What is building information modeling (BIM)?

Building information modeling (BIM) technology is unifying the construction process in the digital world, bringing untold benefits and new ways of working.

Zach Mortice

September 9, 2024 • 20 min read

Building information modeling (BIM) technology is crucial for innovation in the AECO industry, addressing fragmentation and inefficiencies by organizing design and construction data.

BIM enhances collaboration and communication by providing a shared, continually updated 3D model that improves visualization, decision-making, and resource management across all project phases.

BIM technology mitigates risks, reduces rework, and enhances project outcomes by integrating various dimensions that handle scheduling, cost, sustainability, and maintenance.

BIM's real-time data from IoT sensors optimizes building operations and maintenance, contributing to improved sustainability and reduced lifecycle costs.

The adoption of emerging technologies, along with standardized protocols, is expanding BIM’s functionality, despite challenges in interoperability and cultural shifts within the industry.

Building information modeling (BIM) is a digital platform; a visualization tool; and, most important, a way of working in the architecture, engineering, construction, and operations (AECO) industry that translates the unpredictable and dynamic work of design and building into data and organizes it. It’s the fundamental front for innovation in the design and construction world that’s intimately connected to nearly every other industry-wide technological innovation in a sector of the economy in sore need of it. According to McKinsey, large construction projects typically take 20% longer to finish and are 80% over budget on average. Construction-sector productivity has declined since the 1990s, and it’s one of the least digitalized sectors of the economy, second only to agriculture and hunting.

This state of affairs is a result of the extreme fragmentation and atomization of the AECO industry, which is organized as a network of regional and local firms working on wildly different project types in varied geographies, each addressing local conditions and regulations. Essentially, each new building is a prototype created by siloed builders and designers, where standardization and uniformity are rare. This makes it difficult to capture, share, and use data that could streamline production, as is done in more unified industries, such as manufacturing.

BIM for AECO is used by designers at architecture firms, engineers, builders at construction firms, and both operations and maintenance specialists, as well as building owners themselves. Every phase of a building’s conception and operation can benefit from BIM. By sharing a 3D model of a building embedded with data that defines its properties (materials, dimensions, spatial relationships, energy performance, and much more) with the entire team across the cloud, BIM offers incredible control over the entire process.

10 benefits of building information modeling

BIM offers comprehensive benefits across the construction lifecycle, from streamlined collaboration to improved outcomes:

1. Improved collaboration and communication

When BIM is shared across an entire project team, from the owners to the subcontractors, everyone is able to operate from a continually updated single source of truth, thus dramatically reducing the need for lengthy RFIs and crisscrossing emails. The model itself becomes the venue for answering questions, not a data set buried anonymously on a colleague’s hard drive. With greater and greater degrees of automation, BIM coordination technology can generate reports and metrics, disseminating them to the relevant team members.

