How sustainable manufacturing is transforming the industry with green innovation

Sustainable manufacturing—from material extraction to logistics—helps companies cut carbon emissions, appeal to customers, and tap new sources of environmentally focused funding.

Patrick Sisson

August 24, 2022 • 9 min read

Sustainable manufacturing is helping companies cut carbon emissions, appeal to consumers, and tap into new sources of environmentally focused funding.

Every step of a product’s lifecycle—from raw material extraction and transportation to logistics and the manufacturing itself—can change to become more sustainable.

Top firms like General Motors and Airbus, as well as steel manufacturers, are using generative design and circular design to improve energy efficiency and lower their footprints.

Heavy industry, factory towns, and manufacturing conjure visions of smokestacks, not sustainability. Mills, assembly lines, and production facilities for industries such as steel, plastics, and automobiles contribute inordinately to global carbon emissions and pollution, consuming roughly one-third of the world’s energy. And at a moment when it’s more important than ever to conserve materials and energy, nearly a quarter of the carbon emissions in the United States come from manufacturing and industry. It’s up to the industry to reverse this entrenched way of operating—a process that begins with sustainable manufacturing.

What Is sustainable manufacturing?

Sustainable manufacturing is a systemic overhaul of industrial processes that analyzes and reduces the amount of energy, materials, and transportation time and effort spent on making products. And it hasn’t just gained currency among climate activists. Its wholesale appeal—cleaner, less carbon-intensive, and often cheaper products—has brought everyone from consumers to bankers to regulators on board.

Consumer sentiment has swung decisively toward greener options for everything from household goods to cars. Corporations need to meet those demands to compete. Sustainability shifts also bolster their bottom line: A 2021 Deloitte survey of 750 executives found that half agreed that sustainability initiatives helped their corporate financial performance. This is leading industry and finance to in turn demand green practices and measure carbon intensity as a requirement to pay suppliers or provide investment. Geopolitical uncertainty and fossil fuel availability also underscore the benefits of investing in clean, cheap, reliable renewables.

The move toward ESG (environmental, social, and governance) funding has also moved large swaths of the financial community to elevate sustainability requirements for investing. Members of the Carbon Disclosure Project control $5.5 trillion in purchasing power and ask key suppliers to disclose detailed environmental performance data.

A number of significant technological shifts, industry alliances, and regulatory actions have put a green industrial revolution within reach. Even energy-intensive industries like steel have innovated and implemented green production processes; steel factories today can produce the beams that form the backbone of buildings with green hydrogen power and net-zero carbon.

Finally, governments and trade organizations, following the flow of financial power and seeking to meet stringent emissions goals, are establishing more significant standards for industry. Stringent emissions reductions rules for buildings and offices, including local laws in cities such as New York and Boston, will force the entire real estate and development industry to adopt greener materials and processes. Regulations at the state, national, and global levels focus on increasing energy efficiency, reducing carbon emissions, limiting water usage, and minimizing waste.

Corporate groups such as the Mission Possible Partnership have created detailed roadmaps to shift high-polluting industries to more sustainable practices. A recent US/EU trade deal added emissions-tracking requirements to steel, foreshadowing more efforts to leverage trade policy to lower emissions, following the Climate Group’s Steel Zero plan to build demand for carbon-free steel within the wider manufacturing world. Europe, which tends to lead the way on such rules, plans to require items to have a Digital Product Passport that would aid transparency and traceability. Sustainability for corporations is a question of when, not if, and smart investments suggest making the shift now.

How manufacturers can reduce their environmental impact

These changes may seem sudden and wide-ranging. Luckily for manufacturers, nearly every step in the process, from sourcing materials and raising funds to design and production, can evolve in more environmentally minded ways. A recent Autodesk survey found that in 2019, 52% of manufacturing customers had public sustainability goals. Two years later, that number nearly doubled to 75%.

The process begins with data—analyzing supply chains, factory performance, real estate footprints, and transportation and logistics. A number of firms have turned to blockchain technology to digitally track items to improve logistics and transparency, including De Beers Tracr system to monitor diamonds and Walmart’s move in 2018 to force suppliers to monitor lettuce on a company blockchain.

