Water distribution utilities around the world are facing a rising number of challenges to maintain and operate their increasingly complex networks on tighter and tighter budgets. In the United States, 6 billion gallons of treated water is lost daily and 30% of water utility budgets for operations and maintenance are spent on energy costs for pumps and plants. With 12,000 miles of pipes replaced annually compounding these issues, there’s no question that gaining greater visibility and understanding into potable water networks setup, operations, and maintenance cycles would be heavily beneficial.

Commonly referred to as dynamic operational modeling, this workflow of creating a dynamic digital twin hydraulic model of your water network is still a relative rarity in the world of water utilities, but it doesn’t have to be.

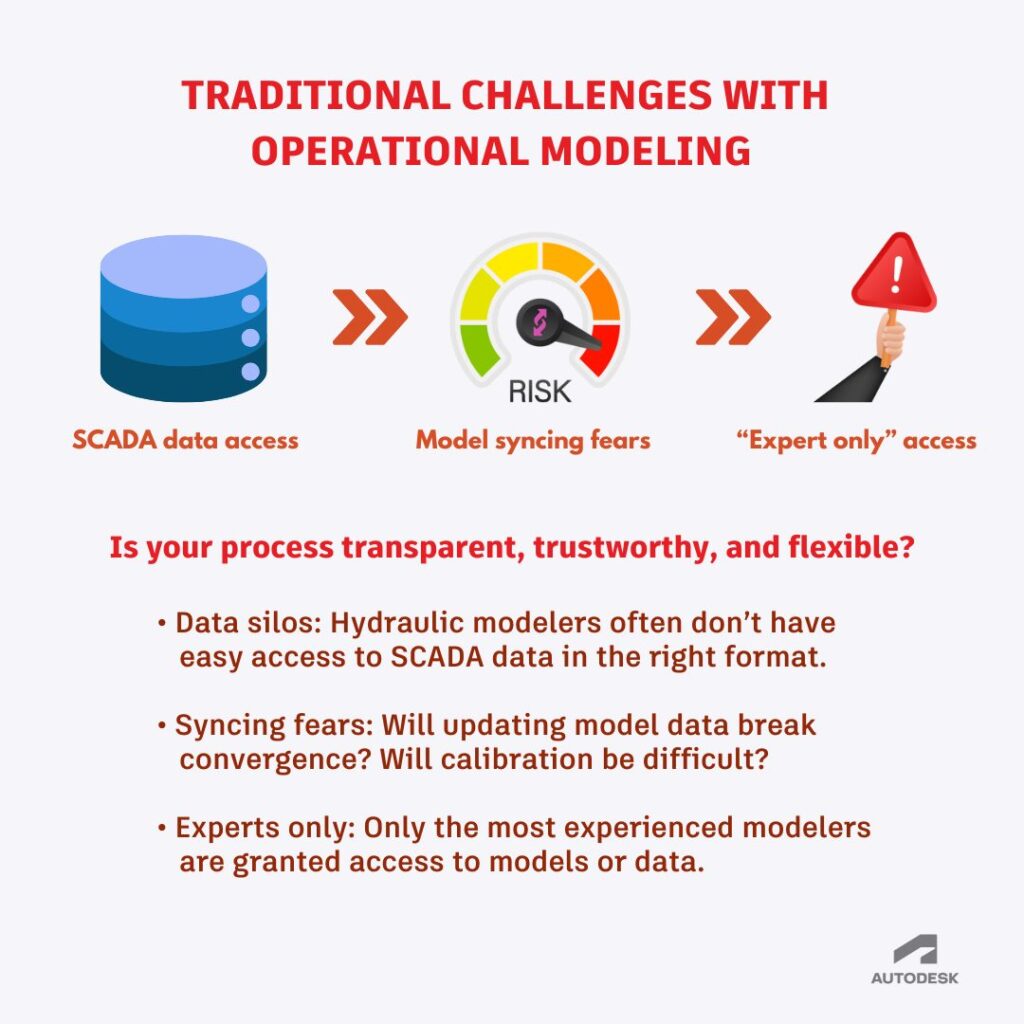

The reason models of this complexity are rare come down to three major factors:

- Data access: Hydraulic modelers and infrastructure owners often don’t have easy access to SCADA data in the right format.

- Model updates: Maintaining the model data means fixing broken links in data, requiring frequent recalibration.

- Model access: Typically, only the most experienced modelers have access to these models and the necessary skills to utilize them.

