Generative design pushes maritime logistics to sail the seas of tech

Global maritime logistics is in transition—see how CIMC Smart Pallets is pushing the industry toward circularity and digitalization.

Betty Wang

December 7, 2021 • 6 min read

As an industry, international maritime logistics and transportation is overdue for digital transformation.

Companies such as CIMC Smart Pallets are pushing for smart technologies and circular business practices.

Using generative design, CIMC is speeding up its iteration and delivery times, increasing efficiency and competitiveness.

The international maritime logistics and transportation industry has a storied history spanning more than five centuries. When Christopher Columbus embarked on his transatlantic voyages in the late 15th century, he sparked the Age of Discovery, which ushered in global transportation and the exchange of goods and culture. In more recent years, China has launched the strategic initiative of a 21st Century Maritime Silk Road for trade.

Today’s industry has seen fast overall growth and an increasing focus on safety, efficiency, environmental protection, and sustainability for everything from small shipping containers to the mega-container ships used in international trade. Supported by relevant industrial policies, small- and medium-size load carriers are taking center stage, gaining increasing prominence in international logistics.

In this context, Shenzhen CIMC Smart Pallets Co. was established. Backed by the CIMC Group’s strong R&D capabilities and extensive resources, CIMC Smart Pallets is driving digitalization and smart technologies in the industry, aiming to bring mobile load carriers into an era of circular business practices.

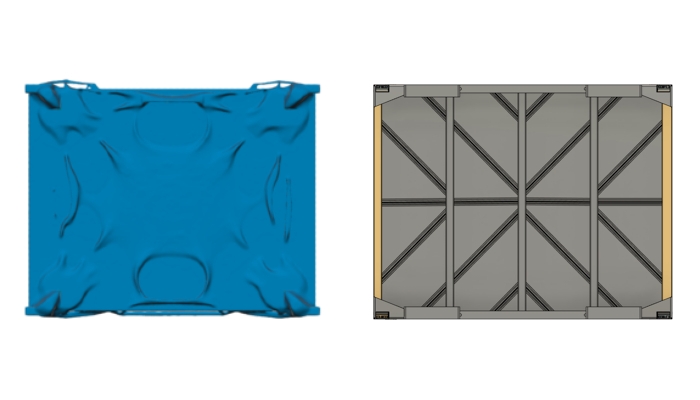

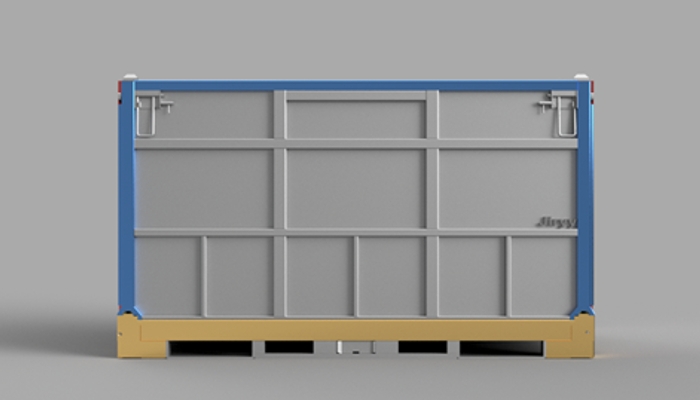

As part of this strategic vision, the company worked with Autodesk to explore innovative solutions to design and manufacture rubber pallet boxes. CIMC is already known for its patented products; now it’s upgrading and transforming logistics load carriers, making them more intelligent and moving away from traditional container design.

Technology yields new manufacturing methods

Going green and collaborating efficiently are the way forward for logistics, as today’s industry has higher expectations for load carriers to be functional and cost-effective. Reusing, leasing, and sharing demands also reinforce the standardization of load carriers.

CIMC’s first-generation rubber pallet boxes were lower quality than competitors’ models and couldn’t fully meet customer requirements. The company urgently needed to innovate its design and manufacture techniques, hoping to achieve a breakthrough in product quality, earn a competitive advantage, and shorten the development cycle. “Customer demands are increasing every day,” says Ming Li, product general manager at CIMC Smart Pallets. “For CIMC to acquire more customers, our products need to surpass the competition.”

