MND

ORIZON™ project: A revolution in cable transport, powered by Autodesk

CUSTOMER STORY

Share this story

Summary

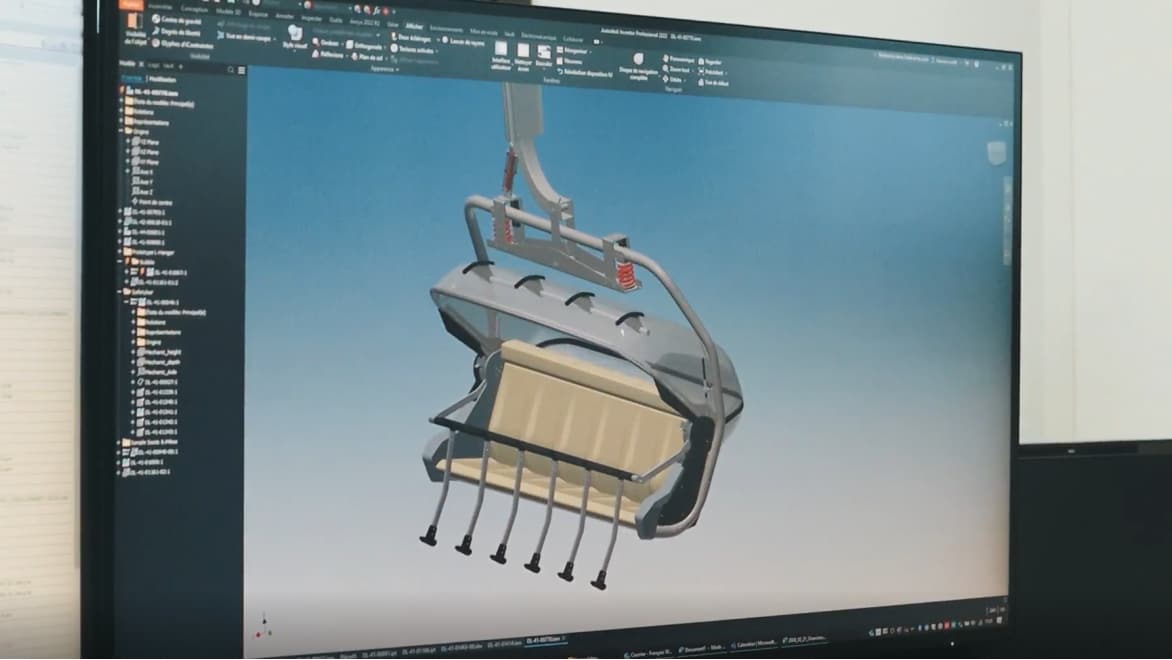

MND, leader in cable transport, pushes the boundaries of innovation with ORIZON™, a range of gondolas and chairlifts for urban and mountainous environments. With Autodesk's advanced solutions for design and data management, MND has halved development time while optimizing operational costs. This approach positions MND as a pioneer in sustainable mobility, combining technology, design, and energy efficiency.

Image credit: MND

MND and ORIZON™: A new era for cable transport

MND is a French industrial group specializing in cable transport, snowmaking systems, mountain safety, and thrilling leisure facilities. This ''made in the Alps'' success story recently launched its ORIZON™ project, strengthening its commitment to sustainable and efficient mobility by offering an innovative range of gondolas and chairlifts for both mountainous and urban environments. Designed to meet the demands of tourism and urban operators, ORIZON™ is a "Made in France" solution that is both reliable and forward-looking. Its mission? To challenge major international historical players and become the new standard in the mountain as well as in the city.

Developed in collaboration with Stellantis Design Studio, the design of this new range embodies the synergy between aesthetics and technology. Drawing on Stellantis Group's automotive expertise, the design of ORIZON™ equipment reflects a cutting-edge approach, integrating lightweight and robust materials to maximize durability while offering an optimal user experience.

Image credit: MND

Custom design and industrialization: Excellence at all levels

Developing the ORIZON™ range was a significant innovation challenge for MND. Designed over a three-year period, this ambitious project is based on cutting-edge technologies that aim to revolutionize cable transport. Optimizing energy consumption was a key goal from the very first stages of design. ORIZON™ incorporates a gravity-driven conveyor system that harnesses the energy generated during passenger transport. Combined with an innovative new motor, this mechanism not only reduces energy consumption, but also allows heat to be recovered to power nearby buildings.

"We designed ORIZON™ focusing on every technical and energy-related detail. The ability to harness gravitational energy and optimize heating processes is one of the innovations we are most proud of", highlights Bastien Duprey, Head of ORIZON™ Design Office.