While these three reasons keep many water utilities from building and utilizing real-time hydraulic models, these hurdles can be overcome and are worth the effort. The overall benefits to improved operation, decrease in leaks, lower pumping costs, and fewer consent decrees are clear, so let’s look at a practical workflow to build a dynamic digital twin hydraulic model.

While most water utilities employ sensors and utilize hydraulic models, as we noted before, they are usually not connected to maximize their impact. How can you connect them? We’re going to walk through the practical skills and tools needed to integrate sensor data and analytics into InfoWater Pro using Info360 Insight. This blog post is based on an extensive Autodesk University class, Using Sensor Data to Drive Dynamic Hydraulic Models in InfoWater Pro with Info360 Insight, so you can also watch the full presentation if you want to go deeper into this workflow.

Operational modeling with InfoWater Pro and Info360 Insight

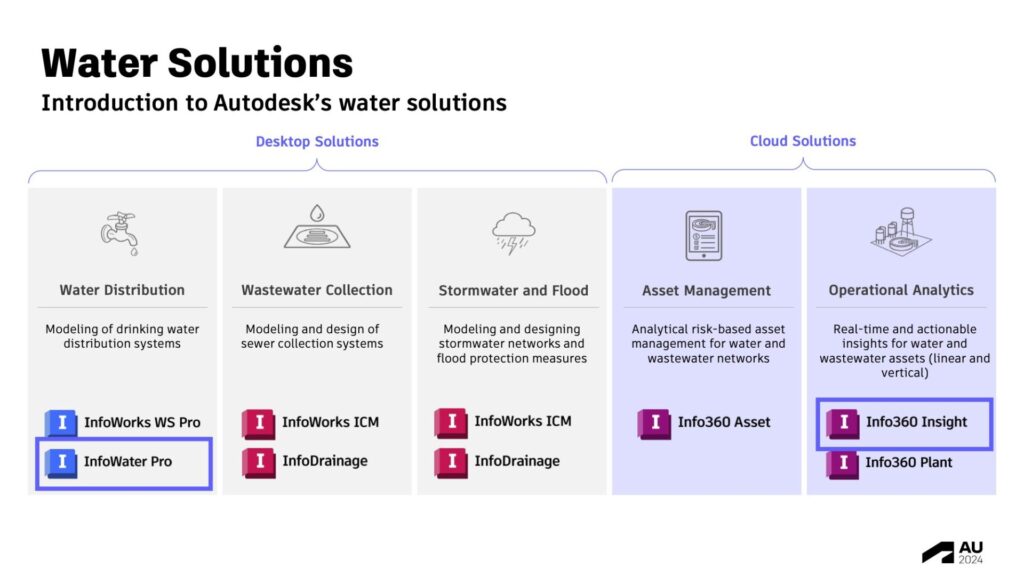

Not everyone is as familiar with the Autodesk water portfolio as we are, so let’s start with a quick background of the two different solutions we’ll use to build dynamic digital twins for water networks.

InfoWater Pro

InfoWater Pro is an advanced hydraulic simulation and modeling tool for water distribution system master planning, compatible with EPANET 2.2, and integrated with ArcGIS Pro. Engineers use InfoWater Pro software to model water distribution systems in an easy-to-use geographic information system (GIS) interface. You can:

- Leverage spatial analysis tools available in ArcGIS Pro to help with model building and management

- Analyze and understand criticality in your system, including pressure transient events

- Present results clearly and share them in ArcGIS Online

Info360 Insight

Info360 Insight is a cloud-based digital twin solution for operational analytics, incident management, and compliance reporting. You can configure sharable digital workspaces to help you unify network data for optimizing operations, understand how your decisions will impact customers, and automate regulatory reporting.

These are the tools we’ll be using to achieve the next generation of digital twins for your water network. Now, let’s discuss the workflows for building out a dynamic operational digital twin.