Design is another key area for addressing sustainability goals. Before taking any actions in the physical world to build and source, design choices can lessen the material input and make a significant difference. Research and redesign can decrease weight, simplify parts, and deploy new, more sustainable materials; Autodesk’s Zoé Bezpalko says that 80% of a product’s environmental impact is determined at the design phase, and resources such as Makersite provide detailed information about material choices and strategies to lessen a product’s impact.

Once a sustainable-design blueprint has been devised, companies can begin altering and evolving their supply chains and manufacturing processes to reduce wasted materials, time, and energy. This includes electrifying warehouses and trucks to create less carbon-intensive logistics networks. A decade ago, UPS instituted ORION, an algorithmically devised routing system that famously reduced left turns and idling to save fuel costs. Other significant changes, including reshoring parts of the manufacturing process, can eliminate significant emissions.

Companies can also require their suppliers to meet strict environmental standards, as well as create more circular economy networks to reuse and recycle material and packaging, further cutting waste from a product’s lifecycle. Global carpet manufacturer Desso created a “cradle-to-cradle” program, designing its carpets with reusable yarn that can be repurposed numerous times while instituting a parallel buy-back program to keep older materials out of landfills. Similarly, Mitsubishi’s elevator division created a unique leasing program that allowed building owners to rent products and reduce the overall use of materials and energy.

Even the factory floor, via the rapid adoption of more automation and robotics, can become a source of more efficiency. Half the electric power in the United States powers electric motors, the workhorses of industrial processes; adopting renewable power at manufacturing sites can greatly reduce emissions. Intelligent City, a manufacturer of prefabricated mass-timber housing, uses robotics and proprietary software to create homes and buildings with a smaller carbon footprint and even runs simulations to design custom solutions that use fewer materials.

Increasingly, the funding necessary for this kind of design approach, or factory retooling, is becoming mainstream via grants, tax incentives (especially for the clean power industry), and ESG investment. States such as California offer incentives for installing renewable power onsite, utilizing electric vehicles or green vehicles, and conserving water.

Recent research suggests that sustainable investing assets now account for $17.1 trillion—or one in three dollars—of the total US assets under professional management. Sector leaders such as BlackRock Chairman and CEO Larry Fink (who has challenged his firm to focus on sustainability for long-term shareholder value) and the SEC (which is formulating rules to require environmental disclosures for public companies) have encouraged more investors to look into ESG.

In addition, new sources of public funding, aimed at bolstering the industries of the future and making US next-generation manufacturing more competitive, offer more avenues for investment, including New York State’s Green CHIPS Act and various manufacturing institutes and programs run through the Department of Energy.

