Kawasaki Heavy Industry

Challenge for 120years of legacy.

DX in Kawasaki’s ‘Changing Forward’

industrial machinery

Share this story

Kawasaki Heavy Industries DX challenge "Energy&Marine Machinery 3D Project"

Kawasaki Heavy Industries, Energy Solution & Marine Engineering Company in Japan, DX challenge "Energy&Marine Machinery 3D Project" successfully rolled out the first parametrically designed centrifugal compressor. Mastering the parametric design reduced design process hours by 30-40%.

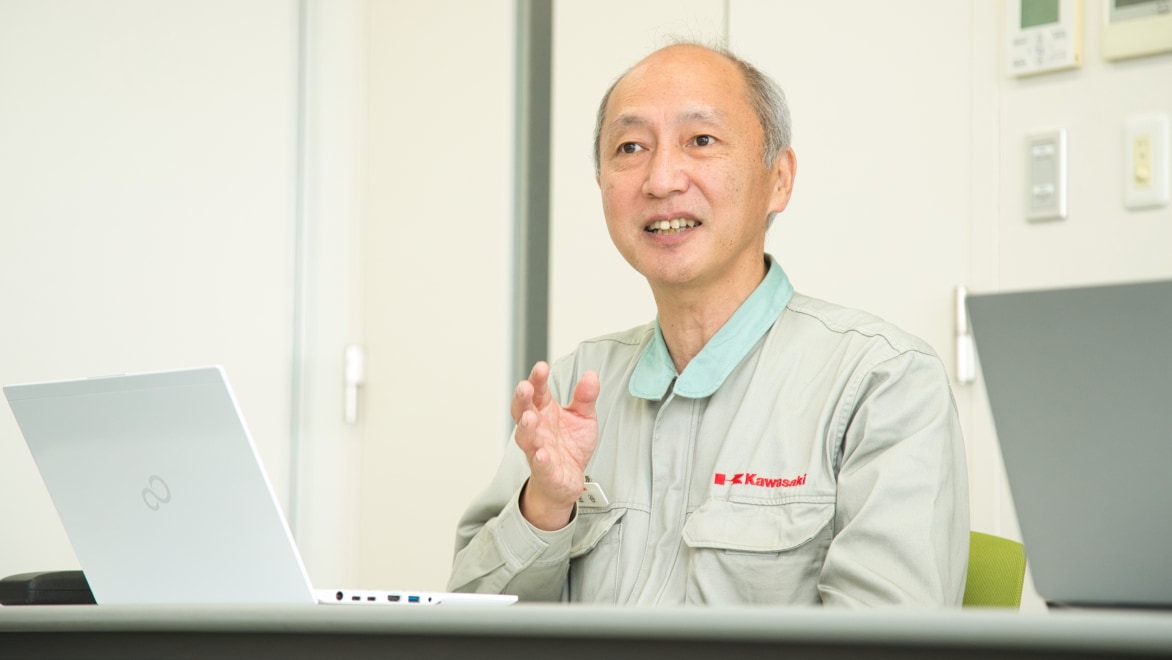

Member of Energy&Marine Machinery 3D Project.

The 3D Promotion Committee was established in 2019, and the current project was launched in April 2020. The building in the background was constructed using Autodesk Navisworks and 3D data integration.

Introduction

The Energy Solution & Marine Engineering Company comprises the energy division and marine machinery divisions. The energy division manufactures energy plants, gas turbines, gas engines, aerodynamic machinery products and steam turbines. The marine machinery division specializes in the production and maintenance of various marine equipment and systems . Those products are designed and manufactured at Kobe, Akashi, and Harima works in Hyogo, Japan.

The Energy Solution and Marine Machinery Business Divisions have been pushing the "Energy&Marine Machinery 3D Project " since 2020. The initiative aims to reform KHI’s production processes.

Moving away from 2D design that heavily relies on paper drawings as well as reforming traditional single-linear manufacturing process. To achieve these goals, the project team first replaced its existing 2D design environment with Autodesk Inventor and Vault in 2020. The project team has seen versatility and scalability as the advantages. Their effort enters a new phase with the shipment of its first parametrically designed product.

Reform the old production flow that could not get rid of paper drawings.

