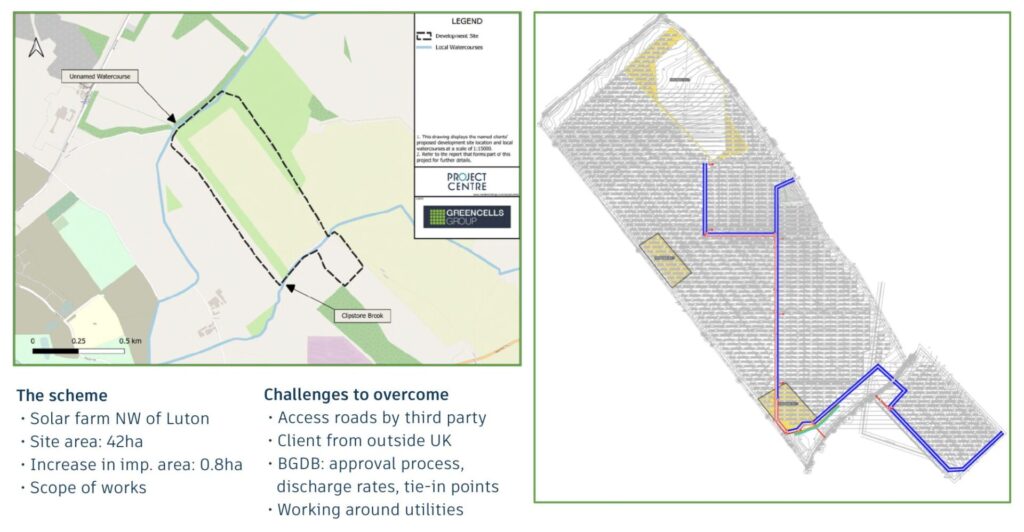

For this project, they were tasked with addressing drainage across a 43ha 20 MW solar farm near the town of Hockliffe, north of London. The site’s plan included a large greenfield with a proposed access road running through the middle to provide workers with access to service the solar panels. However, the land also had an existing watercourse running through it, with a regulatory body overseeing the water’s flow and quality. So, while designing for the site itself was relatively simple, the team was faced with strict drainage design requirements.

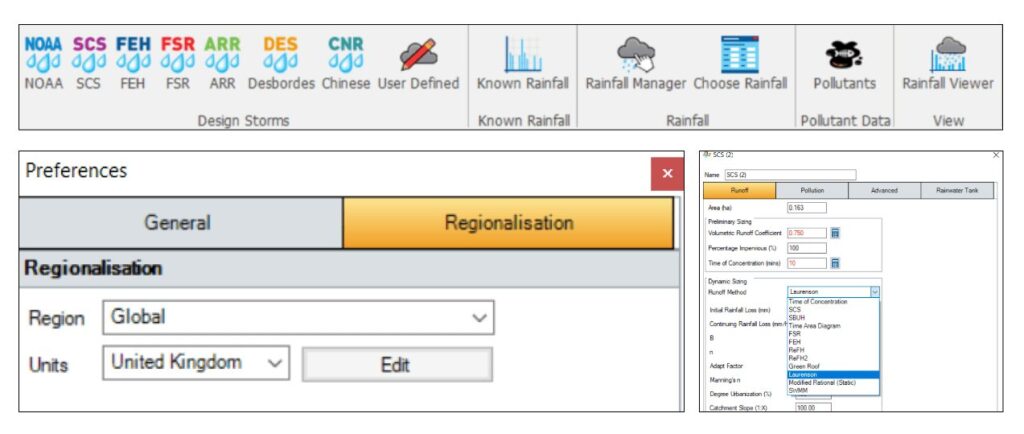

For example, the regulatory body, the Bedford Group of Drainage Boards, mandates that flow into the existing watercourse must be kept constant and that they must attenuate their new discharge rates to match what was already present on the site. Doing so would require an accurate model of the site in Civil 3D, as well as a drainage model in InfoDrainage to ensure that all of the flows matched up, which needed to be completed well before construction began.

One of the main challenges in designing this solar farm’s drainage structures was a lack of space. The main priority of any solar farm is maximum efficiency. They want to generate as much electricity as possible, which means packing the site with as many solar panels as feasible. While this is excellent for maximum power generation, it doesn’t leave much room to solve strict drainage challenges. As such, the access road running through the site was the only area they could use to insert drainage structures.

Project Centre also needed to identify pinch points and work around all the power cables that were strewn across the site. They loaded up the surface in InfoDrainage, ran deluge analysis, and quickly identified where the flow rates were going to be the highest to implement appropriately sized drainage structures.

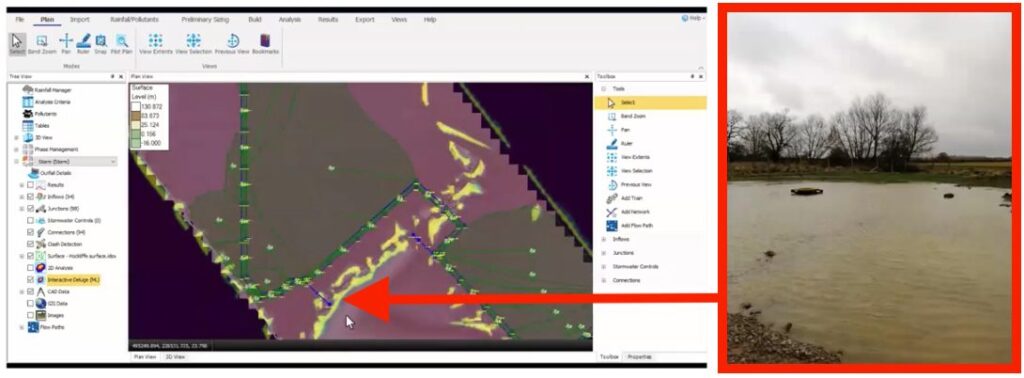

Once drainage structure placements were determined, the team had to ensure the model was verified against observed flooding events. In addition to flow rates provided by the regulatory body, the team also had historic flood images from the customer, which detailed water levels during measured heavy rain events.

