SHANGHAI MUNICIPAL ENGINEERING DESIGN INSTITUTE (SMEDI)

BIM-enabled Design Leads the Future of WWTP Projects in Shanghai

PLANT DESIGN

Share this story

Simulation tools are pushing the envelope for underground infrastructure

Shanghai Municipal Engineering Design Institute Co. Ltd. (SMEDI) worked with Shanghai Chengtou Water Group Co. Ltd. to deliver a mega underground wastewater treatment plant (WWTP) with the aim to make it the most sustainable and intelligent facility of its kind in China. The project is a finalist in the AEC Excellence Awards 2019 for Infrastructure Design medium projects.

Meeting the challenge of building China's largest downtown underground wastewater treatment plant

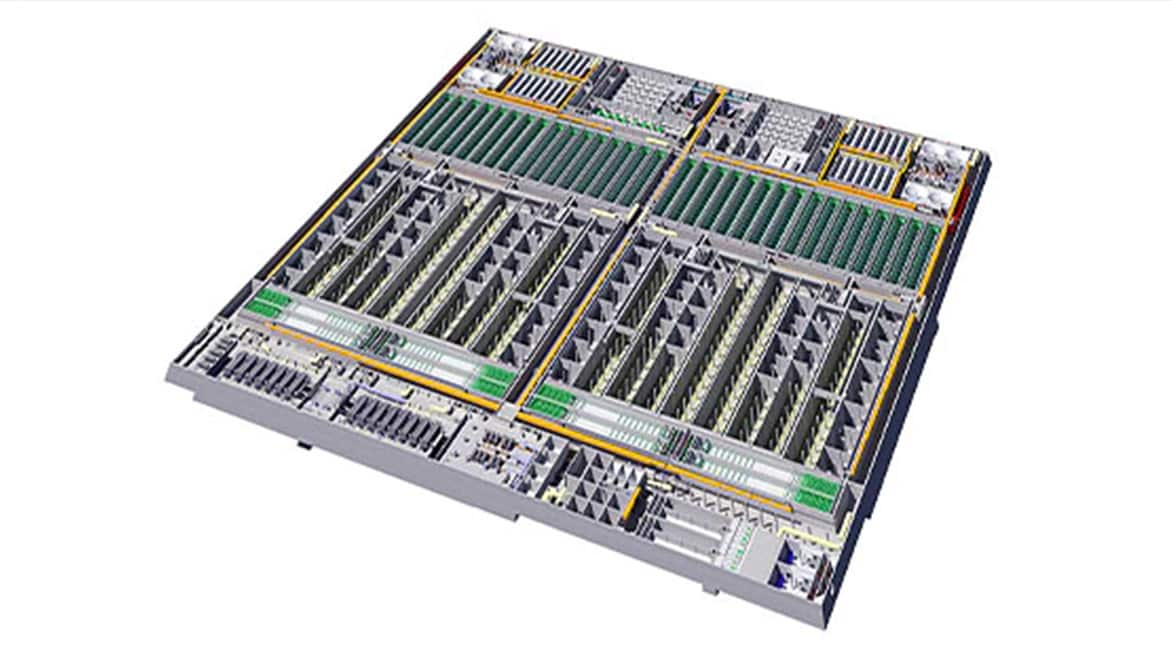

The construction of the WWTP is a complex undertaking. With more than 40 tanks and 7,560 facilities in a compact space of just 36.84 acres, located 17 meters underground, it requires a lot of coordination and precise planning.

With a deadline of 30 months, the project will be delivered on February 2020 overcoming the major challenge of working in China's largest soft soil foundation pit. An efficient construction organization plan capable of balancing safety, time and investment was paramount.

The invisible wastewater treatment plant in the heart of Shanghai

Jingfei Huang, project’s BIM manager explains some other challenges the team had to tackle during the design and construction of this mega project. Issues like how turbulent water flows in small areas can reduce the efficiency of the WWTP and may also cause damage to facilities, or how inadequate ventilation in confined spaces can lead to the accumulation of toxic gases which would be harmful to the facilities' staff, or how the use of conventional ventilation methods that can contribute to excess energy consumption. All of these and other challenges in a project of this nature and magnitude were successfully addressed by using BIM tools throughout the design and constructions of the project.

