SKANSKA SWEDEN

BIM Powers one of Europe's largest building projects

AEC EXCELLENCE AWARD WINNER 2019

Share this story

Leading a global team to build a highly anticipated research facility

When they broke ground in 2014 on the European Spallation Source (ESS) in Lund, Sweden, the 13 member nations began one of the largest building projects on the continent—with an estimated cost of $2 billion USD. When complete in 2025, the facility will be the world’s most advanced neutron source. It promises to give scientists visibility into atomic structures and forces no previous facility has allowed them to see. The project is expected to yield discoveries that could benefit the fields of energy, technology, and the environment. ESS selected Skanska Sweden to lead the project, and Skanska selected Autodesk.

For its high-profile building project, the ESS chose Skanska

Skanska is one of the world’s most sought-after project development and construction organizations. According to Construction Global Magazine, it is the fifth-largest construction company in the world.

In addition to its wide range of construction projects throughout North America and Europe — building bridges, hospitals, schools, and homes — Skanska also provides strategic leadership and oversight on complex infrastructure projects. This is why the consortium of nations making up the ESS chose Skanska to coordinate the development of its 65,000-square-meter research facility.

ESS project team featuring BIM leads from Skanska Sweden, Sweco Architects and AF Infrastructure. Image courtesy of Skanska Sweden.

A project of this scale requires collaboration

This type of complex, multi-year project requires a high level of coordination among teams from planning, design, construction, purchasing, and elsewhere—representing people from 50 countries—and sharing real-time information. Fortunately, these teams had an advantage: many were already working with the same BIM (Building Information Modeling) tools.

“It was decided early on that this project would be a Revit project” says Lukas Nowikowski, manager of VDC (Virtual Design and Construction) and BIM for Skanksa partner Sweco Architects. “A clear majority of the designers work in Revit—and subsequently, collaboration is made simpler through just that fact alone.”

Martin Hörestrand of Skanska and team. Image Courtesy of Skanska Sweden.

Navisworks Manage further enables collaboration, serving as a shared digital environment for clash detection and design review. Martin Hörestrand, Skanska Sweden’s BIM leader, explains: “In the project, we have worked with information chains. We use the same models throughout the process for design, calculation, purchasing, planning, adaptation, construction and for facility management.”

Virtual Reality (VR) helps researchers see their future in 3D

A major goal of the ESS team is to optimize space, the positioning of the massive scientific equipment, and other aspects of the facility to create the best environment for the researchers. “But scientists are not construction experts,” says Marcus Helmbäck, BIM strategist with ÅF Infrastructure, another Skanska partner on the ESS project.

Martin Hörestrand or Skanska Sweden using Holo Lens at the ESS c onstruction site. Image courtesy of Skanska Sweden.

To help the facility’s future occupants fully understand and articulate where the design plans were working and where they needed improvement, the team used 3ds Max and Unreal Engine to create visualizations, movies, and virtual-reality renderings.

“We also used the lighting data from the Revit models to create real lighting scenarios,” Helmbäck says. “Together with the client, we have explored and designed their future work environment inside virtual reality.”

The team also leveraged 3D modeling, using drones and 3ds Max’s Camera Tracker Utility, to improve coordination among the various ESS project teams.

“Using 3D tracking with a drone enabled us to visualize the 3D-modeled designs in actual surroundings, many years prior to completion,” explains Ronald Cruz, BIM Coordinator with Sweco Architects. “Rendered contents from 3ds Max proved beneficial regarding the communications between design, contractors, stakeholders, and the board of directors.”

A shared digital environment saves time and money

When you consider the enormous design and implementation challenges of a multinational project of this magnitude—the costs, environmental implications, health and safety of the facility’s researchers and nearby residents—the fact that Skanska and its partners have remained on time and on budget throughout the project is incredible.

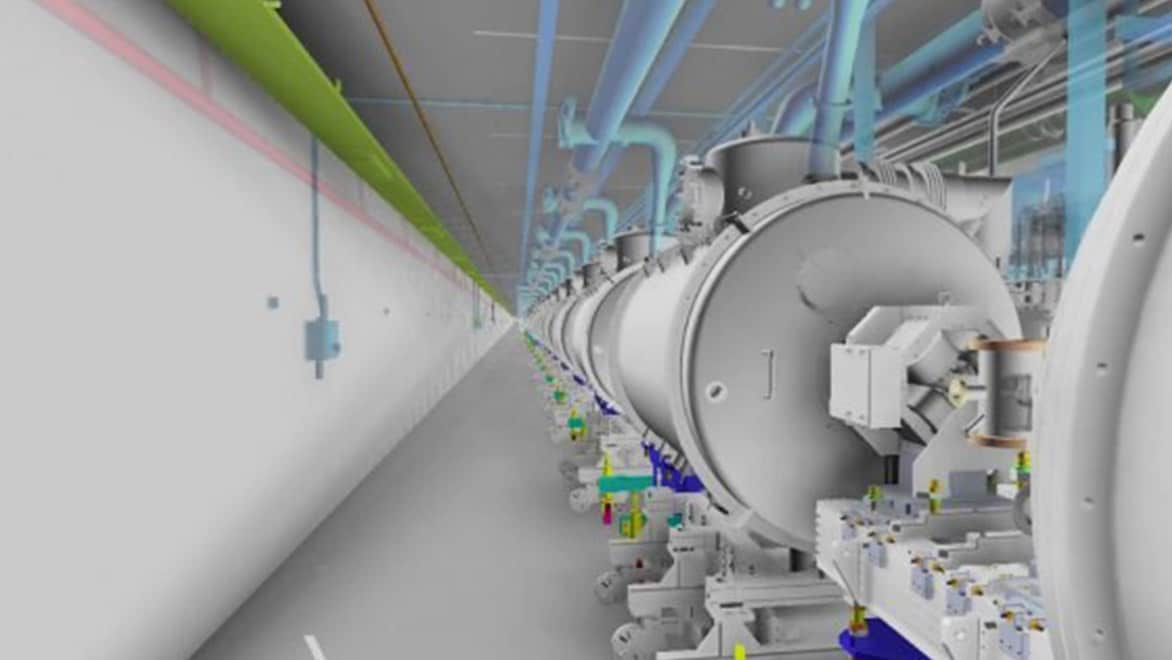

3D BIM Model from the ESS project. Image courtesy of Skanska Sweden.

“We have an outstanding team, the cooperation and support of our member nations, and a shared commitment to deliver a world-class research facility,” says Kristian Gerdtsson, design manager at Skanska for ESS. “But we’ve definitely given ourselves an advantage on every level: quality, efficiency, speed, productivity, and cost-effectiveness by selecting the right BIM software.”