Rise of the super engineers

CUSTOMER SUCCESS STORY

GRAEF's integrated BIM workflows cut months off project timelines

The next generation of “super engineers” at GRAEF has embraced the many benefits of BIM, boosting productivity and client satisfaction, while enhancing the skills and knowledge of their team.

At a time when most firms outsource project detailing for fabrication, GRAEF is doing just the opposite - bringing detailing expertise in-house, and is using interoperable software tools in the Autodesk® AEC Collection to make it a reality. It’s a move that’s already bringing several advantages and setting them apart from their competitors, while shaving time off project schedules, reducing RFIs, and allowing them to deliver higher quality projects, faster.

Interoperable workflows bring a competitive edge

GRAEF is used to being at the forefront of innovation. Over a decade ago, this Wisconsin-based full-service firm was one of the first structural engineering companies in the US to adopt BIM.

GRAEF saw an opportunity to deliver unique services to its clients and the business decision paid off. Then, two years ago, the firm made another change in the way it works, and today, it is reaping the rewards once again.

“We’re a business, so we’re always looking for a competitive edge and a way to be profitable, that’s part of it,” explains Michael Vogel, Principal at GRAEF. “But at the same time we want to provide opportunities for our people that motivate them and bring out their best. That’s what inspires the team, what makes folks want to stay and solve the problem.”

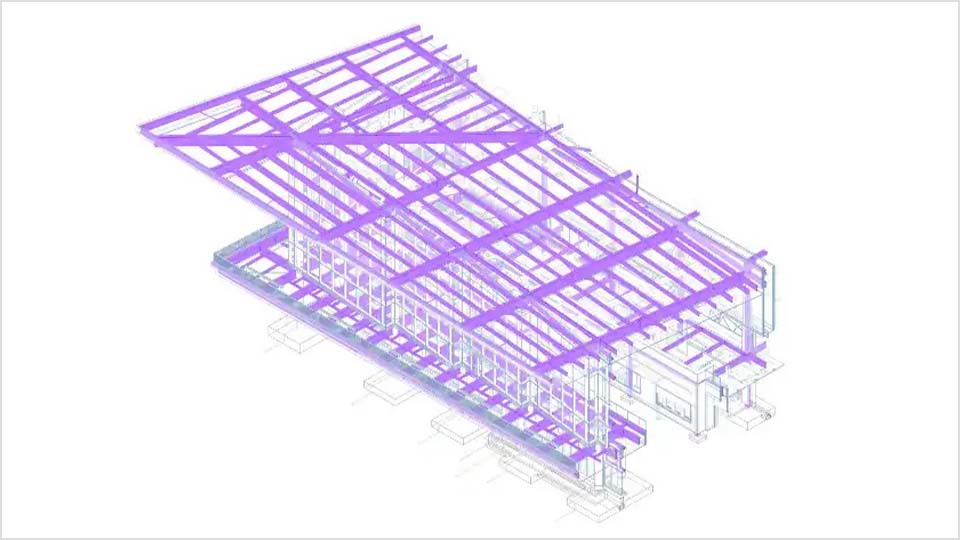

At the heart of this initiative – named GRAEF Accelerate – are integrated BIM workflows using Autodesk® Revit®and Autodesk® Advance Steel®, which are opening new doors to smarter engineering solutions.

At a time when most firms outsource project detailing for fabrication, GRAEF is doing just the opposite - bringing detailing expertise in-house, and is using interoperable software tools in the Autodesk® AEC Collection to make it a reality.

It’s a move that’s already bringing several advantages and setting them apart from their competitors. But for Vogel, the most exciting aspect is how it’s accelerating the development of the firm’s people.

“It’s like the training I had 20 years ago, only on steroids” says Vogel. “By having our junior engineers model connection design in 3D, they get to understand exactly how a steel building fits together. Not only are we accelerating their projects, but we’re accelerating our internal training with our staff.” This experience is quickly developing a new breed of what Vogel calls ‘super engineers’ – well-rounded engineers who can deliver construction documents and detailing with the insight to spot and fix issues before they become problems.

