HYIMPULSE TECHNOLOGIES GMBH

Efficient rocket development with Fusion 360

PRECISION, RESILIENCE, AND PERFORMANCE AT THE LIMIT

HYIMPULSE TECHNOLOGIES GMBH

PRECISION, RESILIENCE, AND PERFORMANCE AT THE LIMIT

Rocket development is all about maximum precision and performance. The materials and components must be extremely resilient. In the coming years, small, low-cost rockets will be increasingly in demand to carry small satellites into space for private companies and research programs. The developers of such rockets must always work at the limit of what is feasible. At the same time, they must keep the cost of materials and labor as low as possible to reduce costs.

Fusion 360 is helping aerospace startup HyImpulse Technologies achieve these goals. That is because the low cost of the CAD software has enabled the company to buy a large number of licenses. This allows more employees to work together on projects. The high functionality and intuitive use also save time through rapid training and efficient workflows between the design department and the workshop.

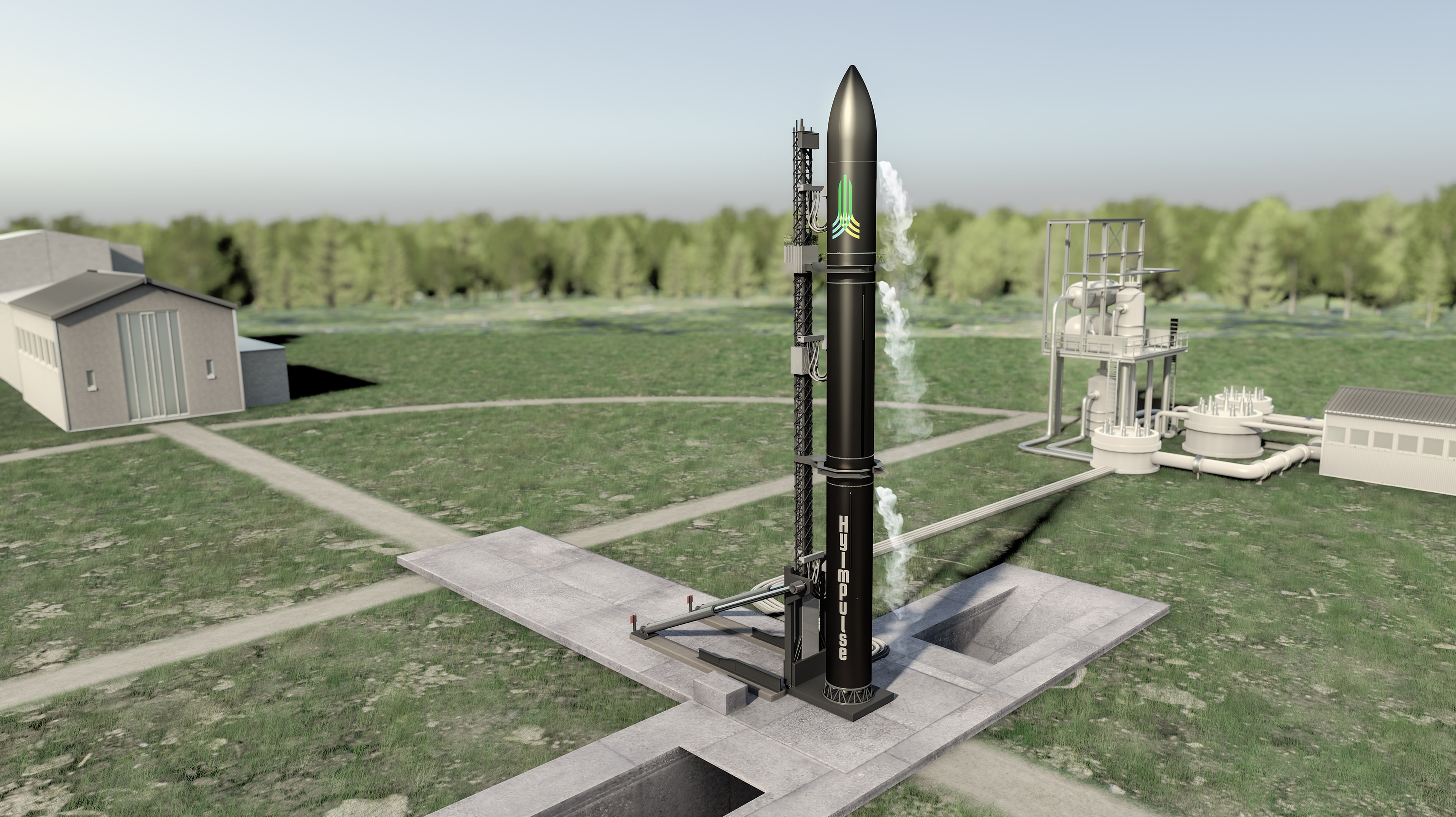

HyImpulse builds rockets with a novel propulsion system that runs on a propellant combination of paraffin and liquid oxygen. When designing launch vehicles that carry satellites into low Earth orbit, the design must be closer to the limits of lightweight construction and stability than for any machine that remains on Earth. It is also important to bear in mind that there are enormous costs associated with space projects and that different interests of the parties involved have to be considered. There is also no German space law yet. This makes it even more important for rockets to launch successfully and deliver their payloads safely into space. To achieve this, the design must be extremely accurate, and the structure and system of the rockets must be very robust. The greatest challenge at present is to bring small launch vehicles to market cost-effectively. HyImpulse is therefore developing the next research rocket, scheduled for launch in 2021, using Fusion 360.

By introducing Fusion 360, we have streamlined and accelerated our development. Features such as 3D simulation and 3D printing make engine and rocket development more efficient for us than ever before.