The workflow for building a dynamic digital twin

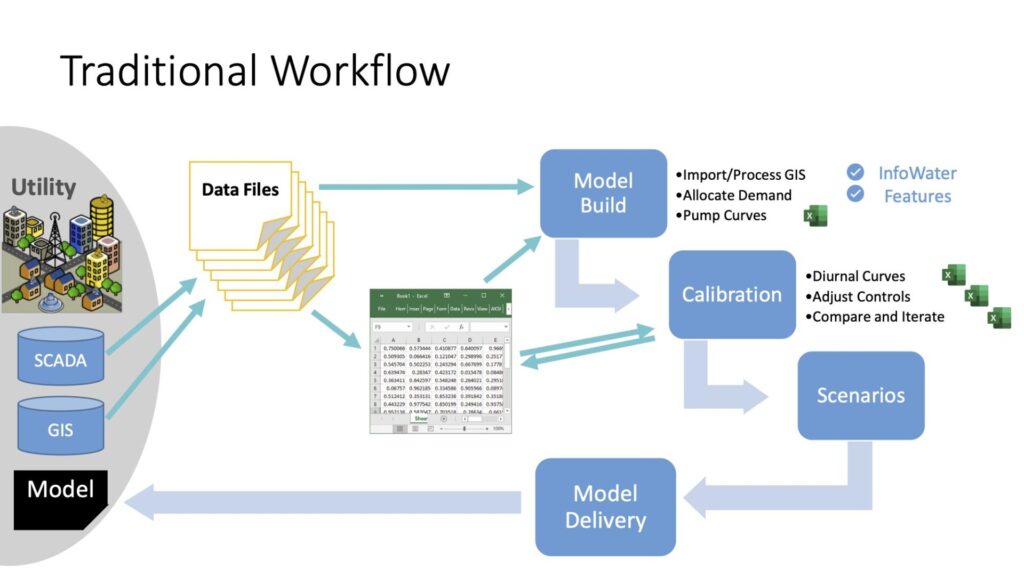

A traditional model building workflow typically involves a variety of disparate data connections, with data flowing from various sources at different phases throughout the process. SCADA and GIS files might have to be manually imported and integrated through the Model Build phase, with Excel utilized to calibrate and validate the model. There’s a lot of back and forth here, which creates the possibility of slight errors and calibration issues throughout the process. Note that this is also not a real-time model.

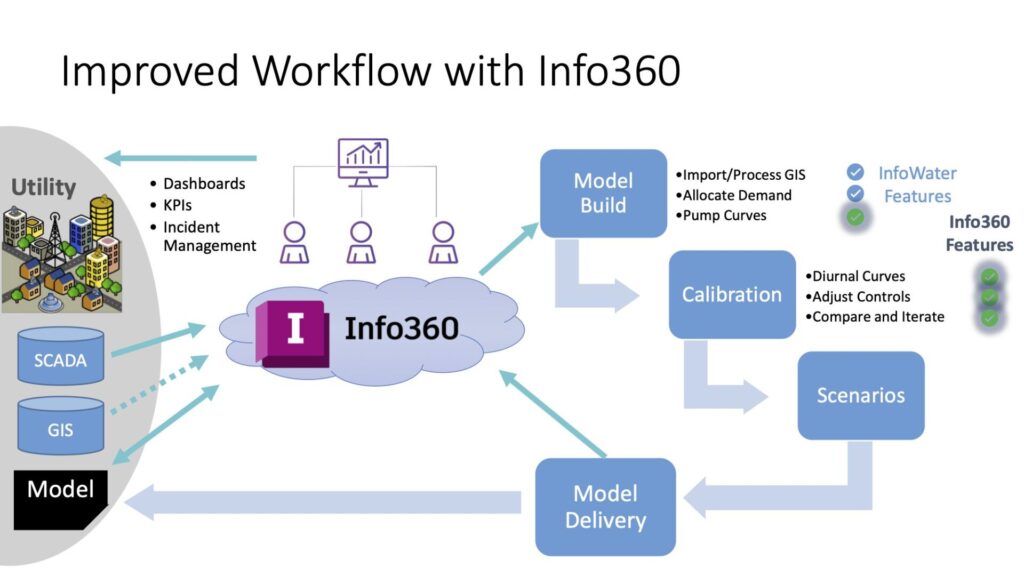

With Info360 Insight in the mix, you can streamline the typical model build process and calibration by providing centralized access to sensor data with analytics for several steps in the process, eliminating much of the back and forth and providing a cloud-based real-time dashboard that helps you utilize a dynamic digital twin.

With the connection between hydraulic modeling and operational analytics data, you’re left with what is essentially a dynamic digital twin of planning, design, and network operations. So then, how can these dynamic digital twins be used to operate water networks more efficiently?

Use cases for dynamic digital twins

There are a variety of uses cases for dynamic operational modeling that can work to reduce and eliminate many of the operational inefficiencies mentioned at the beginning of this article. Let’s look at the five main use cases for these operational digital twins.

