GEISMAR

Better design data management: A key pillar of succesful digital transformation

CUSTOMER STORY

Autodesk Vault: A lever for efficiency and collaboration at Geismar

Geismar, a key player in the rail industry, has adopted Autodesk Vault to centralize and secure its data management, optimizing international collaboration within its global network of design offices. This solution has significantly reduced information transfer times between sites, improving operational efficiency. With critical data now centrally stored, all internal and external teams have real-time access to it. This digital transformation has not only increased productivity but has also strengthened the quality of after-sales service.

Image credit: Geismar

Geismar: Innovation serving the rail industry for over a century

Founded more than 100 years ago, Geismar is a global reference in the railway industry, delivering solutions for the construction, maintenance, and renovation of railway infrastructure.

With a presence in 130 countries, six state-of-the-art R&D centers, and five factories located across Europe and the United States, the company meets the specific needs of each region while maintaining the highest standards of quality and performance for its products. "Our know-how is based on an in-depth knowledge of railway systems, which we tailor to the regional specifics of our customers all over the world", explains Jean-Philippe Antoine, Head of Industrial Performance at Geismar.

Geismar offers a broad range of machines, from portable equipment to impressive multifunctional rail vehicles, designed to tackle the diverse challenges of the railway sector, operating at all levels from product to process and supporting the complex management of large-scale industrial projects.

