5 ways Thermotex embraced digital transformation

UK manufacturer Thermotex was tech-phobic and reliant on outdated processes until employing five tips to pull off its digital transformation.

Kimberly Holland

December 6, 2019 • 6 min read

At 22, Chloe Watmore took over her parents’ UK-based business, Thermotex Engineering, and recognized the need for a digital transformation to modernize the company's manufacturing operations.

Watmore faced challenges in assembling a compelling case for digital transformation, and in convincing the board and team that digitizing data and processes would be beneficial and secure.

One of the major hurdles was the manual method of order processing and tracking. Watmore introduced Autodesk Fusion Lifecycle, a software system that centralized data and improved efficiency.

Watmore suggests not delaying action when a problem is causing difficulties, and the cost of the problem is evident. She emphasizes the importance of regularly taking stock of the progress made.

Many college graduates jump right into the workforce with an entry-level position that lets them cut their teeth. Some land internships; others work in apprenticeships to learn specific trades.

Then there’s Chloe Watmore. At age 22, Watmore took the reins of her parents’ UK-based business, Thermotex Engineering, which produces bespoke heat-tracing and insulation solutions. The Watmores had kept Thermotex running up until then with a small force of employees. They were successful, almost despite themselves: The company had remained largely paper based and was limited in size due to a lack of modernization. Processes were reliant on a handful of strategic individuals who knew how things worked—but didn’t know how to best share or leverage that information.

The young Watmore decided it was necessary, despite the difficulties involved, to make changes. She knew that a digital transformation in Thermotex’s manufacturing operations was in the offing.

Today, as the managing director of Thermotex, 26-year-old Watmore commands an unprecedented era of growth and increased revenue. As she prepares to return to university for her MBA, the managing director shares the lessons she learned as the company grew, as she pushed boundaries, and as lines of business revealed themselves for future expansion and development.

1. Change starts at the top

Watmore’s biggest initial obstacle to going digital was “assembling a compelling case and convincing the board that digitizing our data and processes would be rewarding, that it was a secure and reliable way to handle data, and that we would see return on the investment in our digital journey,” she says.

Another hurdle to overcome: outmoded workflow practices. When Watmore stepped into Thermotex, it was a bit like stepping back in time. “Performing everyday business functions felt very ‘manual’ and seemed to be done differently by different people,” she says.

That’s why getting the buy-in from her team was so important. “The leadership and management have to be on board from day one to support, champion, and ultimately fund the project,” Watmore says. “The journey to digitization can be a tough and long journey but also rewarding.”

Individuals at the top—managers, directors, and other leaders—can help spearhead and sell the culture of change and modernization down the line.

2. Support your team and give them room to grow

Changes in process can feel like a big hurdle to team members, Watmore says. Such changes can also feel threatening. She needed help “convincing team members that technology would help them in their jobs, listening to their concerns, making sure they had the support to learn how to use the software, and being open to adapt along the way,” she says. She had to be intentional about implementing the training and how employees would be included.

“New software may be cumbersome and slow people down, so they may feel nervous about the immediate impact—that it gets in the way of their doing their jobs well,” she says. “Talk to your team. Reassure them, and factor in the time to allow them to get used to the new way of doing things. If team members don’t feel stressed about adopting a new digital process, they’re likely to access the change and acclimatize faster—and may even see the benefit faster, too.”

3. Innovate around the biggest hurdle

For Thermotex, that big innovation hurdle came around order processing and tracking, something that was done manually on paper tracking sheets until Watmore arrived.

“Manually sharing data with new team members was incredibly inefficient,” Watmore says. “We needed a central source of data that was correct, live, and available to everyone who needed it to help the team work smarter, faster, and more accurately.”

