Mastenbroek custom trenchers maximize productivity with Autodesk Inventor

Discover how the Design Engineering team at Mastenbroek design custom self-propelled trenchers and maximize engineering productivity with Autodesk Inventor.

Manufacturer of custom self-propelled trenchers maximizes engineering productivity with Autodesk Inventor

The underlying concept of Mastenbroek is deceptively simple: digging a hole in the ground. What makes this specialized manufacturer stand out from its competitors, however, is a unique ability to push the boundaries of what’s possible in this space, which includes land-based and sea-based trenchers for incredibly diverse applications.

The company’s close-knit team of just four design engineers is less concerned with familiar problems and more excited by the uncommon requests.

That might involve digging a trench through granite in Norway or the softer soil of a sugar cane plantation in Colombia. It may mean digging in the Nile Delta, where the water table sits a couple inches below the crust, or in diamond mine near the coast of Namibia, where breaking the surface brings a massive onrush of seawater.

It can also require working deep in the open sea, where remotely operated machines dig a six-foot trench, then carefully pick up thick power cables and bury them.

“We like the weird and the unusual requests,” says Mark Taylor, engineering director at Mastenbroek. “We will build just about anything that anybody wants if it’s based on digging a hole. We like the opportunity to turn a standard machine into a bespoke, one-off design for a particularly challenging application.”

Founded in 1965, Mastenbroek manufactured its first trencher in 1977 and is still going strong more than 45 years later. The private company, headquartered in Boston, Lincolnshire, UK, now supports the global cable and pipe laying industry with a focus on custom-tailored engineering solutions for a wide range of utility, offshore and agricultural applications.

As you might imagine, subsea environments pose some of the most difficult conditions for self-propelled trenchers. While 450 feet is the average depth of deployment, other trenchers need to operate reliably up to a mile under water. These machines are designed for remote operation and are primarily used to trench the seabed and bury pre-laid offshore cables for wind turbines.

“We bring a great deal of onshore trenching expertise to the offshore sector,” Taylor says. “We call on that experience to create machines that are very productive. The big issue here is that if a subsea trencher has a problem, it costs something like $200,000 to pull it back up for repair.”

Other challenges are numerous. Some of the land-based machines need to be able to trench to depths of 60 feet and beyond, weigh in at 140 tons and are disassembled and transported by multiple vehicles between job sites. (A more standard machine would weigh as little as seven tons and be transported by a single truck.) Offshore machines could be deployed off the back of a vessel, where the cable must be passed through the trencher without breaching its maximum bend radius.

To solve all of these problems, Mastenbroek relies on Autodesk Inventor. In fact, the company has been using Inventor for nearly a quarter century.

"We like the weird and the unusual requests. We will build just about anything that anybody wants if it’s based on digging a hole. We like the opportunity to turn a standard machine into a bespoke, one-off design for a particularly challenging application."

The power and versatility of 3D modeling

Taylor, who has more than four decades of experience designing and engineering self-propelled trenchers, can remember a time when these machines were rendered in ink and the average customer could easily extrapolate how a machine worked by looking at a flat drawing.

“A great deal of that institutional knowledge has disappeared,” he says. “Today it’s more common to work with decision-makers who may or may not have any engineering background. We were starting to hit roadblocks because our audience couldn’t understand what we were showing them with 2D drawings. That’s when we originally moved over to using Autodesk Inventor.”

Moving into the world of 3D modeling significantly increased what Taylor refers to as the “conceptual depth of field,” enabling anyone to grasp the intent of a new design. In fact, these 3D models have become a highly effective sales tool, allowing the Mastenbroek team to generate a lot of excitement for highly bespoke designs, regardless of the customer’s engineering knowledge.

“It’s very powerful to show them a fully formed design that incorporates their corporate colors and logo,” Taylor says. “It really gives it a wow factor.”

While Inventor has become an important part of the sales cycle, it is first and foremost a platform for solving engineering problems. This often starts during the concept phase as the team works through the iterations of customer feedback.

