NORDIC—OFFICE OF ARCHITECTURE

Expanding Oslo Airport with big-picture BIM

THE FUTURE OF MAKING

Share this story

Interdisciplinary project team uses Building Information Modeling for complex airport expansion

Global architecture firm Nordic is known for its expertise in projects ranging from urban masterplans, furniture and product design, visualization, and more. The project team employed Autodesk BIM software—including ReCap, Civil 3D, Revit, 3ds Max, and Navisworks—to design the new wing of Oslo’s international airport. The effort resulted in an extraordinary Navisworks model and a world-class airport.

Oslo’s airport expansion

Oslo Airport is the main international airport serving Norway’s capital city. In the spring of 2017, the airport completed a major expansion that increased its passenger-handling capacity. The expansion project—which almost doubled the size of the original terminal building—included a new wing of the terminal building with 11 fixed gates, 6 remote gates, an arrivals/departure hall, and a baggage-handling system.

The airport owner, Avinor AS, mandated the use of BIM for all project stakeholders. The project architect was Oslo-based firm Nordic.

Autodesk BIM solutions played a key role in the successful delivery of the Oslo Airport expansion.

Image courtesy of Sune Eriksen.

Expansion challenges

The construction of the expansion occurred during full airport operations. Therefore, design and construction had to meet Avinor’s strict requirements for safety and punctuality.

As such, careful planning was needed to reduce construction within the existing terminal and allow for the sharing of MEP and baggage-handling system-design information. In addition, Avinor’s BIM mandate required that all project deliverables—architectural, structural, MEP, and so forth—had to be delivered in the Industry Foundation Classes (IFC) format.

BIM has been a fantastic tool for integrated coordination between all the participants in the project and contributed significantly to high performance and quality.

—Knut-Erik Nordby, Project Director, ÅF Advansia/Avinor

BIM collaboration

Nordic Office of Architecture cites the use of Autodesk BIM solutions as a primary success factor for this project. Architects, MEP engineers, and fire and acoustics specialty consultants used Revit to develop their designs. They used ReCap to capture existing conditions and Navisworks for project collaboration and coordination.

The BIM execution plan demanded all participants to use BIM with the client requiring the use of IFC as the model handover format. Autodesk’s continuous improvement of IFC support over the course of the project, with linking of IFC-models, open source exporter, and so on, minimized the need for a manual conversion processes—saving thousands of man hours over the years.

Revit software for architecture and MEP along with Navisworks played crucial roles in handling huge amounts of data and enabled on-time project delivery. The design team used Revit for planning and design, documentation, visualization, and quantity take-offs. In addition, the software’s certified IFC data exchange feature supported cross-disciplinary workflows and task automation.

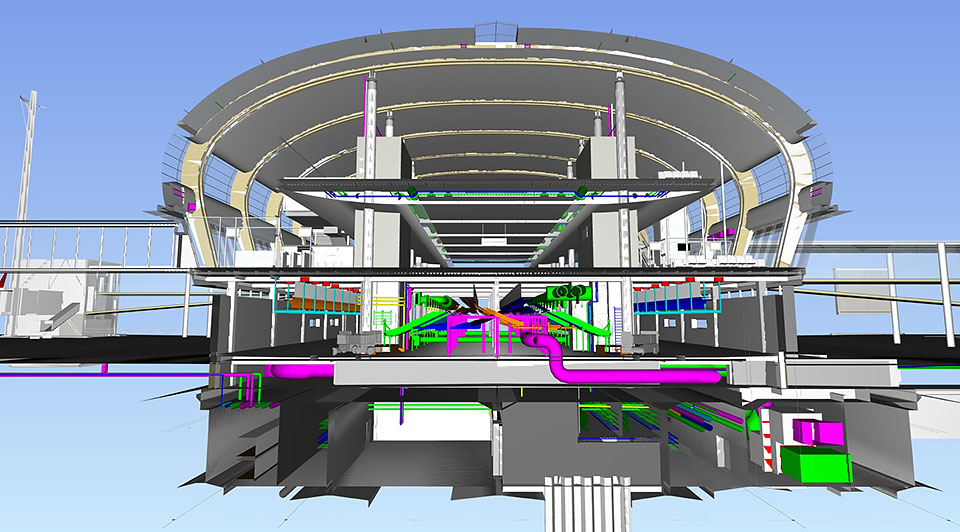

Cross-section of the project view in Navisworks. Image courtesy of Nordic.

