Lightweighting vehicles with Generative Design & Simulation

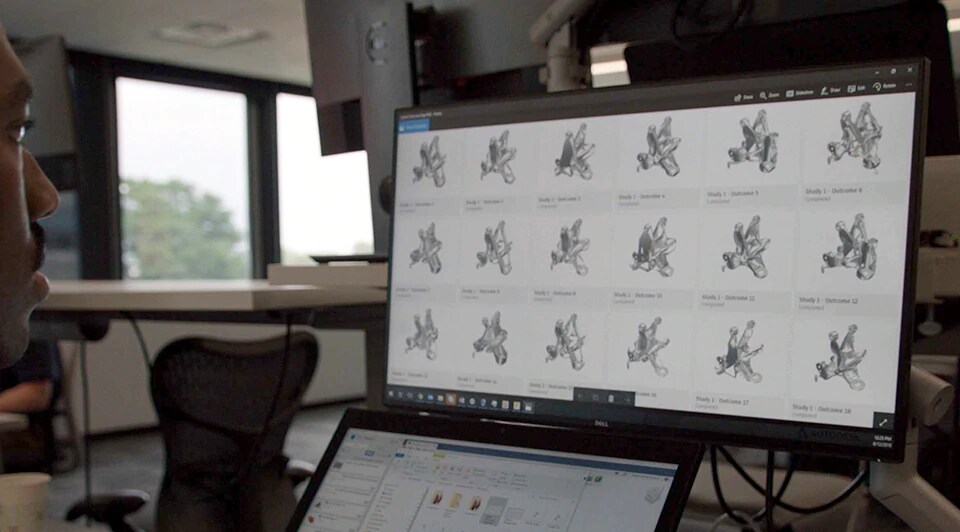

Generative design : Through solutions like Fusion360, Autodesk leverages AI, ML and the cloud to explore different design solutions for parts and components to produce manufacturing-ready designs optimized for varying costs, materials, and manufacturing techniques. This combines the capabilities of designers and engineers and evaluates all possible design permutations to recommend an optimal solution.

This results in intelligent solutions like the 3D printed seat bracket belt developed by GM, which enabled them to go from an 8-part welded bracket to a single piece bracket that was 40% lighter and 20% stronger than the original.

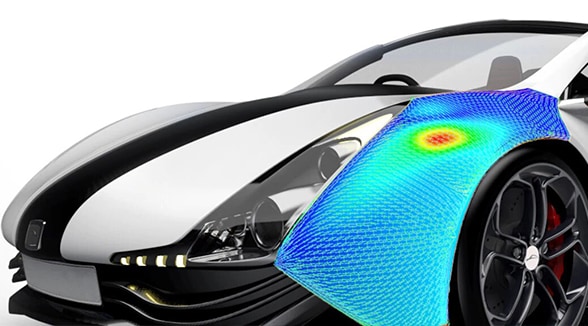

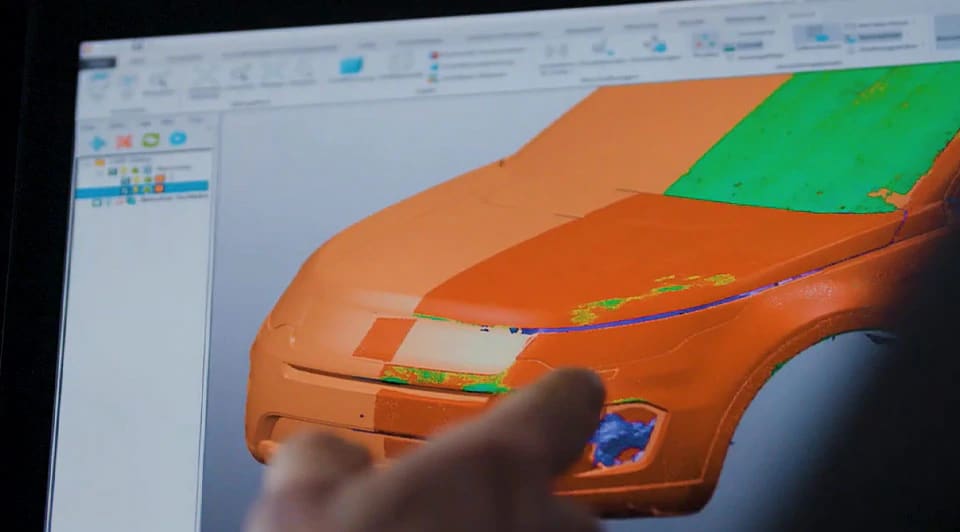

Simulation : Physical prototyping every design option is limiting, due to time, cost and output constraints. Simulation through Audodesk’s tools answers key questions in the design stage, and helps ensure the manufacturability of every part. With this, designers can explore limitless options, experimenting with different variants and materials before making investing in tooling and manufacturing.