“If the customer wants to change the working end of a trencher in a particular way, and we discover that the change causes another problem to arise, we can use the model to show why it is happening and get buy-in on our proposed solution,” says Steve Lindley, design engineer at Mastenbroek. “On the other hand, if a customer comes to us with a request that turns out to be impractical, we can use the 3D model to show them why — as well as demonstrate a more effective approach. It’s very powerful to show these examples in 3D.”

"Inventor enables us to present a clients wish list as a concept trencher and if commercially viable we can then progress through detailed design and drawings for manufacture."

Taking on tough engineering challenges

Once a new trencher has been ordered, the Mastenbroek team assigns the job to one of its four lead engineers. Working backwards from the delivery date, the engineer establishes key milestones based on everything from the typical design time for a machine of a specific size to when core components will arrive from suppliers. Then the actual work starts in Inventor.

“It might be a case where 90 percent of the design is already done and we’re just changing 10 percent of it,” Lindley says. “Or we may be starting from a blank screen. Either way, it comes down to solving problems that are specific to the application, like the 10 meter path the cable has to follow through the trencher. Or clash detection for the hydraulic cylinders through a full range of motion, managing the centers of gravity, and understanding the turning moments of different structures. There is a huge number of issues in every project, and it’s all managed through Inventor.”

It is important to note that the bespoke designs Mastenbroek works with commonly have between 5,000 and 15,000 unique components. The ability to handle these large 3D CAD models is one of the reasons why the company continues to trust Inventor. Another reason is its alignment with the company’s needs.

“One of the best features of Inventor is how it handles sheet metal,” Lindley says. “Sheet metal is our lifeblood. Nearly everything we do is sheet metal. As recently as a decade ago, a lot of our panel work was done in the workshop by skilled technicians who could do it basically unassisted. Those skills are becoming more and more rare. Inventor gives us the ability to generate in 3D what a craftsman from a previous generation would have done by hand. That’s a saving grace for us.”

Taking control of the manufacturing process

One of the most important issues for custom machines is manufacturability. Completing the model is just the first step, followed by analysis to ensure its constituent parts can be machined and assembled. From there, the team must ensure the design meets all applicable regulatory standards.

“We do a lot of finite element analysis to prove that our design is within regulation,” Taylor says. “Inventor is the tool we use to apply those standards to the model, and then see if there are any hot spots from stress. If we can identify a problem in the model and address it before it’s down in the workshop, we obviously save a great deal of time and resources. We don’t have a massive amount of time for any single project. We go from a blank screen to cutting metal in a matter of days, and the machine is rolling out the door in 12 to 16 weeks.”

In this sense, Inventor is a key component of the tight-knit Mastenbroek team’s overall engineering efficiency.

“Inventor basically allows us to do more design work in a given amount of time,” Taylor says. “Our workshop has gone from being a hive of activity with sketchbooks scattered everywhere to one where we have taken control of the entire build for our machines. With an accurate 3D model, we can manage the whole process.”

Once a new design is finalized and actually moved into production, the Mastenbroek team still relies on the 3D model to drive a number of supporting processes.