Ongoing model validation

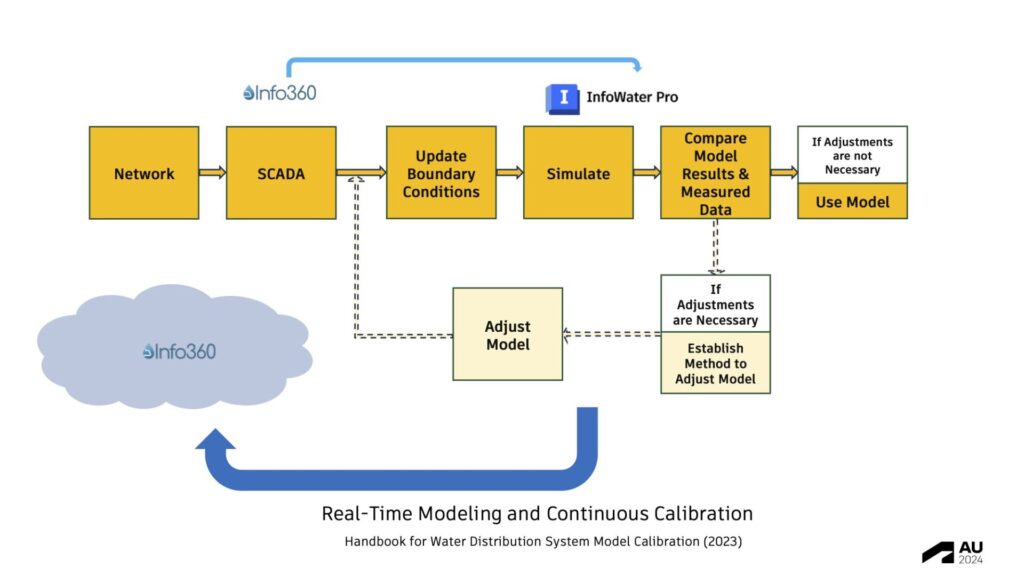

Real-time modeling and continuous calibration of water distribution systems provides utilities with valuable tools to optimize operations and improve efficiency. By incorporating real-time data like flow rates, pressure levels, and usage patterns, utilities can create adaptable models that respond to current conditions in near real time.

Continuous calibration keeps these models accurate, helping to quickly detect issues like leaks, inefficiencies, or bottlenecks. This proactive strategy enables utilities to address problems swiftly, reducing water loss, preventing expensive repairs, and minimizing service disruptions. Additionally, real-time data enhances energy efficiency, improves resource management, and supports smarter infrastructure investments. Overall, real-time modeling and continuous calibration not only save time and money but also enhance service reliability and sustainability, benefiting both utilities and their customers.

Anomaly detection

Drinking water systems are typically designed to operate within a set of expected parameters, often represented by a system schematic. A well-calibrated hydraulic model can accurately reflect these expected conditions. However, there are times when the system operates outside of these norms, requiring increased attention and intervention.

With a digital twin system, you can:

- Identify anomalies through a dashboard, such as tank levels outside of the expected range or unexpected pressure fluctuations in a specific zone

- Place these issues within a specific time frame for better context

- Investigate them visually on the map

- Pinpoint the root causes, such as malfunctioning sensors or incorrect valve settings

- Explore potential solutions to resolve the issues

As water utilities gain more experience with anomaly detection, they’ll develop a deeper understanding of how their systems behave hydraulically, improving their ability to manage and optimize operations.

