REYNAERS ALUMINIUM

Streamlining building product design through digital transformation

DESIGN & MANUFACTURING

Share this story

Global design company unifies product development workflow with Autodesk Inventor, Fusion Manage, Vault, and Revit

Belgium-based Reynaers Aluminium develops innovative and sustainable aluminum systems for windows, doors, curtain walls, sliding doors and other products, both for fabricators to manufacture and for architects to specify in large construction projects. Keeping track of this ever-expanding portfolio of configurable products became extremely challenging for the company, so Reynaers underwent a digital transformation, integrating Autodesk software with other enterprise business systems to create a central, unified source of information for development teams and customers. As a result, the company has streamlined its processes, automated select workflows, and minimized the risk of manual errors.

Developing aluminum products for customers worldwide

Reynaers Aluminium is a second-generation, family-owned global business that designs an extensive portfolio of aluminum doors, windows, sliding systems, curtain walls, solar shading, and many other sustainable building products. Headquartered in Duffel, Belgium, the company employs 2,300 people, serves customers in more than 70 countries, earns revenues of more than 550 million Euro, and has been growing steadily since 2010.

Reynaers delivers detailed product profiles to local fabricators who make and sell these products to their own customers. The company also works directly with architects to develop specialized or custom products for large commercial and residential projects, as well as with homeowners in select markets. In addition, Reynaers validates and certifies its products to meet various national standards, offers configurator software that fabricators can use to serve their own customers, and even provides the machines and automation tools fabricators need to manufacture the products.

“It’s not just the one product, it’s more of a complete package we provide to our fabricators,” says Carl Schelfhout, who oversees CAD/PLM and processes and has been with Reynaers for more than 25 years.

The corporate headquarters of the Reynaers Group in Duffel (Belgium). Courtesy of Reynaers Aluminium.

Managing a complex product portfolio

Because the Reynaers portfolio is so large and diverse, the company must maintain approximately 50,000 pages of documentation at all times—and this amount is growing. In fact, the documentation for every new product system represents about 800 pages of information which is needed by fabricators in order to make the varying configurations of the door or window properly. Maintaining this data, from the beginning of product development to final delivery, can become extremely complicated very quickly.

“I knew we had to automate more of our processes, because we had so many profiles and had to produce so much documentation that we were drowning in our work,” Carl Schelfhout says.

Part of the complexity stems from the fact that every product touches many different systems during its life cycle, including the software used to design it, the ERP system, the configurator, as well as other downstream systems for billing.

“It’s more than digitization, it’s a digital transformation,” says Dimitri Van Nuland, head of development, who leads a team of more than 30 designers. “It’s a continuous focus on making things as easy as possible for our fabricators and other customers, getting that customer intimacy as close as possible, and delivering the best possible solution.”

Reynaers is a leading European specialist in the development of solutions for doors, windows, sliding systems, curtain walls, and more. Courtesy of Reynaers Aluminium.

Achieving digital transformation

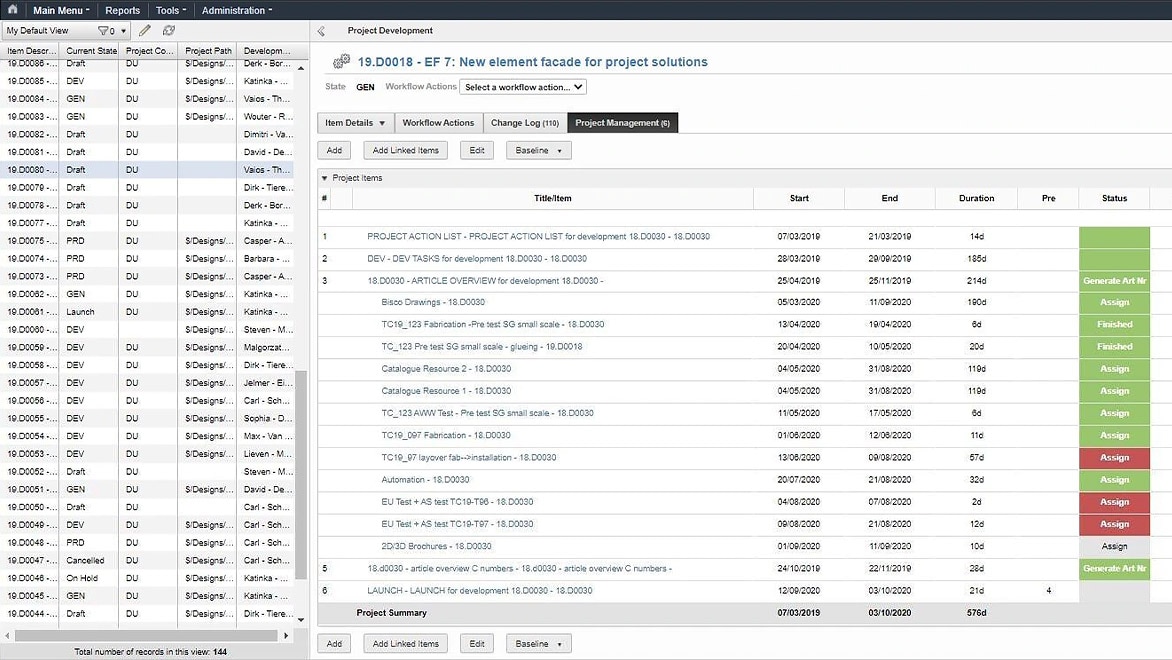

Bringing this transformation to life is a constant journey, but Reynaers has met a number of their objectives with software from Autodesk. The development team creates its design models in both AutoCAD and Autodesk Inventor. For certain applications, Inventor creates select parts of the profile automatically to streamline the process. Then, to manage each product throughout its life cycle, Reynaers uses a combination of both Fusion Manage and Vault Professional.