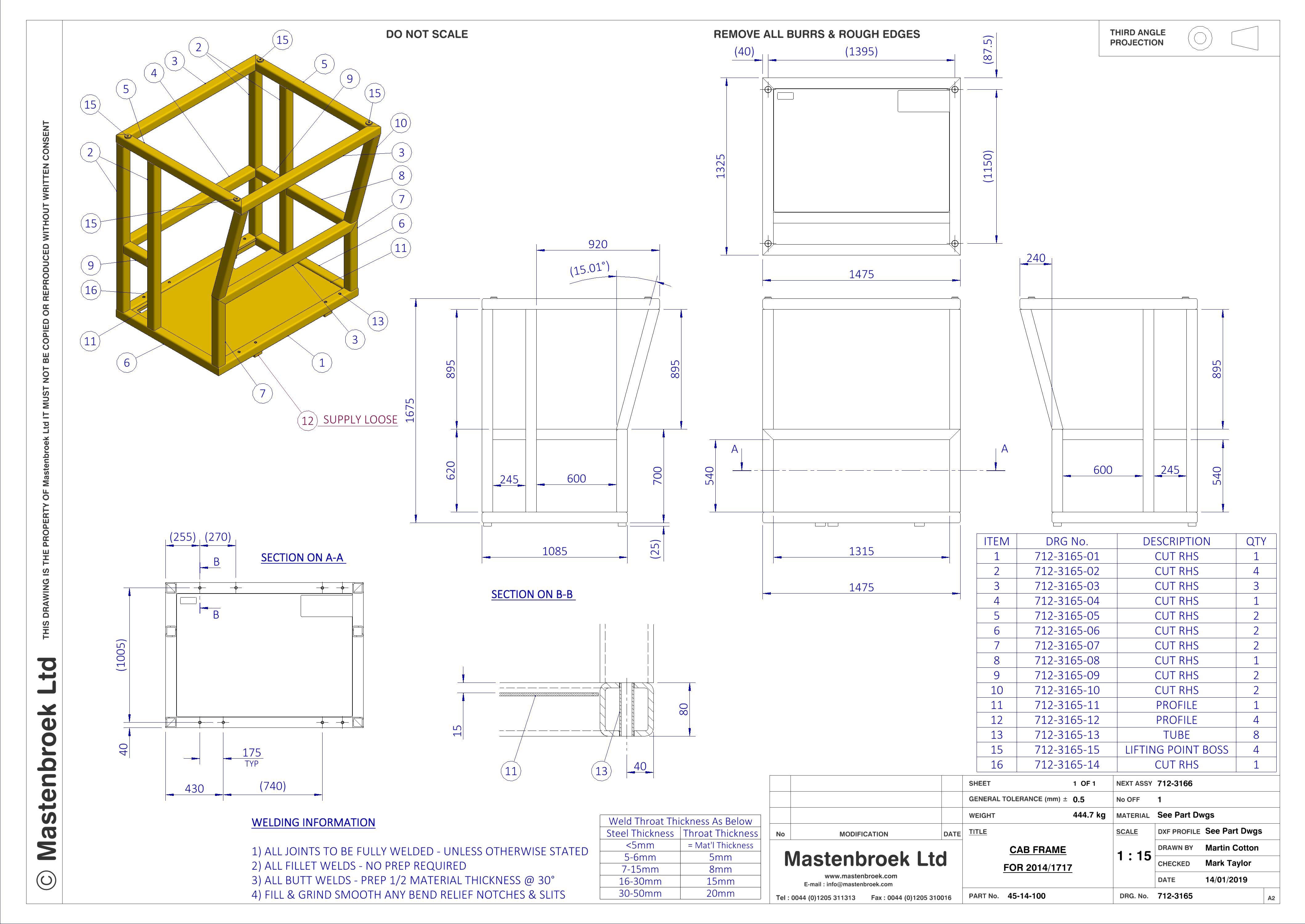

“We use the model to produce the 2D production drawings we send to suppliers for laser cutting,” Lindley says. “Then we use it to create all of the bespoke documentation for that machine, including workshop manuals, machine SOPs, operator manuals, and parts manuals.”

"If we can identify a problem in the model and address it before it’s down in the workshop, we obviously save a great deal of time and resources. We go from a blank screen to cutting metal in a matter of days, and the machine is rolling out the door in 12 to 16 weeks"

Pushing Inventor to its limit

Because the Mastenbroek team has been using Inventor since 2000, they represent an ideal test environment for new features and functions. Unlike other beta testers, however, Mastenbroek drops the new version straight into the normal production environment.

“When we do the beta testing, we’re not treating the latest version as a test platform,” Taylor says. “We carry on with our day-to-day work, using it 15 to 16 hours a day at full capacity. We keep pushing it. We see very quickly if we have a problem, which helps Autodesk improve the software.”

No matter what new features get added to Inventor, however, Taylor’s feedback often has one very important recurring theme.

“Inventor is a bloody good design tool that really helps us,” he says. “You can have all the bells and whistles. But it’s important to not lose sight of the core product. We’ve pushed Inventor to its limit. If you’re prepared to put the effort in, the results are outstanding.”

“You can have all the bells and whistles. But it’s important to not lose sight of the core product. We’ve pushed Inventor to its limit. If you’re prepared to put the effort in, the results are outstanding.”