Since the founding of Kawasaki Dockyard (now Kawasaki Heavy Industries, Ltd.) in 1896, the company's design process has remained predominantly 2D. Although the company switched to 2D CAD for drafting, paper drawings continued to be used in the company's core operations. A great deal of manpower was devoted to this work. Meanwhile, the company has been facing international business pressure to drastically improve QCD (Quality, Cost, and Delivery). The delay in DX (Digital Transformation) was a crisis that had to be addressed.

Mr. Noriaki Kanao, Senior Staff Officer of the Production Process Innovation Section, who is currently leading the 3D promotion project, was very aware of internal setbacks causing unnecessary delays.

“Because people are involved in every part of the manufacturing process, it has become a risk factor that hinders QCD improvement. Although there have been attempts at 3D design in the past, it is only treated as reference data when passed downstream, and the manufacturing department must start by comparing the data with paper drawings. This does not lead to the reduction of work errors or the shortening of lead time. The increase in backtracking work caused by inadequate design study was also an issue,” he said.

There were piles of operational issues, such as the increased cost of eliminating defects caused by manual work, leading to delays in overall lead time.

It is essential to improve operations through DX to accurately respond to the severe demands from the market and to excel the competitors to survive. The project team plays a critical role in design and manufacturing to contribute to increasing product competitiveness by improving QCD.

The Energy & Marine Machinery Divisions has more than 13 product groups, including gas turbines, gas engines, marine engines, and centrifugal compressors. It has become crucial to have cross-sectional control. Thus a cross-sectional project was launched with the same principles and software environment.

Mr. Hiroo Kanaya

Manager of Production Process Innovation Section

Production Engineering Department of Energy & Marine Machinery System

Product Division

Energy Solution & Marine Engineering Company

Promoting the rapid spread of 3D CAD by taking advantage of flexible contracting

Hiroo Kanaya of the Production Process Reform Section (Production Engineering Department, Energy & Marine Propulsion, Production Division, Energy Solution & Marine Company) is one of those who have been experimenting with the introduction of 3D CAD for a long time. This time, he has been involved in the launch of the 3D promotion project and has reflected his previous experience.

Mr. Kanaya says, “We introduced high-end CAD as our standard CAD system in around the year 2000. However the set of rules was not well established, and its use was limited to some design departments only. After that, each design department started using CAD systems of their choice without a common strategy. The dilemma was that only a few users were using expensive CAD environments that would not spread through at the company level. As a result, it would automatically diminish the momentum to use 3D widely.

We knew we were only circling around if the choice is in each department’s hand.”

In this project, the size of the user group has been drastically expanded with the support of the Technology Development Division. Including outsourced CAD operators and those in the training stage, the initiative is applied to 300 3D CAD users in the design department. As of July 2023, 14 core members of the Production Process Innovation Section and 40 leaders are actively promoting the use of 3D design.

This dynamic approach is made possible with the token license format that offers the use of a wide range of Autodesk software as necessary.

Kawasaki and Autodesk have signed a comprehensive agreement (EBA: Enterprise Business Agreement). KHI is utilizing the Token Flex system, which is different from the perpetual or subscription system for software. Tokens purchased on a company-wide basis can be used by necessary users, when necessary, and for as long as necessary. The flexibility to try out various tools matches the needs of the 3D promotion project. This was one of the most influential factors in the selection of the solution.

Since Kawasaki Heavy’s business is to mainly manufacture one-off products, this flexible licensing format fits well into this situation. Their clients' order timing is not uniform. It is essential to minimize the idle cost of the tools not being used during non-busy periods. The ability to manage tokens in a cohesive department and to share them flexibly is an advantage in terms of personnel and costs associated with the 3D design environment.

Mr. Noriaki Kanao

Senior Staff Officer of Production Process Innovation Section,

Production Engineering Department of Energy & Marine Machinery System

Product Division

Energy Solution & Marine Engineering Company

Replacement of the design environment with Inventor The end of FY2023 is the mid-point milestone.

The project team has set the end of FY2023 as the "mid-point milestone" and aims for full 3D compatibility of one product in all participating departments. There is a gap between users with no experience of using 3D CAD and the ones with past experiences. There were voices of resistance from non-Autodesk CAD users to the idea of unifying with Inventor.

Mr. Kanaya recalls, “Inventor is well known today, but at the time of its introduction, it was an unfamiliar tool. When replacing it, we had to respect the opinions of CAD operators using 2D CAD. The design work is highly dependent on the operators, so it is difficult to push through if they say it takes too much time with unfamiliar CAD. This time, we explained the advantages of EBA, which allows them to start using the tool at any time, and we have worked hard to avoid any dissatisfaction while also developing an education and support system to ensure that they are convinced to use the tool.”

