& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Whether you’re a team of one or one person in a team of many, prototyping and fabricating ideas require speed, agility and exploration. They’re certainly not linear processes, but seamless collaboration from the start sets the stage for a successful product development process.

Investigate as many design options as possible, easily ship ideas to fabricators, and keep lines of communication strong internally and externally with the robust capabilities of Autodesk Fusion.

Increase manufacturing throughput with automation, collaboration and software interoperability to reduce non-value add processes from design inception through production.

Connect your design and engineering team with internal or external fabricators to ensure production goals are met and minimise design versioning confusion.

Iterate, simulate and prototype easily with automated, connected workflows to improve product quality and reliability in the early stages of product development.

A faster, digital prototyping process makes space for more ideas, giving you more chances to get your end product just right.

Optimise your prototyping and fabrication processes to increase productivity while reducing material costs, engineering costs and fixed overhead costs.

Leverage digital prototyping, simulation, data management and quality management tools to lessen chances of costly defects.

Seamlessly collaborate with contractors or clients directly in an assembly using Assembly Concurrency. Web browser access enables easy job site access for those who need to reference the 3D models on the fly.

Explore new design opportunities fast using Automated Modelling or take it a step further with Generative Design to incorporate considerations such as manufacturing methods or costs.

Predict the impact design changes have on product performance and manufacturability with finite element analysis (FEA) and injection moulding simulation.

Identify design improvements before manufacturing based on in-canvas rendering, design for manufacturability with Injection Moulding simulation and more.

Publish your product’s manufacturing and fabrication plans with detailed model and assembly drawings to efficiently add clarity to stakeholders.

Prepare for fabrication with sheet metal part sketching and modelling, bending and relief rules, seam gaps, weld callouts and integral nesting capabilities.

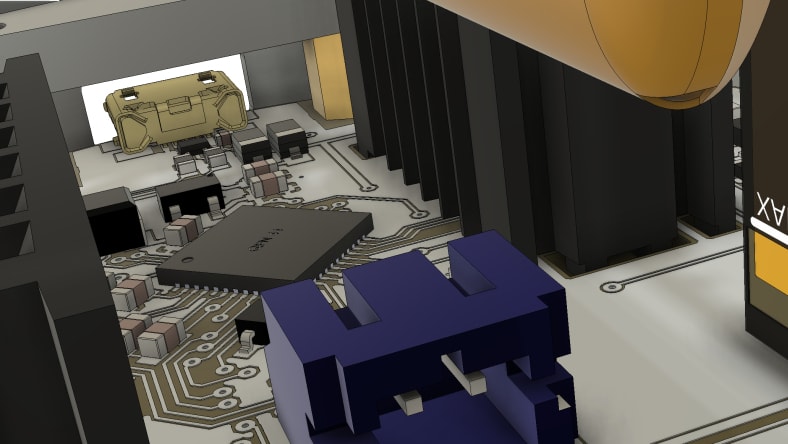

Quickly design circuits, visualise your electronic product’s 3D model aspects and test how the PCB fits within the design assembly with ECAD and MCAD integration.

Generate toolpaths for 2 & 3-axis, 3+2, 4 & 5-axis milling and more with support for additive, subtractive and hybrid manufacturing. Predict potential failures before running the machine.

Flexible purchasing options to meet your current and future needs.

THE ESSENTIALS

Integrated cloud-based CAD and CAM software with 2D to 3+2 CAM, 3D printing in plastics and cloud collaboration.

EXPAND YOUR CAPABILITIES

Create optimised and associative multi-sheet layouts for cutting on CNC machines.

EXPAND YOUR CAPABILITIES

Predict part quality and performance using a wide selection of Finite Element Analysis (FEA) capabilities.

EXPAND YOUR CAPABILITIES

Powered by Ansys. See how your PCB will perform in real life before fabrication with advanced high-speed board simulation.

KEY FEATURES

A subscription to Autodesk Fusion includes:

CAM

Additive (plastics)

CAD

Simulation

Data management and collaboration

KEY FEATURES

All features in Autodesk Fusion plus:

Nesting

KEY FEATURES

All features in Autodesk Fusion plus:

Simulation

KEY FEATURES

All features in Autodesk Fusion plus:

Signal Integrity

Prototyping is the first stage of the product development process. It’s a quick, experimental, rapid stage for ideation and conception. The goal is to come up with as many viable product ideas as possible.

Fabrication is the process of exploring how your prototype will be made for production. You can either fabricate your design in-house or send your design to an external fabricator.

Autodesk Fusion and its Extensions offer a wide variety of tools to support teams during prototyping, including 3D modelling, latticing, electronics design, additive manufacturing, simulation, automated modelling, generative design, rendering and more.

Assembly concurrency and public model sharing enable teams to seamlessly collaborate as they move through the prototyping stage. Flexible pay as you go options empower teams to adjust to changing needs during the product development cycle.

Leveraging the tools available in Autodesk Fusion, teams can generate virtual prototypes to minimise or even eliminate the need (and costs) of physical prototyping. You can quickly discover potential risks, iterate various solutions and communicate changes to internal and external stakeholders – all within Autodesk Fusion.

Manufacturing/Fabricating is simplified with Autodesk Fusion by taking your models and assemblies the next step with designing for manufacturability. Generate toolpaths for CAM and additive productions, design how your sheet metal needs to bend and be cut, optimise your part arrangements on stock material or in the build space, and even get insights on plastic injection mouldability.