In addition to these energy innovations, the ORIZON™ range is characterized by its flexibility. It can accommodate projects with varying constraints, whether in mountainous or urban settings. With a modular design, it can cater to specific requirements in terms of capacity, comfort, and integration into complex environments. "One of the greatest strengths of ORIZON™ is its modularity. Whether for high-altitude ski resorts or ambitious urban projects, our solution adapts to the specific needs of each customer, offering considerable flexibility in terms of configuration and customization", explains Bastien Duprey.

Image credit: MND

Autodesk solutions driving innovation

The success of the ORIZON™ project also relies on the use of advanced technological tools for design and data management. In partnership with ARKANCE, an Autodesk solutions integrator, MND took full advantage of software such as Autodesk Inventor (engineering) and Vault Pro (product data management), resulting in optimized design processes and reduced time to market.

"One of the greatest challenges was efficiently coordinating teams located at various sites, while ensuring seamless data management", explains Bastien Duprey, Head of ORIZON™ Design Office. "With Autodesk Vault Pro, we were able to centralize all the information in one environment, which allowed our teams to work simultaneously and much more efficiently."

With Autodesk Vault Pro, MND was able to complete the ORIZON™ range in just a year and a half, a project that would normally take between three and five years. "We cut development time by almost 50% thanks to Autodesk Vault Pro and Inventor. This would have been impossible without these tools", says Bastien Duprey.

Autodesk Inventor was also crucial for the design of the equipment, especially by enabling the use of reconstituted profiles and stamped parts, a technique borrowed from the automotive industry. "By adopting new manufacturing methods from the automotive sector, we were able to overcome technical barriers and design more robust and aesthetically attractive products", adds Bastien Duprey.

“With Autodesk Vault Pro, we were able to centralize all the information in one environment, which allowed our teams to work simultaneously and much more efficiently. [...] We cut development time by almost 50% thanks to Autodesk Vault Pro and Inventor. This would have been impossible without these tools.”

— Bastien Duprey, Head of ORIZON™ Design Office

Image credit: MND

Concrete results: Optimized collaboration and process acceleration

Using Autodesk Vault Pro and Inventor has transformed the way people work at MND, enabling real-time collaboration between multiple teams across four sites through database replication. "Data centralization has greatly enhanced our efficiency, not only in the design office, but also in the methods, production, and marketing departments", notes Bastien Duprey. Thanks to this digital collaborative approach, the ORIZON™ range was able to see the light of day in just 18 months. This was a record timeline for a completely redesigned workflow.

This acceleration of the process was accompanied by a noticeable improvement in the ability to deliver high-quality products. "Proof of concept via digital mock-ups allowed us to anticipate design issues and resolve them upstream, reducing production errors and boosting the reliability of the equipment", adds Bastien Duprey. Thanks to this enhanced collaboration, we were able to bring an innovative solution to the market while at the same time reducing development costs.

“Proof of concept via digital mock-ups allowed us to anticipate design issues and resolve them upstream, reducing production errors and boosting the reliability of the equipment.”

— Bastien Duprey, Head of ORIZON™ Design Office

Image credit: MND

The future: Toward global integration of Autodesk solutions

Building on this success, MND now plans to expand the use of Autodesk tools across all its operations, especially in the areas of leisure, snowmaking, and safety. "Our goal is to deploy these solutions in all our industrial processes, as well as in our other business sectors", explains Bastien Duprey.

Furthermore, the integration of BIM (Building Information Modeling) technology in future projects will allow MND to optimize data management and collaboration with external partners, especially in complex urban environments. "Autodesk Inventor, Vault Pro, and Revit interoperability allows us to streamline communication with architects and engineers, making it easier to integrate our infrastructure into built environments", concludes Bastien Duprey.

Building tomorrow: A promising future for aerial mobility

Beyond the immediate results, the ORIZON™ project is embedded within a broader approach to sustainability. Each cable transport system is designed to last more than 30 years, while reducing energy consumption, making it particularly suitable for mountain environments and cities seeking sustainable mobility solutions.

"By integrating permanent magnet motors into our infrastructure, we can reduce energy consumption by up to 20% compared to conventional technologies", explains Bastien Duprey. Additionally, the gravitational energy recovery system offers an innovative solution to further reduce the energy footprint of cable transport infrastructure.

With ORIZON™, MND confirms its position as a leader in the field of cable mobility, combining technological innovation, cutting-edge design, and sustainability. By halving development times and optimizing operating costs, this new range addresses the current mobility challenges.

"The future of MND is resolutely focused on innovation and technological interoperability", concludes Bastien Duprey. Whether in the mountains or in the city, ORIZON™ represents a major advance in the field of cable transport, offering a sustainable and efficient alternative to traditional infrastructure.

Related products

-

Product data management software—available as Vault Basic, Vault Professional, Vault Office

Learn more