AKYÜREK TECHNOLOGY

Expertise integrated with technology brings global success

THE FUTURE IS DESIGNED TODAY

Share this story

Operating in Mersin for 48 years, Akyürek Makine is the market leader in Turkey and a trend-setting company internationally, manufacturing high-technology-equipped machinery for processing dry granular agricultural products, particularly legumes, spices, dried nuts and seeds. Akyürek Makine is one of the only three manufacturers of tobacco processing machines around the world, and the only one in Turkey. The company owes its success to creating customized solutions for its clients, using the right technology in the process. In pursuing its national and international goals, Akyürek Makine has been meticulously planning its digitalization while using the Autodesk Product Design & Manufacturing (PDM) Collection in its design and production processes.

The Akyürek brand is recognized in 95 countries

Founded in 1973 in Mersin, one of the agricultural export centers of Turkey, Akyürek Makine has been designing and manufacturing machinery for post-harvest processing of cereals, legumes, seeds and oil seeds and establishing facilities and factories for these activities. Owning 95% of the market share in Turkey, Akyürek Makine also exports to many countries.

Member of the Board of Directors and International Sales Director at Akyürek Makine, İlker Akyürek states that the company has established numerous facilities for the Agricultural Credit Cooperative of Turkey, as well as 95 factories in 216 countries to process cereals, legumes, seeds and oil seeds.

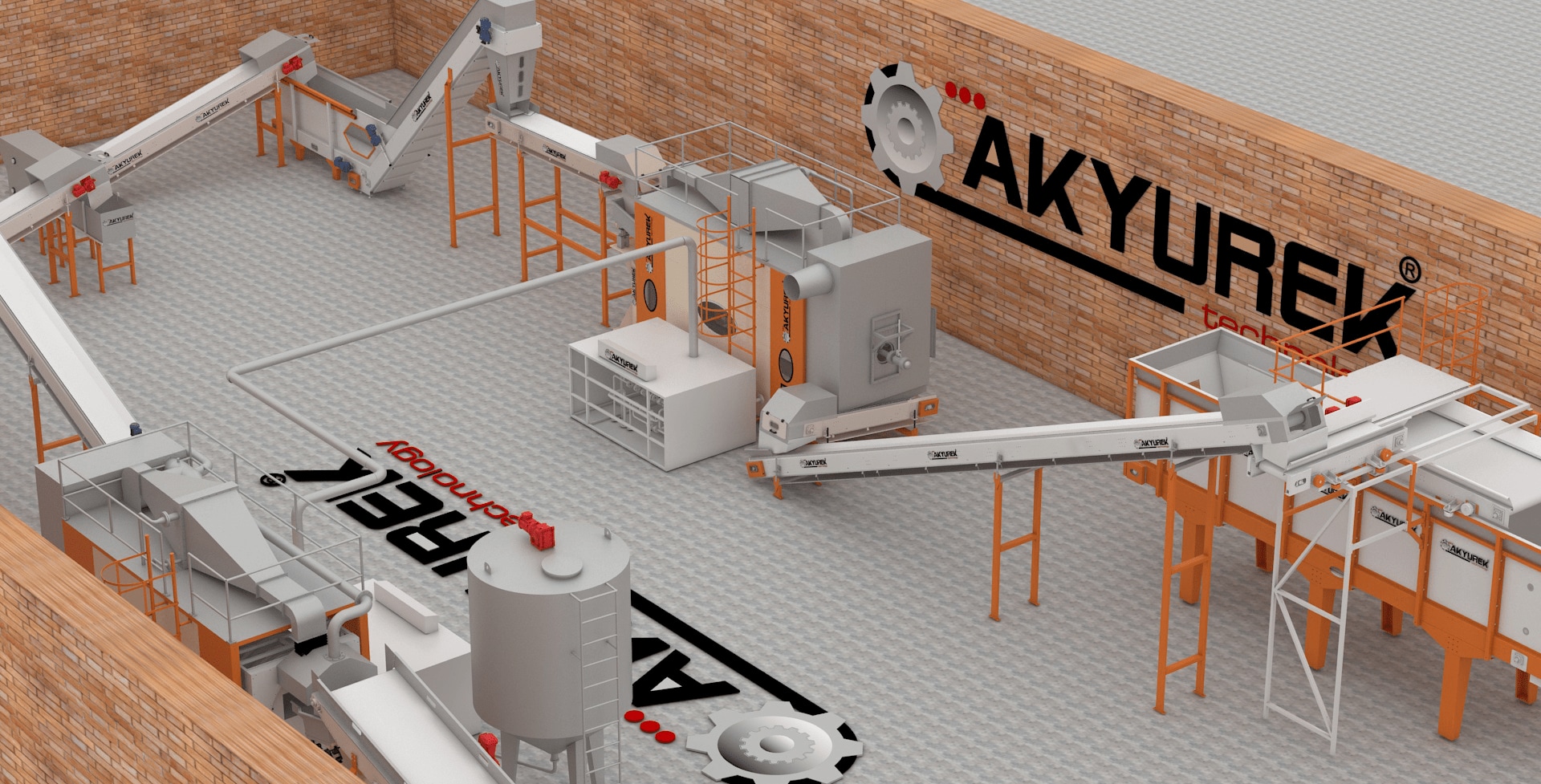

Akyürek Makine is one of the top three companies in the world that manufactures machinery for legume conditioning and offers products for the most critical stages of food processing. Providing its clients with custom-designed machinery to be used in purification, grading, classification and packaging processes, Akyürek Makine is a globally preferred brand that uses the 3D modelling and design product, Autodesk Product Design & Manufacturing Collection (PDMC) solution package in all its design and production steps.

