& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

Professional CAD/CAM tools built on Inventor and AutoCAD

This unit will help demonstrate how multiple assets can be utilized to create a factory layout in AutoCAD and Inventor.

Transcript

00:04

Now let's have a look at layouts.

00:06

A factory layout is basically the container of all your factory related spatial representation.

00:12

They allow you to place assets but also references of the building context.

00:15

For example, you can use one or more existing DWGs in form of an underlay as a reference for positioning.

00:22

Larger layouts or if multiple users need to work on the same layout and parallel for instance,

00:27

can be broken up into so called sub-layouts.

00:30

Inventor's any CAD functionality can be used to reference building context coming

00:34

for example in the form of a Revit project file,

00:37

the layout with all their content is also the file

00:39

that you would synchronize by directionally between the involved tools.

00:43

Let's see how that looks in action.

00:46

Here we are looking at the master layout of a digital factory model created via factory design utilities.

00:52

It consists of different production lines and office space as well as some reference DWG underlays.

00:57

We would merely like to modify the setup of one of the production lines,

01:01

so we opened its sub-layout in order to do so.

01:10

the first changes we would like to apply in birds eye view for convenience,

01:13

so we trigger the synchronization to AutoCAD via the dedicated command in the ribbon panel.

01:18

The layout gets opened automatically with an AutoCAD

01:21

and updated appropriately reflect the same state as we saw inside of inventor.

01:27

Now, we can begin with our modifications.

