Want more time for design? It’s all about prefabrication and lean manufacturing in construction

Learn how mechanical construction firm J.C. Cannistraro uses prefabrication and lean manufacturing in construction to help reduce costs and safety risks.

Architects and general contractors don’t always involve subcontractors in early phases of design and preconstruction. But if they want to prevent time and money from trickling down the drain, they should.

Michael P. Cannistraro, vice president of engineering at Boston-based J.C. Cannistraro, has a strong opinion about that. “The big key to reducing construction time in BIM projects is to involve specialty subcontractors like us as early as possible during the design phase,” he says. “Prefabricated MEP—and so many other trades—is all about planning and collaboration; the sooner we’re involved, the more opportunities we have to contribute ideas that save space and time during construction. We can start conversations and explore the possibilities along with all the other players involved.”

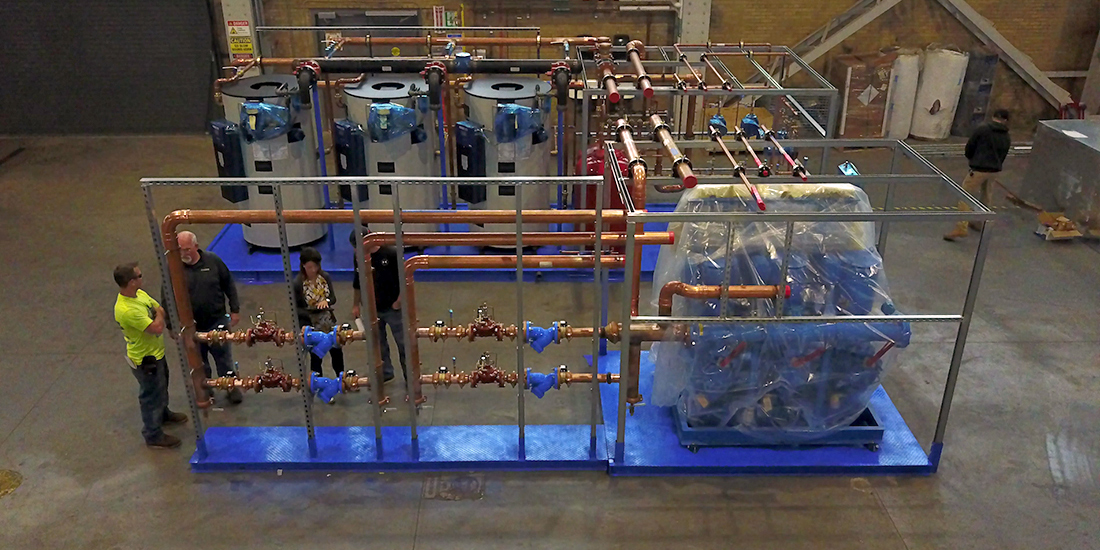

J.C. Cannistraro—founded by John Cannistraro, Sr.—started as a plumbing business more than 50 years ago; now a mechanical construction firm with 500 employees, it specializes in HVAC, plumbing, sheet metal, and fire protection, with an emphasis on prefabrication. Material management, cost, and labor are crucial parts of Cannistraro’s success and risk mitigation on a project, and BIM-driven methods of prefabrication and modular preassembly are two good ways to manage those factors effectively.

Case in point: premade headwall units that are plugged into hospital patient rooms rather than being built on-site for lean manufacturing in construction. “If we can collaborate with the other trades involved,” Michael Cannistraro says, “we have the opportunity to build prefabricated headwall units that are more complete and easier to install, compared to the traditional process.”

Pipe racks are another example. “We’re designing them for nearly all our projects, and there’s no reason that electrical contractors can’t mount their conduit and wiring to the same system,” he says.

Early communication can also lead to fruitful synergies in construction and pre-construction processes. In 2010, Michael Cannistraro published a Case Study on the Value of BIM using historical data derived from $500 million worth of projects over six years.

In the study, he described one of the firm’s early collaboration successes when designing HVAC for a Massachusetts General Hospital building: “Having the subcontractor colocated with the project team during design and coordination revealed HVAC installation details that may have gone unnoticed in a 2D environment. ... Making appropriate adjustments prior to construction ultimately led to savings for the owner.”

During the same project, Cannistraro’s team worked with specialist subcontractors to coordinate delivery times and exact delivery paths when installing eight giant air-handling units. In that crowded construction zone, frequent communication made a big difference and contributed to the hospital’s mechanical room being delivered months ahead of schedule.

“We used to think that BIM was software, but now we realize it’s a process,” Cannistraro says. “And at the end of the day, it’s as much about collaboration as design. We’re communicating better with architects and contractors, and for obvious reasons, conversations enabled with BIM visuals are more effective—a picture really is worth 1,000 words.”

J.C. Cannistraro’s involvement with BIM goes back to the early 2000s, and the firm’s commitment has never wavered. “Compared to sectors like manufacturing, AEC has lagged when it comes to realizing productivity gains from computerization,” Cannistraro says. “So we’ve always felt a need to be progressive when adopting new solutions, and BIM was effective for us even when we were one of the few firms in our area using it. Now a lot of Boston firms have adopted BIM—so, to stay progressive, we’re focused on BIM-based collaboration as the best way for our industry to be more productive.”

The most important metric of Cannistraro’s 2010 case study was reduced change orders on BIM projects, but that’s changing. “Right now, we’re working on a follow-up to that study based on two years of good documentation,” Cannistraro says. “We know that change orders are still down, and so are RFIs [requests for information], but what’s really emerging as valuable are the sticking points we avoid.”

That is, many typical construction bottlenecks are going away. “In the overall timeline of designing and constructing a building, we’re not actually seeing significant change,” Cannistraro says. “But there’s still a big gain; more time is spent in design, and less is spent during actual construction. That’s more efficient and cost-effective because we can do more and better prefabrication. And it’s safer, too, because it reduces exposure to construction hazards.”

Five years ago, Cannistraro identified one set of projects as “lonely BIM”—projects with the firm as the sole stakeholder using BIM technology. “In our region, lonely BIM is going away,” he says. “Interoperability is improving, and in most of our projects, collaborative BIM is now the rule. That’s another reason early involvement of all subcontractors is so important. It’s a way to further leverage the much higher level of BIM expertise that we’re seeing now in Boston.”

Evolving clash-detection methods illustrate that point. The firm’s VDC (virtual design and construction) team has used BIM from early on to detect and eliminate clashes among its HVAC, plumbing, sheet-metal, and fire-protection design teams, and that’s one of the reasons the firm’s early investment in BIM paid off. “Now, if we’re able to get involved early enough, we can extend that expertise to more of a given project and make a really big difference during construction—it’s a smooth process, and many more problems are caught during the design phase,” Cannistraro says.

But does all this collaboration create extra work for J.C. Cannistraro? Cannistraro doesn’t see it that way. “You can call it lean construction, but that’s becoming a buzzword,” he says. “Really, it’s us doing what we feel we’re hired to do. Over the years, we’ve developed expertise in BIM, and so we’re able to make a positive contribution to the entire project, not just our specialty. If a general contractor can recognize that and invite us in early enough to make a difference, of course we’re going to provide all the value we can.”

About the author

Angus Stocking

Angus W. Stocking, L.S. is a licensed land surveyor who has been writing about infrastructure and design technology since 22.