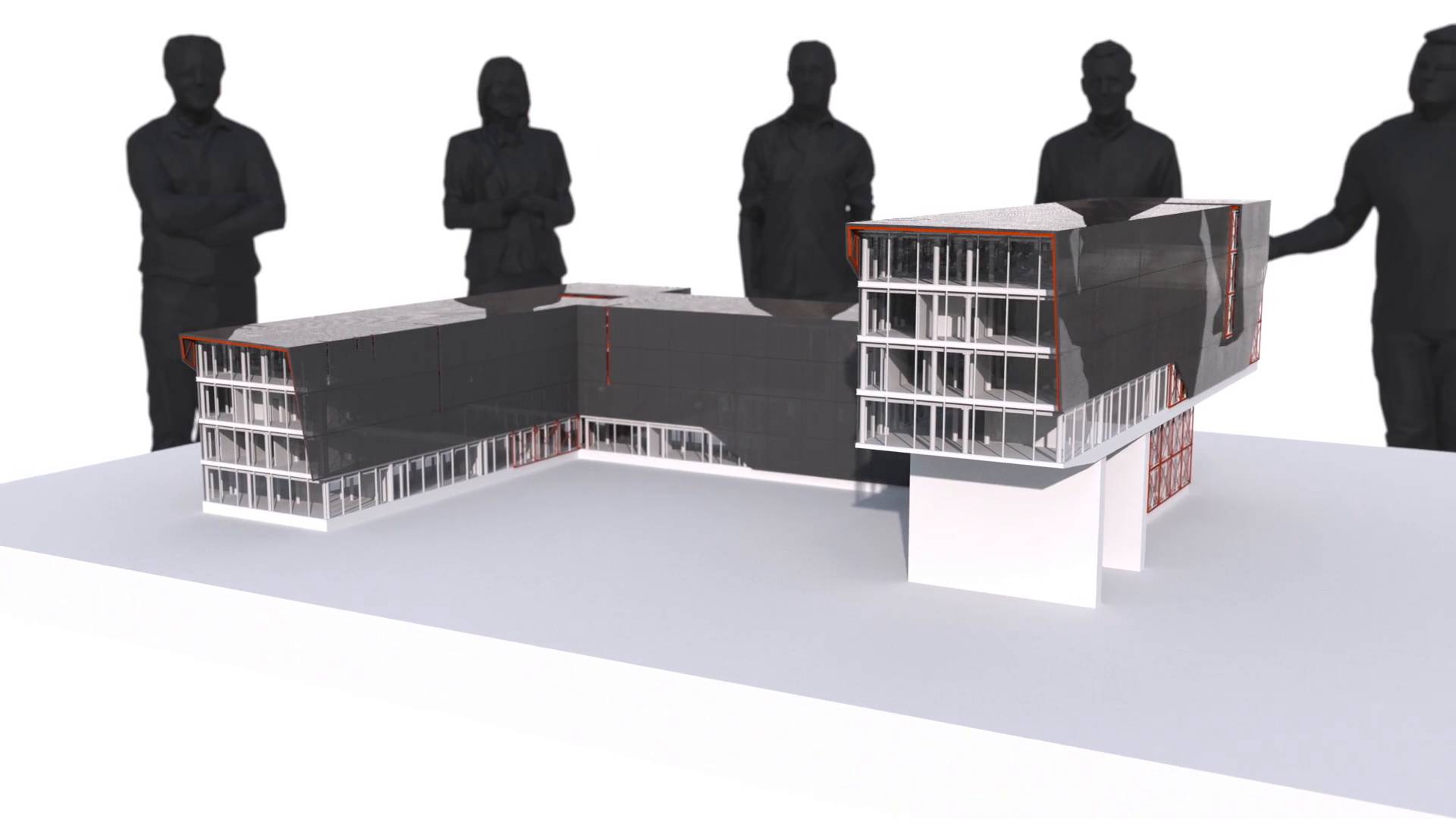

2. Enhanced visualization

Fundamentally, BIM is a modeling tool that requires buildings to be conceived of as a 3D object. This makes it a superior visualization tool, both for architects to refine their designs and to make their pitches to the owners footing the bill. Similarly, builders and engineers can use this visualization capability to peel back layers of structure and facade to better understand thorny and complex problems before they’re committed to in steel and concrete. Public projects that require broad buy-in from diverse communities benefit immeasurably from BIM’s visualization features, as they offer the granular detail necessary to accurately convey the program and function of any building.

3. Enhanced resource management

The purpose of BIM’s digital transformation is to drive efficiency and the savvy deployment of resources at every turn. Because BIM codifies the building process into data, it’s an invaluable aid for assessing building components and budgeting for them, often automating the takeoff process with a far greater degree of accuracy than manual counting.

4. Risk mitigation

From construction safety to cost overruns and delays, many things can (and do) go wrong on a construction site. But BIM can add new layers of security for each of these issues. With all team members working within an integrated, dynamically updated model, clashes and mistakes are easy to spot before they become costly. For example, with clash detection, engineers for China Zun Tower in Beijing reduced change orders by 80% compared to similar projects. Furthermore, artificial intelligence (AI) tools operable within BIM are learning how to automatically assess risk using imagery, in terms of construction safety, delays, and cost overruns.