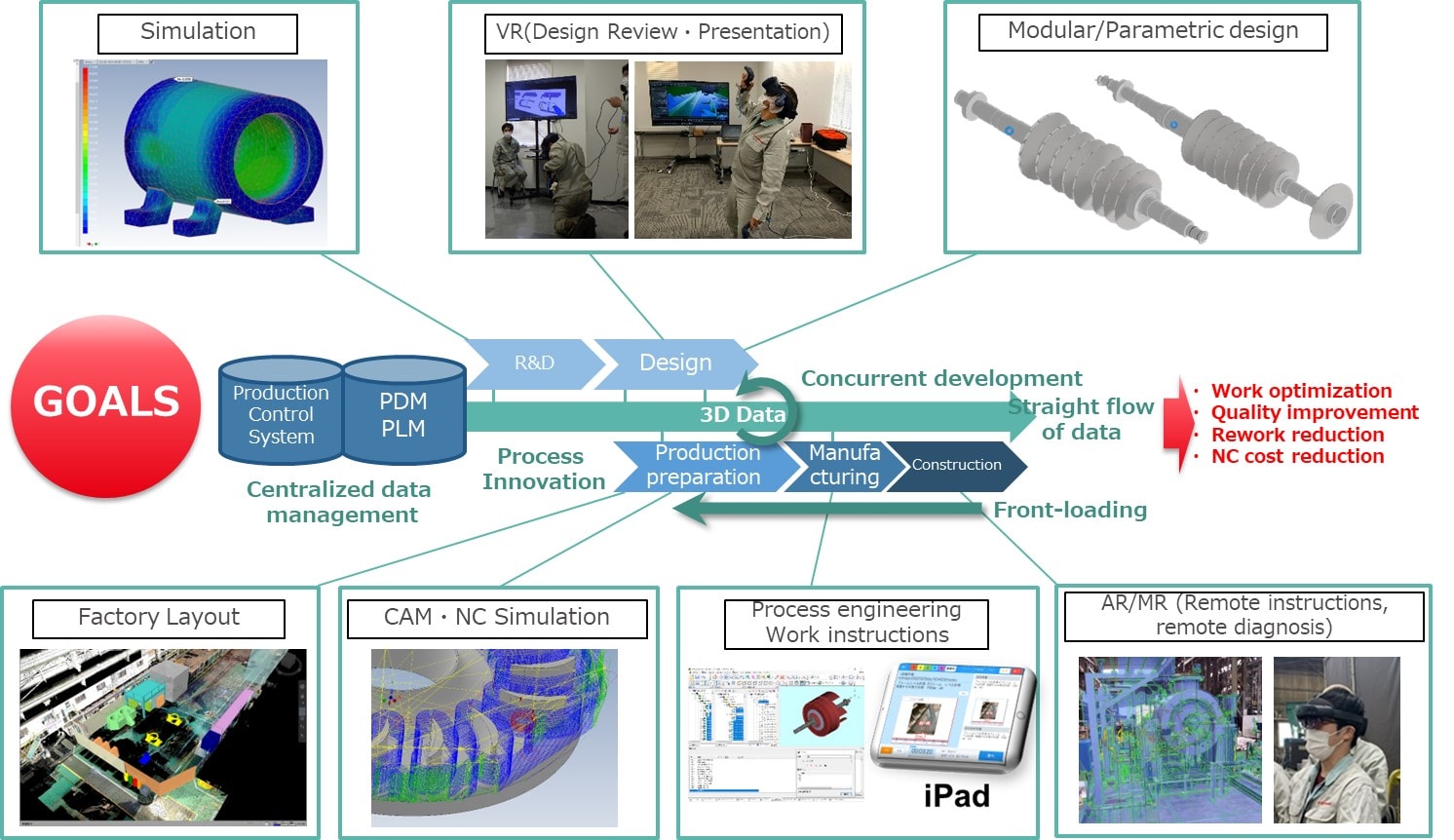

Image of reform of manufacturing process (production flow)

Image courtesy of Kawasaki Heavy Industry.

During the Inventor implementation verification period, the usability of the piping design function was the critical dissatisfaction of Inventor.

