L&T CONSTRUCTION

The BIM Advantage: Redevelopment of SCB Medical College and Hospital, Cuttack

BIM FOR BUILDINGS

Share this story

L&T Construction: A world-class engineering and construction company

L&T Construction is a division of Larsen & Toubro (L&T) a major Indian technology, engineering, construction, manufacturing and financial services conglomerate, with global operations. L&T addresses critical needs in key sectors - Hydrocarbon, Infrastructure, Power, Process Industries and Defence - for customers in over 30 countries around the world.

L&T Construction is India's largest construction organization and ranked among the world's top contractors. It offers EPC solutions to execute large industrial and infrastructure projects from concept to commissioning on a turnkey basis with single-source responsibility. Their multiple businesses encompass distinct but complementary capabilities, that address different segments of infrastructure and industry.

SCB Cuttack Medical College and Hospital artist impressions of the exterior

Photo courtesy of L&T Construction.

Redevelopment of SCB Medical College and Hospital

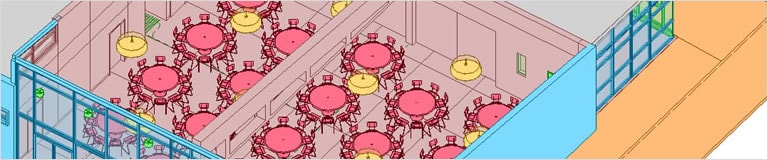

In Odisha, a remarkable endeavour was underway to transform healthcare infrastructure. The SCB Medical College and Hospital in Cuttack was slated for redevelopment and expansion under Phase 1 and claimed to be the largest hospital in Odisha state. A name synonymous with excellence, L&T Construction, had taken the reins as the EPC Contractor. The hospital had served as a beacon of medical care for 30 districts in Odisha, encompassing two vital medical colleges. With a staggering 2058 beds (4 Hospital Blocks), the hospital stood as a testament to the state's commitment to healthcare. However, its potential was far from realized until the ambitious project commenced. Spread across 45.5 acres, the expansive plot became the canvas for innovation and progress. The grand vision included plans to construct structures spanning an impressive 34 lakh sq ft. with two utility buildings, a combined basement, ancillary buildings, and thoughtful external development.

L&T's first hospital building in structural steel.

Photo courtesy of L&T Construction

Technological innovation transforming construction

As the plans took shape, the project embraced technology with open arms. Autodesk products and solutions were fostering creativity and innovation in design and construction. The history-making first structural steel hospital building in L&T's repertoire became a reality thanks to Autodesk Revit. This software enabled precise pre-construction, leading to impeccable execution, while collaboration amongst all services ensured harmonious progress. Pioneering feats continued with the integration of a Pneumatic Tube System (PTS). Autodesk Revit stepped in to seamlessly coordinate the intricate web of 107 stations, including 9 pipes with a 160mm diameter. The system’s success lay in considering accessibility, user flow, and clearance requirements. Trusses and girders spanning a majestic 35m, lending unwavering support to 6 floors. Once again, Autodesk Revit took center stage, simplifying the coordination between architectural and structural elements.

Photo courtesy of L&T Construction.

Integration of Modular OT and advanced hospital system

Modular OT integration brought state-of-the-art surgical precision. Cameras captured every moment, while the main switcher compiled the footage for easy access by hospital staff. The modular OT, equipped with wall-mounted speakers and ceiling-mounted microphones, enabled 360-degree content sharing during video conferencing, truly elevating patient care. The efficiency of the project echoed in the Automated Queue Management System. Arrangement of customer flow and waiting time showcased the commitment to enhancing customer experience. Organized queues became a testament to streamlined processes and the determination for constant improvement. Assets became more than just objects; they transformed into a tracked and managed ecosystem. The Asset Management & Real Time Location Tracking System (RTLS) was deployed. This system, often overlooked, was crucial in tracking the whereabouts, usage, and maintenance of vital hospital assets.

Seamless multi-disciplinary collaboration

Collaboration became second nature in this ambitious endeavour. With multi-location collaboration and over 14 disciplines coordinating seamlessly, the complexity of the project was visible. From the MEP services in the steel building to the 44-acre site plan encompassing PHE sewer and wastewater lines, every detail was meticulously addressed.

Here, Autodesk BIM 360 emerged as the glue binding the project together. Aiding in multi-location collaboration and interdisciplinary coordination, it was the platform through which dreams became blueprints. Autodesk Revit’s prowess extended further, simplifying the coordination of MEP services with structural steel elements, and visualizing the sprawling 44-acre site plan.

Revolutionizing efficiency and sustainability with Autodesk Revit

Optimization of structural steel beam components, a feat that might have been overlooked, was championed by Autodesk Revit. It resulted in a reduction of up to 20% in material wastage, affirming the project's commitment to sustainability. With nearly 2704 construction drawings produced within a limited timeframe, Autodesk Revit championed efficiency, reducing production time by an astounding 54%. The SCB Cuttack Project stands as a testament to vision, innovation, and the seamless fusion of technology and human endeavour. It's a chapter in the history of healthcare infrastructure that will continue to inspire and pave the way for a healthier, more connected tomorrow.