5. Improved project outcomes

BIM means projects get done faster, for less money, with higher-quality results. An international survey by Building Smart International revealed that 77% of firms see a common data environment such as BIM as the best way to share large amounts of information. Two-thirds of firms say BIM is a faster way to resolve clashes and quality issues, to facilitate a collaborative project environment, and to improve the understanding and visibility of design decisions.

6. Optimized operations and maintenance

BIM’s role doesn’t stop at the ribbon cutting. BIM provides critical insight into how buildings function every day, from MEP and HVAC systems to energy usage to solar thermal performance. It’s an irreplaceable measurement of building operations and maintenance and key to reducing building lifecycle costs, which are the majority of a building’s expenditure of energy and effort. By connecting the BIM model to Internet of Things (IoT) sensors, owners get a real-time stream of data on what their building is doing each moment.

7. Improved sustainability

Connecting BIM to both passive and active sustainability systems offers an unapparelled look at the energy and resources a building is consuming and producing. This allows owners to study how a building functions over time and tweak its performance in response, such as routing power generated by solar panels or wind turbines, reacting to the external temperature, or managing stormwater on site. AI integration means that these patterns can be shaped to minimize energy consumption automatically.

8. Rework reduction

This powerful and granular visibility into the construction process means that mistakes are spotted in the model before they need to be fixed in the real world. BIM allows teams to predict where problems might exist in the model, to untangle problems, and to sequence the construction trades needed to address them.

9. Preconstruction prototyping

As of 2022, the majority of architecture firm billings have come from renovations, not new construction. Whether architects and builders are addressing a greenfield site or a much more complex historic building, BIM is a critical tool to assess site conditions and begin the digital design process. Combined with reality capture technology and photogrammetry that integrates site imagery with a building model, BIM gives project teams an exacting understanding of the conditions they’ll be building within: site dimensions, urban context, transit connections, and more.

10. Data management

Building in a digital-native environment means that managing documents and data is far less awkward and cumbersome, with less need to switch back and forth between printed and digital documents. Plans, sections, and construction and detail drawings can be automatically generated for relevant team members, and the underlying data can be sorted and reordered with the ease of a Microsoft Excel sheet. Beyond a centralized location for all documents, BIM also offers a full suite of version and access control tools, as well as document search capabilities.

