Find customer case studies and success stories

CUSTOMER STORY FINDER

Results (21)

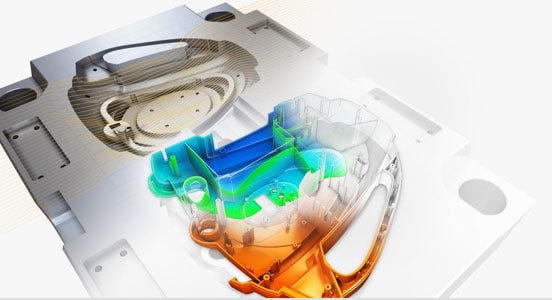

Atomberg Technologies Private Limited

Atomberg used Autodesk Moldflow and Fusion 360 to reduce warpage and improve efficiency, achieving high product quality and cost savings, shaping smart living's future.

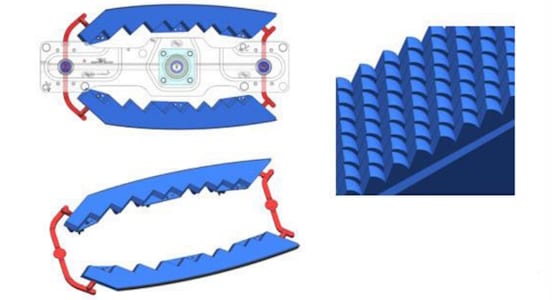

Motherson Utilizes Autodesk solutions for Conformal Cooling Channel Design Validation & Optimization

Discover How Motherson Optimized Manufacturing with Conformal Cooling Solutions – Utilizing Autodesk solutions for Superior Efficiency, Reduced Costs, and Enhanced Product Quality in Auto Component Production

Lumax Industries

Discover how Lumax Industries revolutionizes automotive lighting with Autodesk Solutions, optimizing designs, minimizing defects, and accelerating production.

Pinnacle Infotech Solutions - Madurai

Pinnacle Infotech achieves sustainability and biodiversity goals in its state-of-the-art campus with Autodesk solutions.

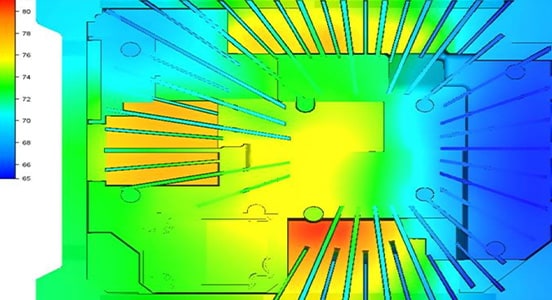

UNO MINDA

UNO MINDA, a leading auto components supplier, overcomes thermal management challenges in EV chargers using Autodesk CFD Ultimate for innovative solutions.

Jendamark India

Early adoption of advanced technology enabled Jendamark to come up with innovative solutions which could provide first mover advantage to customer.

MARQUARDT GROUP

Autodesk Moldflow enables Marquardt to evaluate component Improvement at development stage

Lakshya Digital

Lakshya Digital takes gaming experience to the next level with Autodesk’s Media & Entertainment Solutions.

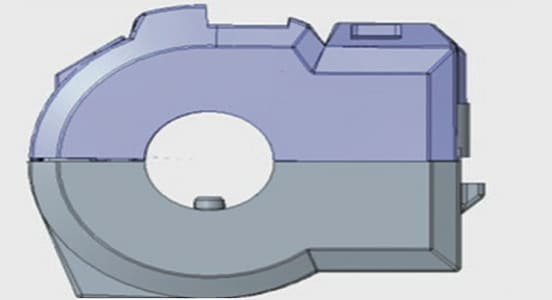

Napino Auto & Electronic Ltd.

Napino utilizes Autodesk Moldflow to successfully resolve deformation of automotive switch case

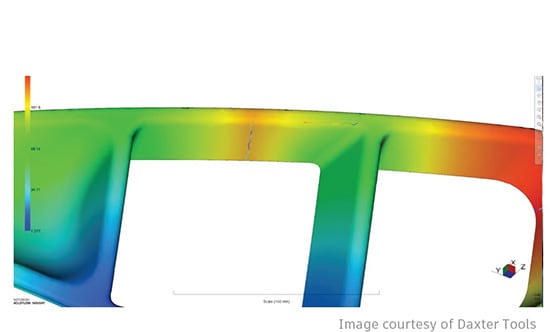

Daxter Tools

Daxter Tools streamlines design & manufacturing giving them a distinct advantage, setting them apart from competitors with superior lead-times, quality and expertise.

Structcore makes a head start with Autodesk's BIM Collaborate Pro

It all began for Structcore Services in July 2020 in the construction management industry as a new-age service-provider. Structcore engaged in projects across residential, industrial, commercial, schools, hospitality, libraries, etc

Jay & Co India Pvt. Ltd.

Know how, Moving from 2D to 3D, Jay & Co. India Pvt . Ltd used PDMC and Revit to streamline design workflows with enhanced data interoperability , addressing the need for customized solutions and closer collaboration with suppliers leading to over 50% productivity improvements.

