& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

From primordial black holes and rogue planets to supernovas and antimatter, space is full of fascinating phenomena. For the average earthling, however, one of the most captivating aspects of space is perhaps one of the least mysterious: weightlessness.

Technically, gravity still exists in space. Astronauts don’t feel its effects, however, because it becomes weaker with distance. The farther one gets from Earth, the more divorced one becomes from its gravitational pull.

In the case of the International Space Station—which has entertained many a space enthusiast with images of somersaulting astronauts catching floating food items in their open mouths—the zero-gravity sensation comes from the fact that its occupants are in free fall: The space station, its crew, and all the objects inside it are falling toward Earth from space at the same rate, which gives them the appearance of floating. Orbiting the planet without actually hitting it is possible due to the fast speed at which the space station is traveling, which gives it a curved path that precisely matches the curvature of the Earth.

If you think about it, this obsession with weightlessness is kind of ironic. Although objects in space seem to exist without regard for terrestrial physics, mechanical engineers know that mass is actually one of the most important considerations when designing a spacecraft.

“Mass equals cost in the spaceflight world,” says Alex Miller, lead mechanical engineer at Newton | Engineering and Product Development.

Spacecraft and their components have to be lightweight to ensure cost-effective launches, fuel and power efficiency, and structural integrity, not to mention maximum instrumentation for mission capabilities.

But reducing mass is no simple task. To make it easier and faster to design lightweight spacecraft, NASA and companies such as Newton are turning to a unique tool powered by artificial intelligence (AI): generative design.

Generative design is based on physics and a number of manufacturing-aware optimization algorithms working together to generate multiple solutions that meet the problem definition and requirements as specified by the user. The parameters that algorithms ingest are detailed engineering requirements, and the products they produce are finished designs that NASA Research Engineer Ryan McClelland calls “evolved structures.”

“They look somewhat alien and weird, but once you see them in function, it really makes sense,” McClelland said of evolved structures in a 2023 interview with NASA.

Evolved structures are “alien and weird” because AI has no predetermined notions of what something should look like, the way a human engineer does. Instead, algorithms problem-solve to find the best, most efficient way to satisfy design requirements. To do so, they often use geometries that would be all but impossible for humans to wrangle, which creates organic forms that would be improbable for most humans to conceive.

“What has surprised me the most about generatively designed structures is how the resulting designs are both novel, in that most humans would not think of them, and obvious, in that once I see the solution it makes intuitive sense,” McClelland says.

The generative-design process is both straightforward and speedy. First, human engineers specify technical requirements such as the load the finished structure will have to carry and what forces it will be exposed to in space. Then, they enter the requirements into software that can spit out myriad design iterations in a matter of hours.

“The user enters the requirements into the system, and then the AI comes up with the design, then tests the design by finite element analysis to make sure it works to verify the requirements,” McClelland explained in an episode of NASA’s Small Steps, Giant Leaps podcast. “And then it also does a fabrication simulation to make sure it can be fabricated.”

Whereas humans can do one design iteration every week, McClelland notes, the AI can do one design iteration in minutes. “You get a lot more iteration cycles,” he says. “And because of the more iteration cycles, you get more optimal designs much, much faster using this evolved-structures process.”

Speed is a major advantage. But it isn’t the only benefit—quality also improves.

“We found it actually lowers risk,” McClelland says. “We find the parts generated by the algorithm don’t have the stress concentrations that you have with human designs. The stress factors are almost 10 times lower than parts produced by an expert human.”

And there’s cost, a major consideration when it comes to the bespoke design for which NASA is known. “The major cost driver for structures at NASA is nonrecurring engineering, rather than manufacturing,” McClelland says. “Unlike a car or bike company, NASA is developing thousands of unique parts at any given time. There is only one Hubble, one Webb, so this technology is particularly valuable for us.”

Finally, there’s the critical issue of mass: Evolved structures can save up to two-thirds of the weight compared to traditional components, according to McClelland. “They’re somewhere on the order of three times better in performance,” he said on Small Steps, Giant Leaps. “And when I say performance, I mean really the stiffness-to-weight ratio. So they’re very stiff and very light, and they’re also quite a bit stronger than human-designed structures.”