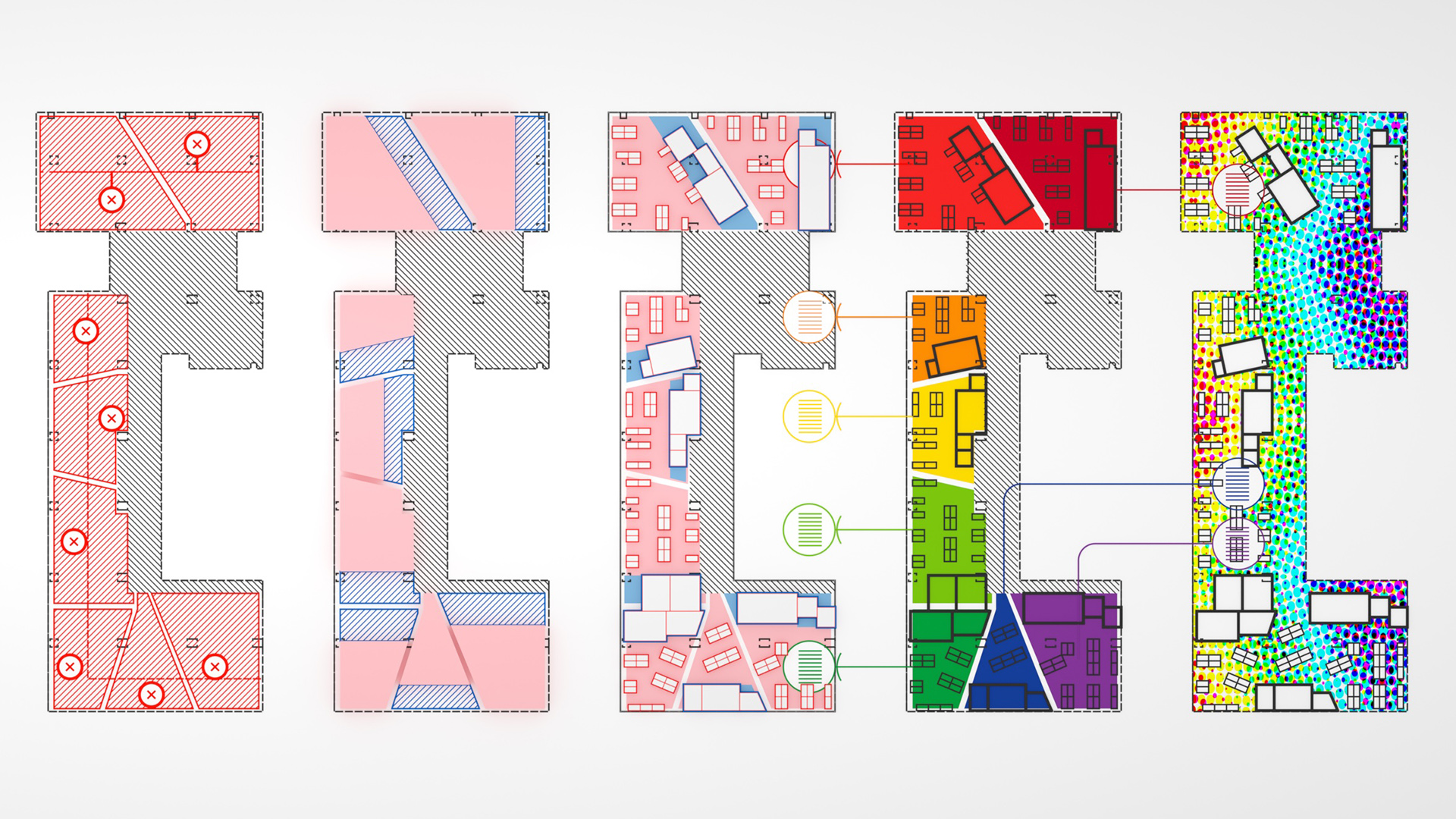

Deep dive into BIM components

From its baseline as a 3D-modeling platform, BIM continues to expand its functionality with added “dimensions.” For example, 4D BIM is typically defined as integrating project scheduling and sequencing, allowing builders to see in real time how individual elements under construction align with the overall plan and verify their correct and sequential installation. 5D BIM refers to cost, assigning dollar values to individual elements that generate updated budgets in response to changes on the construction site. The next few dimensions of BIM are less well-defined, though 6D BIM has been defined as managing the sustainability and carbon footprint of building elements, and 7D BIM has been identified as incorporating maintenance, management, and operations data, juggling maintenance schedules, warranties, inspections, and more.

These features are spread over many software tools, such as Autodesk’s Revit. BIM software can be attuned to specific industries (architecture, engineering, construction) and to individual building systems such as MEP or structural systems. Additional software modules focus on project scheduling, sequencing, and collaboration.

The profusion of BIM platforms has necessitated a united set of standards and protocols that is gradually gaining acceptance. Developed in the UK, Standard 1192 was an early BIM-standard forerunner. In 2018, it evolved into Standard 19650, which essentially delocalized the first standard to create one that would be applicable internationally. This standard prescribes best practices using BIM, defining roles and responsibilities; milestone and deadline structure; and ways to share information, graphic standards, bidding documents, and more.