Source tracing

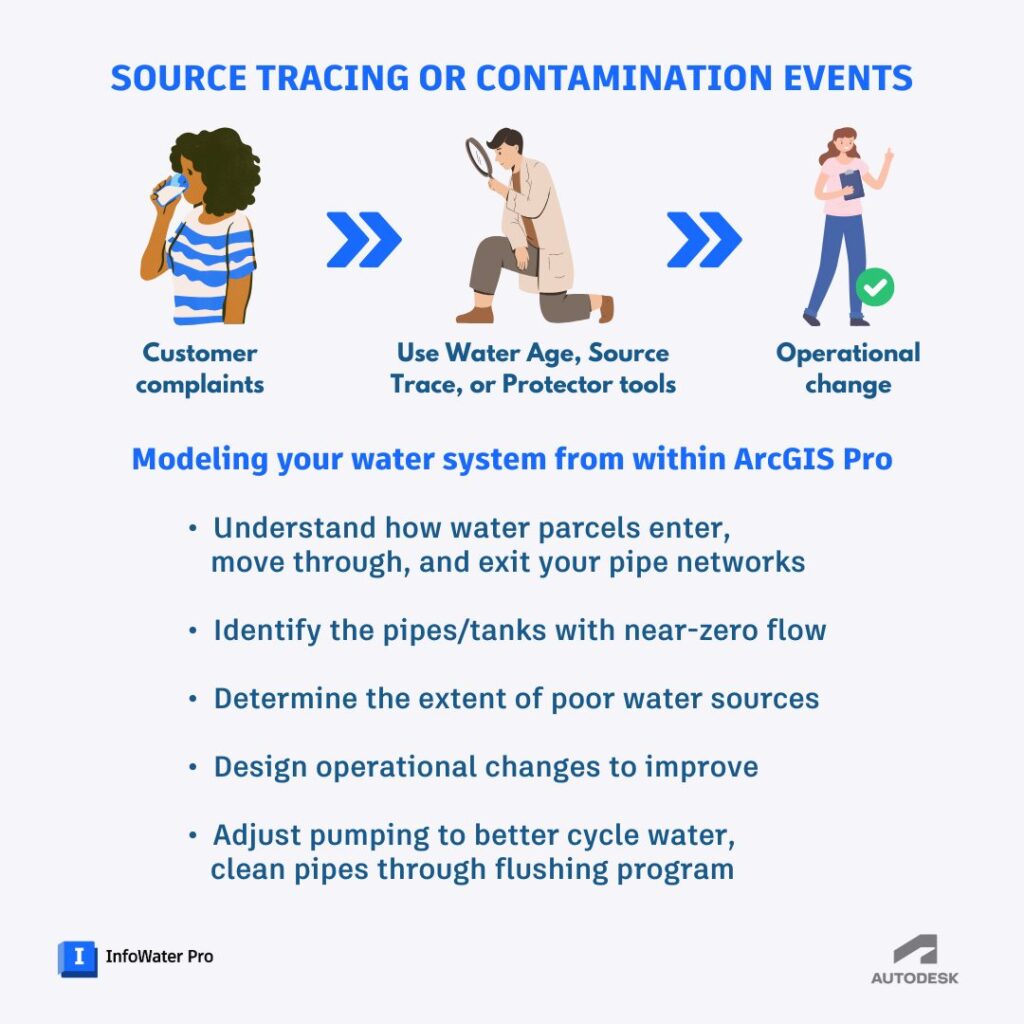

You can use operational modeling to trace water sources, identify factors contributing to poor water quality, and explore potential solutions. Here’s what that process might look like:

- Geolocate customer complaints: Map out where water quality issues are being reported

- Simulate water age and trace sources: Track the age of water and identify its path through the system

- Test control changes: Experiment with system adjustments to enhance water quality

- Plan flushing activities: If needed, schedule targeted pipe flushing to improve water quality

This ultimately results in your ability to:

- Pinpoint and address stagnant water areas

- Gain insights into water flow throughout the network

- Optimize water distribution and cycling for better overall quality

Post-event analysis

Events like pipe bursts or power outages can disrupt distribution systems and have lasting consequences. Analyzing these events helps utilities improve their operations and prevent future issues. When you have a dynamic digital twin hydraulic twin, your process for post-event analysis could look like:

- Event dashboards: Info360 Insight delivers real-time alerts and interactive dashboards, providing data-driven analytics to quickly assess and understand the issue.

- Simulate the event: Once the data is integrated into Info360 Insight, InfoWater Pro can simulate the incident. This allows modelers to evaluate the full scope and impact of the event beyond what sensors alone can reveal.

- Explore alternatives: InfoWater Pro allows the creation of various scenarios, helping modelers test different operational changes like re-zoning valves or adjusting pumping strategies to mitigate the event’s impact.

- Action plan recommendations: Results from the simulations in InfoWater Pro can be sent back to Info360 Insight, where an operations team can review and develop a response plan.

With this workflow, you can gain insights from previous incidents to improve your future responses, streamline reporting and analysis, and create actionable plans to address and prevent similar disruptions in the future.

