Autodesk Education Community

Make real products as you learn

Whether you’re new to CAD & CAM or are a seasoned expert, these hands-on projects will create a spark. They include everything you need to get started with Fusion 360.

Autodesk Education Community

Whether you’re new to CAD & CAM or are a seasoned expert, these hands-on projects will create a spark. They include everything you need to get started with Fusion 360.

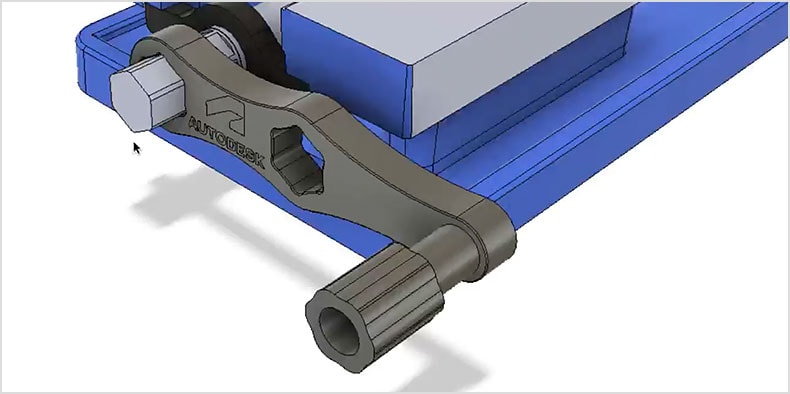

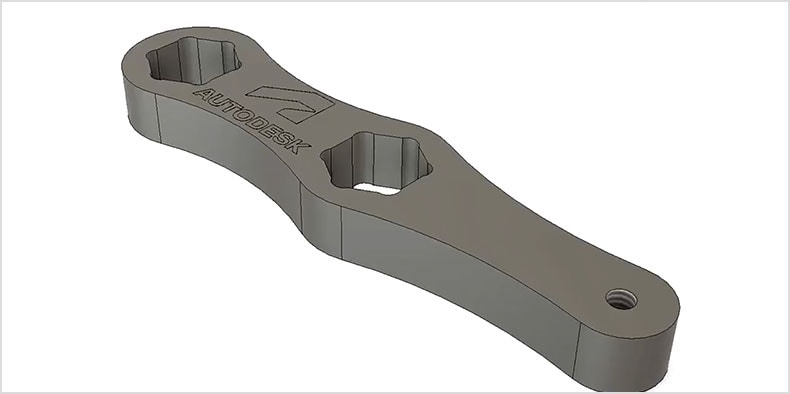

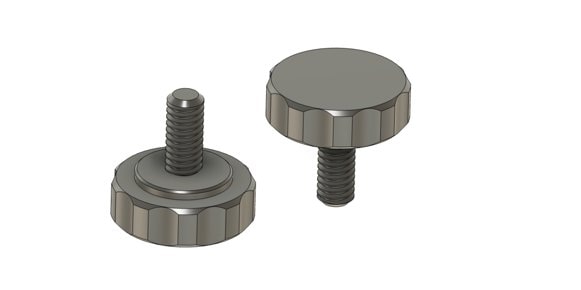

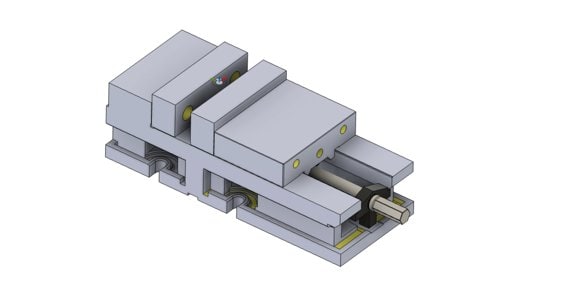

This project-in-a-box will lead you through simple CAD and CAM workflows in Fusion 360 to design and build a speed vise handle. It includes descriptive videos, setup sheets, drawings, and a machine tool library. By the end, you will be able to create an actual speed vise handle that you can then use in the shop.

Watch videos from this Project-in-a-Box to make a real speed vise handle that you can use in the shop.

This video will introduce you to the concepts you’ll learn with the Speed Vice Handle Project-in-a-Box.

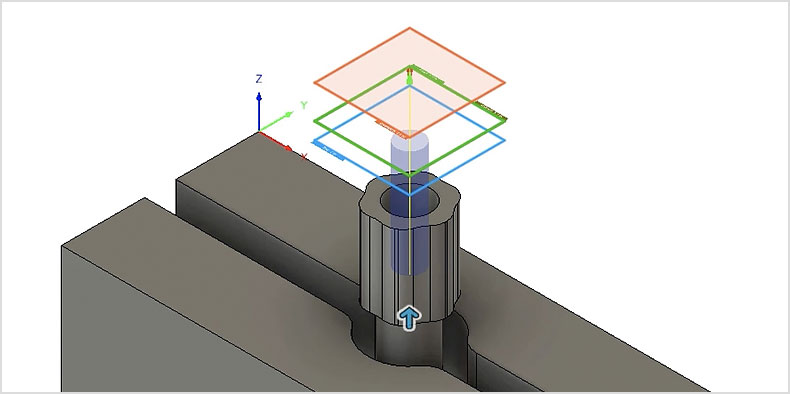

This video will take you step-by-step through the design of a speed-vise handle, teaching you how to use the CAD platform in Fusion 360.

