YAMATO SCIENTIFIC CO., LTD.

Synchronizing data under one suite of solutions to increase efficiency

Design & Manufacturing

Connected data among manufacturing, architecture, and computer graphics (CG) leads to winning prime projects

Yamato Scientific is a general manufacturer and trading company that creates science and technology equipment, research facilities, analysis and measurement equipment, and industrial testing and inspection equipment. Positioned at the intersection of architecture and manufacturing, it became critical for Yamato Scientific to unify data from multiple design and manufacturing systems to grow their business.

By adopting a suite of solutions, including Autodesk Product Design & Manufacturing Collection and Revit, Yamato Scientific optimized their workflows and is now able to win more business–including being awarded bids on one of the largest pharmaceutical development laboratories in Japan and an exciting virtual reality project in partnership with the University of Tokyo.

Creating state-of-the-art testing and research facilities

Yamato Scientific has been in business in the science technology industry for more than 130 years. Founded initially as a wholesaler of medicinal glass containers, they have expanded their business to a wide range of fields, from laboratory glass containers to science and technology equipment, and most recently, to industrial equipment.

Akio Nakamura, Katsuhiro Matsumura, and Masahito Nakada. Image courtesy of Yamato Scientific.

Akio Nakamura, Katsuhiro Matsumura, and Masahito Nakada. Image courtesy of Yamato Scientific.

Driving the expansion of their services was Yamato Scientific's desire to respond to a wide range of customer needs. They not only supply equipment to national and local governments, universities, and research institutes, but they also handle the entire design to delivery process for test and research facilities, including development, manufacturing and sales, consulting, and post-completion maintenance.

Disconnected data results in disconnected workflows

The company has two focus areas, manufacturing and architectural design. The primary manufacturing division of Yamato Scientific is based at a factory in Minami Alps City, Yamanashi. This factory performs integrated production from sheet metal processing to painting and assembly. Research and development departments are spread across four locations in Japan, primarily at the company's headquarters in Harumi, Tokyo. A key challenge of Yamato Scientific's stemmed from the fact that they used various manufacturing and architectural design tools throughout their subordinate departments.

Previously, the manufacturing department used Pro/ENGINEER® and other various CAD software for their 3D modeling, but they constantly struggled to fully utilize their design data. Yamato Scientific's architectural design team used 3ds Max for renderings and perspective drawings, and data between Pro/ENGINEER and 3ds Max was incompatible. This meant that even though the architectural design team was creating renderings in 3ds Max when bidding on new projects, that data would not port over into their CAD system without many errors, and the manufacturing team ended up spending extra time on design rework.

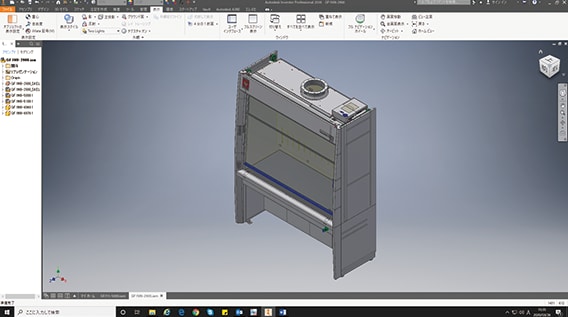

Model of scientific equipment created in Inventor. Image courtesy of Yamato Scientific.

Model of scientific equipment created in Inventor. Image courtesy of Yamato Scientific.

Another example of Yamato Scientific's struggle with these disconnected data sources came about when they needed to update their product catalog every two years. Instead of manufacturing and taking photos of their products–which would take excessive time and material to produce all versions of their many specialized product offerings–they wanted to use their existing manufacturing data created in their former CAD solution to create renderings that could be used in the catalog. The data would not flow through from their manufacturing team to the team producing the catalog, so they ended up rendering each product from scratch in 3ds Max.

"Because Pro/ENGINEER is a fairly high-specification 3D CAD software, there was a lack of data transferability. When we tried to use the data with the 3D computer graphics program, 3ds Max, there were many errors, and it took a lot of time to fix," says Katsuhiro Matsumura, Executive Officer, Research Facility Division at Yamato Scientific.

Competing for a large-scale project

Yamato Scientific started to consider the possibility of how they could make better use of their design data when they participated in a competition with general contractors and design firms to win the project for a pharmaceutical development laboratory. Completed in 2011, the laboratory was created to be a state-of-the-art, energy- and CO2-saving scientific research center, and it is now one of the largest of its kind in Asia.

Competing for the bid on a pharmaceutical development laboratory. Image courtesy of Yamato Scientific.

Competing for the bid on a pharmaceutical development laboratory. Image courtesy of Yamato Scientific.

Matsumura was a key player in the competition. He looks back on those days and says, "A significant task was working on the renderings for the presentation. In 2007, we were using both Form-Z and 3ds Max as our 3D computer graphics programs, but to meet the request from a partner stakeholder, we needed to provide data created in 3ds Max."

In the end, the winning point in the competition was the presentation video Yamato Scientific made with lifelike renderings in 3ds Max. There were not many 3D computer graphics program presentations at that time, and the high-quality video was praised as "easy to visualize."

