& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

The metaverse—also referred to as spatial computing applications—while still largely undeveloped, is a collection of online, immersive 3D virtual worlds and spaces where users can work, learn, create, communicate, play games, shop, and practice digital tourism. With metaverse technology, anything that can be made physically can first be designed, simulated, tested, and refined in a digital space without wasting physical resources or putting people at risk.

For the most part, the current metaverse works more like multiple metaverses of online virtual 3D spaces and worlds that are closed off to each other. If advocates like the nonprofit industry consortium Metaverse Standards Forum are successful in establishing open metaverse data standards, the future metaverse could become a single, interoperable, persistent virtual space where users’ avatars could move fluidly throughout, using digital assets from any source with continuity.

The current metaverse, however, offers various levels of immersion. The large majority of the 600 million monthly active metaverse platform users cited as of October 2023 are playing virtual world games on mobile devices and desktop software—the most popular being Fortnite, Roblox, and Minecraft. The media and entertainment industry creating those metaverse games is also busy creating metaverse environments for growing use cases like e-commerce virtual fitting rooms and health and fitness applications.

Meanwhile, interest in accessing a more immersive metaverse through mixed- and virtual-reality headsets is growing, with headset shipments more than tripling from 30 million in 2022 to 105 million by 2024. And the most common reasons for new metaverse adoption include work and education.

Immersive spatial computing technologies can make it easier to teach difficult concepts and high-level skills, including on-the-job training to address widening skills gaps in fields such as manufacturing and construction. For work purposes, spatial computing technologies foster smooth collaboration between team members working remotely and increase design and engineering efficiencies. Stakeholders can simulate real-world performance in the metaverse with digital twins—3D-modeled representations of products, structures, or systems—helping them refine designs quickly and inexpensively before spending resources on physical production.

The 3D virtual worlds that compose the metaverse rely on extended reality (XR) technologies for people to access it. XR comprises reality-creating or -altering technologies that will continue to enhance work, education, and entertainment: augmented reality (AR), mixed reality (MR), and virtual reality (VR).

These different XR technologies ascend in order of how much they transform the physical environment around the viewer. With augmented reality, the front-facing camera of a device like a smartphone or tablet shows the viewer’s surroundings while virtual objects and information are overlaid on the screen, providing data-synced context and augmented views of the real world.

Mixed reality goes a step further, where the viewer wears goggles or smart glasses such as the Microsoft HoloLens or Apple Vision Pro, so the virtual objects of the metaverse are more immersive and interactive, but viewers can still see through to their outside surroundings. Finally, virtual reality headsets create the effect of a fully immersive virtual world, where the viewer has no visual of the physical world and can commit fully to training simulations, games, and so on.

In addition to industry-specific uses, the metaverse and spatial computing serve as points of industry convergence, where the workflows of all the industries below come together to create new value.

AECO

In the architecture, engineering, construction, and operations (AECO) industry, metaverse technologies are currently used for spatial simulation throughout planning, designing, and interactive architectural visualization. Clients and stakeholders can virtually walk around or through the digital twin of a building or any other asset. AR and MR are also used on construction sites to experience how the building should look.