—Dr. Christian Schmierer, Co-Chief Executive Officer, HyImpulse

The low licensing fees have made it possible for the young company to purchase Fusion 360 for 30 of its 50 employees. Collaboration in the team has greatly improved thanks to its wide availability and powerful features; the minimal learning curve has also contributed. Whether it is rendering, 3D modeling, part or assembly design, 3D simulation, or sharing models and drawings: Fusion 360 is very intuitive to use. Employees coming from other 3D CAD programs immediately find their way around. This is particularly important for HyImpulse, because the construction of prototypes and their presentation must be carried out quickly in the aerospace industry. The fact that 3D prints can be created easily using the data from Fusion 360 is therefore an important function of the software for the company from Neuenstadt in Germany.

A particular challenge in space research at present is to build smaller and more cost-effective rockets. These are of interest, for example, to private companies that want to observe the Earth or traffic. The cost depends largely on the payload and can quickly run into the double-digit millions. 20 kilograms or less can quickly make a difference of up to 500.000 USD. Therefore it is important to go to the limit with materials and design, and that means designing, testing prototypes, and redesigning.

The app functions in Fusion 360 are particularly interesting for HyImpulse. Because with their help, design and manufacturing departments can work together quickly and easily: Models and drawings are available on the smartphone and tablet via the cloud and can be passed on to colleagues at any time – even if they are in a different location and have no access to a computer. Manufacturing employees, for example, who are currently working on a prototype in the workshop, receive the latest information directly on their mobile device and can implement it seamlessly.

The intuitive operation and high level of functionality of Fusion 360 significantly reduce the time required to design and build rockets – and thus also reduce costs, which subsequently makes space research accessible to a larger market.

Fusion 360 is so intuitive to use that all 30 employees from our design and manufacturing teams were able to learn how to use it without further training.

