& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

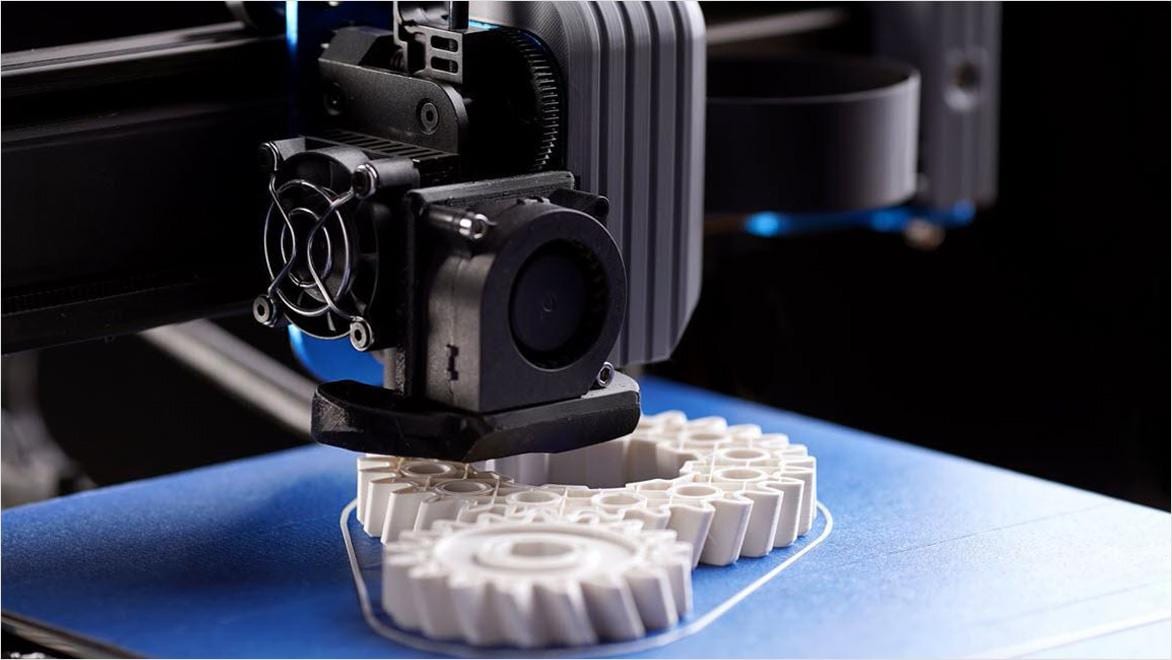

3D printing, also called additive manufacturing, is like magic for making physical objects from digital designs. Imagine you have a picture of something cool on your computer. 3D printing design software helps you take that picture, create a 3D model of it, and turn it into a real-life object by building it layer by layer.

3D printers can use a number of different materials, including plastic (usually PLA), resin, wood, metal, and even cement. 3D printing devices range from small, desktop-sized machines to those that can print entire houses. But the secret to the technology lies within the software.