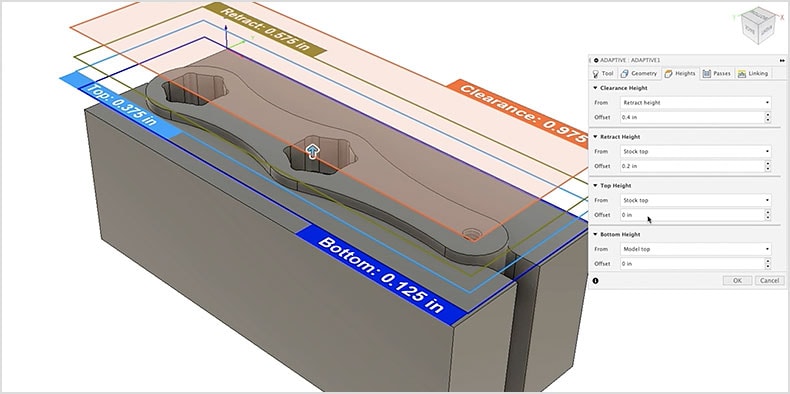

This video will help you ramp up on the manufacturing workspace of Fusion 360, explaining in detail how to create toolpaths for a speed vise handle.

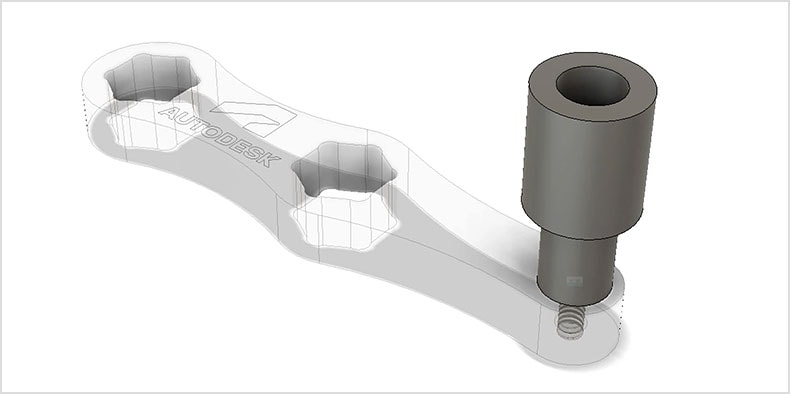

This video will sharpen your skills on the manufacturing platform in Fusion 360, showing you how to create a knob that attaches to the speed vise handle.

This video will show you how to link the knob into the design so any changes you make in the original will propagate in the new file.

This video highlights in-machine footage of the CNC operations.

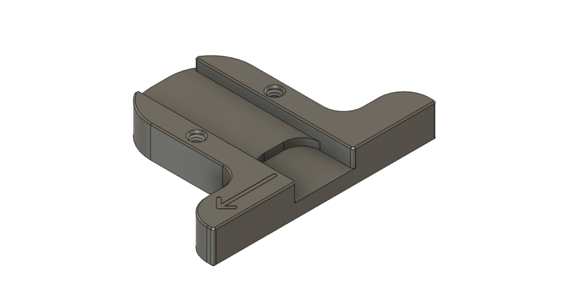

This project-in-a-box will lead you through both CAD and CAM workflows in Fusion 360 to design and build a caliper depth base attachment. The videos below will walk you through each step and should be followed in order.

Create the base for the assembly and lay the foundation for the rest of the project.

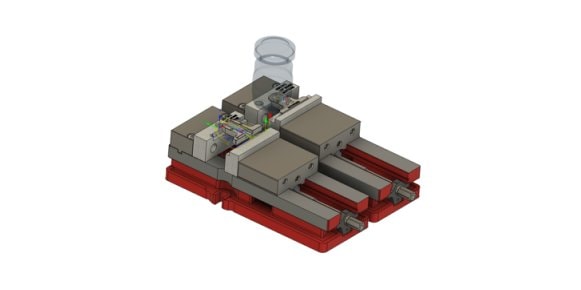

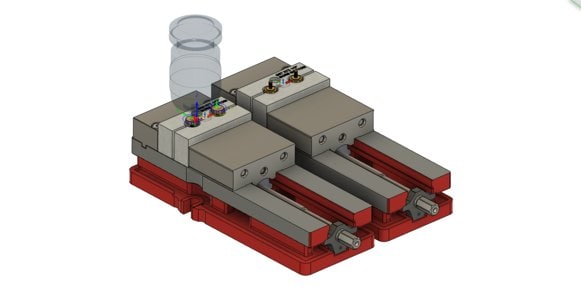

Import a vise model and add intelligence in Fusion 360. Creating a smart vise will save you and your students time and reduce errors.

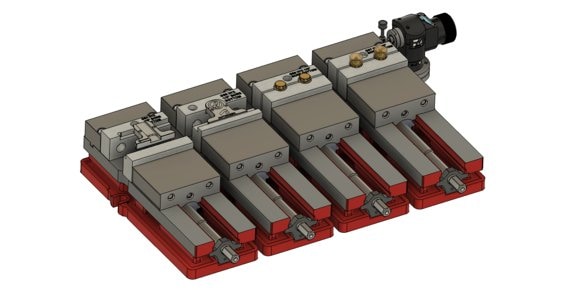

Leverage the power of integrated CAD/CAM to create a manufacturing assembly to drive production of the components.

Considerations and steps for creating effective toolpaths for the base component.

Considerations and steps for creating effective toolpaths for the knob components.

This step-by-step project shows how to design and apply tooling paths through Fusion 360 to create a fidget spinner. Included are detailed instructions that you as an instructor can use in the classroom as well as the needed part files. By the end, your students will be able to apply basic CAD skills, CAM tooling paths, and export that to a CNC machine.