These photos helped them visually see that the model of the site they built in InfoDrainage was accurate to reality, but they also leveraged the regular Deluge and ML Deluge tool inside of InfoDrainage to establish exactly where the flooding hotspots were, simulating a rain event that presented areas of ponding and channeling graphically in the app. “The Deluge map that they put together in five seconds matched perfectly with the flooding photos the customer shared with us,” says Soto.

Pairing InfoDrainage with Civil 3D

Like many drainage designers, the team was leveraging Civil 3D for site design. In fact, all the site’s data was captured in their Civil 3D model. “MicroDrainage was not easy to interact with Civil 3D,” says Soto, but “InfoDrainage’s interconnection into the Autodesk ecosystem was a game changer,” bridging the gap between site design and hydraulic modeling.

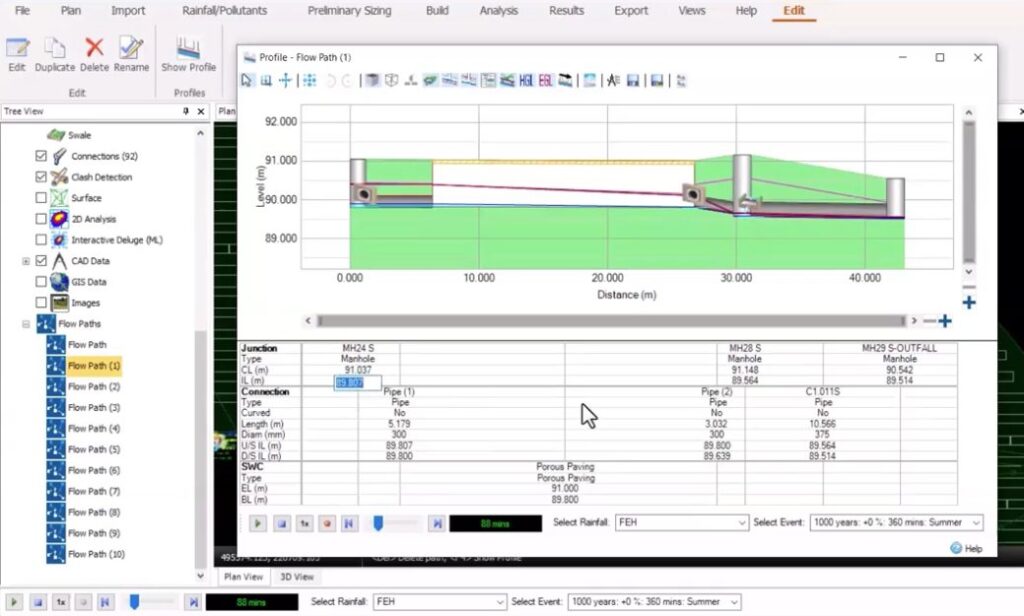

The team also calls out InfoDrainage’s Profile tool, which allows you to see a representation of your site in a “live” and responsive profile view, which you can also output to Civil 3D or as an image. In general, they found the user interface radically different, but in a good way. “It is mind-blowing compared to what we had in the past,” says Soto. “You can change whatever you want, wherever you are, in whatever view you are in. Schedules, Profile view, Site view – you can make responsive design decisions and see that they’re updated everywhere in the model.” With InfoDrainage’s integration with Civil 3D, this also meant that the corresponding Civil 3D model was updated whenever changes were made.

Making changes easily was not always a strong point of MicroDrainage. Once you laid down a sub-catchment, you couldn’t always edit or move it, which often meant deleting and redrawing a catchment. But since sub-catchments are independent objects in InfoDrainage, designers can now seamlessly edit their catchments.

“Need to change all of your drainage structures from pipes to ditches? InfoDrainage allows you to select everything and change it all at once,” says Soto. “In other software, you’d have to do this all manually, changing 300 structures one by one. It’s clear that the makers of InfoDrainage worked in the industry and knew what they were doing.”

Watch the webinar. Download the PDF.

Soto and InfoDrainage Product Manager Samer Muhandes walked through the entire project in a recent webinar. They provide demonstrations of the features at work for this project, and they show you the tools they used like the Machine Learning Deluge tool, which leverages Autodesk AI.

Want a shareable version? Feel free to grab a copy of this case study as a PDF.

Go deeper into the story

- Curious about solar farms? GreenMatch has an excellent primer on the subject: The Solar Landscape in the UK: An In-depth Look at Regional Solar Farms

- Peruse the Central Bedfordshire Solar farm development flood guidance, which has some excellent best practice recommendations.

- What’s driving so much resistance to adoption of solar in the UK? It’s often the misguided perception that the land will be wasted if not farmed. Why supercharging solar in Britain isn’t at odds with safeguarding food security.

- A lot has changed from MicroDrainage to InfoDrainage. Here’s 10 things you can do in InfoDrainage that you can’t do in MicroDrainage.

- Want to give InfoDrainage a try? Download the 30-day free trial (no credit card needed).