Using BIM to aid collaboration from design to construction

A team of more than 40 engineers, specialized in a wide range of disciplines, worked together to find optimal solutions for the layout of the underground WWTP. By using BIM software and workflows to design, analyze and simulate all the models and data, SMEDI was able to decide the preliminary layout in just a few weeks; a task that would have been much more difficult and time consuming to complete by using 2D drawings alone to envisage spatial arrangements.

Furthermore, the ability to truly comprehend the spatial layout of the project was vital. Viewing the positions of 7,560 facilities and the location of 800 km of pipes, ducts and trays, from any angle, was crucial in reducing mistakes in the design scheme. To do so, the project planners implemented parametric adjustments in Dynamo (for Revit) after using Formit to quickly sketch various schemes. Then, the team collaborated on the geographic information system using Infraworks, and imported models from Formit to Revit to finish the details of each water treatment tank.

A bird view of the construction site of Shanghai Taihe WWTP

Finally, by integrating all models and running simulations of the entire construction sequence in Navisworks for conflict examination and developing immersive visualization experiences (VR) through Revit Live and HTC Vive, the team was able to reduce mistakes, minimize the environmental impact of the project, and ensure construction safety. Moreover, the construction efficiency was greatly improved.

Enhancing efficiency and reducing risk with Navisworks and Revit

The project involves 600,000 meters of cable laying, with no margin for error. A smart solution was key, so the project team used an automatic cable laying tool developed on Revit. By using Navisworks and Revit, construction risks on site were avoided and the construction efficiency has been greatly improved.

Once the facilities and cable trays were laid out, the tool designed the optimal path for the cables, and generated the cable inventories and order lists accordingly. It also generated an efficient construction sequence, facilitating the procurement and installation of cables. That installation could also be accelerated as fittings and elbows of ducts and trays could now be fabricated in advance based on the BIM-enabled design models. This approach significantly reduced the waste associated with cutting to fit on site.

Computational Fluid Dynamics delivers higher performing facilities

Optimal schemes for the flow of water and air can be validated using CFD (Computational Fluid Dynamics). In this way, using Robot Structural Analysis for analysis and simulation, the project team were able to assess the feasibility of the excavation scheme. As a restricted underground space makes the water flow more severe, the potential for hydraulic loss is even greater. SMEDI was able to make the required adjustments in CFD to find the right design to lower energy loss ensuring higher safety performance and reducing damage to the facilities.

A rational layout underground of Shanghai Taihe WWTP

“We singled out an optimal water flow scheme that can reduce turbulence by 50 percent”

—Jingfei Huang, BIM manager, SMEDI

Working towards the goal of delivering a green and sustainable WWTP, the team used CFD to prove the design could deliver the best arrangement of ducts and deodorizing facilities to meet emissions standards while minimizing operational energy consumption.

Saving time and money through smart analysis

The goal in placing the facilities underground at the Shanghai Taihe WWTP was to return most of the ground level space to a public use parks scheme and minimize the impact on the surrounding environment.

The AEC solutions from Autodesk helped the team share all outcomes at any time, which would have taken a long time to gather and coordinate separately, as in some above-ground WWTP projects.

“The team spotted more than 1,200 collisions among 800 km of different types of pipes, ducts and cable trays in Navisworks.”

—Li Yijun, Chief Engineer, SMEDI

The project team calculates that by using Robot to perform these calculations to determine the best excavation sequence from top to bottom across 30 separate openings, the team was able to reduce the construction term by almost three months.

The project team also estimates that the cost of pit excavation was reduced by 40% compared to the conventional methods thanks to the analysis and simulation tools available from Autodesk. These provided a reliable and effective way to solve problems, where traditional calculation means would have failed. Thanks to its intelligent design, the Shanghai Taihe WWTP is well on its way to meet the demands of continuous population growth and the pressure on environmental resources to keep the water flowing in Shanghai.

A photorealistic image of the inlet pumping station by Autodesk Rendering®

Key takeaways

- BIM tools and workflows enhanced collaboration and helped minimize the energy consumption and material cost.

- Virtual Reality allows the design team to comprehend the spatial layout of a complex underground project.

- Robot helped SMEDI calculate the optimum excavation sequence, speeding up construction by three months.

BIM for plant

Autodesk solutions supports plant professionals across the project lifecycle. Deliver better BIM solutions using the AEC Collection.