01:29

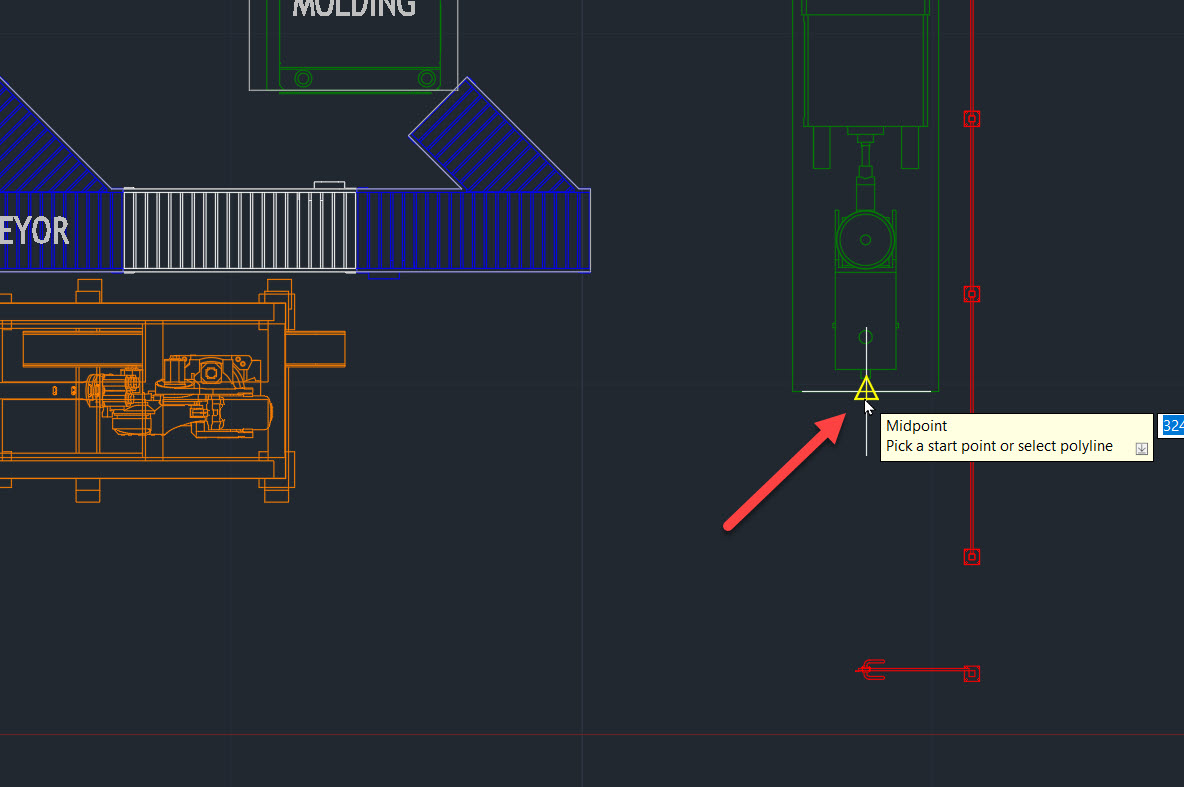

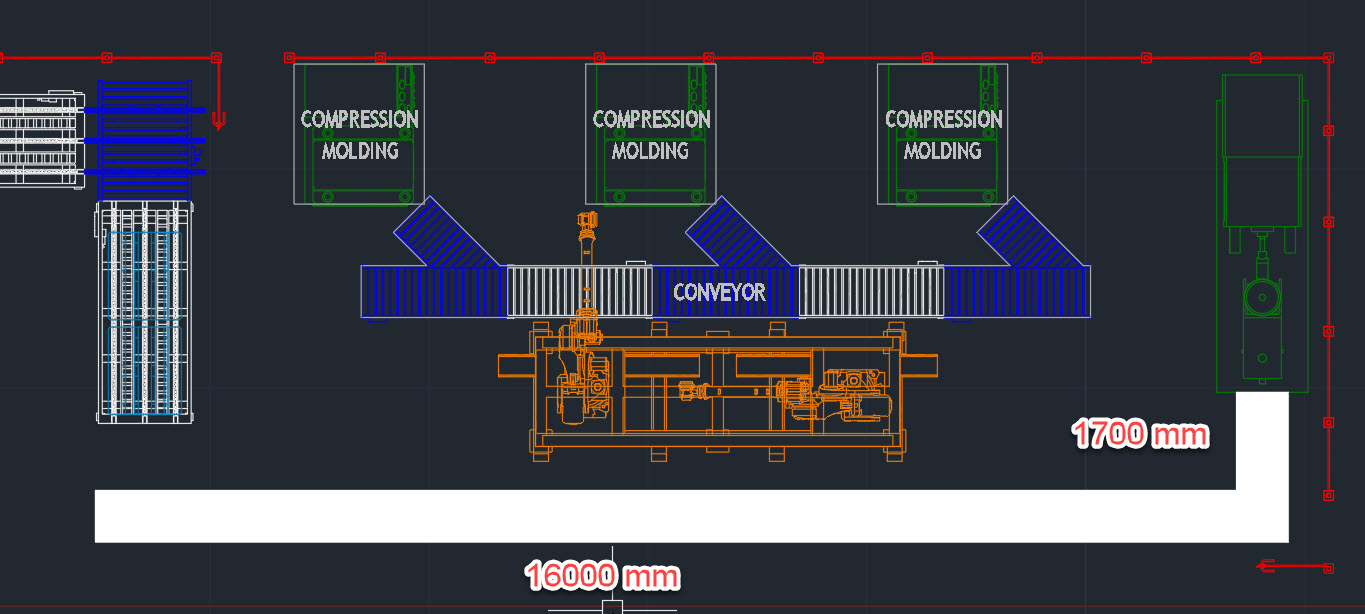

We would like to add a conveyor system from one machine through the whole production area.

01:33

Let's say the customer requested this to reduce time spent by factory workers to move the product to packaging.

01:39

We therefore access our asset library on the right hand panel and brought for the correct conveyor.

01:44

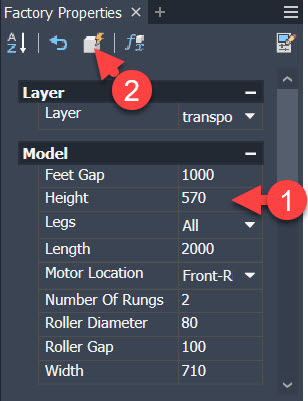

In this case we also leverage some built in automation in form of our configured as chain asset.

01:50

As we drop polyline representing the middle of the route Our conveyor should run along

01:54

and trigger its conversion to an asset chain via the ribbon command.

01:58

Instances of the asset are placed fully automatically connected to each other

02:02

and visually represented within the layout.

02:06

After confirming that the positioning and dimensions are correct.