How generative design can make manufacturing greener

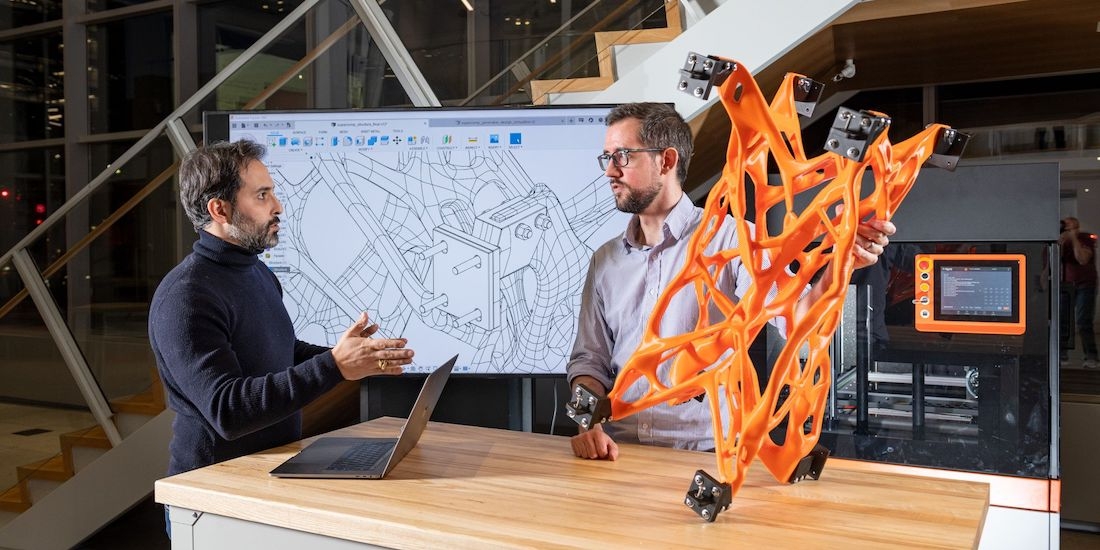

Generative design in particular holds the potential to accelerate sustainability in the manufacturing industry in the coming years. By using artificial intelligence to rapidly create and analyze solutions for a given problem, generative design greatly reduces the time required for iterative problem-solving. During the past decade, the technology has gained traction steadily within the manufacturing sector as computational processing power and software improve.

To date, lightweighting product parts—finding ways to reduce a part’s mass while retaining its functionality, typically achieved through additive fabrication processes—has been the most common use case for generative design in manufacturing, removing unnecessary bulk, and cutting energy use and carbon emissions throughout the supply chain.

For example, General Motors (GM) employed generative design to consolidate an eight-part seat bracket into a single part, at the same time making the new bracket 40% lighter and 20% stronger. Airbus also used generative design to re-create interior partition panels for the A320, which yielded a divider that uses substantially less material than standard models. Making parts stronger in addition to lighter can also extend their lifespan, which in turn reduces the need for repair, replacement, and spare-parts inventory.

But generative design’s potential environmental benefits go beyond lightweighting for individual parts. As the technology continues to improve and opportunities arise within manufacturing lifecycles, new use cases will emerge, tackling the entire process instead of single parts.

Benjamin Moses, director of manufacturing technology at the Association for Manufacturing Technology (AMT), is focused on greening the manufacturing process. Everything from factory layouts to workholding solutions and tool paths can impact a company’s environmental footprint, he says. By looking at their entire operation as a design challenge, manufacturers can take advantage of algorithmic tools to identify greener ways of working.

“Applying the iterative design process that generative enables will allow us to change the entire ecosystem of designed goods within manufacturing and really evolve how manufacturing engineering goes about its day-to-day process for creating these tools and processes,” Moses says.

Companies leading the way in sustainable manufacturing

Sustainable manufacturing in practice can look radically different across industries. In Chicago, Method’s manufacturing plant features on-site wind and solar power generation and was the first LEED Platinum–certified manufacturing facility due to its focus on smarter material choices and energy efficiency.

In the forests of Magnor, Norway, outdoor furniture manufacturer Vestre recently opened a $30 million cutting-edge sustainable factory that shows what’s possible. Using an array of techniques, including passive house design, a robotic factory floor, water recovery and purification, and a rooftop covered in solar panels and local vegetation, the building cuts energy consumption by 60%, reduces emissions by 55%, and actually stores carbon due to its use of cross-laminated timber. It’s a singular structure, but it suggests that the physical footprints of industry—the buildings and factories where work happens—can be radically reimagined for efficiency and environmentalism.

Across the North Sea, Dutch design firm Joris Laarman Lab used generative-design technology to create a 3D-printed pedestrian bridge that spans an Amsterdam canal. This enabled the team to greatly simplify the structure so that it could be printed in one piece (though the designers chose to print it in several). The new digitally enabled design process also points to other ways to save time, energy, and effort: Digital testing could supplement, or eventually replace, physical testing.

The potential for digital-performance verification points back to what Tim Geurtjens, chief technology officer of Joris Laarman Lab, says is a key benefit of generative design and the larger impact of a sustainable shift in manufacturing: the ability to see the world in a new way. “We can move away from what we already know and start thinking with a completely open vision,” he says. “Start thinking about what we really want to do, not what we are used to doing.”

Sarah Wesseler contributed to this article, which has been updated. It originally published September 2020.

About the author

Patrick Sisson

Patrick Sisson is a Los Angeles–based design and culture writer who has made Stefan Sagmeister late for a date and was scolded by Gil Scott-Heron for asking too many questions. His work has appeared in Dwell, Pitchfork, Motherboard, Wax Poetics, Stop Smiling and Chicago Magazine.