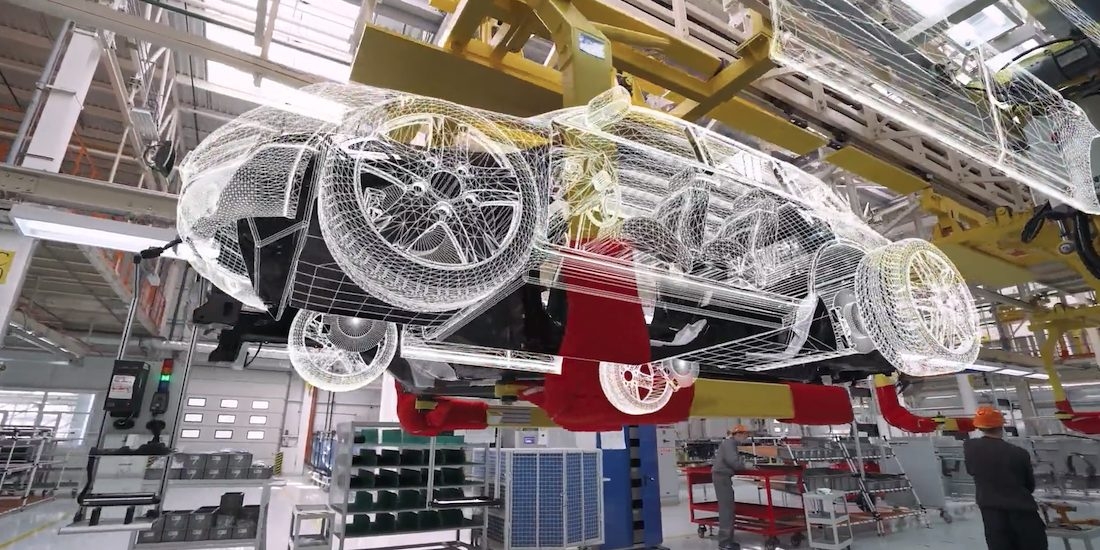

Watmore knew the outline of what she needed in software: user-friendly, affordable, customizable, and compatible with existing hardware systems. It needed to be a robust system that would strengthen the company’s credibility throughout regulated sectors such as oil, gas, nuclear, and construction, in which Thermotex already had a foothold. The answer: Autodesk Fusion Lifecycle.

“Fusion Lifecycle software gave us the brains of our operation,” Watmore says. “Thermotex achieved the latest accreditations in a trio of sought-after core-management system ISO standards after amalgamating our management systems into Fusion Lifecycle. Its stage-gated process design gave us an intuitive and controlled way to run our processes and track them along the way.

“Achieving those standards demonstrates our competency and credibility, and we’re invited to take part in large, prestigious international contracts,” Watmore continues. “The level of control and security has built our reputation with our customers within regulated industries by helping to keep us compliant, whilst also giving us a stable foundation on which to grow.”

4. Be open to where the road goes

Since joining Thermotex in 2013, Watmore has found new lines of business for the company. A new division, Fortivus, launched to model particularly complex thermal challenges, as well as offer engineering consultancy services.

“We’re researching and conceptualizing solutions and taking them all the way to prototype and creation—or any chunk of that journey,” she says. “We’re also helping SMEs [small to medium enterprises], leveraging our in-house design at Fortivus to fast-track engineering and complete briefs faster to be competitive.”

This is a special part of Fortivus’s work because it addresses issues Watmore faced within Thermotex. “Often SMEs struggle with lacking resources, particularly time, and we want to help them compete and grow,” she says. “Having struggled with this very problem ourselves in Thermotex for years, it’s a real privilege to now help other SMEs on their journeys.”

5. Don’t deliberate for too long

Watmore says if something is causing you a headache, and you can see the cost of the problem piling up in front of you, don’t be afraid to jump. “If you’ve found a solution that ticks the boxes for you, then it’s probably time to take the plunge,” she says. “There’s never a ‘good’ time, so why not now?”

Watmore adds that digitizing is meant to help you leverage your efforts so your team can work smarter, not harder. “Ultimately, don’t make it more complicated or more time consuming than it needs to be,” she says.

And don’t forget to appreciate what leaps your company has made in such a short period of time, she says: “Make sure you take regular breaks, stand back, and look at what you’ve achieved.”

About the author

Kimberly Holland

Kimberly Holland is a lifestyle writer and editor based in Birmingham, AL. When not organizing her books by color, Holland enjoys toying with new kitchen gadgets and feeding her friends all her cooking experiments.