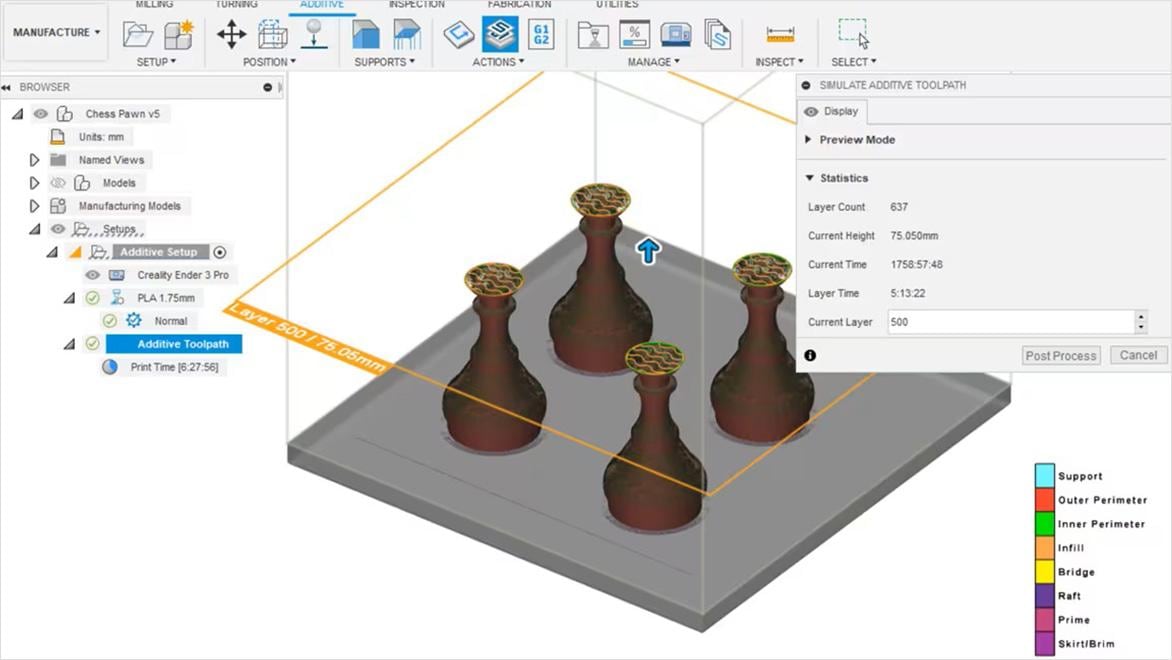

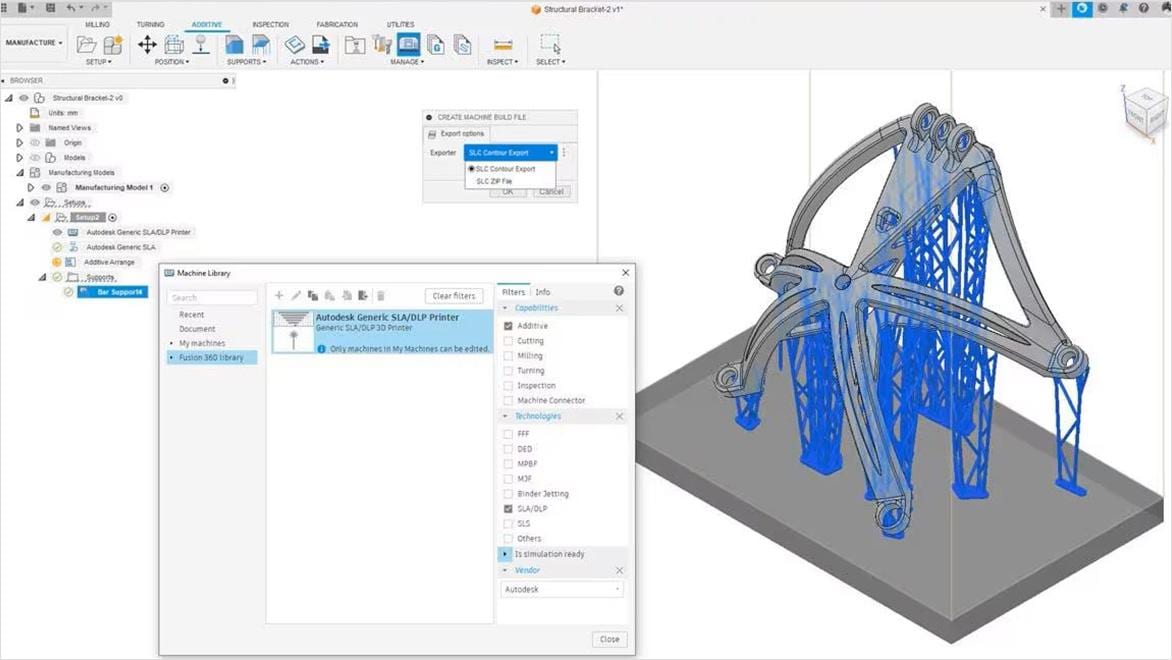

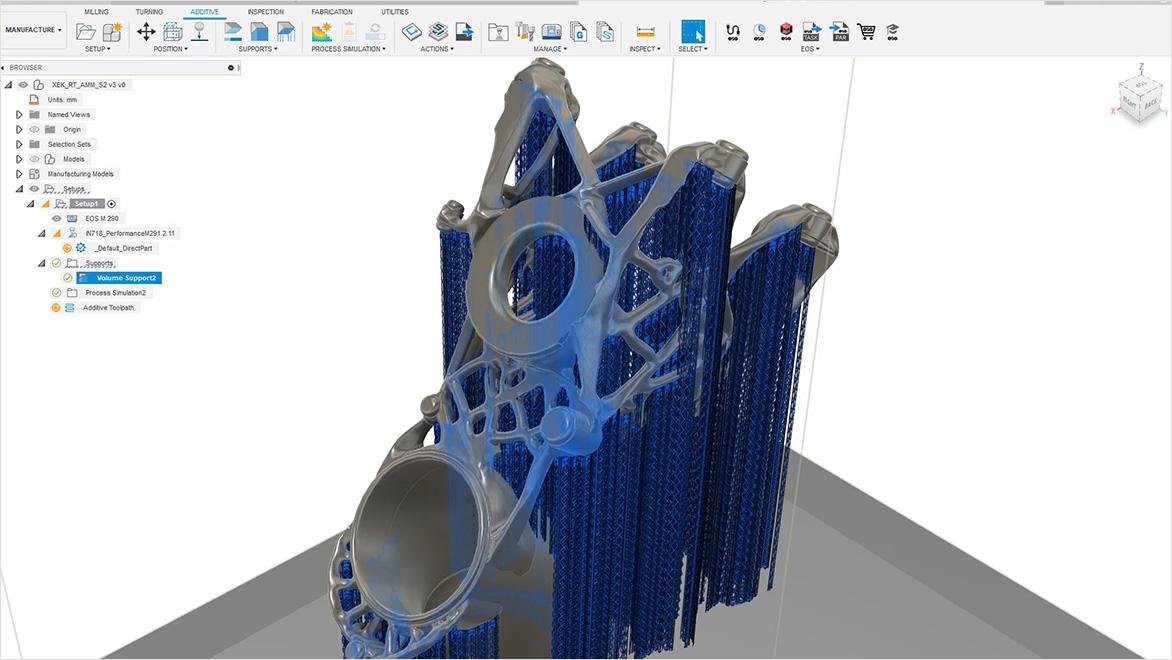

3D printing software like Autodesk Fusion is a vital tool for preparing 3D models for printing. As a leading 3D CAD software for 3D printing, Fusion simplifies the design and manufacturing process from start to finish.

The process begins by creating or modifying a 3D model using Fusion’s advanced features. After finalising the design, the software slices the model into horizontal layers, creating a file that guides the 3D printer in constructing the object layer by layer.

What sets Fusion apart as a top design software for 3D printing is its support for a wide range of materials from plastics like PLA and ABS to metals, ceramics, and even wood composites. No matter what project you’re working on, from prop-making in a Bollywood film to helping build homes, Fusion can help make your 3D model a reality.

3D printing using Fusion is as easy as it gets. Follow these steps to get started.

Fusion has the tools to automatically orient and arrange your parts within your 3D printer’s build volume. If necessary, Fusion can also generate support structures. Once your setup is finished, you can slice your models to create the layers and connect to your printer to start the printing process.

3D printing opens up a world of possibilities in both personal and professional settings. For personal uses, Fusion’s design software for 3D printing can be used for crafting custom items like unique home decor or jewellery and educational models for hands-on learning in subjects like science, technology, and engineering.

In professional settings, the applications are even more impactful. Let’s take a look at a few.

3D printing design software empowers Bollywood filmmakers and entertainers to bring their ideas to life. Whether it’s futuristic props for sci-fi films or historical costumes for period dramas, 3D printing makes it easy to conceptualise and create these items on-the-fly. With 3D printing software, set and production designers have no limit to what they can build.