An exceptional project model

At the beginning of the project, the team laser scanned and modeled the existing terminal in Revit to help ensure that new construction would not interfere with current operations. The point cloud of existing conditions was used in Revit by the design team to inform their developing design efforts, providing a highly accurate interface between existing conditions and new designs.

The aggregated Navisworks project model gave project stakeholders greater insight into both the project’s design and progress. For example, they were able to visualize design variations for different building interfaces. In addition, the 4D modeling features of Navisworks helped stakeholders visually distinguish new versus existing and designed versus constructed. Moreover, Navisworks enabled the design team to quickly inspect for collisions, which helped drastically reduce building errors.

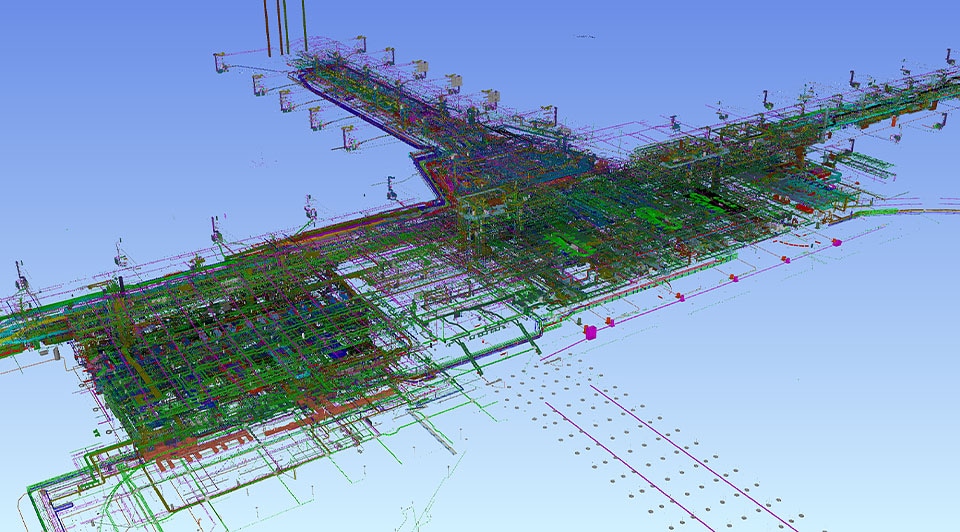

Revit was used for the airport expansion’s planning and design, documentation, visualization, and quantity takeoffs.

Image courtesy of Nordic.

This project model consisted of hundreds of discipline-specific models that all had to be managed and assessed for quality. The aggregated Navisworks project was extremely complex, with over 2 million unique objects – from doors, walls, and columns to connectors, sprinklers, plumbing, and lighting fixtures—each with their own unique product identifications. Including rebar, Navisworks handled 3.3 million objects in total, producing a 1.4GB file. The 3ds Max production model of 41.1 million polygons pushed the hardware to the limits.

Project analysis, simulation, and visualization

The design team also used BIM software and the Autodesk models to analyze and simulate many different technical aspects of the building, such as analysis, electrical capacity, lighting, short circuits, crowd simulation, sun/shadow analysis, air capacity, and so on.

In addition, the design team used its BIM model in Navisworks and 3ds Max to generate whole-project visuals and animators for public outreach and to better inform the design team and client during their decision making.

Intelligent model-based design and Autodesk BIM solutions helped stakeholders visualize the whole project's progress and end result. The Autodesk software enabled collaboration between the design team and the contractor, regardless of underlying design platform, with the help of the IFC compliance of Revit and Navisworks.

Rendering of Oslo Airport expansion project in Autodesk 3ds Max. Image courtesy of Nordic.

Results

Autodesk BIM software helped the project team meet its main goal for sustainability, design, construction, and operation. Success was achieved in the face of a high degree of project complexity.

The $2B project was delivered on time and under budget with a dramatic reduction in building mistakes and design errors. And construction of the new terminal occurred while the airport functioned with uninterrupted operations and continual traffic growth. Highlights of the project include:

- Increased capacity from 20 million passengers per year to 32 million per year.

- Achieved BREEAM Excellent rating. Energy use reduced by more than 50% and climate gas emissions reduced by 35% through the extensive use of wood.

- Using snow from the winter months for cooling during the summer; artificial light complementing daylight; energy wells; and district heating.