—Konstantin Tomilin, Operations Manager, HyImpulse

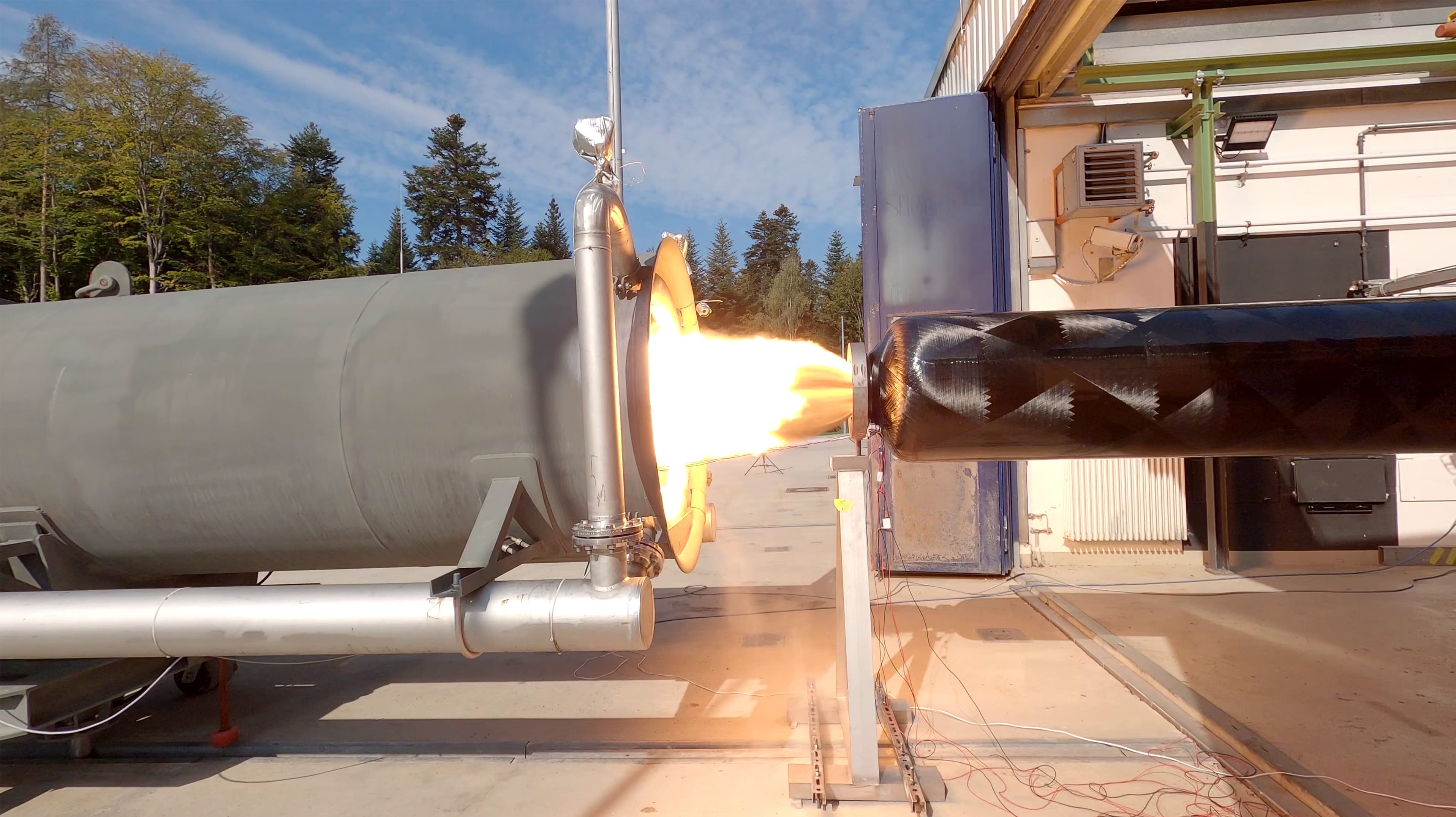

When designing and building engines, engineers must also consider how the various systems are mechanically attached to the supporting structure. To do this, the load acting on the supporting structure is simulated to determine how the rocket systems can be optimally designed. Particularly valuable here are the simulation tools in Fusion 360, which allow engineers to virtually test the effects of mechanical loads.

The straightforward structuring of the software is just as helpful as the clear presentation of the functions and the comprehensive libraries. The icons look similar and have the same functions as in other CAD solutions. All common file formats are supported, so HyImpulse employees found the switch to Fusion 360 quite easy and were able to develop new components for nozzles and combustion chambers in a very short time after installing the software.

One trend in space research is that rockets will no longer be built specifically for particular missions. Rather, lower-cost series will be in demand in the future. HyImpulse plans to build up to 50 rockets per year and manufacture around 400 engines over the next ten years.

This is where the "digital twin" comes into play, which is intended to further reduce the effort involved in rocket design in the future. Digital models will then be used to simulate all the key parameters, reliably showing long before launch whether the design will work as intended. In digital factories, production is to run automatically so that engineers can concentrate fully on engineering and design. The "time-to-market" is thus significantly reduced, and valuable resources and money can be saved.

Following a successful project in rocket development – the design and launch of the "HEROS 3" – five employees of DLR (the German equivalent of NASA) founded HyImpulse Technologies GmbH in 2018, based in Neuenstadt (Germany). The space start-up is one of the leading developers of novel rocket technologies. HyImpulse's goal: to make launch vehicles smaller, more cost-effective and thus more widely accessible over the next ten years. To this end, the company is supported by funding programs from the European Space Agency ESA.

True to the motto "High risk, high reward ", HyImpulse expects to generate sales of up to two billion USD over the next ten years. To achieve this goal through greater efficiency in the development, design and testing of its rocket systems, HyImpulse switched to Autodesk Fusion 360 software in July 2020.

50 employees, 13 countries: The HyImpulse team is very international. © HyImpulse Technologies GmbH

50 employees, 13 countries: The HyImpulse team is very international. © HyImpulse Technologies GmbH

Simulation of HyImpulse's new sounding rocket with an innovative fuel combination of paraffin and liquid oxygen, as it is scheduled to launch in 2021 © HyImpulse Technologies GmbH.

Simulation of HyImpulse's new sounding rocket with an innovative fuel combination of paraffin and liquid oxygen, as it is scheduled to launch in 2021 © HyImpulse Technologies GmbH.

A new engine in a live test: This is how HyImpulse engineers ensure the stability of the propulsion system and the supporting structure © HyImpulse Technologies GmbH.

A new engine in a live test: This is how HyImpulse engineers ensure the stability of the propulsion system and the supporting structure © HyImpulse Technologies GmbH.