& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

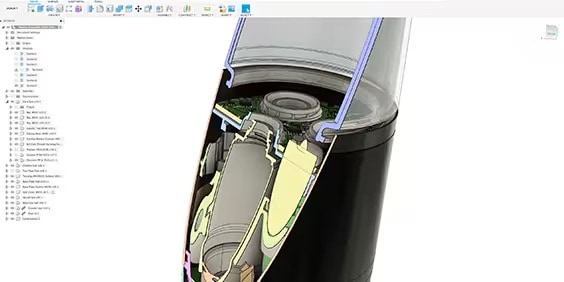

ECAD (electronic computer-aided design) software is used to design and create electronic structures. MCAD (mechanical computer-aided design) software is used to design and create mechanical systems.

Intelligent products require integrated electrical and mechanical characteristics. Thus, it is vital that our design and engineering workflows are also integrated. ECAD and MCAD (US Site) need to work together to enable true interoperability.

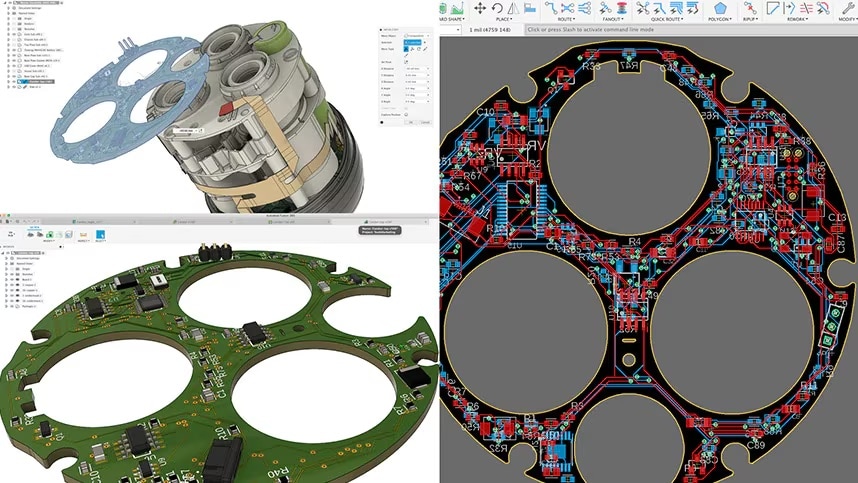

Autodesk Fusion enables ECAD and MCAD designers (US Site) to work natively and independently on the same design project and within the same design management platform. You never have to integrate any third-party software, translate, exchange or export STEP, XDF or IDF files, ever.

Autodesk Fusion offers a complete online collaboration (US Site) experience for PCB, mechanical and data management, making sure that every stakeholder is part of the product development cycle. Design changes are automatically managed to enable you to revise your board shape, component placement update or modified enclosure.

With integrated ECAD and MCAD in Autodesk Fusion, 3D PCB (US Site) data such as board copper, core material and components can be analysed, verified and validated on the MCAD side to make sure they meet the product design specifications.

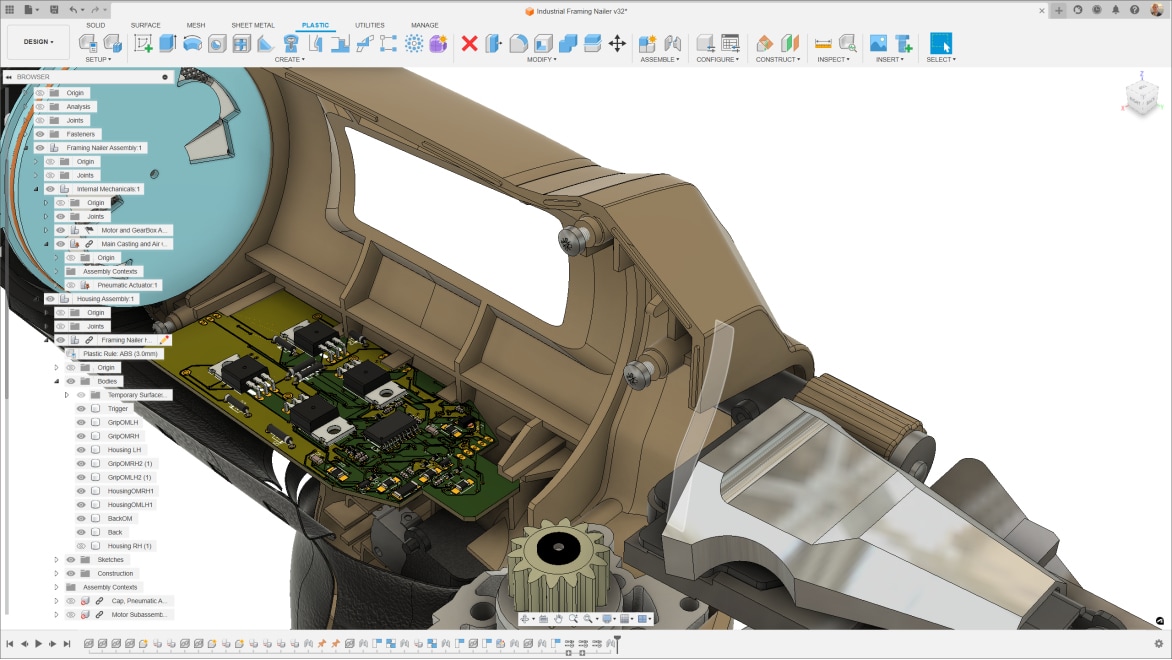

Product designers require solutions that help them bring consumer products to market faster and to easily transition from design to production. Autodesk Fusion enables seamless integration of ECAD and MCAD.

