7 steps of digital transformation herald a connected era of manufacturing

Digital transformation in manufacturing evolves traditional processes and creates a flexible, platform-based strategy for the future.

Srinath Jonnalagadda

December 2, 2021 • 7 min read

The pandemic has handed the manufacturing industry an opportunity to embrace digital transformation, overcome longstanding challenges, and meet today’s demands.

Traditional manufacturing methods are out of step with consumer expectations, and products are failing to meet profit margins.

As companies move through the steps of digital transformation in manufacturing toward a platform approach, data connectivity helps them achieve better outcomes.

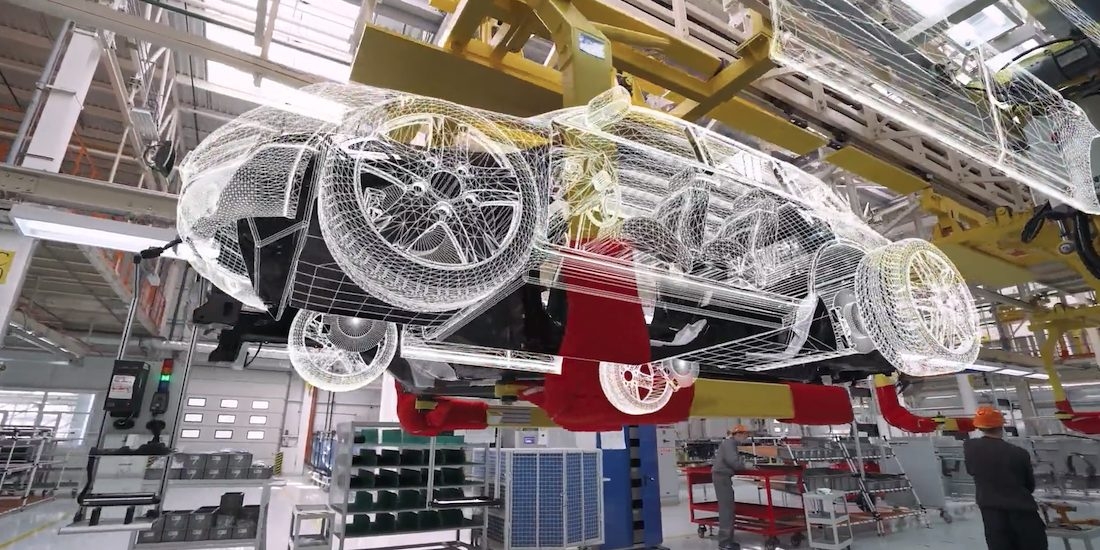

Imagine the future of manufacturing, when robots, autonomous vehicles, and artificial intelligence (AI) run production while humans orchestrate operations. Productivity is high, processes are lean, and every product is customized. The industry is not far from this digital transformation wonderland, but it still has hurdles to clear.

Before 2020, manufacturing was struggling with a labor shortage, a skills gap, and a plateau in productivity. The COVID-19 pandemic compounded these problems, and almost overnight, companies also had to manage distributed workforces and evolving safety protocols. Consumer demand was like a pendulum, as people abruptly stopped buying things—then, quickly swinging the other way, started stockpiling goods. This demand shock caused the supply chain to seize up.

Now, manufacturers are under pressure to adapt to evolving expectations: better products, greater customization, faster production, and lower costs—all with a worker shortage. But with disruption comes the opportunity to do things better. Companies are addressing their longstanding issues with technology. They are flocking to the cloud and accelerating digital transformation in manufacturing.

To help guide companies toward a resilient, agile, customer-centric, and data-driven future—a new, connected era in manufacturing—here are seven steps of digital transformation to follow. Each step flows into the next, and each offers on-ramps that manufacturers should choose according to what’s appropriate for their digital transformation journey. The first step connects processes in the traditional manufacturing lifecycle; the next five steps change that lifecycle through mass customization, design collaboration, flexible manufacturing, and smart services; and the final step incorporates a platform approach that breaks down silos and empowers the industry.

1. Connected manufacturing lifecycles

Product development and manufacturing comprises a series of steps performed by multiple disciplines: conceptualize, design, produce, sell, operate, retire. Traditional manufacturing lifecycles rely on manual processes, incompatible software, and fractured communication. That creates a siloed environment where one person hands off a huge file to another person, who practically translates it to get what they need. It’s inefficient, time-consuming, and costly.

To change that, the first step for companies is to find their on-ramp to digital transformation—which might be automating one process or department. Stitching together automated environments creates a single ecosystem where all stakeholders have access to what they need to make faster, better decisions. The World Economic Forum (PDF, p. 13) found that the most digitally advanced manufacturers increase production output by as much as 140% and reduce design-iteration time by as much as 98%. Creating a common data experience means frictionless workflows and a transparent process. In this scenario, design and make flow seamlessly, with data as the connective thread.

