Tata Consulting Engineers Limited

TCE gets future-ready with Revit to exceed delivery expectations

BIM for MEP Engineering

Share this story

Introduction

Tata Consulting Engineers (TCE) established, six decades ago by the house of Tatas, as an end-to-end engineering consultancy firm, provides conceptualization to commissioning to project management and asset life cycle management services globally to critical sectors like power, mining, infrastructure, and chemicals.

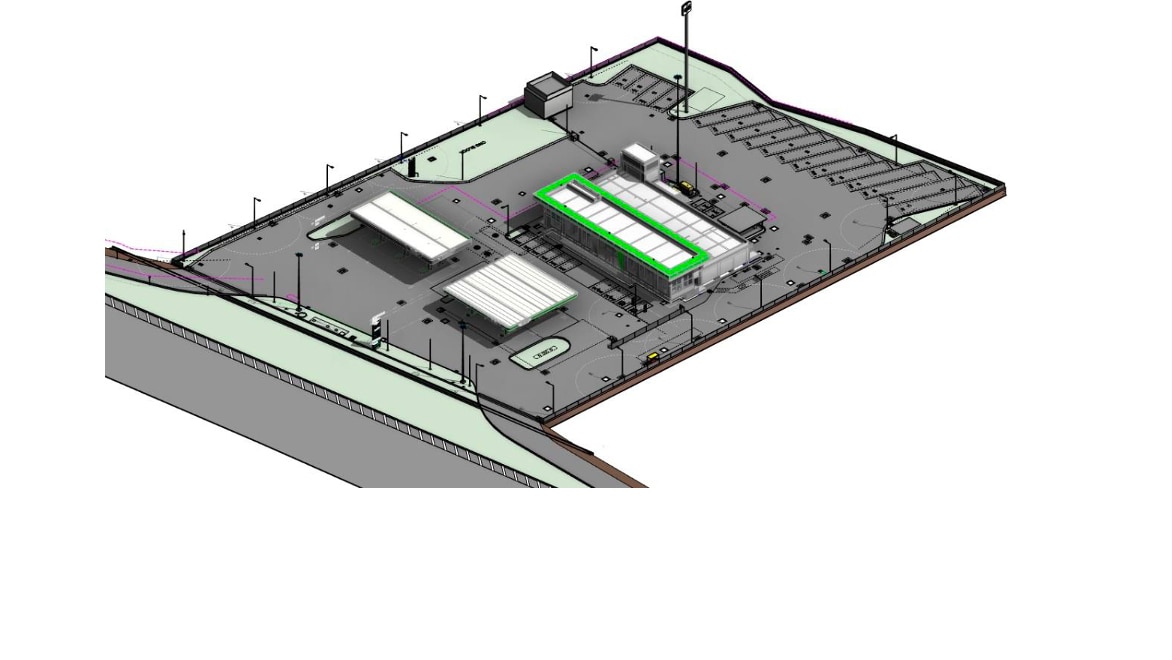

Photo courtesy of TCE.

About the Project

TCE was designated to be the construction design engineers for a large oil major in India. The project entailed expansion of the fuel retail network by setting up outlets across India.

The first phase of the project involved Engineering, Procurement and Construction (EPC) management services for setting up of nearly thousand retail outlets by 2023 (40 to 50 outlets per month approx.) in the southern and western regions of the country. The 2-year project was started during the pandemic and had the following important deliverables:

- Development of three-dimensional (3D) and mechanical, electrical and plumbing (MEP) layouts of fuel retail outlets/sites/stations

- Development of statutory drawings for approval from authorities like NHAI

- Creation of construction documentation docket containing site specific construction drawings and Bill of Quantity (BOQ)

Photo courtesy of TCE.

Scaling new peaks with Autodesk’s BIM Model

The biggest challenge of this BIM project was to create and manage a high-volume of 3D construction drawings with a sharp precision and in a constrained timeline.

For creating flawless site designs, an adaptive drawing environment was a must and Autodesk’s Revit truly lived up to its reputation. Using Revit, TCE was able to create three to four design options in three dimensional formats for the client to choose from. Upon finalising one of the options, Revit helped create perfectly optimised site designs for statutory approval in a record time limit of 3 days.

Statutory designs that were created required to be drawn with extreme precision as well as faster speed. A rapid roll out of these drawings is a much-needed requirement to keep pace with the tight timeline set by the authorities for giving statutory approvals.

Also, for any BIM service provider, managing site designs is increasingly complex due to the involvement of multiple project stakeholders. Intelligent information management, simplified design workflows, cross-discipline collaboration, clash detection, etc. are much needed prior to the construction phase for the success of any BIM project.

Autodesk’s Revit came in handy for TCE in rolling out a large number of drawings keeping up with the deadlines by eliminating rework and iterations (to less than 1 percent) to make the entire project delivery super-efficient. Since the construction drawings were already in three-dimensional formats, Revit helped in reducing the project development time from an average of 1 month to only about 5 days.

Complexity, simplified!

Real challenge for TCE only began post receiving the statutory approval on the construction drawings from the authorities. The construction documentation stage of the project tends to be much more complex than what is perceived. However, with Autodesk’s Revit at work, TCE brought down the level of complexity significantly.

Generating site specific 3D drawings – civil, mechanical, plumbing, electrical (MEP), instrumentation, fuel piping, markings to indicate no-hazards to nearby facilities, etc. – is fairly complex, as each discipline has different drawing requirements with a high possibility of clashes. However, clash detection in 3D drawings done using Revit was much simpler and efficient. Revit extended great flexibility of reusing the existing 3D structures and ensured that mechanical, electrical, and plumbing disciplines remained independent of the other and does not encroach any other discipline, which further leads to enhance design accuracy, improved collaboration, better cost estimation and efficient project management.

Additionally, clashes management related to external vendors becomes next to zero as Revit allows the specific requirements to be incorporated in the drawings at the conceptualization stage itself. For example, if a DG set is required on the site, the 3D drawings created using Revit will have a provision of the same prior to even the client finalizing the DG set vendor.

Most risks are tightly controlled as 3D designing is significantly standardized in Autodesk’s Revit. Also, most risk scenarios have been taken into account while designing the conceptual drawings.

Faster designing with minimal customization

Autodesk solutions enabled TCE engineers to create drawings for different disciplines – civil, mechanical, electrical, plumbing (MEP) and instrumentation – concurrently, thus making the entire team highly productive. This helped to lower the project design documentation docket from 1 month to a mere 5 days. Standardized process and themes made the entire project design much faster. TCE used Revit, for example, to divide designs into two main themes:

- Design Option 1 (wide) – where the frontage is 60 meters and above with specific design criteria.

- Design Option 2 (narrow) – where the frontage is less than 60 meters with specific design criteria.

With Revit’s BIM capabilities at work, out of nearly a thousand outlets, only about 20 percent sites required customised designs. More than 80 percent of the retail outlet sites had the standard implementation (the design that was approved by the client initially) irrespective of the geography challenges.

Once the construction designing was completed, Revit also enabled TCE to create BOQ for each site that was based on the type of design (both design options) that was implemented for a particular site.

TCE received a lot of appreciation from the Indian oil major (the client) for making it possible.

“The combination of Autodesk Revit and TCE’s experience made a potent combination. Anywhere, anytime access for project team members and seamless communication was the key to timely project delivery. Construction design and delivery would have been a grave challenge for a project of such a massive site quantum in the absence of Revit. However, TCE not only met but far exceeded the delivery expectations”, said Pawan Rallabandi, AVP & Business Unit Head – Digital & Advanced Technologies.