Mr. Kanao says, “We held discussions with the Autodesk account team for the improvements and additional functions. The piping design function was evaluated at low score when Inventor was first introduced. We had to customize the functions with an external engineering vendor. . Autodesk listened to our voice and had some piping-related functions adopted as standard Inventor features in a minor version upgrade in 2023. I understood that this is how Inventor evolves in response to user needs. I have high expectations for the future.

Mr. Norikatsu Yamada Senior Staff Officer

Engineering Section 2

Aero-Dynamic Machinery Department

Energy System Group, Energy Solution Business Division

Energy Solution & Marine Engineering Company

Parametric design achieved. The design process for the first model showed a reduction by 30 to 40% in design time.

“The project went better than I had expected," Mr. Noriyuki Yamada, Aero-Mechanical Designer, recalls.

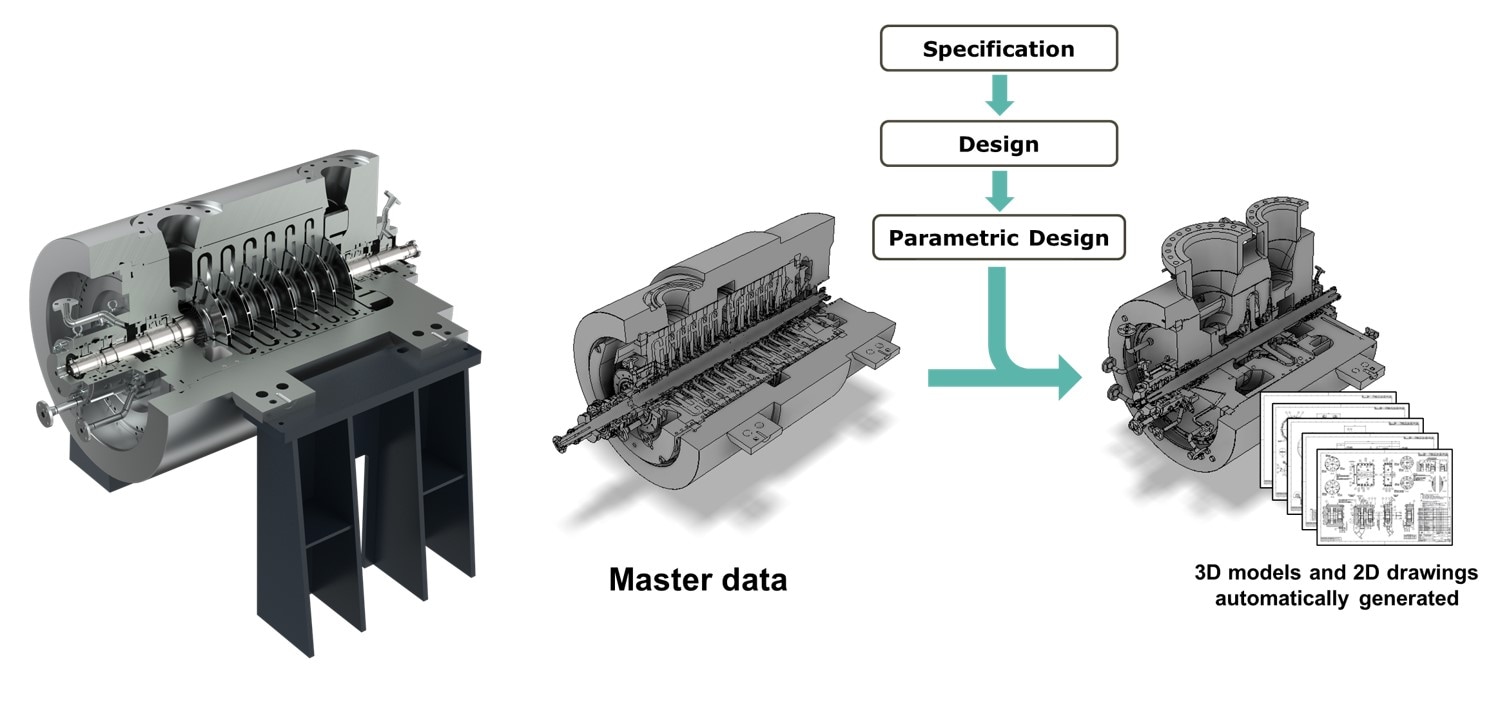

The product with the parametric design effort for the first time was a centrifugal compressor for pumping gas from offshore gas fields to land, and the delivery of the first compressor is in 2023. The uniquely designed in-house components amounted to more than 1,000 parts, and the 3D model of the main unit was created to the point where it could be controlled almost entirely by numerical parameters. The company estimates that the use of Inventor has reduced the design time for the main body of the compressor by 30-40%.

