The Viessmann smart factory is pumping up the heat

Heating and air-conditioning specialist Viessmann is using digital factory planning to boost production at its new heat-pump smart factory.

Susanne Frank

May 8, 2023 • 6 min read

The heat-pump market is booming, and heat-pump manufacturers across the globe are investing in automated production sites.

Viessmann uses digital technologies to optimize manufacturing processes at its new Polish smart factory, which will start heat-pump production in the autumn of 2023.

Digital planning for the Viessmann smart factory project will provide the blueprint for the construction of future production facilities.

Heat-pump sales have skyrocketed in recent years. The German business daily Handelsblatt calls this the “decade of the heat pump,” and considers heat-pump manufacturers to be champions of the transition to renewable energies.

This current boom for heat-pump technology has long been on the horizon. In 2021, 154,000 heat pumps were installed in Germany; just a year later, that number rose to 236,000. Although the growth rate in the United States lags behind Germany, sales rose above 4 million units for the first time in 2022, outpacing gas furnaces. The UK has even more catching up to do to achieve the government’s target of 600,000 heat-pump installations per year by 2028.

The German association for heat pumps, Bundesverband Wärmepumpe e.V., predicts that 500,000 heat pumps will be installed in Germany every year from 2024 onward, and that the total number of heat pumps in use will grow from 1.4 million units to 6 million units by 2030.

US-owned international heating and air conditioning specialist Viessmann, based in the central German town of Allendorf, is investing €1 billion ($1.08 billion) in green heating technology over the next three years. One-fifth of this, or €200 million, will go toward constructing a new 50,000-square-meter (536,196-square-foot) production site in Legnica, Poland, a city just over 80 km (approx. 50 miles) across the border. Viessmann intends to support Europe’s geopolitical independence and play a key role in the fight against climate change and fossil-fuel dependence. In May 2022, the company reported that demand for heat pumps had been up 41% before the war in Ukraine began, resulting in record sales in 2021.

The current political situation and the German government’s efforts to become independent from Russian gas supplies will boost sales even further. Viessmann is preparing for increased demand by massively expanding its capacity for producing heat pumps. Last year, it doubled the number of employees in this business unit.

Production in Legnica will start less than two years after the initial plans were developed and just over a year after ground was broken in summer of 2022. “It couldn’t have happened without digital planning,” says Norbert Schmidt, former digital-factory expert at Viessmann. Although he retired in 2021, Schmidt continues to advise the company on industrial engineering, passing on his many years of experience.

Digital factory planning accelerates production

The concept design for the Polish factory started in September 2021, and the detail design phase began a year later. “We then detailed the specific tasks to be performed in the various sections of the building,” Schmidt says.

All the tasks for the various building trades are merged into a comprehensive 3D planning model using cloud-based Autodesk BIM 360. Having a single source of truth improves coordination and ensures that everyone involved can access up-to-date plans. Viessmann is the principal for the factory, and the Polish branch of Bilfinger Tebodin is the general planner. Coordination and management of BIM (building information modeling) have been entrusted to E3D-Ingenieure, an engineering office based in Aachen, a city in the far west of Germany. Schmidt says the responsibilities are divided so that BIM tasks “can be carried out separately from those that are the responsibility of the various building trades.”

Autodesk Navisworks is used to check the model and run the critical clash-detection tool to ensure that work on the construction site goes smoothly. “Conventional construction projects used to require a lot of back and forth before you could find out what was wrong and how to fix it,” Schmidt says. “We’ve been able to reduce—and sometimes even avoid—this before the work on-site has even begun.”

Some of the machinery and equipment is installed during the final construction phase, which will allow the facility to start producing heat pumps as soon as construction is complete. Because all the companies involved have access to up-to-date plans at all times, project partners such as Schnepf Planungsgruppe Energietechnik (which provides MEP building services) and Jungheinrich (which supplies high-bay racking and conveyor technology) can plan at an early stage and start prefabricating components and production equipment.

