Summary

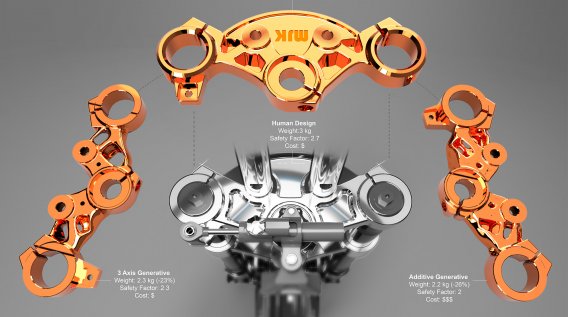

Generative design, to date, is innovative, but creates wildly different designs without taking cost into account. That's a problem, because most designs are only suitable for small-scale additive manufacturing techniques and not the large-scale subtractive techniques required for practical production.

Generative design fuels the idealistic side of engineers, allowing them to create increasingly complex, but sometimes unfeasible, geometries. When engineers employ generative algorithms to take cost into account, it often hampers innovation and adds time to the design process.

Next-generation generative design allows engineers to assess cost, treating it as a variable that’s tracked across the design process. This cost-analysis strategy allows engineers to evaluate costs across common manufacturing techniques and using regional economic information. They can input the production volume, material details, and geometry to obtain an estimated cost and explore the resulting outcomes.

Generative design has long been an idealistic virtual assistant but it is now getting reined in, allowing engineers to create smart, on-target designs. As a result, generative design is now a source of innovation as well as pragmatic efficiency for the engineering community.