& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

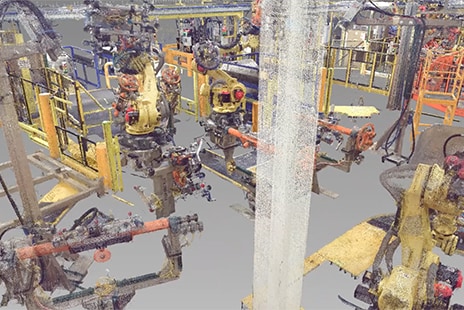

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

In the factory world, teams working in silos and using disparate tools leads to clashes, delays, and rework. Integrated factory modeling connects, organizes, and optimizes all phases of factory projects by centralizing data management and allowing everyone to work from a single source of data–in real time.

Learn how one engineering pro helped companies digitalize their processes to save time and reduce costs with integrated factory modeling.

When the market drives change, retool and reconfigure the factory even faster to improve time to market.

Coordinate the many complex disciplines involved on factory projects in a common data platform.

Offer more value to manufacturing clients by extending critical services across the factory lifecycle.

– Chris Mounts, Director of Laser Scanning and CAD Services, Production Modeling Corporation