& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

As you grow, Fusion Operations evolves with you, ensuring scalability and leadership. Don't let outdated systems hold you back. Embrace the future of MRP with Autodesk Fusion Operations.

Autodesk Fusion Operations's MRP capabilities ensure that you have the right materials, in the right quantities, at the right time. By leveraging real-time data, it helps in effectively managing both independent and dependent demand items.

From raw materials to human resources, Autodesk Fusion Operations ensures that every component of your manufacturing process is utilized efficiently. This is crucial for manufacturers adhering to Lean Manufacturing methodologies.

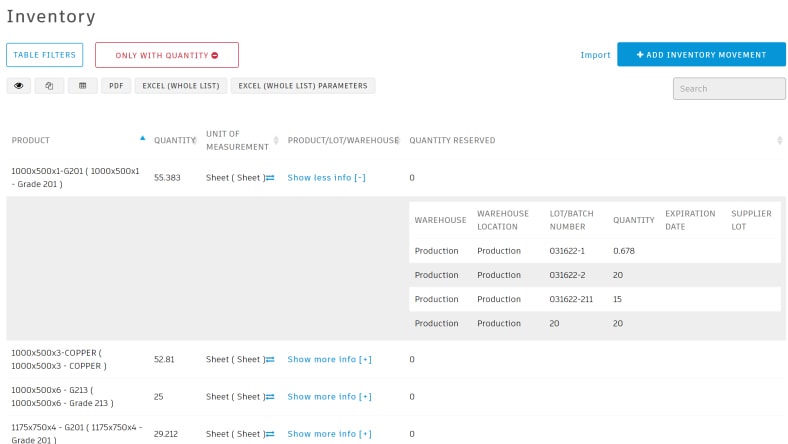

By optimizing inventory levels, Autodesk Fusion Operations helps in reducing carrying costs and potential stockouts.

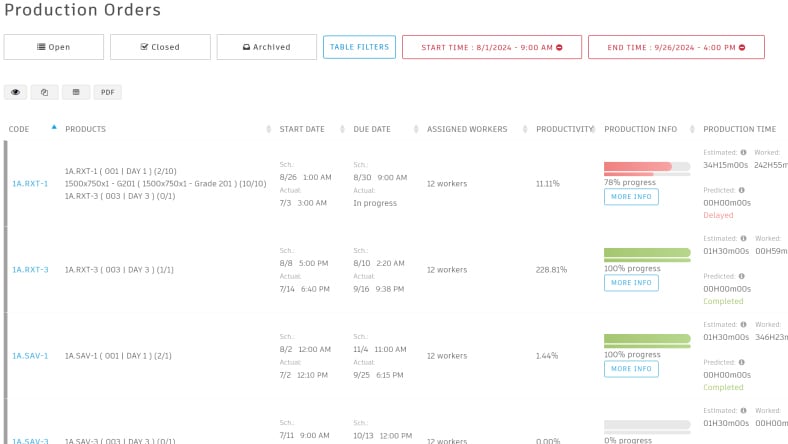

Utilize accurate production planning and scheduling to make the most of your labor and equipment. With improved operational efficiency, offer your products at competitive prices without compromising on quality.

Productivity increase year over year, reported by ReChaco, a division of Chacos.

Less rework year over year, reported by ReChaco, a division of Chacos.

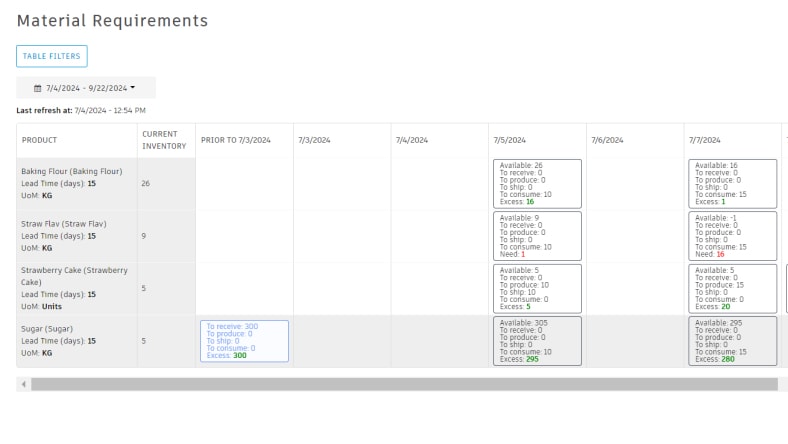

Visualize supply and demand to understand material needs and expected inventory over specific date intervals for products.

