ROBERT BIRD GROUP

Delivering project certainty with 4D construction visualization

CUSTOMER SUCCESS STORY

Share this story

Construction engineering team leans on BIM and VDC technology to reduce project risks

Robert Bird Group has earned a reputation for their application of engineering expertise to support the construction process on the world's largest and most complex projects, including advanced engineering facilities, stadiums and airports. RBG creates virtual environments with the tools provided in the AEC Collection to communicate advanced logistical solutions and validate project approaches, ensuring certainty for their clients and project teams.

Crown Sydney – Sydney, Australia. Photo courtesy of Robert Bird Group.

Creative solutions to complex project challenges

As an industry that relies on certainty, design and construction requires precise coordination of information, design, process, and execution. The COVID-19 pandemic has been a challenge for everyone, but fortunately, mitigating uncertainty is nothing new to the AEC industry. We are equipped with widely available tools and technology that help us adapt to change and validate ideas, providing project owners and teams with confidence in the success of proposed solutions.

One firm bringing the use of technology to the benefit of its clients is Robert Bird Group (RBG), an international engineering firm of more than 600 employees and a focus on structural, civil, and construction engineering for some of the world's largest and most complex projects. RBG uses the power of building information modeling (BIM) and virtual design and construction (VDC) to bring value to their clients and their projects in many ways.

"For us, VDC is really about giving the client an insight into the risks they may face. It helps us communicate our methodologies and proposals for mitigating those risks," says Paul Mullett, director of engineering technology at RBG.

Typical roof shell construction depicted on AAMI Park, Melbourne, Australia. Photo courtesy of Robert Bird Group.

Evaluating risk with BIM and VDC

With an ideal that projects should be “designed for delivery", RBG finds tremendous value in BIM and VDC to inform its Construction Methodology and Erection Systems (CMES) approach, helping their clients manage risk and ensuring a seamless transition from vision to reality.

The tools provided in Autodesk's AEC Collection — including Revit, Navisworks, 3ds Max, and AutoCAD — enable the team at RBG to virtually sequence the coordination and erection of permanent structures and associated temporary works structures, in effect providing a “Digital Construction Rehearsal" before anything happens on site. "We use BIM and VDC processes to show clients our proposals," says Mullett. "We can virtually show the team the process of how our proposed engineering solutions would actually work.

Visualizing logistical constraints

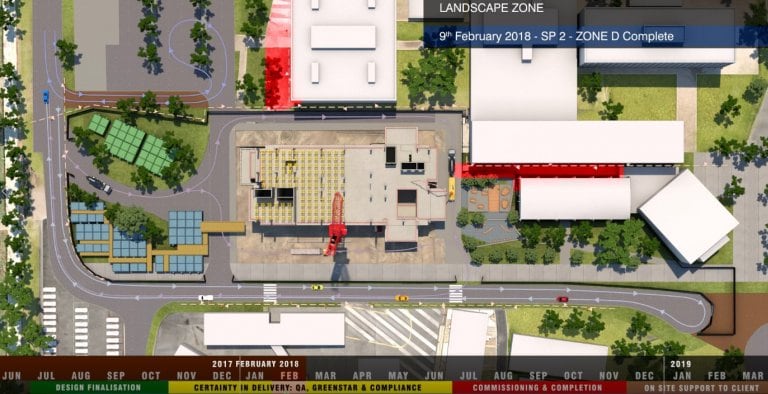

For the new Biomedical Learning and Teaching Building on Monash University's busy Clayton (Australia) campus, the project team used VDC to inform the temporary works design and detailed site logistics to support the construction of an 11,400-square-meter, world-class biomedical and learning space, containing “flexi-labs" to support adaptive learning environments.

The visualization helped communicate how the temporary works and position of equipment positioning might affect campus access. This provided stakeholders and contractors with an understanding of what was required on-site, from lay down areas to construction zoning, ensuring access to other university buildings during construction and improving overall safety on-site.

“We were able to show the client our construction methodology and provide detailed site logistics. This ensured construction traffic did not impede public, pedestrian, and vehicle access on this busy, active campus."

—Stephen Lester, Virtual Design & Construction Manager for Australia, New Zealand and Asia, Robert Bird Group

4D construction methodologies

-

![]()

Plan view

Site logistics plans showing vehicle and pedestrian access, temporary works, and equipment positioning allows for ongoing access to surrounding buildings during construction.

-

![]()

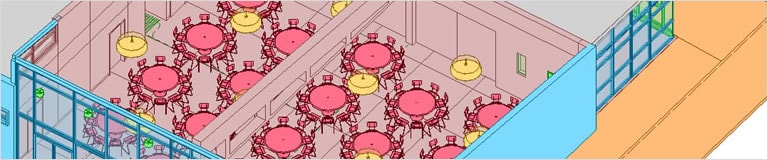

Perspective view

Detailed perspectives of activities such as micro-sequencing the façade installation give stakeholders and contractors a far greater understanding of what is required on-site.