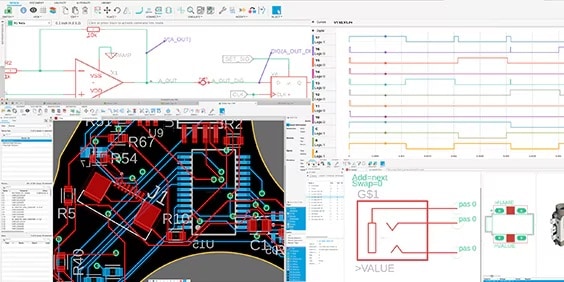

Comprehensive full-featured electronics tool for your schematics, PCB, simulation, library management, manufacturing and more.

Fully functional and powerful 3D design and modelling, including PCB integration, sketching, rendering, sheet metal and assemblies.

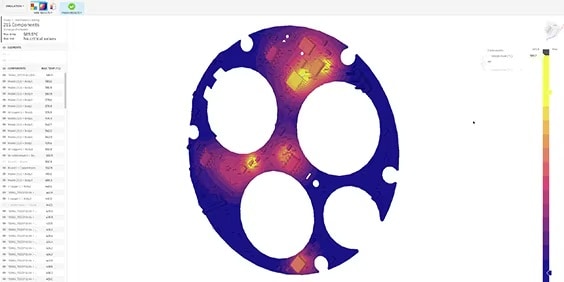

Easy to use yet powerful e-cooling simulation to verify and validate thermal design of your printed circuit board (PCB) early and often.

Autodesk and Cadence have partnered to optimise the experience for Allegro X and OrCAD X users with Autodesk Fusion, delivering a seamless ECAD MCAD design workflow.

This partnership facilitates real-time updates, such as defining or updating enclosure outlines in Fusion, seamlessly adopted by the Cadence PCB or fine-tuning component placement in Fusion and, in moments, receiving alerts in Cadence. This will enhance design efficiency and eliminate the need for disruptive file conversions.

Get started with ECAD MCAD with these tutorials, guides, tips and tricks.

ECAD MCAD integration is a necessity in today’s world. See how Autodesk Fusion can make electronics to mechanical workflows easy.

Fusion makes electronics to mechanical workflows easy with seamless ECAD MCAD integration.

Let’s explore the three main benefits of using PCB design software to combine ECAD (electronic computer-aided design) and MCAD (mechanical computer-aided design).

Learn how to easily and quickly define your PCB outline from a mechanical design.

Want to maintain an automatic connection between your PCB and enclosure when updates occur? Edit in Place ensures your MCAD and ECAD designs always stay in sync.

MCAD – mechanical computer-aided design and ECAD – electronic computer-aided design, when combined, can help streamline crucial development processes.

Yes, Autodesk Fusion unifies MCAD and ECAD workflows. Whether you’re an electrical engineer looking for a cloud-based PCB design tool or an industrial designer looking to incorporate PCBs into your work, Autodesk Fusion is the solution for you. The electronics workspace is a comprehensive and affordable end-to-end solution that includes 999 schematics, 16 layers and unlimited board area.

Electronic Computer-Aided Design (ECAD) software is used to create and modify both 2D and 3D diagrams and layouts to design Printed Circuit Boards (PCB).

MCAD (mechanical computer-aided design) software is used to create and modify 2D and 3D CAD geometry to design and document mechanical components.

Using two separate software tools to create one functional prototype can be frustrating and time-consuming. PCB design software collaboration optimises PCB assembly and reduces the risk of error. MCAD and ECAD integration allows for a one-stop-shop solution for accuracy.

Manually collaborating between ECAD (Electronic Computer-Aided Design) and MCAD (Mechanical Computer-Aided Design) can lead to several potential issues:

ECAD/MCAD collaboration is crucial in today's design and manufacturing process largely due to its ability to enhance efficiency and foster innovation. By integrating ECAD and MCAD, mechanical and electrical engineers can work simultaneously on the same project, ensuring consistency in design and reducing the time to market. This multidisciplinary approach is vital in modern product design, which often incorporates both mechanical and electrical components. A collaborative environment helps in early detection of design errors, leading to cost savings by avoiding expensive reworks later on. Companies leveraging ECAD/MCAD collaboration gain a competitive edge, as they can bring innovative products to market more quickly.

Yes, Autodesk Fusion is both an ECAD (Electronic Computer-Aided Design) and MCAD (Mechanical Computer-Aided Design) software. It offers integrated ECAD and MCAD functionalities, allowing 3D PCB data such as board copper, core material and components to be analysed, verified and validated to meet product design specifications. Fusion enables ECAD and MCAD designers to work natively and independently on the same design project within the same design management platform. It eliminates the need for third-party integration, translation or exchange of files.

To ensure successful ECAD MCAD co-design, it's important to use integrated software that allows real-time collaboration and reflects changes across systems, like Autodesk Fusion. Clear communication and defined roles for each team are critical. A centralised platform should be maintained for all design data, serving as a single source of truth to prevent discrepancies. Regular design reviews involving both ECAD and MCAD teams are essential to catch errors early.