3D printing makes it easy for manufacturers to quickly deliver new products with precision. Using Fusion, engineers can create shapes and planes, see how they work, and print them into real-life models. This saves significant production costs and ensures the final output is in line with customer needs. Manufacturers can also use 3D printing for small-batch production, testing and changing parameters as needed before launching into large-scale production.

3D printing is used for building detailed models and structural components in architecture. Fusion allows for real-time feedback and iterations between teams—architects, engineers, and designers—thus, saving time and facilitating a more efficient process to produce models that can be used for client presentations, structural testing, and even direct fabrication of building components.

3D printing software allows for the creation of custom prosthetics, implants, and medical devices tailored to each patient's needs. By designing these critical healthcare components to fit individual patients, doctors can improve patient outcomes, speed up recovery times, and enhance their quality of life after treatment.

Learn about different use cases of 3D printing design software.

3D printing is used to create rapid prototypes for prop-making, costuming, and or even set miniatures in Bollywood.

3D printing helps create structural components that are strong but not too heavy, reducing fuel and energy emissions, in production and post-production.

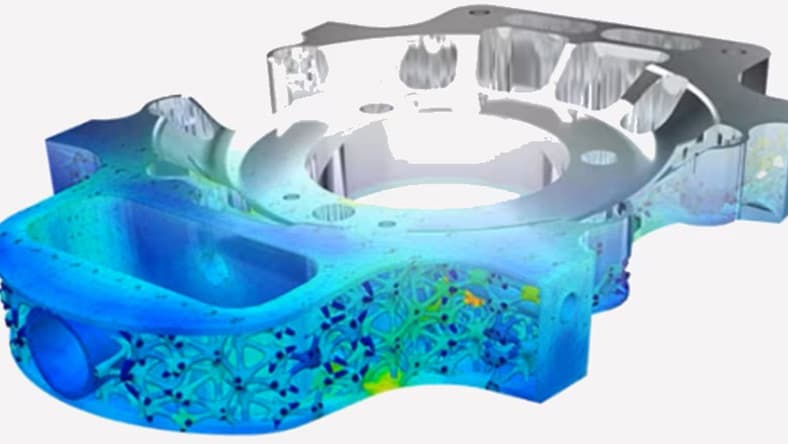

3D printing removes many of the constraints imposed by traditional manufacturing processes that prevent engineers from designing for optimal performance.

3D printing helps doctors and scientists make tiny models of body parts or organs to study how things work or to test new ideas to find better ways to treat people.

3D printing makes it easy to create complex geometries and intricate details in plastics that are difficult or impossible to achieve with traditional manufacturing methods.

Entire homes can be constructed with minimal material waste using advanced 3D printing software, allowing for the development of sustainable, eco-friendly structures.

3D printing has a number of benefits from prototyping to cost and material optimisations.

One of the most useful advantages of 3D printing is its flexibility. Unlike traditional manufacturing methods, which have limitations in tooling and machining, 3D printing lets you create complex, innovative designs. Engineers and designers can explore geometries, internal structures, and custom features that would be expensive or impossible to achieve with conventional techniques.

3D printing accelerates the product development process by enabling quick and cost-effective prototyping. Design iterations can be rapidly produced and tested in a fraction of the time required by traditional prototyping methods. This shortens development cycles, allows for easier iterative design, and reduces costs.

For low-volume or customised production, 3D printing design software offers massive cost advantages by eliminating the need for expensive moulds. Traditional manufacturing methods have large tooling and setup costs that make small production runs prohibitive. 3D printing doesn’t require these costly upfront investments and enables economical production of small batches or one-off items.

Traditional manufacturing processes—particularly subtractive methods like machining—often create a lot of waste because excess material is cut away to achieve the final shape. In contrast, 3D printing adds only the material it needs to build and support the object. This approach greatly reduces waste, making 3D printing a more sustainable and environmentally friendly option.