Implementing BIM and measuring ROI

Effectively implementing BIM requires both administrative organization and soft-touch interpersonal HR patience. A plan to implement BIM, often called a BIM execution plan (BEP), should be assembled by the entire building team. It should define roles and responsibilities for all members: the client, architects, builders, engineers, and all manner of subcontractors. A key baseline decision will be which BIM software platforms to use; other elements will include project deliverables and schedules, parameters outlining when and how team members will share information, key project milestones, and an overall timeline. (Much of this will overlap with BIM standards.) More granular elements of the BEP might include the level of visual fidelity and embedded data in models, meeting schedules, required construction tolerances, file-naming conventions, quality-control procedures, BIM-iteration and version-control procedures, and data transfer management.

There is no established standard for measuring the ROI of BIM, and it’s a difficult task because BIM benefits often come through preventing negative outcomes (that would be easier to quantify if they occurred) from happening. Likewise, investment returns that accrue to a single group within the team might be easy to calculate, but BIM benefits are spread over the entire team in diverse and unique ways that might be harder to quantify.

But there are a handful of consistent costs (or investments) in time and money that must be contended with in all scenarios to reap these BIM benefits. First, there are the start-up costs to get BIM running in a given firm. That can include computer hardware and software, as well as training on the tools. Second, given BIM’s customizability, another ramp-up phase includes the cost to tailor BIM to a specific project. Finally, a more ambiguous layer of longer-term expense outlays associated with BIM includes changing internal processes that are difficult to quantify. A BIM model may benefit from incorporating different amounts and types of data at different times than in traditional workflows.

Meanwhile, BIM adopters should expect several levels of returns. At the most basic level, there should be a financial return on investment that accrues to the firm from the project itself by finishing projects faster, for less money, and with higher quality, winning the AECO team esteem and return customers. There are also returns that are harder to calculate and are more diffused across the entire firm. These might be increased staff competency, technical facility, and workforce retention. With BIM, firms could offer new services and increase their overall productivity.

BIM in action

Science Park in Mumbai, India

This coiled steel and glass domed structure by Hiten Sethi & Associates, currently under construction, is partially covered in a diaphanous shroud that was developed with parametric modeling. A 3D model of the building’s site was generated with Autodesk ReCap Pro, and its complex, delicate geometry was generated with Autodesk Revit and BIM Collaborate Pro, which guided fabrication and material selection parameters. Infused with a desire to teach future generations the value of environmental stewardship and with cutting-edge sustainability technology, it won a 2023 Autodesk Design and Make Award.

Quay Quarter Tower in Sydney

Completed in 2022, this adaptive reuse project “upcycled” a 45-story high-rise. The engineering firm BG&E used BIM to make sure that 70% of construction materials used on the adaptive reuse were salvaged from the old building. That meant saving 12,000 tons of embodied carbon and 13 months of work. A BIM digital twin was used to test the viability of existing materials in order to minimize demolition. With team members spread across the UK, Middle East, and Australia, BG&E tapped the cloud collaboration features of BIM 360 to make sure that progress could be gained whenever and wherever there was a workday. The team used Autodesk Navisworks for clash detection, and the precision of Revit made sure that the historical legacy of this heritage-listed building would remain intact.

Roche Tower 2 in Basel, Switzerland

Designed by starchitects Herzog & DeMeuron, Roche Tower 2 is Switzerland’s tallest building. The architects won this ambitious plan’s approval from their client, the biotech company Roche, by strapping stakeholders into virtual reality goggles and taking them on a tour of the BIM model while it was still under construction. This digital twin, created with Autodesk Revit and BIM 360, is rich with metadata, including granular details such as noting where each power socket is located. Its elevator systems run automated diagnostics, and the digital twin monitors energy and drinking water consumption.

BIM’s impact on AECO projects

BIM technology is applicable to all lifecycle phases of a project. For initial project planning, developing a model of a building site can be as critical as developing an accurate model of the building itself, especially when complex, tight, or intensely urban sites are involved. Reality capture technology can be deployed within BIM to track site dimensions and context. With this tool, teams can collaboratively plan muster and staging points for material delivery and installation, as well as circulation routes through the construction site. BIM’s ability to organize project phases and schedules shines during the preconstruction planning phase, as does its capacity to organize documents; generate reports; and extrapolate plan, section, and detail drawings.

