& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

& Entertainment

Entertainment content creation tools, including 3ds Max and Maya

CAD/CAM refers to the integration of Computer-aided design (CAD) and Computer-aided manufacturing (CAM). CAD/CAM software is used to design and manufacture prototypes, finished products, and production runs of products using a single development tool.

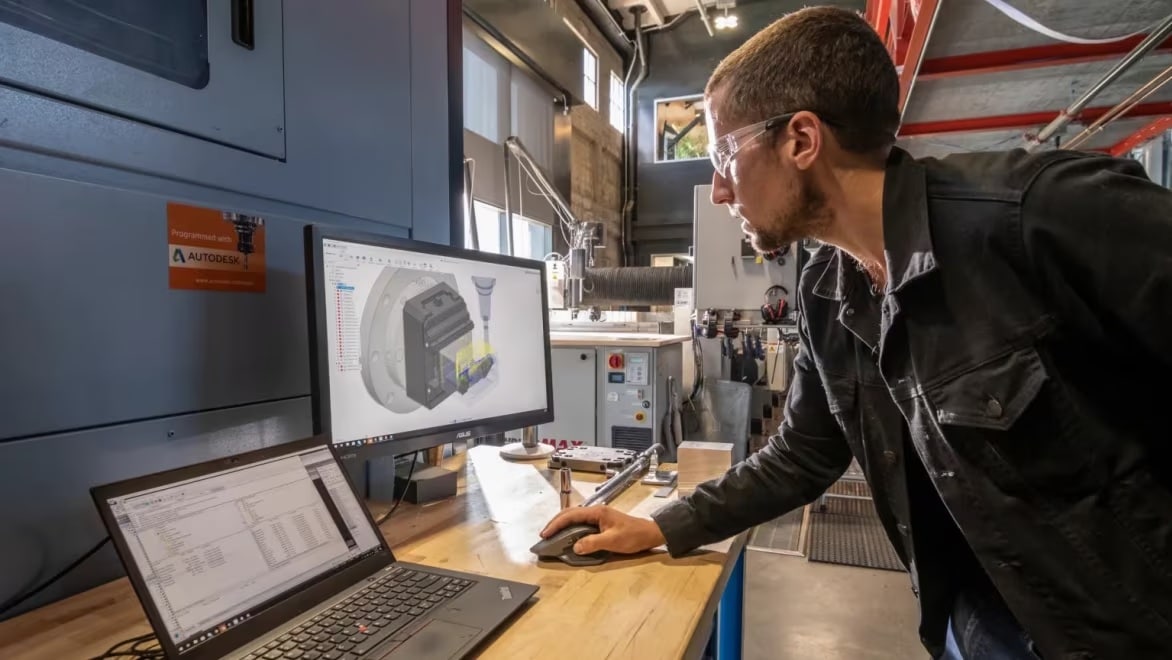

CAD/CAM software is used to both design a product and program manufacturing processes, specifically, CNC machining (US Site). CAM software (US Site) uses the models and assemblies created in CAD software, like Autodesk Fusion, to generate toolpaths that drive machine tools to turn designs into physical parts. CAD/CAM software is used to design and manufacture prototypes, finished parts, and production runs.

Autodesk Fusion replaces fragmented design-to-manufacturing processes with unified CAD-to-CAM workflows. While maintaining communication with customers, suppliers, and internal stakeholders, you can create your parts correctly the first time and on schedule. Integrated CAD/CAM in Autodesk Fusion allows you to:

Now more than ever, you need modern, integrated CAD/CAM manufacturing tools to help you remain competitive. Utilize the most cost-effective CAD/CAM solution available in the market to streamline your production processes. For professional designers, engineers, and machinists, Autodesk Fusion is the solution for all your CAD/CAM needs.

Autodesk Fusion seamlessly integrates both CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) functionalities into a single product development and manufacturing platform. This integration allows for a streamlined workflow, as users can design their products and generate toolpaths for manufacturing (US Site) within the same software.

Eliminate the need for multiple tools and get rid of the headache of data translation issues. Start streamlining your workflows, optimizing designs for manufacture, and produce higher-quality, cost-effective parts.

Autodesk Fusion extensions expand the CAD/CAM functionality of Autodesk Fusion by enabling sophisticated machining, additive manufacturing (US Site), simulation, generative design (US Site), nesting and fabrication, and data management capabilities.