According to Mr. Yamada, to realize parametric design, the customary rules are now being reorganized, and the process of clarifying the rules is being carried out with the manufacturing department in a step-by-step agreement.

Model image of centrifugal compressor (existing shipping example) &

Concept of improving work efficiency through parametric design

Image courtesy of Kawasaki Heavy Industry.

Mr. Yamada says, “We had been making similar but different products for a long time, and the number of variations had increased to the point where there were too many. First, we narrowed it down to the necessary variations and identified whether there were any areas that could be standardized. The design and production departments discussed to decide a set of design rules. The standard rules even define how to draw simple lines and curves parametrically as well as annotate them on the drawings.

Mr. Kanao described, “The products Yamada is in charge of are mainly made-to-order. The shape of the product changes each time according to the client's specifications. We were so accustomed to spend a long time to review the specifications and drawings before production began. However, when Yamada first came up with the idea of parametric design, he said he would start by organizing the parameters to be used in the 3D model. I was skeptical and asked him if it was possible, but he replied, "I will set every single factor.” As a result, he accomplished the transformation from metadata design to parametric design. Things speed up when a PIC is willing to dive in as well as persuading others in the department and breaking through. In contrast, departments that are taking too long to promote the change need a proactive push from the project team.

Mr. Kazuo Kudo

Associate Officer

General Manager

Production Division

Energy Solution & Marine Engineering Comapny

The goal is to reform the entire design and manufacturing process through a common use of data.

With the introduction of Inventor, design drawings have been converted to 3D, and through data management by Vault, all employees involved in manufacturing can view the 3D data at any time. Once 3D models are passed through parametric design, design data can be used to create NC programs and forms, design jigs and tools, etc. In the new phase, the goal is to utilize 3D data in many different applications with less effort.

Mr. Kazuo Kudo, General Manager of the Production Division, who is responsible for the 3D promotion project, explained,” The goal is not to convert design drawings from 2D to 3D but to overhaul our design flow by using 3D. We anticipate that manufacturing process reform will cover all the production factors by this. The goal is to achieve a state where downstream work instructions and production preparation become easier and more reliable. It would be much easier to utilize the 3D data in every scenario once the production department gets involved in the design process, shares common intent, and understands the logic behind design and make.”

For the manufacturing department collaboration, Kawasaki Heavy also took full advantage of the Flex Token. They have adapted AutoCAD Electrical, AutoCAD Plant 3D, Autodesk Inventor CAM, as well as Autodesk Navisworks after enjoying the flexibility in evaluating these on a necessary basis.

Kawasaki Heavy has developed their own PDM system. This system will be developed into a PLM to make corporate decisions faster. In it, they are aiming to link databases and visualizing all the data with 3D models being centralized.

Carrying on the history of manufacturing while responding to the changing times

After the adaption of the 3D design flow has been completed, the next goal is to achieve a wider spread and integration into our design flow by the end of FY2025. Accelerating front-loading and concurrent engineering will be the goal of this phase. For example, a flow in which design and production preparation proceed concurrently could occur.

Mr. Kudo said, “At what level of the 3D data are created in which stage of the design process? If we can visualize this, we can involve the production, quality assurance, and procurement departments at the time of the design review and create a state in which downstream production preparations are in progress when the design is complete. We would like to make patterns and improve the entire business process."

Looking back on the project up to this point, Mr. Kudo believes that the secret to its success is that it has been a bottom-up project rather than a top-down DX project.

Mr. Kudo explained, “We are driving this initiative with the manufacturing perspective rather than requirements from the upper layers. There were many people who potentially wanted to work in 3D. The cross-sectional project successfully realized the will. Manufacturing simulations bridging the physical and virtual methods are already becoming the norm. If we sit on our hands and fail to keep up with this disruption, we may be eliminated as a company. We believe it is our duty to inherit the history of manufacturing while adapting to change."

Mr. Yamada's words left a strong resonance in Mr. Kanao,“We have been using paper drawings for more than 120 years, but there is no future for 2D drawings. We are at the point where we must change.

The 3D design initiative that began at the production site of Kawasaki Heavy Industries is on its way. This change will progress forward even further as in Kawasaki's corporate message "Changing forward”.