“For every project we initiate, it starts with a request for development, whether that is a new product range, an extension of an existing product, a thermal calculation or even a BIM model,” Schelfhout says. “That is fully integrated with Fusion Manage, so our project management cascades from there. Technical teams evaluate the request and if it’s accepted, it gets a development number. This is automatically communicated to both our ERP system and to Vault, so it’s the same number no matter where you look.”

This unified source of product information makes it easier to manage the entire process because team leaders or developers or fabricator partners have a complete overview of everything at once.

“They can follow up on anything,” Schelfhout says. “Is it ordered yet? Is the prototype approved? Has stock-building started? All the different phases are visible in Fusion Manage.”

For architects, the process is slightly different, although the concept is the same. In these cases, Reynaers teams can create BIM objects using Revit BIM software. In both cases, however, the benefits are the same. The process flows automatically from step to step, there is less time spent moving and managing large amounts of complex product and configuration data, and there are significantly fewer errors—the kind that can often result when profiles are moved from system to system manually.

Project management in Fusion Manage. Courtesy of Reynaers Aluminium.

“For every project we initiate, it starts with a request for development, whether that is a new product range, an extension of an existing product, a thermal calculation, or even a BIM model. That is fully integrated with Fusion Manage, so our project management cascades from there. Technical teams evaluate the request and if it’s accepted, it gets a development number. This is automatically communicated to both our ERP system and to Vault, so it’s the same number no matter where you look.”

—Carl Schelfhout, PDM/PLM and Process Manager, Reynaers Aluminium

Bringing a vision to life

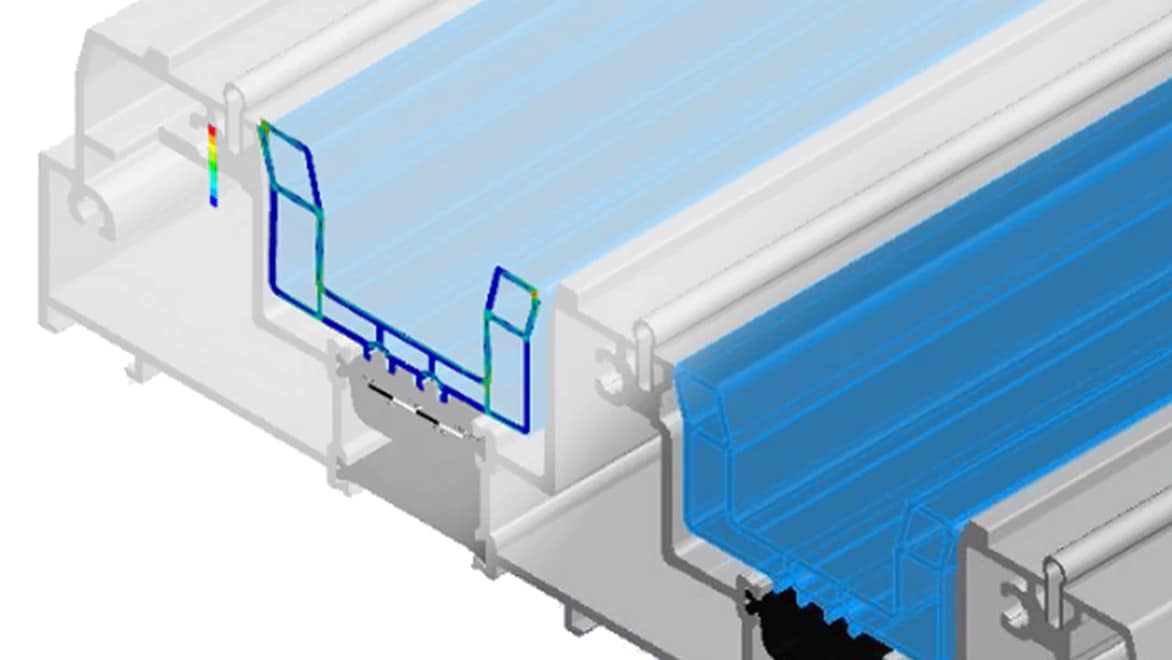

Of course, the vision that Reynaers has for its digital transformation is a never-ending one. Right now, the company is investigating how to integrate a flow from Inventor, to Fusion 360 with ANSYS simulation software for thermal optimization and virtual certification.

“For me, the ultimate goal is that Fusion Manage is a platform used across all sides of Reynaers, where everyone can see which requests/projects are running, which research programs are running, what tests are running,” Van Nuland says. “It’s all part of our goal of customer intimacy—making sure we have the right solutions on the spot, whether that customer is a fabricator or an architect. It’s very crucial for us because we’re thinking cradle to grave for the product life cycle, and our products can last 30, 40, 50 years or more. No matter what happens, all that detail will be available.”

Image courtesy of Reynaers Aluminium.

Get started with the collection

The Product Design & Manufacturing Collection is an integrated set of professional-grade applications that connect everyone, from concept to production, with shared tools to streamline your product development process. The collection enables you to create your most ambitious ideas, collaborate efficiently, automate busywork, and explore more design options than ever before.