TDINDUSTRIES

How TDIndustries’ technology journey is leading to greater client satisfaction

CUSTOMER SUCCESS STORY

Share this story

Data exchange and collaboration changed the game for TDIndustries

As one of the largest mechanical engineering and plumbing subcontractors for the Southwest U.S.’s building industry, TDindustries has evolved their processes and technology so that it can adapt to – and stay ahead of – the challenges of the changing engineering landscape. By adopting integrated BIM workflows using Autodesk® Revit®they’ve been able to reduce traditional schedules by 30% and increase estimating efficiency significantly, allowing them to reallocate 50% of resources onto higher value, more client-centric activities.

Mounting pressure to deliver better builds

Faced with increasing project complexity, sky-high stakeholder expectations and mounting pressure to deliver better builds – faster, TDIndustries stays focused on its core objective: delivering exceptional client satisfaction.

As one of the largest mechanical engineering and plumbing subcontractors for the Southwest U.S.’s building industry, the firm has evolved its processes and technology so that it can adapt to – and stay ahead of – the challenges of the changing engineering landscape.

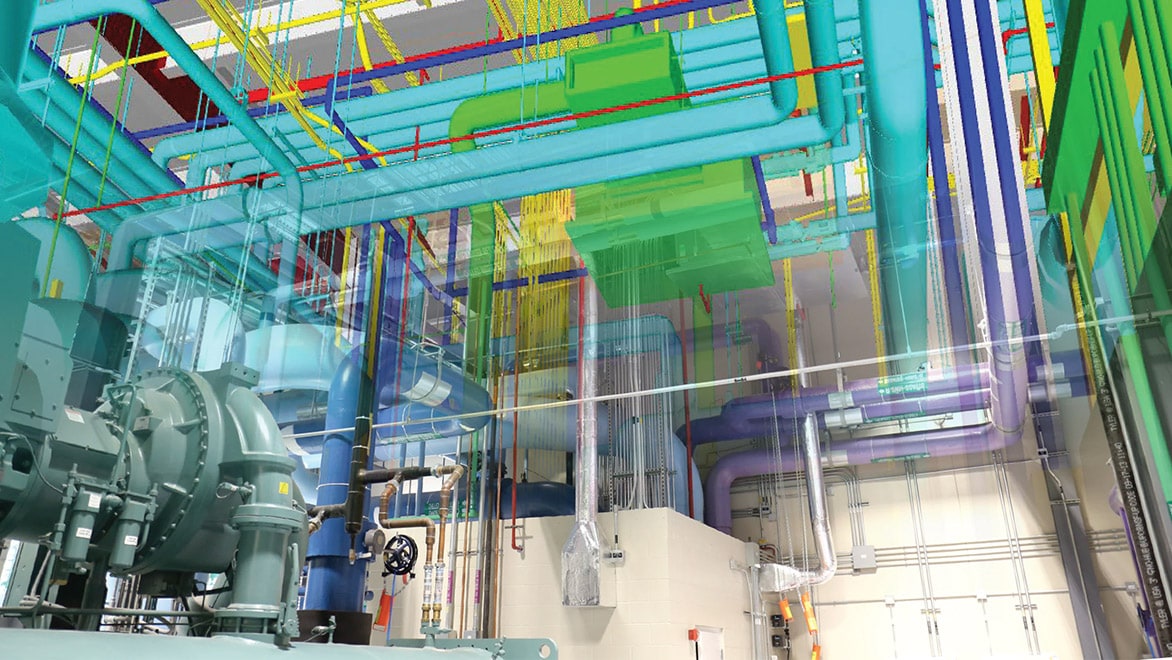

Image courtesy of TDIndustries

Text-only; 1 column

“Our end-goal is to make sure that the owner has a product they are delighted with,” explains Ken Luong, Project Manager at TDIndustries. But it can be challenging, he says, “Customers and owners are looking for their building to be built faster, and for everything to be seamless.”

Achieving this is no easy task. Especially when you’re delivering large-scale, complex projects like stadiums and arenas with team members involved at every stage of the project lifecycle. With a focus on owner’s varied requirements, TDIndustries must deliver every single project at the highest standard and in the shortest possible timeframe.