Adding value to the design process by informing construction sequences

Projects that involve working on active campuses and facilities are particularly challenging, according to Lester. Add in the challenges of regulatory requirements, nearby activity on both the ground and in the air, and the need to ensure no disruption to ongoing operations. These types of projects would require complex coordination and sequencing efforts.

A recent large, complex project completed by Robert Bird Group in the Middle East embodied all these challenges, requiring the development of a detailed Construction Methodology and Erection Sequence (CMES) and the design of temporary works supporting the permanent structure.

RBG's knowledge of VDC and the tools provided in Autodesk's AEC Collection helped keep the project on track by verifying the proposed solution would allow work to continue on the permanent structure, mitigating a schedule that was already under immense pressure.

By creating a 4D construction simulation of the CMES, using Navisworks for clash detection and coordination, along with Dynamo scripts for automation of design tasks, “the team could experience the process of where the temporary works would be, watch the pieces being put in place, with a clear understanding of scale and where the equipment would go, or where it might impede progress, " says Mullett.

Digital visualizations provide confidence to the client when signing off on a construction approach, freeing the design team to continue its use of BIM and VDC through the journey of the design process itself with Revit, Navisworks, and 3ds Max.

Precise coordination of elements, such as structural works and MEP systems, is instrumental for construction teams. RBG uses Revit and Navisworks to coordinate multi-disciplinary designs and undertake clash-detection for any elements that do not fit together. This analysis is a critical step in ensuring constructability of designs and avoiding rework in the field and determining what components need building in advance before being installed on site.

One of the most time-consuming challenges for these highly complex projects is that they are often designed with a lack of repetition and require detailing, fabrication, and installation of unique geometric elements. Generating the construction documentation of these elements would typically require a manual build of multiple iterations of Revit models, wasting countless hours of design time. The RBG team came up with a creative solution to this problem, performing options analysis using Dynamo.

"On a recent project, we looked to Dynamo to automate the production of the documentation," says Mullett. "We'd pull engineering analysis models into Revit and use an in-house scripting process RBG developed using Dynamo to automatically push those through to the documentation." RBG further automated the process by using 3ds Max to perform sequences based on the project’s requirements. "We were able to incorporate all of the processes through all of the various stages using BIM as a center," he says. The time savings on the processes benefitted the entire team, shortening overall design time and allowing for collaboration and coordination through to design and construction teams and a quick turnaround of any necessary changes.

"For us, it's all about buildability. We apply the entire suite of Autodesk BIM tools, not only for coordination among all team members, including the designers, engineers, and specialty trade contractors but also for documentation and rendering iterations."

—Paul Mullett, Director of Engineering Technology, Robert Bird Group

AAMI Park construction methodology. Image courtesy of Robert Bird Group.

Supply chain benefits

RBG also used 4D simulation and visualization for the roof shell fabrication at the 30,050-capacity AAMI Park in Melbourne. The lightweight "bio-frame" roof required only about half the steel as a typical cantilevered roof. However, the roof was unable to support its own weight until the final structural support was installed. The team's simulation efforts confirmed envelope dimensions and clearly communicated details about site access and logistics, equipment and crane locations, temporary works and the propping and de-propping of each shell that comprises the roof structure.

The simulation also contributed to considerable time savings across the project. During the design and planning phase, the simulations reduced the amount of documentation required and saved development time during the roof transportation analysis, allowing for faster decision-making on splicing locations needed to fabricate each of the roof segments.

RBG also used visualization to establish proper fabrication sequences in order of installation for “just-in-time" delivery from the fabrication facility to the site. The result was significant savings on cost and schedule due to transportation efficiency and mitigating safety risks on site. "Visualizations and simulations using 3D digital models allowed the team to understand the work processes, understand the scale, and 'see' the project’s execution, which is not possible with traditional drawings," says Lester

What’s next?

The team at RBG is excited to take the advancements in VDC software to create interactive and immersive simulation models.

Using the Unity Gaming Engine Platform in conjunction with the full suite of Autodesk open and interoperable products, RBG has been able to launch RBG REVEAL. This proprietary, in-house platform enables project stakeholders to virtually experience, interact with, and collaborate on built assets that are either completed or under construction.

"What evolved from our VDC experience is our use of the whole suite of tools to solve the problems holistically," says Mullett. "It's changing the way we work. It is now about developing those workflows and providing our clients with interactive experiences. BIM and VDC are transforming the way we communicate and design for construction."