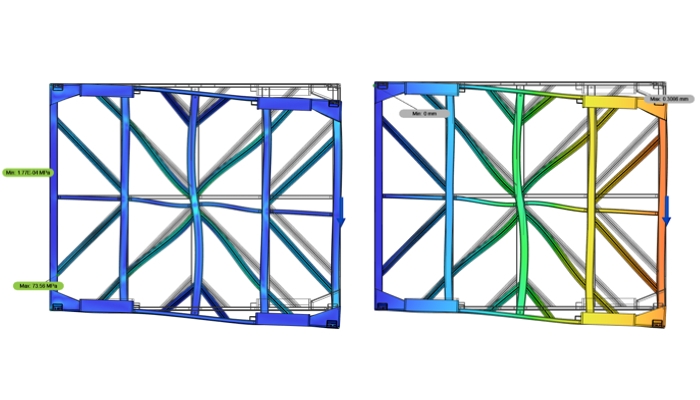

Looking for a breakthrough at the product-design level, CIMC chose Autodesk’s generative-design technology to disrupt its traditional 2D design workflow. Generative design is a tool that integrates machine learning and artificial intelligence algorithms. With generative design, designers input design constraints and other ancillary conditions, then the computer leverages algorithms from machine learning to generate endless design options. Generative design can also consider factors such as material savings and manufacturing feasibility, helping companies balance cost and quality.

Revolutionizing product development: CIMC's success with generative design

Since adopting generative design to produce its second-generation rubber pallet boxes, CIMC has overcome its team’s longstanding difficulty integrating 2D and 3D designs. The design, testing, and iteration processes are performed digitally throughout the product-development cycle. As a result, the product-delivery cycle has been significantly shortened: CIMC completed the design and manufacturing plan in just three months and finalized the product in six months.

These second-generation pallet boxes boast 20% higher rigidity and are 80% less likely to become deformed than previous models. Significant improvements have also been made in key metrics such as net load space, folding compression ratio, unladen stack quantity, and unladen pack quantity. All these factors helped CMIC Smart Pallets secure three industry patents.

“What’s surprised us the most has been the significant improvements in our design efficiency and product-delivery turnaround times brought by generative design,” Li says. “Previously, we needed around one-and-a-half to two years. Now, we’re able to complete product design in four months.”

Changing the business model

Aside from its innovative design approach, a new business collaboration model is the other factor that’s been crucial to the success of CIMC’s second-generation rubber pallets. According to Li, Autodesk recommended a high-quality service provider to join the CIMC project as a technical team from the initial stages. CIMC contributed design ideas, Autodesk contributed the solution, and the service provider was responsible for technical implementation. All three parties worked together as one entity throughout the collaboration.

A multiparty business-collaboration model can garner many benefits using development roadmaps. Li says that as part of the plan for CIMC’s business, the company will continue to focus on developing rubber pallet boxes. “This is our flagship product, which brings both sustainability benefits and customer value,” he says. “We will also continually improve these products with the aim of completing our product lineup and reaching an economy of scale.”

In the past, Li says, the traditional product R&D process at CIMC was lengthy and could narrow opportunities—plus, the single closed-door design approach is not conducive to improving product competitiveness. In contrast, a multiparty collaboration—in which each party focuses on its strengths and can compensate for other parties’ resource shortcomings—can help companies significantly cut development costs and speed up the overall R&D process. It also enables higher-quality products to be launched faster.

Smart operations shape the future of logistics

The maritime logistics industry is continually expanding, as is CIMC’s business. CIMC has two decades of experience designing and manufacturing load carriers—it is now actively building a network of circular operations assisted by advanced technology. These efforts help drive both the digitalization of the industry and digital industrialization.

The company currently has business operations in Vietnam, Thailand, Indonesia, and Malaysia, as well as in Australia, continental Europe, and the United States. According to Li, building a smart, all-encompassing value chain based in collaborative creation and sharing helps the company expand its reach globally.

CIMC’s planned smart-load carrier operations platform is still in the infrastructure-building stage. Once built, the platform will intelligently interconnect products, containers, shipping statuses, clients, and all other elements of the process. Stakeholders will be able to participate in managing the shipping status. It will be a circular, organically developed smart digital system that optimizes processes including production, procurement, logistics, transportation, warehousing, distribution, delivery, and recycling.

In the future, the smart logistics industry will usher in broader development opportunities involving technological innovations such as big data, the Internet of Things, cloud computing, and artificial intelligence. From generatively designed products to upgraded value chains, digital technology integration and smart manufacturing will drive the transformation of load carriers—and push the industry to adopt the broader, more circular, strategies.

About the author

Betty Wang

Betty Wang is a freelance writer who focuses on technology trends. She specializes in writing stories on technology innovations with rich cultural significance. Her extensive professional experience in technology consulting over the years has given her a deep knowledge and understanding of architecture, software, hardware, and data centers. Wang holds a degree in international journalism from the University of Sheffield, where she developed a forward-looking journalism vision and a unique cultural perspective.