Autodesk Enables Swift Digital transformation for Jendamark

Early adoption of Autodesk Product Design and Manufacturing Collection suite and Vault helped increase their productivity level by 30 % and invoked a cost optimization to the tune of 15% and proved instrumental in their digitalisation journey.

Simple Energy

Autodesk's solution has helped Simple energy in speeding their entire design workflow. Simple Energy used ALIAS Surface to build realistic-looking 3D models from product sketches.

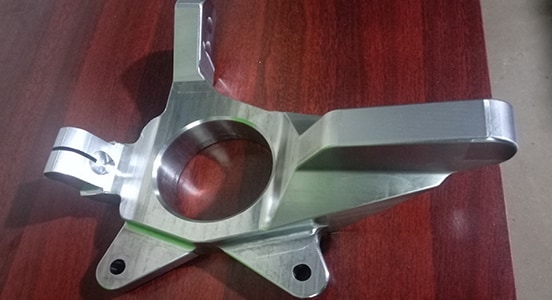

CIRES India

In three years of operations, CIRES india has carved a special place for itseld in critical components industry. PowerMill has helped to reduce the cycle time by 15-20%. Which helped save overall machining hours

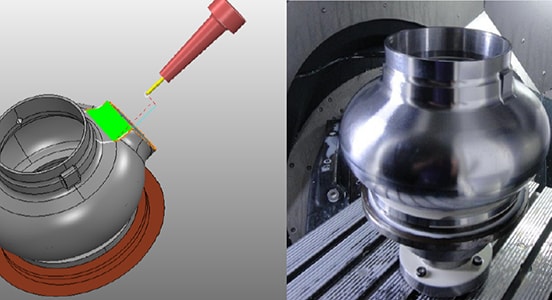

Marvel Machining System

PowerMill offers special strategies for blisk machining which can simplify impeller machining and make complex part manufacturing effortless

MNC 5D

Since its inception, MNC 5D has been using Autodesk BIM 360 Docs with repeated benefits for the customer as well as the company.

NYX, LLC.

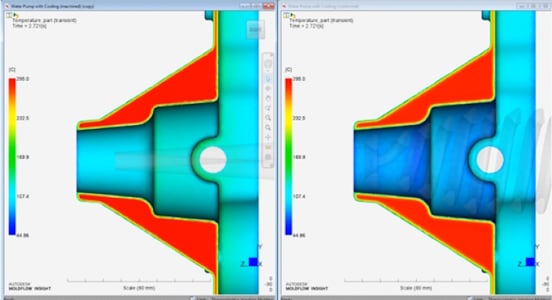

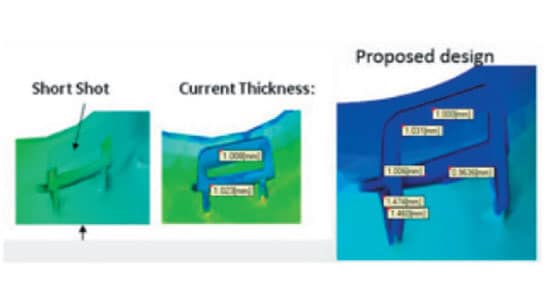

Through Moldflow simulation, NYX could clearly understand the filling behaviors and predicted weld line locations before actual production.

EMERSON INNOVATION CENTER

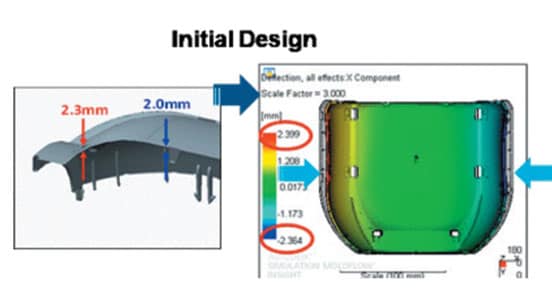

With the help of Autodesk® Moldflow® analyses, Emerson was able to make effective design changes and optimize processing parameters successfully to achieve an outstanding result of more than 90% improvement on part warpage.

INFINEON TECHNOLOGIES ASIA PACIFIC PTE LTD

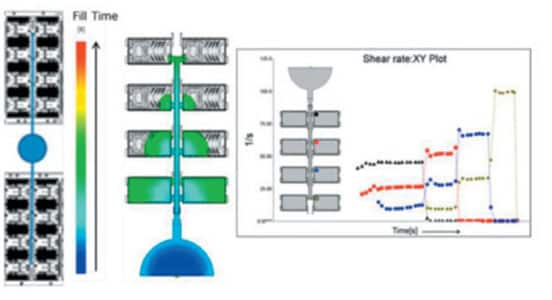

Autodesk Moldflow technology enabled Infineon to identify real challenge faced due to flow parameters that significantly impacted on the filler homogeneity and adhesion developed by a mold compound with lead interfaces.

Titan Engineering & Automation Limited (TEAL)

With the help of Autodesk Inventor, TEAL is solving complex and challenging engineering problems for its customers.