A technology platform that supports global goals

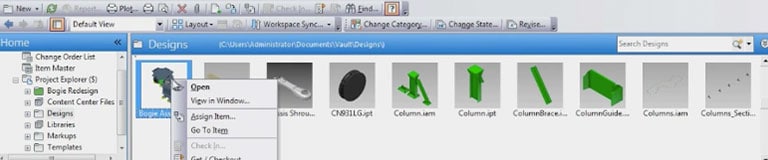

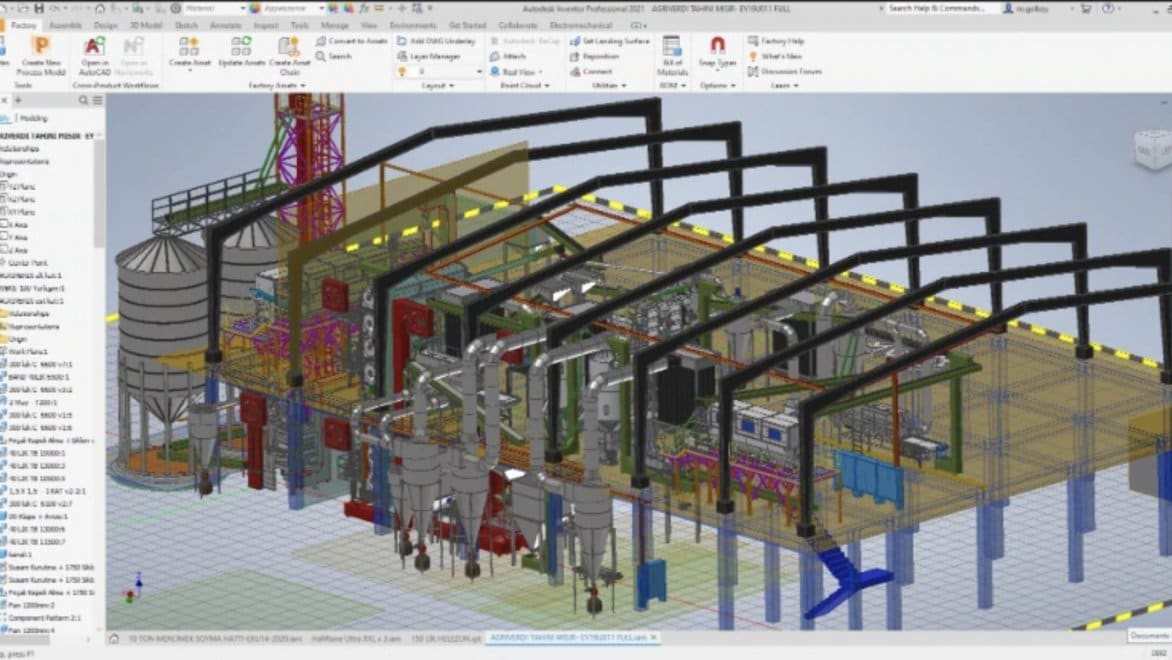

In 2016, Akyürek Makine switched to Autodesk Inventor for 3D modeling and design and later began using the Autodesk Product Design & Manufacturing Collection. The Akyürek Makine team was initially trained for using the Inventor, Factory Utility and Advance Steel software, which are all part of the Autodesk Product Design & Manufacturing Collection. Recently, the company has also been considering using the Vault software for its integration needs.

Member of the Board of Directors and Supply Chain Director at Akyürek Makine, İpek Akyürek states, “As a global player, we need to use a technological infrastructure that can integrate with our operational processes, strengthen our innovation skills and accelerate our design and modeling processes. We have to enter into production without any mistakes and minimize the number of errors that can happen during production. Autodesk PDMC provides us with the most suitable infrastructure that meets our expectations.”

“As a global player, we need to use a technological infrastructure that can integrate with our operational processes, strengthen our innovation skills and accelerate our design and modeling processes. We have to enter into production without any mistakes and minimize the number of errors that can happen during production. Autodesk PDMC provides us with the most suitable infrastructure that meets our expectations.”

—İpek Akyürek, Member of the Board of Directors and Supply Chain Director, Akyürek Makine

Optimal solutions for client needs

The machines designed and manufactured by the Akyürek Makine team using Autodesk Product Design & Manufacturing Collection, which is an integrated CAD, CAM and CAE system, can purify dried food (cereals, legumes, seeds and oil seeds) by removing foreign substances that got mixed in during or after harvest, such as dust, dirt and stones, and by removing imperfect products, such as those that are broken, immature or crude. The machines can then sort and package the products by size.