A blueprint for factories of the future

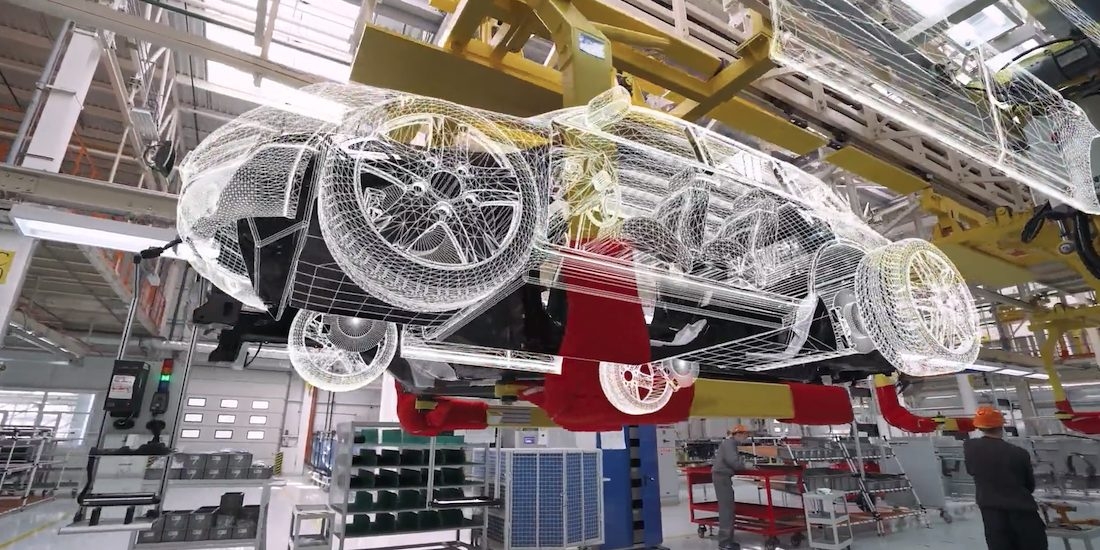

Schmidt says that Viessmann’s digital factory planning for the Legnica facility—the first time it has been used so comprehensively—could serve as a blueprint for the construction of future factories, a flagship project for its application of multiple digital technologies. Viessmann’s use of technology is not limited to BIM: It used Autodesk Revit and AutoCAD for the architectural planning, as well as other technologies to automate and improve processes in production, assembly, and logistics during the commissioning.

Modular production offers flexibility, and the high degree of automation makes it possible to increase production. Unity AG, based in the northern German city of Hamburg, uses Autodesk Inventor to plan all the factory processes that will run once it’s constructed.

A digital twin also plays a key role in meeting sustainability targets and making the factory carbon-neutral. This comprehensive digital model uses the building’s properties to calculate the factory’s total consumption and emissions in advance. “Polish legislation stipulates that these values must be established before construction is completed,” Schmidt says.

Internal digital knowledge transfer

Schmidt says that construction plays an important role in the spread and acceptance of digital tools. Having extensive experience with the possibilities offered by digital tools, he is pleased that factory building has finally started to go digital.

“Augmented, mixed, and virtual reality are visionary tools,” Schmidt says. “And so are 3D visualization and laser scanning.” He adds that the project’s success is due in part to the “commitment and enthusiasm” Viessmann’s staff has brought to these opportunities. Using digital modeling to construct production facilities and digital factory planning for its manufacturing needs ensures seamless coordination. Schmidt says the new factory in Legnica is an exemplary project in terms of integrated factory planning and proof that this convergence between architecture and manufacturing is actually happening.

Keeping the digital twin alive

Digital planning will not stop once the factory begins production. Viessmann plans to convert the factory model into a digital twin to be used for computer-aided facility management, which will allow repairs to be carried out efficiently. Such data can even provide an early indication that a machine might break down and make it possible to take preventive measures. “We’ll continue to feed the digital twin and keep it alive so we can continue to reap the benefits while the factory is in operation,” Schmidt says.

About the author

Susanne Frank

Susanne Frank studied American studies, English, and theater studies (MA) at the Friedrich Alexander Universität Erlangen-Nürnberg before training as an online journalist. She was responsible for public relations in the marketing department of a medium-size software company for 11 years before switching from PR to journalism in 2015. She has occupied roles as editor and editor-in-chief at several prominent German trade magazines and has been working as a freelance journalist since 2019.