PD&M

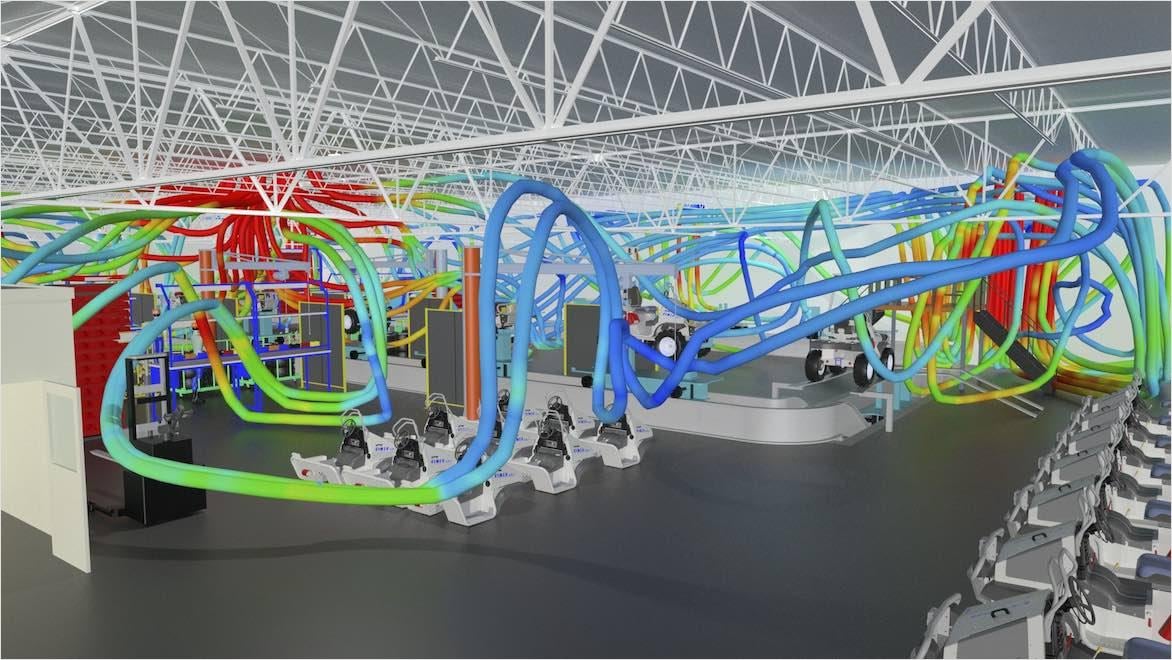

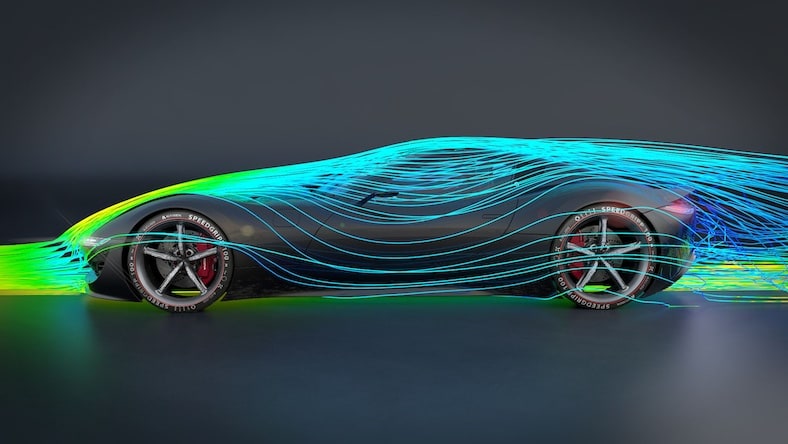

The product design and manufacturing industry also uses digital twins to iterate on complex designs such as cars without having to build physical prototypes. Digital twins of entire factories and warehouses in the industrial metaverse provide insight into processes, predictive maintenance, and supply chain issues. They also enable workers to undergo virtual training on machines and factory processes safely and efficiently, without shutting down production. The industrial metaverse mirrors physical facilities and supply chains in a digital world, taking advantage of technology to help firms better automate processes, monitor systems, upskill workers, and heighten productivity.

M&E

The media and entertainment industry is largely responsible for making the 3D models and environments of the metaverse, like immersive VR games, a real-time concert held inside a virtual world, or the many educational XR platforms that can apply gamification to learning. Creators also use spatial computing technologies to create entertainment, such as directors who use AR and VR visualization to make choices for directing scenes. As this industry continues to adopt open standards, artificial intelligence (AI), and cloud platforms for production, those tools will be key enablers of metaverse entertainment experiences.

Image courtesy of Marie Henry

The metaverse offers significant cross-industry benefits that make meetings and group reviews more effective, training safer and more accessible, and projects more efficient and sustainable.

Whether reviewing designs or evaluating processes on the construction site or factory floor, the metaverse allows co-workers and stakeholders to see the same thing at the same time and collaborate on equal footing from anywhere in the world as if they were in the same physical space.

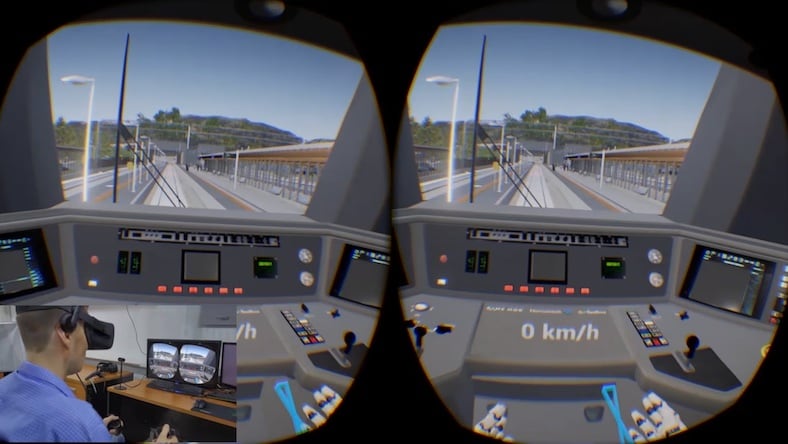

The metaverse and spatial computing can present more accurate virtual representations of environments, systems, and objects, providing an excellent platform for education and on-the-job training. People can learn potentially complicated or dangerous skills—such as welding, operating heavy machinery, and much more—in perfect safety and at a fraction of the cost.