Although the scientific and business merits of good performance are obvious, it can be advantageous from a staffing perspective, as well. “From a personnel standpoint, structural analysts are always in short supply,” McClelland says. “I think this can help alleviate the pressure on structural-analysis specialists by creating stiff and strong designs quickly, which will reduce the need to iterate later.”

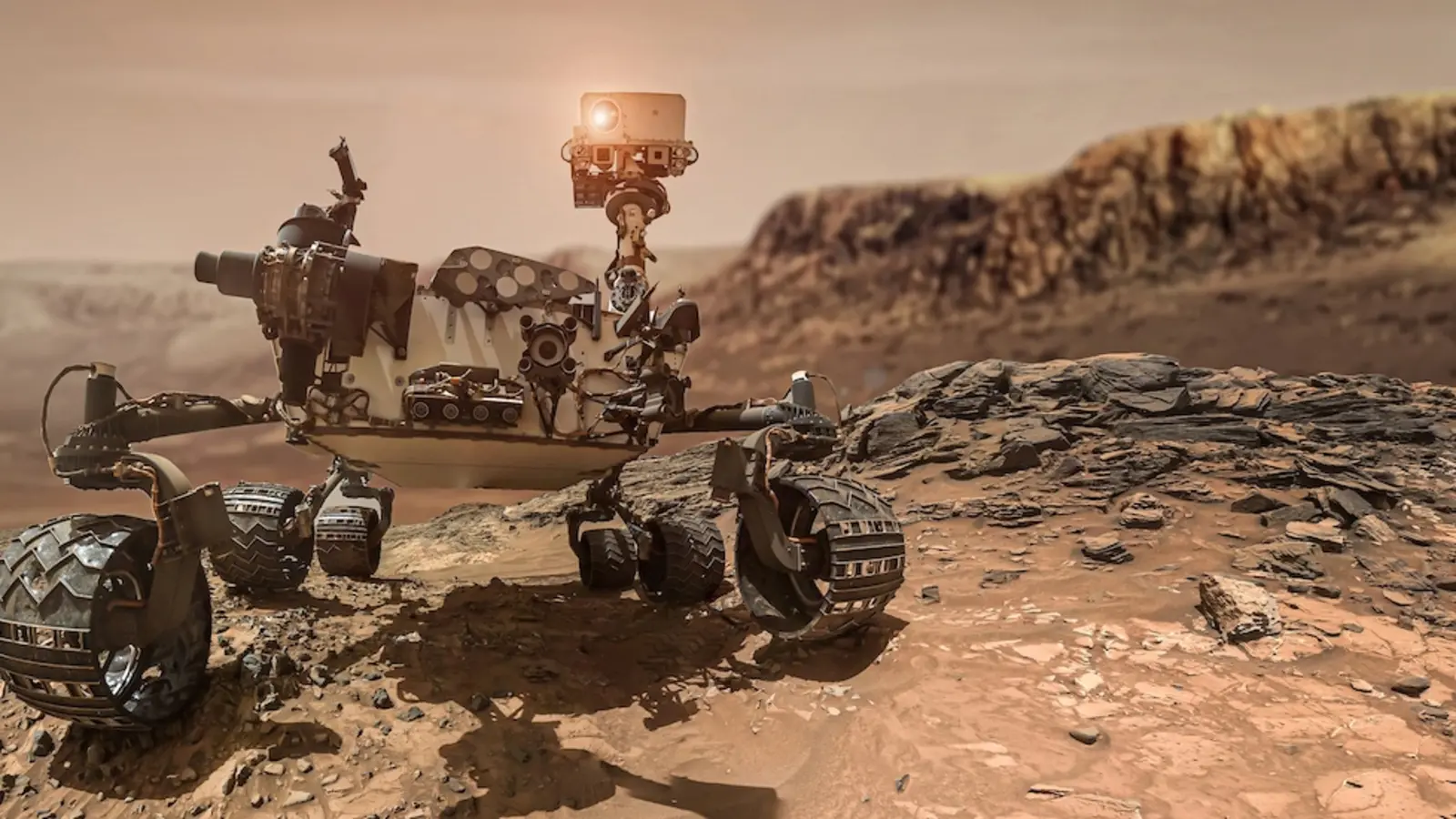

Two NASA missions that embody the potential of generative design for optimal spacecraft engineering are the EXoplanet Climate Infrared TElescope (EXCITE) and the Mars Sample Return Mission.