Get started with CAD/CAM with these tutorials, guides, and tips.

Learn how Autodesk Fusion, a cloud-based, integrated CAD/CAM software, can transform your design process.

This article expands upon CAD, CAM, and CAE, advantages across crucial touchpoints in the end to end product development process.

Learn about how cloud-based CAD software makes collaboration easy, with an all-in-one repository for data that works faster and smarter than other solutions.

Make your CAD/CAM experience official with a Autodesk Fusion certification. Explore the six different certification options and registration process.

Read about the importance of digitally upgrading the manufacturing shop floor, the benefits of digital product development, and how it can improve your company’s manufacturing process.

Access video tutorials and self-guided courses for 3D modeling, CAM/CAM design and programming, cloud CAM software, and manufacturing through the Autodesk Fusion Learn & Support Hub.

There are many different types of CAD/CAM software available today. The one you choose very much depends on the work you typically do and the tools you're going to need to be successful. One excellent choice for those wanting to design and manufacture products is Autodesk Fusion for personal use (US Site). The free version of Autodesk Fusion for personal use combines powerful 2D and 3D CAD modeling tools with entry-level CAM programming capabilities. This is the ideal choice for hobbyists, startups, and small businesses to drive a variety of 2- and 3-axis CNC machines. As your business needs change, you can choose from various subscription options to unlock more advanced CAD and CAM capabilities.

Autodesk develops a range of software tools to meet the different needs of industries such as architecture, engineering, and construction (AEC), design and manufacture (D&M), and media and entertainment (M&E). These software products typically provide computer-aided design (CAD) and/or computer-aided manufacturing (CAM) capabilities that can be used to design and manufacture the buildings and products that we use in our everyday lives. Autodesk AutoCAD is one of the most famous software products developed by Autodesk. It is CAD software that architects, engineers and construction professionals rely on to create precise 2D and 3D drawings of the buildings in which we live and work.

By comparison CAM software, like Autodesk Fusion, goes beyond designing products on a screen and provides additional tools that can be used to help to convert the 2D and 3D designs into physical products that can be sold and used. CAM software typically provides the ability to generate additional data that is used to control different types of manufacturing machinery, such as CNC milling machines, CNC lathes, or 3D printers, to convert a 3D digital design into a physical part.

The price of CAD/CAM software varies depending on the product that you choose and how you prefer to pay for it. Autodesk offers a range of different software products with tools designed to meet the needs of different industries. Autodesk Fusion for personal use is free to use and provides entry-level CAD and CAM capabilities ideally aimed at hobbyists, startups, and small businesses. As your business needs increase, you can pay for a subscription to Autodesk Fusion to unlock additional CAD and CAM capabilities. Autodesk offers a range of payment terms, including yearly, monthly, and daily Flex access, meaning you only pay for the tools you need when you need them.

If you’re already a medium-sized business with more advanced needs, you may wish to consider subscribing to the Autodesk Product Design & Manufacturing Collection . The collection is a powerful set of applications that provides extended capabilities to Inventor and AutoCAD for engineers who design complex and custom products, equipment, and systems.

There is a wide choice of CAD/CAM software for CNC (computer numerically controlled) programming and machining. Autodesk offers a number of products, with different capabilities to serve the needs of different industries and applications.

Autodesk Fusion – is a cloud-based 3D modeling, CAD, CAM, CAM, and PCB software platform for product design and manufacturing. It provides integrated CAD and CAM, CNC programming tools for 2D, 2.5D, 3-axis, 3+2, and 5-axis machining applications. A range of subscription options exist, including a free option for personal use, a commercial subscription (

Autodesk offers alternative CAM software products for other industries and applications, including:

There are many different software tools that can be used for woodworking (US Site), including Autodesk Fusion. Autodesk Fusion is easy-to-use 3D modeling software that allows you to design, test, modify, and visualize your projects in 3D before bringing them to life. Each phase of the product journey is integrated into one CAD/CAM solution. Autodesk Fusion is cloud-based, which greatly improves collaboration within your business and across your supply chain, helping you be more productive and bring your products to market faster.

For design, Autodesk Fusion provides parametric tools, advanced 3D modeling, sculpting, advanced nesting and arrange functionality to help optimize material utilization and reduce waste. For manufacturing, Autodesk Fusion provides highly efficient CAM programming tools to simplify the process of generating NC machining code for a range of 2D and 3-axis routers.