2. Mass-customization capabilities

Mass customization is now a must-have capability. People love the personalized experience their smartphones offer and want to replicate that with other products. Delivering that without sacrificing time to market gives manufacturers a competitive edge.

As companies update operations with additive manufacturing and automation, personalizing becomes possible. A great example is Porsche’s new facility (PDF) in Stuttgart, Germany, where the company makes the all-electric Taycan. It’s a digital factory where autonomous vehicles have replaced the assembly line, moving each car through stations per the customer’s order. Manufacturers can also deliver personalized user experiences with AI, data, and software. Peloton does this by curating content for each stationary-bike customer.

3. 24/7 design collaboration

Even in Industry 4.0, manufacturing relies on human collaboration. With digitalization, teams can communicate with the entire value chain, establishing an ecosystem of stakeholders (like suppliers and subcontractors) working in tandem for successful outcomes.

A centralized environment supports interoperability, allowing different disciplines to collaborate in real-time from the same files, reducing missteps. At Logitech, the computer accessories manufacturer, geographically distributed teams collaborate through Autodesk Fusion 360. Working from the same data-centered model, everyone has 24/7 access to up-to-date information.

4. Flexible manufacturing for greater agility

Manufacturing has long operated by the just-in-time philosophy pioneered by Toyota. Companies ordered materials as needed—not a second before or after—for efficient inventory management. But this approach assumes supply chains always work; as the pandemic has proven, they’re actually quite fragile.

Flexible manufacturing is a backup plan for supply-chain disruption. If there’s a demand shock and the usual suppliers become inaccessible, or shipments are stuck in a backlogged port, companies can quickly pivot to produce materials in-house with additive or subtractive manufacturing, or they can source materials locally. Flexible manufacturing relies on a connected ecosystem, under one roof or within the supply chain, so manufacturers don’t have all their eggs in one basket.

5. Enhanced customer experiences

Consumers’ expectations are changing rapidly. They want things faster, smarter, and better. With traditional manufacturing methods, companies are slow to adapt to these demands. In fact, 72% of product releases fail to meet profit margins. Manufacturers must give consumers what they want and deliver value by leveraging technology. If they don’t, their competitors will.

One idea is to create virtual browsing experiences. It removes the consumer’s risk and engages them differently. For example, bridge fabricator Mabey Bridge offers a 3D tool through which customers can select specifications for a digital rendering of their bridge—before placing an order. Customers gain a sense of control, which builds trust and makes the relationship stickier. This also leads to repeat business.

6. Smart services for customer longevity

As companies transition to data-driven operations, extending digital capabilities of their products generates greater value. Think about smartphones: The hardware is a one-time purchase, but customers build on the relationship with the manufacturer by adding applications.

With products that generate data when they’re in the hands of the customer, companies create revenue streams and opportunities to build relationships. As a result, smart services yield insights that improve the manufacturer’s ability to compete effectively.

7. Platform as the ultimate ecosystem

This digital journey culminates at its final step: platforms. People engage with platforms every day by using smartphones, streaming movies, or hailing rideshares. Platforms are ecosystems of different technologies where data connects everything in the value chain, across disciplines or industries. By automating processes, connecting teams, and creating visual data models in a single environment, platforms improve coordination across all product development and manufacturing.

Companies can build onto platforms, adding capabilities to create the desired experience. This is the foundation of Autodesk Forge, a cloud-based platform that combines design and make to deliver greater value from people, processes, and technology.

At Walt Disney Imagineering, creating attractions for global theme parks requires collaboration among disciplines such as architecture, engineering, design, industrial manufacturing, digital media, animation, and 3D modeling. A platform creates a connected way to work together on such complex projects.

Think about designing and building a rollercoaster. Each person uses the software platform in a way that feels like one single application, even though they each experience it in their own way. The motion-design animator experiences the platform on a touchscreen, using a stylus. The data from this is connected to the mechanical engineer, who experiences the same platform in a different way, working on the track-wheel assembly in a CAD program. An electrical engineer accesses the data to lay out the ride’s electrical system. Collectively, it looks like one single software. Why is this important? It reduces cognitive breaks as these different personas go back and forth, enhancing mutual workflows on a collaborative project.

Manufacturing is at a crossroads—rooted in traditional methods incompatible with future needs, hovering on the brink of change. But the path forward is clear: Embrace a digital-transformation mindset, find an on-ramp, and work toward a platform strategy.

About the author

Srinath Jonnalagadda

Srinath Jonnalagadda is vice president of industry strategy for Design & Manufacturing at Autodesk. He has more than 24 years of experience in the mechanical CAD industry, 20 of which are with Autodesk. As strategy lead, Jonnalagadda has driven business growth for Fusion 360; formed meaningful relationships with market-leading partners such as Haas Automation, Apple, Microsoft, McMaster, Protolabs, and Xometry; created new business models for product lines; and established innovative new processes to gain richer insights from analytics.