BIM was first widely introduced to the AECO industry via architects who leveraged its ability to visualize and refine form with unparalleled control. It has always been a superior design tool, allowing architects to share models and collaboratively alter details. Parametric modeling applications, which can generate thousands of formal variations within a given set of parameters for designers to sort through, can be integrated into BIM, instantly integrating abstract formal experiments into a detailed 3D model to see if a variation will work within the tightly defined functional requirements embedded in the model. BIM’s collaborative nature also means that the buildability of a given plan can be verified by structural or civil engineering teams members quickly and efficiently.

The construction phase of a project is when BIM’s most advanced features take center stage. BIM and construction work together to coordinate the most dynamic, and sometimes chaotic, phase of a project’s life. Within BIM, a digital model of the building under construction can be continually updated with reality capture technology so that mistakes and clashes can be spotted immediately and safety risks can be assessed and flagged. For example, reality capture platforms such as GAMMA AR allow builders to peel back layers of a digital model even as it’s overlaid on the physical build site (on a tablet or smartphone), allowing for inspection of plans for structural members, water and gas lines, and HVAC ducts. Embedded metadata (measurements, materials, properties) are integrated, and each element can be labeled with audio clips, text, and images. This type of detailed documentation, combined with BIM’s fundamental understanding of how individual elements of buildings relate to each other—how a facade panel hangs on to structure, that a wall must meet a floor, that a door is an opening between two rooms with different but related functions—means BIM technology can be proactive in spotting mistakes. For construction safety, platforms such as Newmetrix Construction Cloud and Autodesk’s Construction IQ can interpret a daily construction schedule in order to rerank the top safety risks as activity on the construction site changes.

When connected to IoT sensors, BIM technology can provide a real-time picture of what is happening in a building during construction and beyond. BIM in operations provides unparalleled insight into how buildings function every day, from MEP and HVAC systems to energy usage to solar thermal performance. When used with the right set of sensors, it’s an irreplaceable guide for real-time building maintenance and is key to reducing building lifecycle costs, which are massive; 70%–80% of a building’s overall lifetime cost occurs after its construction. By immediately locating problems within a data-rich 3D model, BIM sets the stage for rapid interventions from a multidisciplinary team.

BIM allows owners to fine-tune standard operations and refine maintenance regimens, but it also helps building owners go further. This data is equally critical for renovations, additions, and retroactive commissioning. Any way that owners want to improve their building, small or large, can benefit from having a living, dynamic model of the existing building with BIM. How will new solar panels integrate into the old system? How will the new wing of the hospital add to the facility’s water needs? Will new facade panels fit into the legacy structure? An up-to-date digital twin can quickly and definitively answer these questions. Looking even further afield, access to BIM data will likely help onboard new digital building technology that hasn’t even been invented yet.

Emerging BIM technology

A digital twin is the apotheosis of BIM: a dynamic model that reflects the as-built (or “as-operating”) condition of a building in real time. But new technologies are being integrated into BIM in more nuanced and complex ways that stretch its functionality and ease of use.

AI and machine learning are broad fields of technology that are making their way into BIM. AI powers technology platforms that can detect and predict safety risks on a construction site and its BIM digital twin, as well as monitor construction schedules and flag delays. AI can coordinate IoT networks, fly drones, and extrapolate new layers of metadata to be embedded in BIM models. In most cases, these AI algorithms are looking for time and cost efficiencies, as well as ways to minimize carbon emissions. For example, Bimmatch is a product identification and procurement platform that uses AI to select ideal materials and components for a given project, evaluating them by cost, carbon footprint, and more. The platform (which functions as a Revit plug-in) can automatically generate a bill of materials and promises to reduce the time spent manually searching for materials and components by 75%.

Given BIM’s ability to organize construction phase schedules, some compatible platforms use parametric processes to generate myriad methods and sequences to build projects. Users can reconfigure these constraints mid-flight and model contingencies in advance. In addition to cutting construction timelines, the company also says this level of detailed management can create more accurate construction bids.