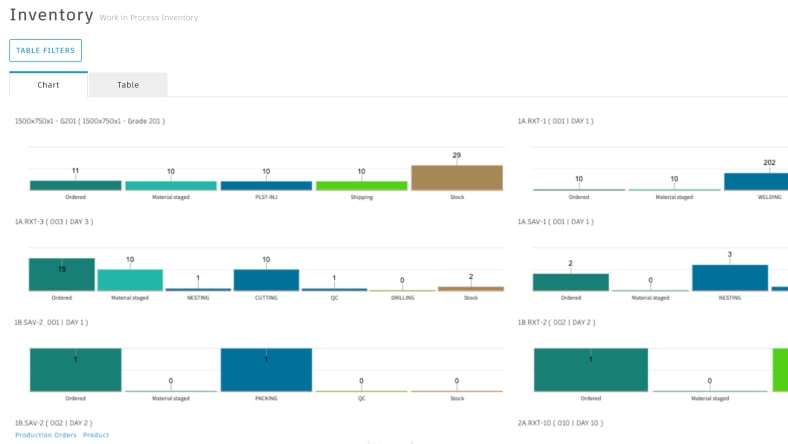

Quickly identify inventory that is in production at any given time with a visual display specific to each product manufactured.

Create sales orders to base production orders off of to help ensure real-time synchronization between sales and production activities.

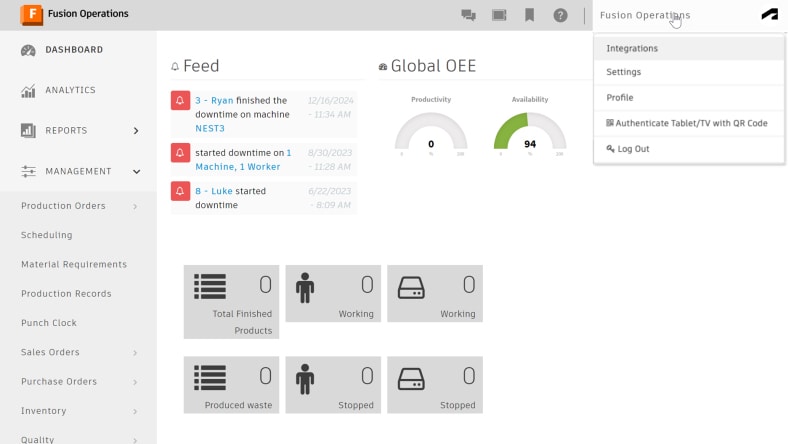

Customize integrations to third party applications using the Application Programming Interface, API.

Minimize the risk of running out of materials with real-time inventory counts that update based on production records.

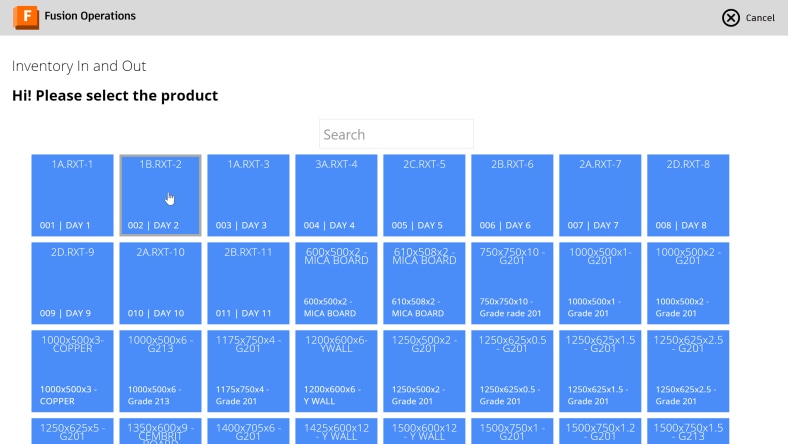

Simplify recording of "stock out" (Shipping) and "stock in" (Receiving) movements to help refine sales order management.

Start effectively planning, managing, tracking and analyzing your manufacturing shop floor production with Autodesk Fusion Operations.

A Manufacturing Execution System (MES) is a software solution to automate and digitize manufacturing processes. Manage, monitor, and track the transformation of raw materials into finished products in real-time. Gain insight into manufacturing operations to see how to improve performance, lower costs and increase production efficiency.

Autodesk Fusion Operations brings together MES and ERP capabilities, consolidating the number of tools used, streamlining your workflow to require fewer tools, and enabling communication of relevant information back and forth.

Autodesk Fusion Operations is a multi-capable tool, used by manufacturing engineers, production managers, quality managers, fulfilment, and shop floor fabricators.