Maximizing their potential by synchronizing data

Winning the large laboratory project gave Yamato Scientific a taste of what they could accomplish if they effectively used their design data in all use cases. Yet, they still faced the challenge of creating an environment that could handle a variety of projects. They needed their manufacturing workflows to be efficient enough to bid on large cornerstone projects, and in particular, they wanted to make it possible to use processing data directly from their 3D CAD system.

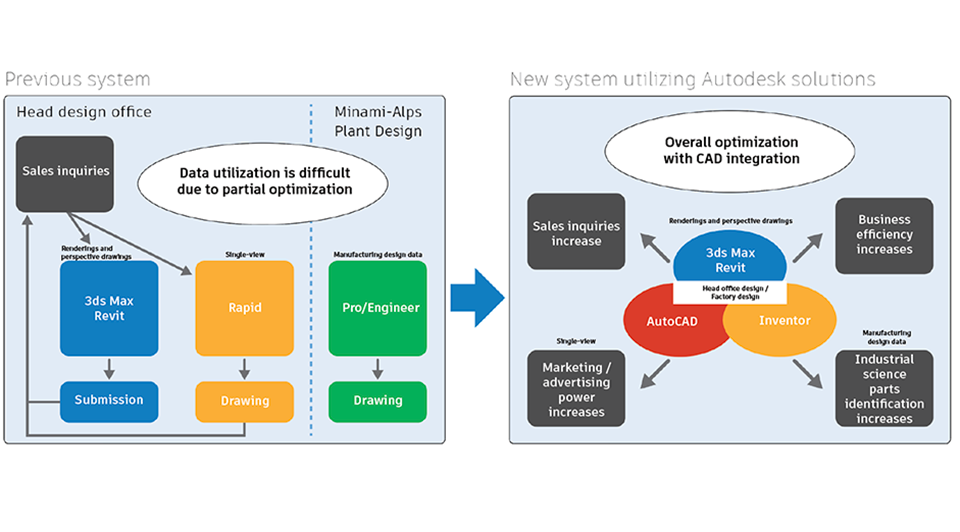

Even though the Yamato Scientific manufacturing team had devoted 10 years to creating a workflow that worked for them using their former CAD solution, they eventually realized the incompatibility of their data and the data of the architectural design team was becoming a barrier for them to grow. They came to a turning point in 2016 when they decided to enhance the cross-functional collaboration between divisions by standardizing all teams on Autodesk solutions.

Increasing efficiency by getting everyone on the same platform

Masahito Nakada, General Manager, Technical Department, Research Facility Division, talks about the process at the time as follows, “Around 1995, when we introduced Pro/ENGINEER, there were few options for 3D CAD software, but we had more options as time went by. It became easy to imagine the efficiency of having a single source of data to be used for multiple purposes, on top of reducing costs. We chose Autodesk so that we can have all solutions for our company from one vendor, and we adopted Inventor for manufacturing and Revit for architecture, in addition to 3ds Max."

He continues, "We prepared a detailed plan and made the transition. We asked a professional consulting company to build the design environment tailored to our use case. All the designers carefully planned and executed the ways to reuse the huge amount of design data we had created so far. In particular for the CAM aspect, we used to generate toolpaths with Pro/Engineer, but now with Inventor, we can use the exact same data from design to machining."

With a unified suite of solutions, Yamato Scientific is able to improve design and manufacturing efficiency by linking data between design departments.

With a unified suite of solutions, Yamato Scientific is able to improve design and manufacturing efficiency by linking data between design departments.

Supported by these efforts, Yamato Scientific currently uses AutoCAD LT for construction and specification drawings, Inventor for creating manufacturing drawings, and 3ds Max for presentation materials and product catalogs. They are ready to use Vault Professional for centrally managing data created by each software.

"Centralized data management in Vault is straightforward to understand. There is a Japanese-owned company in Vietnam that supports design and estimation in the construction industry, and since last year, we have been supporting them with drawings. We also work with the local site through Vault, and there is no problem at all. We have realized firsthand that it is possible to make good use of overseas staff, such as those in Vietnam, and to collaborate with other companies smoothly," says Matsumura.

Extending data to Virtual Reality

Now, Yamato Scientific is finding ways to use its design data in new ways. In addition to their newfound ability to show customers concepts in 3D, they plan to start using Autodesk VRED to create virtual showrooms for customer meetings.

The company is also currently working on a Virtual Reality (VR) project in collaboration with Professor Yoshiko Tsuji, Director of the Center for Environmental Safety Research at the University of Tokyo. As part of an environmental safety education program to prevent human accidents in the laboratory, Yamato Scientific creates a virtual space of a laboratory where one can experience what kind of operational errors, assumptions and misunderstandings by oneself or others in the same room can lead to accidents.

Virtual showroom of laboratory. Image courtesy of Yamato Scientific.

Virtual showroom of laboratory. Image courtesy of Yamato Scientific.

Since the data from Yamato Scientific's testing and research facilities is used directly in the VR using Revit, the result is very realistic. In addition, they are currently working on making it possible to experience the five senses, including sound and smell.

With a new suite of solutions and data utilization in their toolbox, Yamato Scientific expects to make further progress with innovation that supports their customers' needs.