In response, TDIndustries has adopted integrated BIM (building information modeling) workflows using Autodesk® Revit® – and it’s ushered in a new era of competitive advantage.

Josh Robinson, estimator at TDIndustries puts it this way, “We have to grow with technology to utilize all the tools we can to give a better product to our customers.”

This new approach has not only helped them achieve the excellence they strive for, it’s also increased accuracy across all their projects and led to efficiencies which have had a big impact on their bottom line.

Coordinated data gets teams speaking the same language

With projects as complex as the ones TDIndustries delivers, small inefficiencies are magnified across the project lifecycle – and can become a barrier to project success and client satisfaction.

Before they adopted Autodesk software, data was partitioned by job role. Recognizing that constantly having to “translate” data between architects and engineering teams was inefficient, TDIndustries now uses BIM to speak a common language with architects and engineering teams. As soon as they switched to a more integrated approach, leveraging a centralized Revit model for storing and sharing data, they started to see the benefits.

For Ken, one of the biggest innovations has been to leverage integrated workflows in Revit for full visibility across project teams, “Number one is being able to design everything in Revit and be able to use that model in multiple operational units – engineering, coordination and estimating. Everything now is more real-time, everything’s a lot quicker when we need responses to pricing, to design changes.

I think that’s huge.” says Ken.

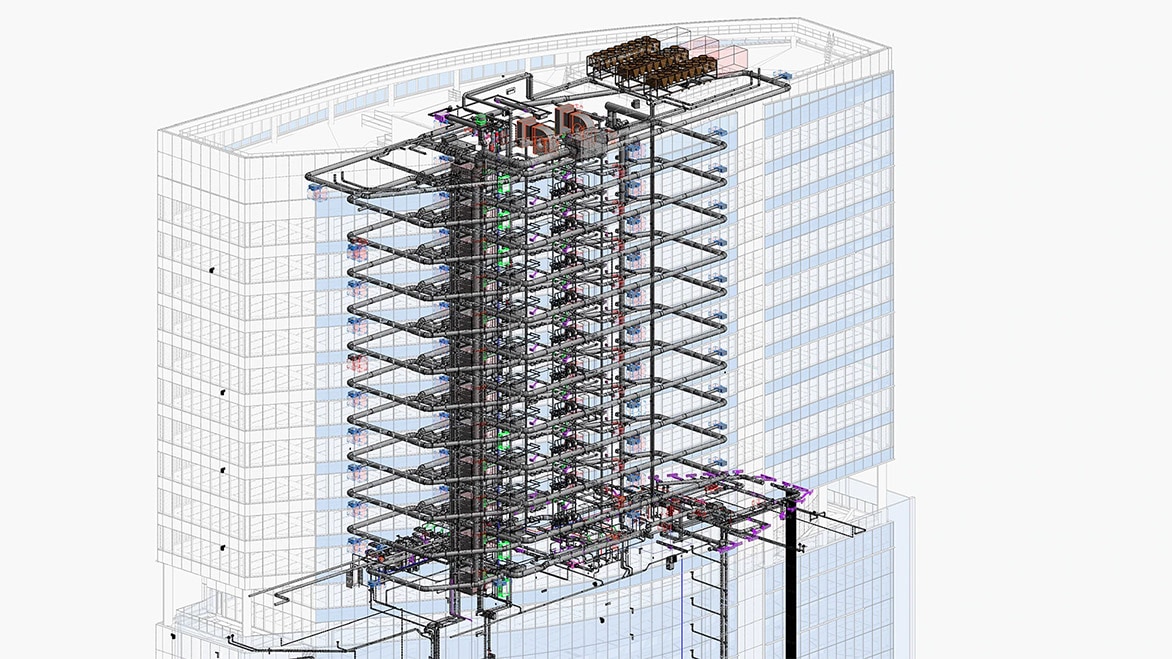

Image courtesy of TDIndustries

“Before, we had multiple databases that would not talk to each other very well. Now, there’s no translating. We’ve created one umbrella for the database. So that just helps us increase efficiencies.”

—Ken Luong, Project Manager, TDIndustries

A competitive strategy for winning more work

TDIndustries’ commitment to client satisfaction is evident right from the start of their projects. And being able to demonstrate that in the bid phase is giving them the edge over their competitors.

