& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Andrew Anagnost, President and Chief Executive Officer, Autodesk: The last three years have fundamentally shaken the foundation of manufacturing worldwide.

People used to think that longer and longer supply chains, chasing lower and lower manufacturing costs was going to be the way they were going to build and maintain their ability to make things. The pandemic, the shifting geopolitical environment, inflationary pressures, it’s changed everybody’s point of view.

Mike Haley, Senior Vice President of Research, Autodesk: The old world of how we’ve worked digitally has always been based on files, and moving files around, and having the right product to the right program to open a file and to do something with it. The first premise of a cloud-based platform is that goes away. It’s about decomposing what is traditionally in a file into its constituent components, each one that’s useful to different people under different circumstances, and just putting it in the cloud. So it’s behind the scenes, and the cloud can just give you what data you need whenever you need it.

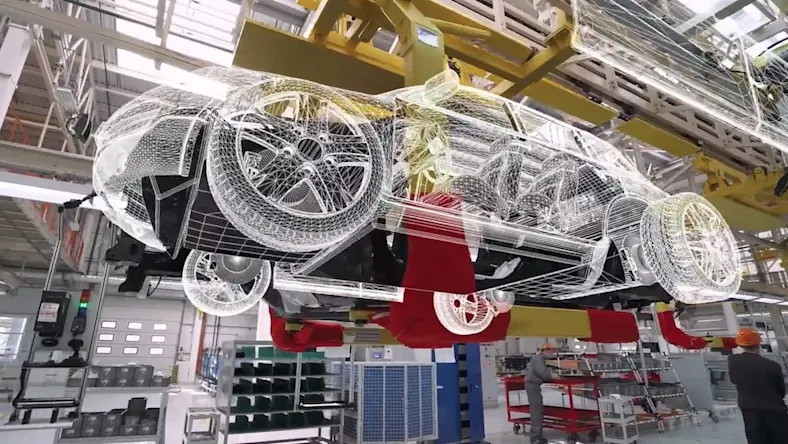

Jeff Kinder, Executive Vice President, Product Development and Manufacturing Solutions, Autodesk: Everything is connected where data flows seamlessly from design through to make, through to even operate on the shop floor. And how we use that data to help make our processes smarter and more efficient and more productive.

So much data is generated in the design and manufacturing process. 80%, maybe more of that data falls to the floor. We’ve laid out a vision for industry clouds, which is a bringing together of the point solution products and making them interoperable with data that flows back and forth. You’re able to get insights throughout the process.

Fusion is our model of an industry cloud. We always saw that that was the way to achieve breakthrough productivity gains for customers, when you bring design and make together and connect that with the data.

Haley: A cloud platform only really works if it’s extensible and customizable to what customers need. So it has to have APIs. It has to have the ability to build extensions on it that anybody can now take those, either they build them themselves or they buy them in a marketplace, and they connect it directly into their existing workflows.

Anagnost: Right now, something gets designed and somebody tries to figure out how to manufacture it. But when you have highly connected data and highly connected flows and simulation and augmented design capabilities driven by AI sitting in between those things, you are gonna be able to make sure that what you design is manufacturable from the get-go because it’s gonna tell you how to manufacture it, or it’s going to solve the manufacturing problem in real time while the designer’s working on it.

Kinder: AI will further the simulation revolution where you no longer have to produce big batch runs to see if a designed product works. When you think about the components of a building, they have windows, they have doors. Each of those are parts that need to be manufactured to tight specifications, otherwise your window won’t close, otherwise your door won’t close.

By bringing the manufacturing CAD models together with architectural CAD models, you take historically disconnected, inefficient steps in a process and you weave them together. So a builder can look at hundreds of options, and they can pick a design that works best.

Anagnost: We talk about this doing more with less all the time. It’s like it’s almost a cliché in any technology industry, but we’re really on the cusp of enabling people to do more projects with the same amount of people and with less negative impact on the world.

Because we can manage all that complexity, all that analysis, all that data gathering for them. We can remove the overwhelming aspects of trying to make better design decisions and free them up to just actually make the better design decisions.

Kinder: AI will be a tremendous way to augment the capabilities of employees. We don’t think AI replaces employees. We think it makes everyone more productive and enhances their creativity or their efficiency and productivity.

Haley: When all of this comes together, if I see that we’ve helped the world create and our customers create these ecosystems of people coming together, tackling really tough problems like waste in our oceans, and climate change, and migration problems, and urbanization. These are massively complicated problems that no one government or one company is going to solve. It’s going to require a collective effort and tools and technologies that enable that, that would really make me feel that we’ve done our job.

Executive insights

Emerging Tech

Emerging Tech