Image credit: Geismar

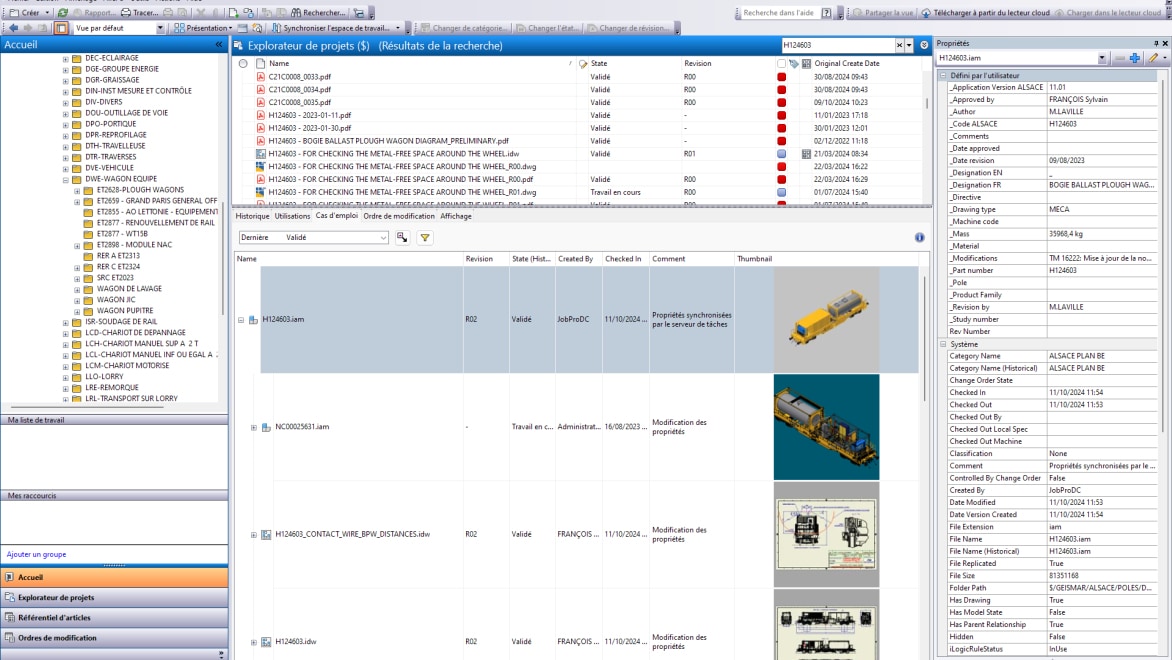

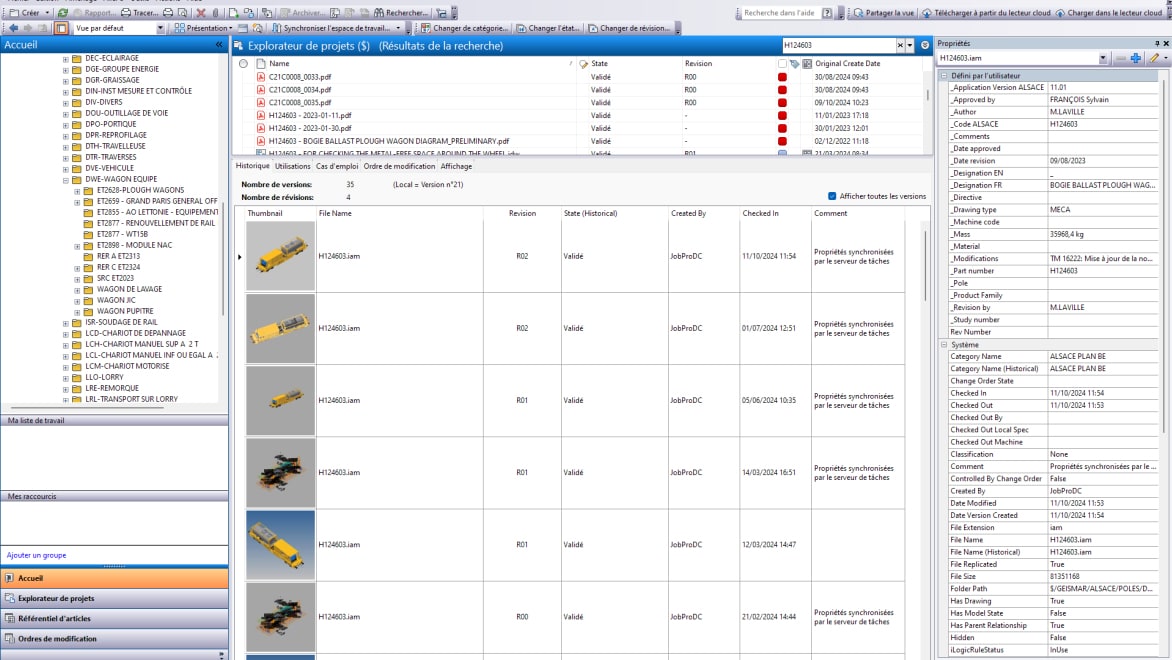

Vault: Meeting the universal challenge of data management

Like many industries, Geismar is facing an escalating problem: data management. With design offices spread across multiple regions and varied work systems, the accumulation of data and the lack of a centralized system made processes complex, inefficient, and prone to numerous redundancies. "We had a diverse situation, with design offices using various working methods and storage systems," explains Jean-Philippe Antoine. To streamline its processes and improve collaboration, Geismar selected Autodesk Vault, a product data management system that centralizes and safeguards critical company data.

Several factors motivated the decision to implement Vault, including the opportunity to reduce costs by optimizing software licenses and the need to standardize practices throughout the company. According to Autodesk, poor communication and data management can lead to as much as 52% more work, and 13% of team time is lost searching for information. "The opportunity to streamline licenses and standardize our processes was too important to ignore", adds Jean-Philippe Antoine, confirming that Vault emerged as the key tool for the transformation of data management practices at Geismar.

"We had a diverse situation, with design offices using various working methods and storage systems. [...] The opportunity to streamline licenses and standardize our processes was too important to ignore."

— Jean-Philippe Antoine, Head of Industrial Performance, Geismar

Image credit: Geismar

A complex but necessary transition

The implementation of Vault at Geismar was not without its challenges. The diversity of work processes across the different sites, as well as the lack of in-house expertise in PDM management, required a rigorous structuring of the project. Each site had its own standards and methodologies, which did not facilitate cross-site collaboration. To overcome these challenges, Geismar designated "key users" at each site and mobilized management to ensure team buy-in for this transformation project. "Management involvement was crucial in successfully driving this change and securing the project's success", explains Jean-Philippe Antoine.

In addition, Geismar enlisted ARKANCE, an Autodesk integrator, to assist with the training and deployment of Vault. This partnership ensured a smooth transition despite the differences in practices between the design offices. "Our subsidiaries had developed automated systems and practices that, although solid, did not foster smooth collaboration", shares Jean-Philippe Antoine. With Vault, Geismar was able to streamline processes by establishing standardized product lifecycles, shared data categories, and a common library.

Image credit: Geismar

Concrete results: Productivity and time savings

Since implementing Vault, Geismar has seen significant gains in its operational efficiency. Design offices report an increase in productivity due to reduced times in transferring plans between sites, estimated at between 10% and 20%. By centralizing product data in a "digital vault," Vault makes it possible to store and safeguard all critical information, which is accessible in real time by both internal and external teams. "The two-year return on investment was possible thanks to the time saved in accessing information", explains Jean-Philippe Antoine, highlighting the positive financial impact of this solution.

Furthermore, all the technical documents required for after-sales service are now available in Vault, allowing after-sales teams to respond more promptly to customer requests. With 187,500 2D/3D drawings and 140,000 technical documents centralized, Vault boosts cooperation between design offices and optimizes operations. A project initiated at one site can therefore be finalized and assembled at another, increasing the company's agility.

"The two-year return on investment was possible thanks to the time saved in accessing information."

— Jean-Philippe Antoine, Head of Industrial Performance, Geismar

Image credit: Geismar

Toward full harmonization: The next steps at Geismar

Encouraged by the results, Geismar has no intention of stopping here. The company is now planning to test a PLM (Product Lifecycle Management) solution to further centralize the management of bills of materials and enhance its technical documentation. This step will allow Geismar to track the life cycle of each product, from its design to its maintenance, while further improving consistency across the different production sites.

At the same time, Geismar plans to align factory processes with a centralized item database and a reinforced connection with its ERP system. This harmonization also aims to improve synergies between purchasing and production to optimize costs and minimize lead times. "Vault is just the beginning of our digital transformation", concludes Jean-Philippe Antoine. "Our ambition is to go even further to build a robust, harmonized architecture, capable of supporting our international growth and addressing the challenges of the rail sector of tomorrow."