Autodesk Fusion is considered one of the best CAD/CAM software for manufacturing (US Site) due to several reasons:

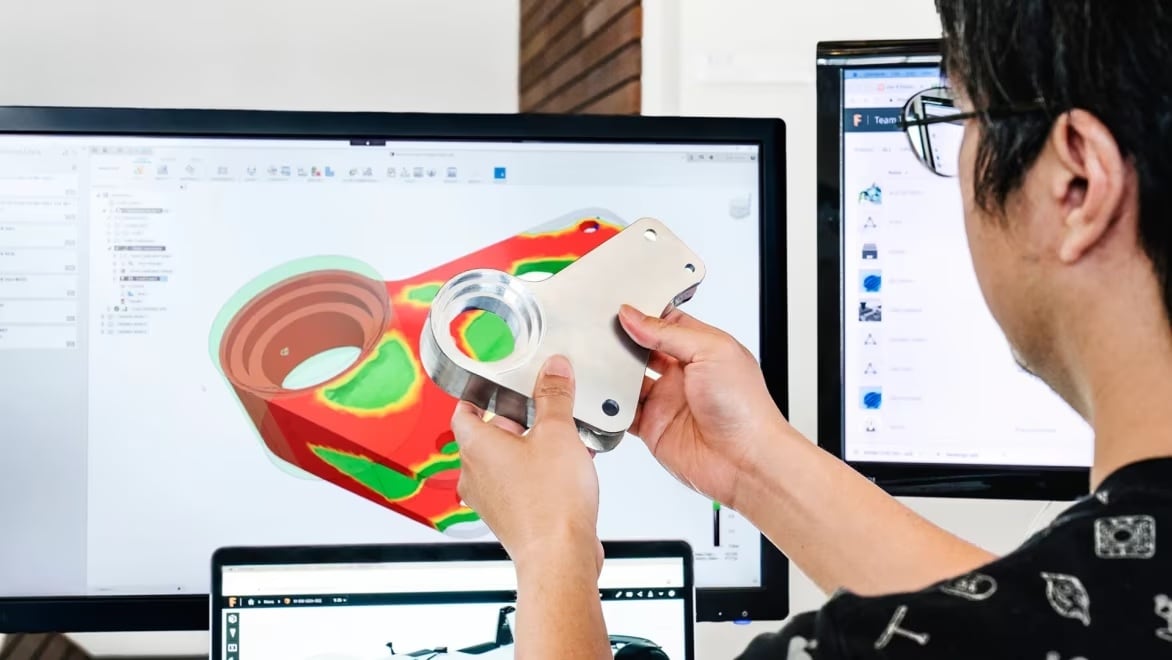

Comprehensive Features: Autodesk Fusion offers a wide range of features that cover the entire product development process, from concept design to manufacturing. It includes 3D modeling, simulation, rendering, CAM toolpaths, and collaboration tools, all in one platform.

Integrated CAD/CAM: Autodesk Fusion seamlessly integrates both CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) functionalities. This integration allows users to design their products and generate toolpaths for CNC machining or additive manufacturing within the same software.

Cloud-Based Collaboration: Autodesk Fusion is a cloud-based software, enabling real-time collaboration and data sharing among team members. This feature is particularly useful for distributed teams or when working with external stakeholders.

Accessibility and Affordability: Autodesk Fusion offers flexible subscription plans, including free options for students, educators, and startups. This accessibility makes it a popular choice for individuals and small businesses looking for a cost-effective CAD/CAM solution (US Site).

Regular Updates and Support: Autodesk regularly updates Autodesk Fusion with new features and improvements based on user feedback. They also provide comprehensive documentation, tutorials, and a supportive community, ensuring users have the resources they need to succeed.

It's important to note that software preferences can vary depending on individual needs and workflows. Other CAD/CAM software options may also be suitable for specific manufacturing requirements.

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are two different but related technologies used in the design and production of products.

CAD primarily focuses on the design and creation of digital 2D or 3D models and drawings of products or structures. It helps engineers, architects, and designers create detailed visual representations of their concepts. CAD software allows users to create and manipulate geometry, define materials, add annotations, and simulate how the designed object will function or look. It is used for drafting, modeling, and visualization.