Expected to launch as early as fall 2023, the former is a balloon-borne telescope that will study warm exoplanets orbiting distant stars. The size of an SUV, it features at least two generatively designed elements: a titanium scaffold for the back of the telescope and an “optical bench” that will hold the optical components of one of its instruments, an ultraviolet imaging spectrometer that will make continuous observations about planets as they orbit their host stars.

“Of the current applications, the optical bench is probably the most impressive,” McClelland said in architecture and design magazine Dezeen. “It is a radical departure from typical optical benches and has far better structural performance. It also consolidated what would have been around 10 parts into a single part.”

The Mars Sample Return Mission will use a series of vehicles to collect rock samples that may contain evidence of prior life on Mars and, ultimately, bring the rocks back to Earth. For this mission scheduled to launch in 2027, Newton used Autodesk Fusion 360 to generatively design a critical component called the capture lid mechanism.

As part of the mission, the Mars Perseverance rover is currently collecting samples on the surface of Mars and placing them in metal tubes. The rover will transport the tubes to the Sample Retrieval Lander, where an ESA-provided robotic arm will place them in the lander’s rocket. In turn, it will launch itself into Mars’s orbit with the samples inside. There, it will rendezvous with yet another spacecraft: an orbiter tasked with receiving, sterilizing, and depositing the samples into a final spacecraft for delivery to Earth.

That’s where the capture lid mechanism comes in. The samples will be “tossed” from the rocket to the orbiter’s Capture, Containment, and Return System to catch the samples in a lidded container that will have to close immediately to secure them. Thanks to generative design in Fusion 360, the lid is 30% lighter compared to human-generated designs.

“Once the samples float in, the lid needs to close very quickly to keep the samples from bouncing out, as well as limit the contamination of the samples,” Miller says. “It requires a very lightweight and strong door to be able to do this. That’s where generative design in Fusion 360 came in to help us with the structure of the lid.”

The opportunity is plain: With cheaper, lighter, and better-performing components, spacecraft can go farther into space for longer periods of time and perform more intricate and significant missions.

Yet generative design isn’t an immediate home run. There are practical barriers with which organizations must contend.

One of the most prevalent is perception, according to McClelland, who says stakeholders see the strange designs that AI creates and assume they can’t actually be fabricated. In reality, many generative designs can be produced easily and affordably using additive manufacturing, subtractive CNC milling, or hybrid manufacturing that combines both additive and subtractive techniques.

“People see these crazy-looking organic structures and think that they can never be CNC-machined out of our standard materials with normal CNC-machining processes,” McClelland told Small Steps, Giant Leaps. “It turns out that CNC machining has actually come way further than people think, and you can make absolutely almost anything you can imagine with 5-axis CNC machining these days.”

There are software limitations, too, according to McClelland, who says current tools can’t process thermal parameters. As technology evolves, however, he expects that to change. “Thermal and structural design challenges are often interrelated at NASA,” he says. “In the future, I hope generative design can take both structural and thermal requirements into account, such as limiting thermal conductivity while still meeting structural stiffness requirements.”

For now, one thing is clear, according to Miller: Generative design is here to stay. “I truly believe that humanity is at the dawn of the age of AI, and using generative design is absolutely essential for any engineering team to remain competitive in the future,” Miller says. “It’s a critical tool in our mission to provide customers with optimal solutions and ensure success.”

Matt Alderton is a Chicago-based freelance writer specializing in business, design, food, travel, and technology. A graduate of Northwestern University's Medill School of Journalism, his past subjects have included everything from Beanie Babies and mega bridges to robots and chicken sandwiches. He may be reached via his website, MattAlderton.com.

PD&M

Courtesy of e.GO Mobile AG

Emerging Tech

PD&M