The Fusion Manufacturing Extension allows you to create subtractive finishing operations and machine precise features with high-quality surface finishes.

Curiosity 3D, an Autodesk Learning Partner, collaborates with Autodesk Education in India to tackle challenges in traditional engineering education. By integrating Autodesk Fusion 360 and 3D printing, their programs shift students from theory-driven learning to hands-on skill development. Participants receive a 3D printer for at-home practice, gaining practical experience and earning an Autodesk Certification that highlights their expertise and industry readiness.

Learn the best way to use your 3D printer with Autodesk 3D printing tutorials.

Learn how to prepare models for additive manufacturing using additive fused filament fabrication (FFF) and stereolithography (SLA) technologies.

Learn how to prepare parts for additive manufacturing using metal powder bed fusion (MPBF) machines using the Fusion Manufacturing Build Extension.

Explore free 3D printing resources and learn how to make the most of 3D printing with Autodesk software.

Explore this comprehensive guide to grasp 3D printing and 3D modeling basics. Learn crucial terminology, different types of 3D printers, and how Fusion can enhance your projects.

3D printing and additive manufacturing may be synonymous terms at the surface level, but as the industry grows, additive manufacturing becomes more of an all-enveloping term. Learn about the differences here.

Autodesk Fusion makes 3D printing easy by providing an integrated CAD/CAM environment, an additive manufacturing extension, helpful add-ins, and more. Take a tour and see how it can help you achieve your objectives.

The future of 3D printing is promising with advancements in speed, material quality, and manufacturing capabilities. These improvements aim to enhance accessibility and productivity while reducing costs. Learn what this means for your industry.

3D printing has transformed industries with on-demand part production, personal creativity enhancement, and swift prototype development. Its affordability and flexibility have ushered in new manufacturing and design opportunities. But what does this mean for your business?

Beyond plastic, 3D printing is expanding to include materials like metal, wood, and even concrete, paving the way for faster, more sustainable, and cost-effective manufacturing in industries from automotive to construction. Read on to learn the best materials for your use case.

Learn more about using 3D printing software with these questions frequently asked by users.

3D printing is a rapid prototyping process that can create complex shapes and objects other engineering and manufacturing methods can’t achieve. As a digital technology, it requires no tooling changes, so you can quickly update designs or produce new products with no downtime.

Yes, Autodesk Fusion has a dedicated additive manufacturing space, marrying design, engineering, simulation and manufacturing all together.

3D printing a part is a combination of the material that you wish to use and the volume. Because 3D printing can output using a plethora of plastics and metals, the cost of a part can vary dramatically depending on what you are using. However, it can be more affordable per part than other processes.

Autodesk Fusion is an excellent choice for creating CAD models for 3D printing. It allows you to create not only "prismatic" models such as gears or brackets, but also more "organic" models using T-Splines, including characters, plants, and vehicles. You can use Fusion to create and then edit your objects for 3D printing, bring in models from other software, and make modifications, such as de-featuring them. Fusion can export as an OBJ or STL file format that is read by most 3D printing software. It also has the ability to print directly to your 3D printer.

CAD software 3D printing software allows you to conceptualise, design, and optimise your models for fitting production technologies.

Autodesk Fusion can be used with any 3D printer. It provides a wide range of printer and material profiles, and exports models in STL format, which is compatible with most 3D printers.

Yes, 3D printing software can significantly improve the quality of your prints. The software allows for precise control over many variables in the printing process, such as layer thickness, print speed, and infill density. It can also help you identify and fix potential problems in your design before printing, reducing the risk of print failures. Fusion even offers simulation tools, which can predict how the print will behave under various conditions, helping you optimise your design for the best possible print quality.

Yes, Autodesk’s 3D printing software can be used on any computer, provided it meets the system requirements. For instance, Autodesk 3ds Max is only available in a Windows version, but it can be run on a Mac using Boot Camp. Fusion has a complete workflow for 3D printing, including modeling and slicing, and is focused on usability which makes it accessible for users of different skill levels.