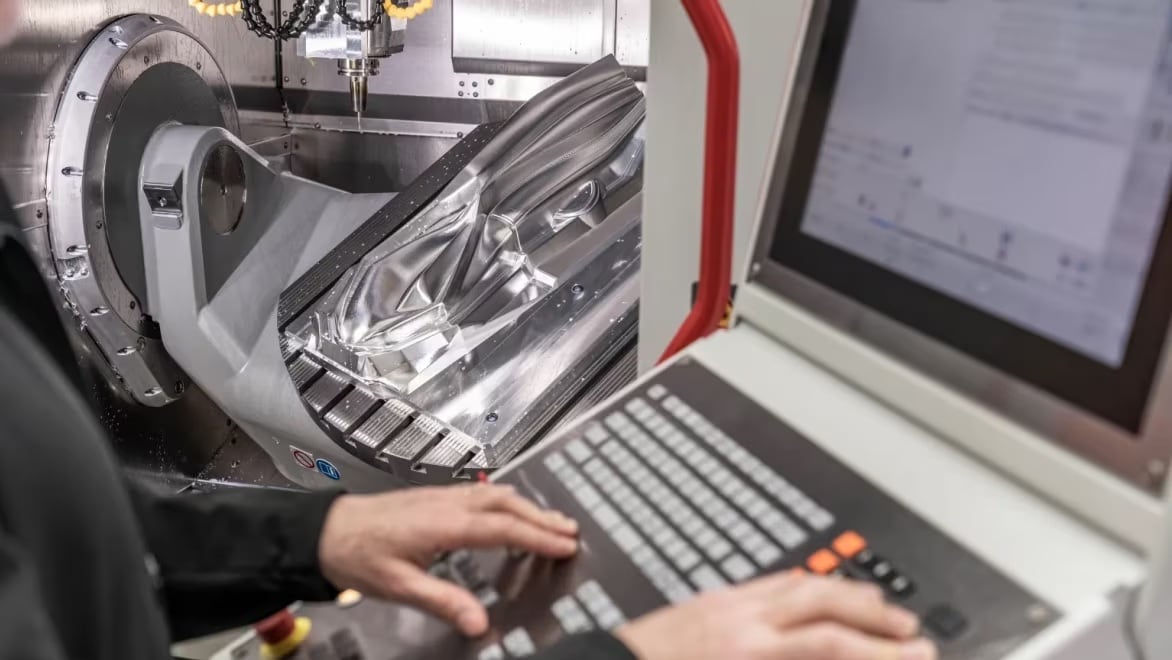

CAM, on the other hand, focuses on the manufacturing and production aspects. It involves using computer software and machinery to automate and control the manufacturing process based on the CAD design. CAM translates the digital design into instructions for machines and tools. CAM software takes the CAD design and generates toolpaths and instructions for CNC (Computer Numerical Control) machines, 3D printers, and other manufacturing equipment. It determines how to cut, shape, or build the physical object based on the digital model.

Together, CAD and CAM (US Site) streamline the product development workflow and help bring digital designs to life in the physical world.

CAD or computer-aided design and drafting (CADD), is the technology for design and technical documentation, which replaces manual drafting with an automated process. If you are a designer, drafter, architect, or engineer, you have probably used 2D or 3D CAD programs such as AutoCAD or AutoCAD LT software. These widely used software programs can help you draft construction documentation, explore design ideas, visualize concepts through photorealistic renderings, and simulate how a design performs in the real world.

CAM or computer-aided manufacturing is the use of software and computer-controlled machinery to automate a manufacturing process. CAM software is used to create 3D toolpaths that instruct a machine how to make a product. These instructions are converted into machine-specific NC code that is then sent to the CNC machine. The CNC machinery (US Site) is then used to turn raw material into a finished product either by subtracting material from it (CNC machining) or by depositing material onto it (additive manufacturing or 3D printing).

CAD/CAM software is used to design (CAD) and manufacture (CAM) products that we all use in our daily lives. From the chair that you're sitting on, to the desk that you're sitting at, to the computer or smartphone that you're using to read this article. All of these products have been designed using CAD software and then converted into physical objects using some kind of computer-aided manufacturing (CAM) process.

Autodesk CAD/CAM software is widely used by many of the worlds leading designers and manufacturers in diverse industries, including; aerospace, automotive, construction, medical, consumer goods, and more. You can learn more about Autodesk customers (US Site), and how they are partnering with Autodesk to design and make a better world.