& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

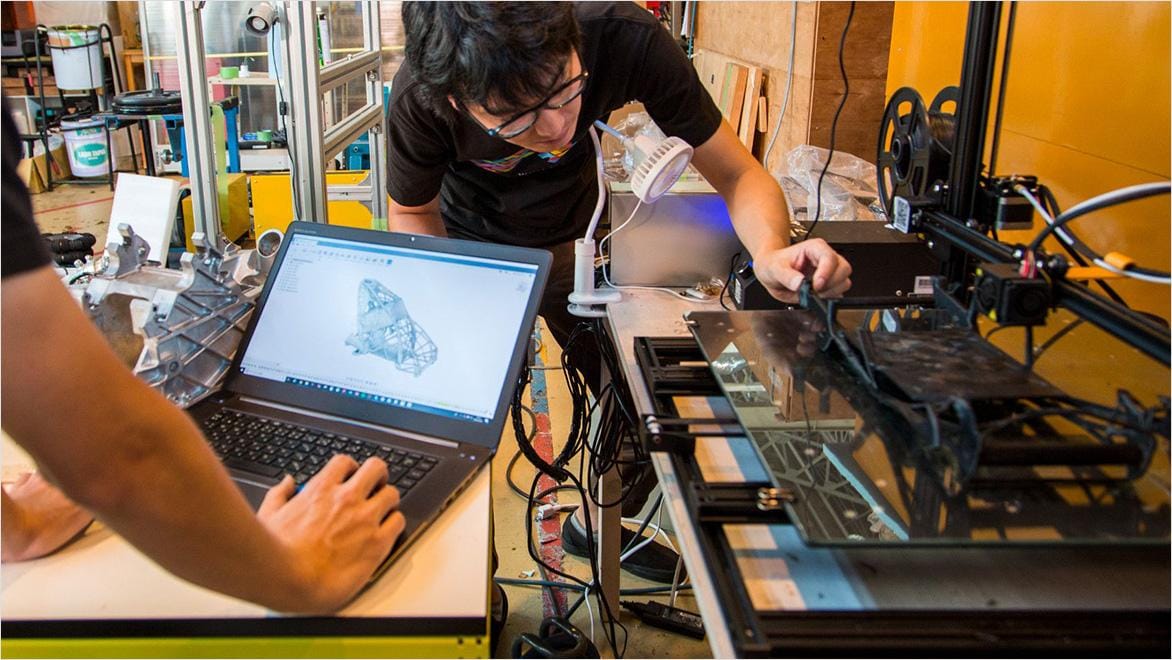

Rapid prototyping is the process of quickly creating physical models from digital designs to test ideas and improve them faster. Using tools like 3D modelling software and 3D printers, designers can turn concepts into physical objects in hours instead of weeks. This approach saves time and money by allowing for multiple test versions before final production.

The key benefits of rapid 3D prototyping include speeding up the design process, reducing costs by using cheaper materials, and allowing for quick iterations to perfect the product. It also encourages creativity by letting filmmakers experiment and innovate without wasting resources.

Taking an idea that exists only in your head and bringing it to life is no small feat. Whether you’re working on an ad, video, or a feature-length movie, directors and production designers are often required to create something out of nothing including props and costumes to sets and, sometimes, entire worlds.

Technological advances (US Site) like 3D printing are impacting the way teams, artists, and filmmakers create and distribute media, challenging professionals to find better, faster ways to bring their stories to life and achieve creative goals. But it’s all for the better. Props that used to take weeks can now take advantage of rapid prototyping 3D printing to turn a sketch into a physical object.

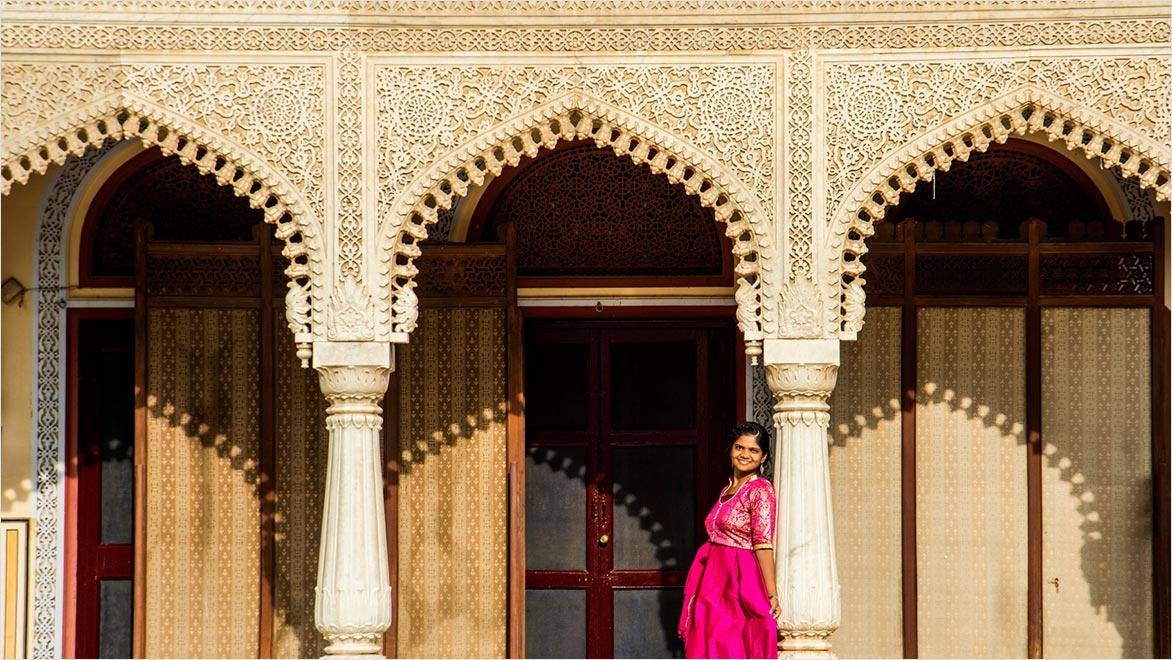

Bollywood is one of the most prolific film industries worldwide, producing an estimated 1500 to 2000 movies every year. These movies are famously known for their colourful aesthetics, heightened dramatics, musical numbers, and dance. They are fantastical yet culturally rich, telling stories about people, romance, legacy, and action.