Across industries, the metaverse and spatial computing enable time- and cost-saving simulations to inform decision-making. Media and entertainment creatives can simulate production; the design and manufacturing industry can simulate prototype function and factory processes; risk and safety simulations benefit construction; and the AECO industry benefits from spatial and operational simulations.

With the metaverse, companies can design, simulate, test, and validate products, buildings, and systems virtually. That allows them to make crucial changes before building anything physically, cutting down on resource waste.

NORCONSULT

To speed up the validation of the sign and signaling system for a new rail tunnel in Norway, infrastructure firm Norconsult put the system’s BIM and CAD 3D models into a VR game engine so train operators could test the signaling system in the metaverse prior to installation—saving costs, reducing errors, and accelerating approval.

Image courtesy of Norconsult AS/Bane NOR/Baezeni

HISTOVERY

The immersive and interactive augmented reality tour/exhibit Notre-Dame de Paris, the Experience placed the famous cathedral’s history and post-2019 fire restoration into the metaverse, giving many thousands of visitors an unprecedented look into 21 re-created scenes from Notre Dame’s history, as well as architectural details from the church’s beginning to its current state.

VIESSMANN

German HVAC company Viessmann utilizes all forms of extended reality for its newest heat-pump smart factory. Using digital factory planning, Viessmann made a comprehensive digital twin of the factory, effectively placing it in the metaverse for computer-aided facility management, which can predict machine problems before they break down.

The metaverse and spatial computing have the potential to revolutionize product design and manufacturing.

McKinsey has estimated that metaverse economic activity could hit $5 trillion as soon as 2030. If fully adopted, the metaverse has the potential to transform the way people design and make.

In both architecture and product design, the creative process in the metaverse will be collaborative, interactive, and immersive so that designers and engineers can iterate on projects seamlessly in a virtual space. Whether making a consumer product, an entire factory, or an infrastructure system, stakeholders can participate in immersive design reviews in XR. On a construction site, for example, workers using mixed reality could virtually walk through and examine the digital twin as it’s being built.

The developing world of spatial computing, which includes metaverse capabilities but casts a wider net, also has enormous implications for industrial applications. Spatial computing has the potential to essentially break down the boundaries between digital assets and the physical world, through the pervasive use of technologies such as AR smart glasses, the Industrial Internet of Things (IIOT), edge computing, 5G connectivity, AI, and cloud connectivity. With spatial computing and XR, great leaps could be made in monitoring facility performance, onboarding employees faster through simulations, and making work environments safer for workers and better prepared for risk avoidance.

The metaverse will also have collaborative effects on media and entertainment production at the same time as new permutations of entertainment inside the metaverse are being developed. The lines between interactive gaming and passive entertainment could blur. Viewers, for example, could watch a movie as if they’re actually in the fictional world of the film and even influence the unfolding of the story. AI in the metaverse could make storytelling and gaming more personalized, with the participant having more and more say in the appearance and activities of the virtual world. The media and entertainment industry will also create the metaverse environments for real-time, large-scale participatory gatherings where people can shop; hold their own virtual events; and virtually visit foreign cities, historical sites, museums, and other destinations.

The combined technologies of XR—virtual, augmented, and mixed reality—are crucial for designing, making, and experiencing the metaverse, and they are making diverse industries like product design, manufacturing, health care, education, architecture, and construction safer, more effective, and more efficient.

Both the AECO and media and entertainment industries pour tons of resources and talent into building 3D virtual worlds. Interoperable data and metadata standards could allow both industries to share data to their mutual benefit while accelerating the building out of the metaverse.

Architectural visualization benefits from real-time immersive experiences in the metaverse as much as video games. New industry partnerships are infusing architectural design software with powerful real-time rendering game engines, as well as advocating for open data standards that can ensure the metaverse is interoperable.