“It’s the type of experience you can’t gain by sending the detailing to be done overnight by a subcontractor. You’re missing out on understanding all of these things that lend themselves to the next project, carrying all that efficiency and value into the process,” says Vogel.

"Not only are we accelerating their projects, but we’re accelerating our internal training with our staff."

Schedule savings are the new norm

First, the efficiency gain has a notable effect when it comes to schedule.

“There are considerable schedule savings with every project,” says Vogel. “The amount varies depending on how the project is being delivered. Where we have one design deliverable, it’s saving us four to six weeks. Where we’re delivering multiple design packages, we’re saving three months in terms of the schedule. It’s very attractive to our partners.”

Key to GRAEF’s success here has been making full use of connected engineering workflows, which has led to a significant increase in productivity across the business. “Because of the great integration between Revit and Advance Steel, we’re able to layer connection information into our structural engineering models from the very beginning” says Vogel.

This is different from standard practice in the industry, which tends to produce these sequentially. “We’re leveraging the best attributes of each piece of software and getting them to talk to each other throughout the entire project. Having the information synced and linked into the 3D environment is really awesome.”

GRAEF is also using Autodesk® BIM 360® coordination tools to bring its steel detailing in Advance Steel together with the Revit model to help the firm collaborate with architects. “We can overlay the Advance Steel model over our Revit model and shoot a section over to the architects” explains Vogel. The same coordinated model can then be used to automate shop drawing production as designs evolve, helping to cut down timelines.

Then, once they enter the construction phase, general contractors can coordinate their MEPs using the same accurate up-to-date model to optimize installation, and cost and schedule predictability.

"We’re leveraging the best attributes of each piece of software and getting them to talk to each other throughout the entire project. Having the information synced and linked into the 3D environment is really awesome."

Better collaboration, better quality

The new way of working has also helped GRAEF’s engineers resolve quality issues more efficiently, as Vogel explains.

“Normally, if a detailer has a question, they ask the fabricator, who has to ask the construction manager, who has to ask the architect, who has to ask us – and then go all the way back around. We short circuit all that because we’re doing it and sitting next to people that understand the downstream product. In turn, it’s driving more value into the structural steel details from the get-go.”

Michael Vogel, Principal at GRAEF, has also experienced the benefits. “We’ve been able to deliver large structural steel projects with minimal RFIs,” he says. “We can overlay the Advance Steel model over our Revit model and shoot a section over to the architects saying, ‘Hey, this window interferes with this kicker’.

These are the kind of things that the architects are just eating up – being able to see and feel those things in a model that they can pull into their own.” This integrated approach to collaboration has led to far less rework and much greater process efficiency, resulting in significantly lower costs to the business.

"The chance to reinvent such a mature industry is really exciting."

Building the future with integrated engineering

GRAEF is a firm with a sixty-year heritage. But that hasn’t stopped it from embracing the future. The firm sees this way of working becoming the norm for structural engineering within the next few years.

“There’s a hole in the industry on the detailing side – owners, builders and architects all see the benefits of the ‘one model’ approach,” says Vogel. “It’s a journey for all of us, but it’s closer this way than I’ve ever seen it.”

Along the journey, the firm is exploring new opportunities to fully integrate structural analysis into the ‘one model’ environment by enhancing data flows between Autodesk® Robot Structural Analysis Professional® and Revit which it believes is the natural next step.

For GRAEF, building a future around BIM is more than just about a competitive edge, explains Vogel. “As a team, we all know how special this is. The chance to reinvent such a mature industry is really exciting. This is what drives people to want to solve the problem and become this new breed of ‘super engineers’. We want to provide opportunities for our people that motivate them and bring out their best. We’ve seen how this puts a glimmer in people’s eyes and I hope it continues!”