The sorting process can be done two ways, by width or length, or by mass and color, a process which increases purification quality and makes product classification possible. In short, the facilities designed and set up by Akyürek Makine can perform the most detailed sorting and elimination processes.

Member of the Board of Directors and Supply Chain Director İpek Akyürek states, “We can design and manufacture machines with different capacities based on our clients’ needs. Using Autodesk Product Design & Manufacturing Collection as our design infrastructure, it is now easier for us to customize the modules in our product library and develop optimal solutions for the area where facilities will be built. We can also offer different options to our clients, such as mechanical or computer controlled, depending on their budget.”

End-to-End Processes Are All Managed on Product Design & Manufacturing Collection

In addition to its design and manufacturing processes, Akyürek Makine uses the Autodesk Product Design & Manufacturing Collection for managing installation, after-sales support and maintenance services, gaining overall efficiency in all its activities. The Autodesk Solution Package makes it possible to create step-by-step 3D videos of the area where the facilities will be built, which is then shared with the installation crew. This allows for the installation process, an important determinant of customer satisfaction, to go faster. Periodical maintenance and support services can also be managed using Autodesk Product Design & Manufacturing Collection. Member of the Board of Directors and International Sales Director at Akyürek Makine, İlker Akyürek, states that spare parts and maintenance for the machines outside of Turkey are managed by their offices abroad.

“Using the Autodesk Solution Package benefited our production processes in many ways. During the modeling phase we can use the software to predict how often the machine could get jammed, or other possible problems that might occur during product flow. This process allows us to foresee all the problems that can take place when real production begins and to eliminate them. Autodesk’s strong technological infrastructure allows us to use our engineering skills to the fullest. Together, we minimize production errors and the costs related to these errors.”

—İlker Akyürek, Board of Directors and International Sales Director , Akyürek Makine

Innovative solutions generated by R&D

Having a strong franchise network with numerous offices outside of Turkey, Akyürek Makine has gained significant speed in customized product modeling as well in the presentation and customer-approval processes of these models since using the Inventor software for 3D modeling and design.

The company has established many facilities, mainly in the Balkan countries in Europe, and also in Africa, including those in Sudan, Nigeria and Ethiopia. Sesame seed processing has been a highlight. Member of the Board of Directors and International Sales Director at Akyürek Makine, İlker Akyürek states “We have particularly gained expertise in sesame seed processing over the last three years using a machine that sorts the seeds, dehulls them and turns them into tahini.”

Akyürek Makine owes this success to the R&D center established three years ago, as well as to the Autodesk Product Design & Manufacturing Collection infrastructure, which supports its innovation work. İlker Akyürek adds, “Our engineers at the R&D center are always busy, carefully listening to our clients and designing new products completely based on their expectations”.

Cost and wastage calculations are more clear

Member of the Board of Directors and Supply Chain Director, İpek Akyürek, highlights that they have been able to expand their product libraries since switching from 2D modeling to 3D and explains how this increased efficiency: “Our new designs are being modelled on the Inventor software in 3D form, and then the components of the products are added to the library. Since 2016, we have been gradually transforming all our 2D models to 3D.”

“This enriches our product library. In time, we have been able to quickly select the necessary products and make new configurations when modeling new orders. When we configure a new machine, we clearly see how much from each material is needed and how much wastage is generated.”

“This was possible because we standardized the dimensions of our raw materials. Now we can design projects and calculate costs much faster, which in turn gives us an advantage in pricing and competition. When we reach the desired point in ERP integration, our efficiency will be even higher.”

Production errors minimized

Member of the Board of Directors and International Sales Director at Akyürek Makine, İlker Akyürek, emphasizes how the Autodesk Product Design & Manufacturing Collection helped lower costs during production: “Using the Autodesk Solution Package benefited our production processes in many ways. During the modeling phase, we can use the software to predict how often the machine could get jammed, or other possible problems that might occur during product flow.”

“This process allows us to foresee all the problems that can take place when real production begins and to eliminate them. We also use additional software which helps us choose the right sheet metal in terms of static electricity. This way, we use the optimal materials and achieve the necessary durability. Autodesk’s strong technological infrastructure allows us to use our engineering skills to the fullest. Together, we minimize production errors and the costs related to these errors.”

Reliable partnership on the way to achieving Industry 4.0 goals

Akyürek Makine’s next goal is end-to-end digital transformation. İpek Akyürek explains the company’s meticulous transition into Industry 4.0: “We began laying the groundwork for investing in a new factory, taking all of our steps based on our Industry 4.0 goals. In addition to our 60 thousand square meters of land, we are also investing in 155 thousand square meters of land located in an organized industrial zone, for which we are hoping to break the ground this summer. Our new factory will be end-to-end digitalized. Our goal is to take solid steps in our digital transformation with reliable partners like Autodesk.”

Related products

-

Get Inventor + AutoCAD + Autodesk Fusion + more—Professional-grade tools for product development and manufacturing planning.

-

Product data management software—available as Vault Basic, Vault Professional, Vault Office

-

Professional-grade product design and engineering tools for 3D mechanical design, simulation, visualization, and documentation.

Learn more