Their integrated way of working is a key factor which helps them impress clients and win new projects. Accurate estimating and pricing are increasingly becoming key – and helping clients visualize their project with a 3D model has been a game changer.

Josh says that the market is moving towards delivering as-built 3D models for clients and the effect on potential clients is noticeable. “If you can show a client a 3D model with their pricing when you walk into an interview or you’re trying to win a job,” Josh explains, “It gives them more confidence in you.”

Liz Welch, Mechanical Engineer agrees: “Using Revit in the early stages of pre-bid and design has been advantageous and gives us a competitive edge,” she says.

Leveraging faster, more accurate pricing

When you’re working against the clock to deliver complex projects in a short timeframe, any time savings is an advantage. And TDIndustries has managed to increase estimating efficiency significantly, allowing them to reallocate 50% of resources onto higher value, more client-centric activities.

Image courtesy of TDIndustries

Text-only; 1 column

How?

By creating a Revit model early on and incorporating the latest engineering data to give faster and more accurate pricing estimation.

Now, TDIndustries can make adjustments as part of the natural progression of design, and relay pricing impacts in a more timely fashion – eliminating the need to redraw or recreate the data.

“We’re able to turn around pricing faster now because we’re all linked into one database,” says Josh. “This has significantly reduced lead times and helped TD keep on top of pricing updates that need to be made after every design change.”

It’s a sharp contrast to the old industry standard where engineers were updating plans which they often had to start from scratch. “Instead of redrawing everything, we’re tweaking the model to include all the costs inside that job,” says Josh.

“So a process that would take two weeks is now cut down to a week.” Liz adds, “With Autodesk® ESTmep™, and a readily available visual model, estimators have visual confirmation that parts will work as intended. It’s transformed our takeoff process into more of a review than start-from-scratch planning,”

“Already we can see a lot of return on investment. We’re saving so much time, which has added value, to not only ourselves but our end users and the owners.”

—Ken Luong, Project Manager, TDIndustries

Improving constructability by bringing design and coordination together

With data-rich Revit models available from the very start of a project, TDIndustries can bring in real-world fabrication parts into the Revit model and its cut timelines, streamlined coordination and increased accuracy.

On a recent design-build project with critical lead times, TDIndustries combined its 3D initial pricing model with a fabrication database to identify parts, order them ahead of time, and update the budget for a more accurate estimate.

Image courtesy of TDIndustries

Text-only; 1 column

It’s improving constructability too. Using the model, TDIndustries and the trades can communicate any issues in design and construction much earlier in the process and make the changes needed to ensure the building will operate at maximum efficiency.

“As we’re starting to move into coordination and trying to use fabrication, we want to bring our actual real-world fabrication parts into the model so that we can more clearly understand if the design is constructible” explains Ken. With Autodesk tools like ESTmep for accurate pricing models, Revit to identify constructability challenges, or Autodesk® BIM 360®for maintenance input, TDIndustries comes to the table with critical information that helps everyone design a better, more constructible building.

For TDIndustries, all this adds up to better ROI on projects. Working with accurate models, they're able to eliminate labor-intensive rework, cut the construction schedule and reduce the number of RFIs through more effective collaboration.

They’re seeing that, in many cases, these integrated design-build projects can reduce a traditional schedule by up to 30%. Using Revit and Autodesk® Navisworks®to identify virtual design coordination challenges early is the main contributor to realizing this benefit.

An even brighter future for TDIndustries

While the integrated engineering journey has only just begun for TDIndustries, the success they’ve experienced so far has encouraged them to continue, while keeping their focus on creating more value for their clients and greater efficiencies for their firm.

TDIndustries is now exploring how technology like VR can help equip clients and field partners with the tools they need to visualize the engineer’s vision early on.

“Looking at it in the 3D model – we’ve even been experimenting with some virtual reality – it helps our field partners to see how the engineer envisioned it,” explains Liz.

While the firm looks set to continue, “doing flashy things with our VR, with BIM 360, with the Revit models,” as Ken puts it, the desire to deliver excellence and create value for their clients will continue to be the driving force behind TDIndustries’ commitment to evolving its technology and processes.

Image courtesy of TDIndustries