Operational forecasting

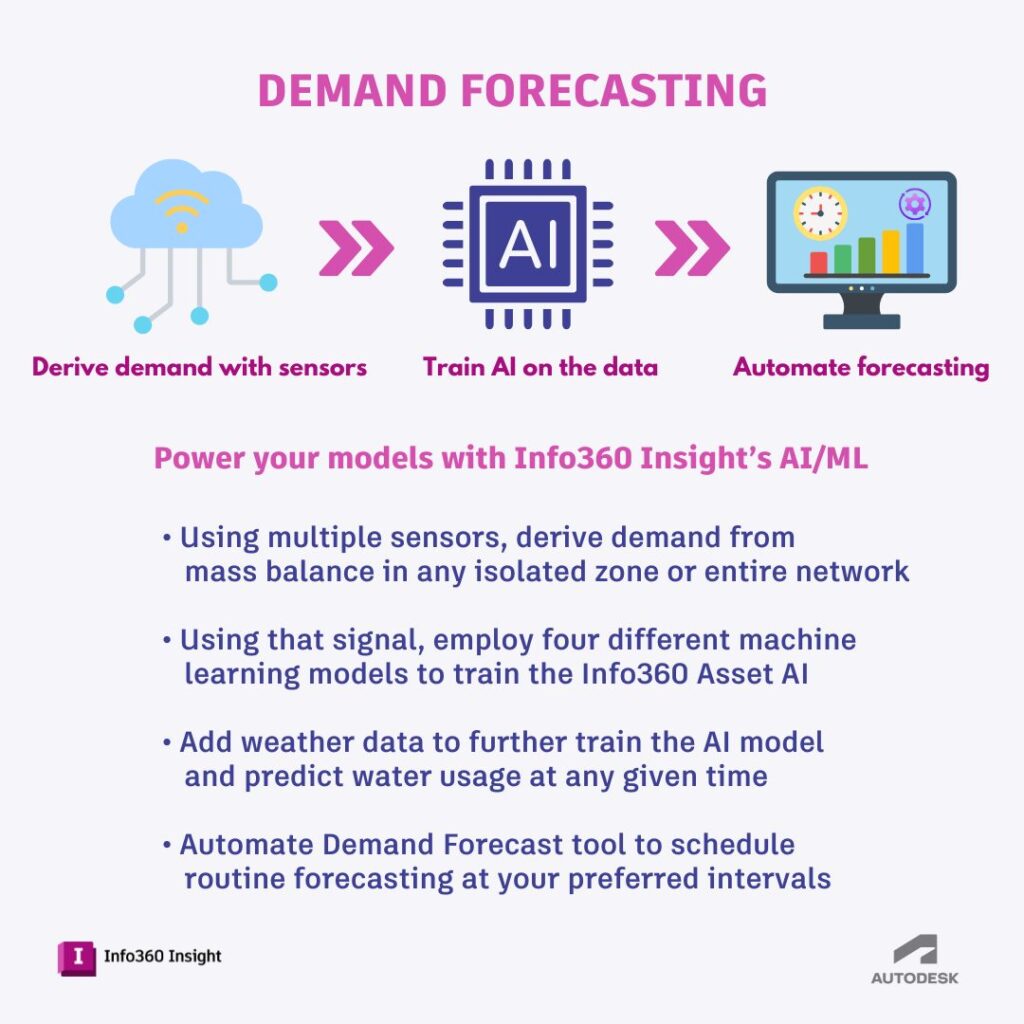

Forecasting operations helps water utilities plan and optimize their actions before they’re put into motion. With tools like Info360 Insight, operators can use the Demand Forecast tool for specific zones or DMAs, which analyzes historical data and weather patterns to train the AI using four different machine learning models. This allows you to accurately predict how much water will be needed and when.

From there, InfoWater Pro can take those demand forecasts and current boundary conditions to model future scenarios at a detailed asset level. Operators can create and test multiple control scenarios to determine the best strategies for water delivery or even plan maintenance activities. Once simulations are complete, the results can be shared back to Info360 dashboards, allowing operations to track and adjust their approach as real-world conditions unfold. This proactive approach helps reduce operational risks and boosts overall performance, leading to lower energy costs, better water quality, and less non-revenue water.

Moving to the next generation of operational digital twins

At the end of the day, the tools already exist for water utilities to ingest, understand, and utilize hydraulic models alongside sensor data for better operations. While you might not be ready to embark on this a live modeling journey just yet, understanding the processes and tools available to you is vital to guiding your digital transformation journey.

If anything we’ve discussed in this blog piques your curiosity, you can watch the fantastic session on this blog’s topic from AU 2024 to dig into the process more granularly. Want to know more about Info360 Insight? This interface walkthrough covers the high-level details.