As many construction firms struggle with talent shortages, embracing technology like the metaverse, spatial computing, AI, robotics, and others can attract workers and make efficient use of existing teams.

With the proliferation of the metaverse, demand for volumetric video—3D-compatible live-action video—will skyrocket. Learn more about how software for the metaverse is making volumetric video easily accessible to 3D artists and other content creators.

Real-world uses of the metaverse created from AR and VR experiences are transforming virtual tours, astronaut training, and storytelling itself.

People access the metaverse through a variety of devices—both traditional mobile devices and computers and extended reality (XR) devices. Those XR devices—including augmented reality (AR), mixed reality (MR), and virtual reality (VR)—confer the most immersive experiences and advantages of the metaverse. However, 3D virtual worlds in games such as Roblox and Fortnite, which can be considered part of the metaverse, are currently the most popular metaverse destinations and are overwhelmingly accessed through mobile devices and computers.

Speaking literally, the metaverse contains digital data on cloud servers that make up a growing number of participatory, immersive virtual worlds. What people can do in these spaces is the spirit of what’s in the metaverse. Already, people are using spatial computing and the metaverse to work, socialize, and connect with other people living anywhere in the world. People also create music, art, and videos; play games; learn new skills; shop; and exercise in the metaverse. With time and imagination, the metaverse should have even more to offer.

No one owns the metaverse outright. However, many companies have their own versions of the metaverse, including Meta, Microsoft, and Epic Games (makers of Unreal Engine and Fortnite). There are bound to be many metaverses, some of which will be overseen by a single company and others that will be open and interoperable to encourage as many creative participants as possible.

Because many people use different types of virtual worlds, and a hard definition of what is and what is not the metaverse doesn’t really exist yet, it’s difficult to say exactly how many people use the metaverse. However, video game versions of the metaverse—large, multiplayer game worlds such as Roblox, Minecraft, and Fortnite—have more than 100 million monthly active users each.

According to statistics published on LinkedIn, the total monthly active users for all metaverse platforms topped 600 million in October 2023—the vast majority of those being kids and tweens in non-VR virtual worlds.

The industrial metaverse may end up being the next phase of Industry 4.0. In the industrial metaverse, factories and businesses use spatial computing technologies to accelerate operations, boost collaboration, optimize supply chains, and and help streamline processes such as manufacturing and worker performance. They do this by combining XR applications and spatial simulations with the Industrial Internet of Things (IIOT), digital twins, advanced robotics, AI, and other tools for remote collaboration and virtual interaction.

Exactly what the metaverse will be is still unknown. It depends on many circumstances, including user adoption and enthusiasm; privacy and security policies; advancements in AI, machine learning (ML), and other technologies; and other issues like interoperability. Will the companies most invested and advanced in the metaverse insist on funneling users into their world only, at the exclusion of other creators, or will organizations come together and create open data standards so that everyone’s contributions to the metaverse can be used fluently?

One example of the metaverse is Mesh for Microsoft Teams, the tech giant’s play at making a metaverse for the work world that blends the efficiency of working from home with the sociability and camaraderie of working in an office.

Although the metaverse has many implications beyond gaming and entertainment, 3D virtual gaming worlds like Roblox, Minecraft, and Fortnite are the most commonly used current metaverse examples. The first example of the metaverse, Second Life, launched in 2003 and is still active.

The metaverse is used in daily life for communication among friends, family, and co-workers; education and job training for versatile skills from welding to surgery; designing and engineering products as complex as sports cars and sports stadiums; and for making creative decisions for media and entertainment production.

Entertainment is the most popular current use of 3D virtual worlds by far, with games such as Minecraft, Fortnite, Roblox, and others accumulating hundreds of millions of monthly active users.

The industry most impacted by the metaverse today may be product design and manufacturing. In this field, spatial computing technologies help designers and engineers virtually prototype products and simulate their function to refine designs and speed up the design process before physical production. Factory managers also use digital twins of the factory in the metaverse to oversee key production data, plan processes, predict machine problems before they happen, and more. Metaverse digital twins and simulations even help with supply chain management, inventory, and training employees on the job.

Like many new technologies, the metaverse is inherently neither harmful nor beneficial. It has the potential to help individual people and humanity at large by training people to do important jobs without risk, such as performing surgery, flying aircraft, and operating manufacturing and utility facilities. It can also democratize and demonetize other types of education for people of all backgrounds.

The metaverse also has the potential to be harmful if people become addicted to it or use it to haze other people with a veil of anonymity or steal personal information. The metaverse itself, however, is neutral.