AI can be used to generate forms, as well, with generative design. At the scale of a building or an object, generative design (integrated with Revit) creates variations on form within given parameters, often solving problems and meeting goals in ways that no human would ever find intuitive. These tools can maximize rentable square feet, minimize material usage, optimize daylight, or fine-tune circulation routes by simply placing furniture.

From the construction phase onward, much of BIM’s potential lies in the IoT technology that is required to feed accurate data into the digital twin model. These sensors can detect ambient temperature and moisture, the location and circulation paths of staff and visitors, energy consumption levels, and much more, all of which are critical to fine-tuning the operations of a building.

Virtual reality (VR) and, especially, augmented reality (AR) are adding deeper levels of immersion to BIM that are key to its role as a collaborative tool. AR is used to add visual layers (seen through goggles, a tablet, or a smartphone) of a BIM model onto an existing jobsite so that builders walking through can see the path of HVAC ducts not yet installed or structural supports still being craned up. Some platforms, such as Fologram and Twinbuild, use AR to add step-by-step wireframe construction guides that spell out where the next brick or shingle goes. Wholly interactive, visually rich VR and totally immersive digital environments, often called the metaverse, are playing a larger role in design and construction, as well, offering new heights of spatial simulation and walk-through potential.

Challenges and considerations with BIM and emerging technologies

Managing the cultural changes and anxieties around implementing BIM and adopting a radically different way of working are critical to the process. Because working collaboratively within BIM tends to level hierarchies that are well entrenched in the AECO industry, there can be a perceived intrusion of one trade or profession onto another’s turf, causing tension. Experts advise that very early in the process, leadership should focus on getting grassroots buy-in and specify each team member’s role to clarify potential ambiguity.

In terms of training, it’s important to identify the best staff members to take lead roles in managing their firm’s use of BIM. Top-level managers might not have the time or technical abilities to take on operational roles with the new system, so lower-level employees might make better BIM managers.

Once the team is assembled and ready for BIM, it’s best to start BIM implementation on projects that have already begun, because new projects are more likely to get delayed or canceled. With a project already in midstream, designers have a baseline level of familiarity that will help see them through the uncertainty of learning a new design process—and help them see how BIM will help solve problems they had been struggling with through traditional methods. The transition to BIM might start by asking about pain points in the traditional design process and explaining how BIM can ease them.

With the transition to an all-digital workflow, firms implementing BIM will also need to invest in staff training, data management, and security measures. And while the relevant security tools exist, they have not yet been sufficiently adapted to BIM’s specific security challenges and protocols, though both encryption and blockchain-based technologies hold potential for BIM.

The fragmentation of the AECO industry that BIM hopes to solve has remnants in the use of BIM applications. The lack of data interoperability among tools is a significant challenge. A recent National Institute of Standards and Technology study revealed that the lack of interoperability in facilities management costs building owners $15.8 billion annually. That’s 23 cents per square foot per year. BIM goes a long way toward addressing this gap, but there is no guarantee that all BIM tools will work together well. However, openBIM platforms, which do not restrict users to any specific proprietary platform, are increasingly available.

The future of BIM

Several nations have mandated BIM for public projects, and the tool’s visualization powers are being boosted by the adoption of video game design software, like the Unreal engine. AI is offering greater automation in the BIM process, and reality capture tools, mounted on a robot or extracted from smartphone photos, are flowing more and more data into the model. With each year, BIM is getting closer to tracking each electron of electricity and swing of the hammer that moves across a construction site.

A day will come when BIM ceases to be a discrete tool or part of the design and construction process. Eventually, BIM will grow to encompass design and construction itself, absorbing and refining each step of the process, becoming synonymous with it. Like most long-running technological breakthroughs, BIM will reach its zenith as it fades into the background, leaving only a transformed AECO industry in its wake.

This article has been updated. It originally published in August 2018.

About the author

Zach Mortice

Zach Mortice is an architectural journalist based in Chicago.