For a typical Bollywood production, set designs and visual effects play a big role. Early on, filmmakers relied on practical effects teams to manually sculpt or fabricate props, often at a considerable cost of time, money, and resources. These days, the rise of digital tools and computer-aided design (CAD) has transformed the process, making it possible to realise creative visions faster, more affordably, and with better quality.

Instead of building physical scale models for set construction, filmmakers can save production time and effort with access to 3D prototype printing software like Autodesk’s Fusion, Maya, and 3ds Max. These tools are increasingly used in Bollywood films, improving overall quality and experience and enabling collaboration with skilled professionals across the world.

Let’s look at how Autodesk helps conceptualise and execute ideas, including examples of how the software can be used in recent Bollywood hits.

In the Bollywood Adventure Epic, Kalki 2898 AD, a city fights against maxi-sized competitors for a chance at a better future. Autodesk’s Fusion can be used to design its futuristic armour and costumes. With Fusion’s generative design (US Site) capabilities, the production team could simply input desired parameters for any object—such as weight, materials, and strength—and let the software generate multiple design alternatives so you get the perfect look before printing.

Creating an immersive, large-scale environment is expensive. Fusion could help you realise your dreams and stay within budget through miniatures. By prototyping and 3D printing your fantastical cityscapes and towering structures at a fraction of the size, you can simulate large-scale battles and expansive scenes without needing full-size set builds. It’s not only cost-effective but also allows you to film scenes that fit your movie’s aesthetic and meet practical requirements like functionality, stability, and mobility.

Using Fusion, you can transform everyday objects into futuristic designs or period pieces. A basic helmet, for instance, can be redesigned to resemble a sleek space explorer's headgear with carefully placed 3D-printed modifications. The vehicles in Kalki 2898 AD can be designed by overlaying mechanical elements and unique textures on a base model. Once the design is finalised, the add-ons are 3D printed with materials that make it easy to fashion lightweight, durable props that work and look realistic in action scenes.

Wonder Dynamics powerful AI-toolset Wonder Studio empowers creators and artists to focus more on the iterative and creative aspects of storytelling. You can turn your footage into live-action animated films, commercials, music videos, and more with AI-powered Wonder Studio.

Replace live actors with 3D characters and seamlessly capture facial, body, and hand movements with Wonder Studio's AI mocap technology. Get complete motion capture data for your project in USD or FBX formats, with advanced character bone retargeting and export-ready animations.

Gain ultimate flexibility for precise character placement and movement control with the Camera Track Tool. Match movements of a virtual camera to real-life scenes for realistic alignment and motion and detect the planes within your scene using Point Cloud.

Export selected project elements enabled during Render Setup. From Clean Plate, to Camera Track, and Alpha Masks, customize and download your desired outputs to see exactly what you need for the creative task at hand.

Autodesk Fusion helps turn simple sketches into a physical model. Its parametric modelling features transform your idea while simulating the prop or object’s functionality. This ensures moving parts work as you expect before physical assembly begins, saving a lot of production time and ensuring it looks and works the way you, the crew, and the actors need.

3ds Max and Maya can help artists and filmmakers design and animate digital characters, environments, and other visual effects. The 2024 Bollywood horror comedy Stree 2, directed by Amar Kaushik, is the sequel to the 2018 hit Stree. Starring Shraddha Kapoor and Rajkummar Rao, the film follows Vicky and his friends as they confront a new supernatural menace in the town of Chanderi—a headless ghost known as Sarkata. 3ds Max and Maya can be used to bring this dark presence to life and model the haunted village to set the movie’s atmosphere and environment.

Used together, Fusion, 3ds Max, and Maya enhance your and your team’s capabilities on-set. With them, you can create fictional worlds that immerse your audience and feel real.

With cloud-based collaboration, designers and engineers can work together no matter where they are. Designers can share their Fusion models with directors, producers, and other team members, who can view, comment on, and even modify the designs in real-time. This speeds up production, reduces miscommunication, and ensures everyone is working from an aligned vision.

Find out everything you need to know about prototyping, from its necessity for your product to non-negotiable steps and potential production costs.

Get all the details about 3d printing rapid prototyping with Autodesk’s Fusion and understand all the ways Fusion can support you through the development cycle.

Get familiar with Autodesk Fusion and its powerful extensions that offer a suite of tools for prototype 3D printing, including electronics design, automated modelling, simulation, generative design, latticing, rendering, and more.

Rapid prototyping is a process of creating physical models from 3D computer-aided design (CAD) data. It works by using additive manufacturing techniques, such as 3D printing.

Rapid prototyping allows for quick iteration, testing, and refinement of designs, reducing time to market and development costs. Designers can test concepts in physical form, making it easier to spot flaws and make adjustments.

Industries like automotive, aerospace, consumer electronics (US Site), healthcare, and entertainment (such as films and video games (US Site)) widely use rapid prototyping for design and product development.

Rapid prototyping is faster, more flexible, and less labour-intensive than traditional manufacturing, focusing on design validation rather than large-scale production.