02:10

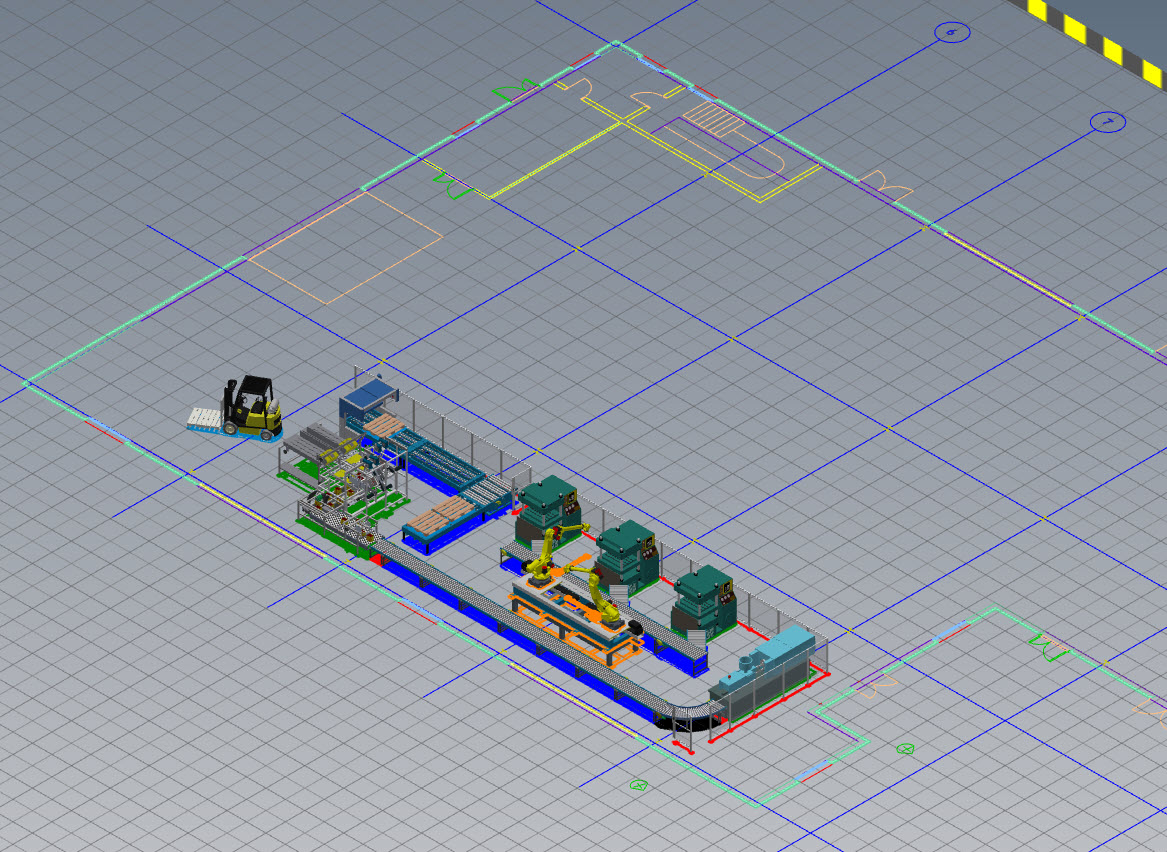

After population, we can then synchronize it back to inventor in order to review our updates in 3D space.

02:27

The 3D geometric representation is fetched from the factory assets file and populated within the 3D context as well.

02:34

Within Inventor.

02:35

First the 2D representation is updated and then the layer is populated with the associated 3D models.

02:41

You can see the different instances of the conveyors also being added in the model browser.

02:45

To keep things organized,

02:46

we assign them to the correct layer and simply move them to the dedicated folder that we created prior

02:51

or have setup within the layout template.

02:55

Now we unfortunately forgot to also add the receiving packing machine when we were in AutoCAD,

03:00

but not to worry as mentioned the same drag and drop mechanism to place assets is available inside inventor.

03:05

Again we browse to the library and start the placement by double clicking on the desired piece of equipment.

03:11

Note that as we move the preview of your assets to review,

03:14

the connectors that are available to connect to start reacting to each other,

03:18

making it easy to correctly align our packing machine.

03:21

Once placed,

03:23

we can exit out of the placement mode via right click done and tidy up the model browser again.

03:31

To close the loop with the rest of the team,

03:32

we save the changes and will get a notification within our Master layout

03:38

that there have been some updates to one of the sub-layouts.

03:41

Upon refreshing, we will see all the updates also reflected in the full digital factory

03:46

and we are ready for checking it in the modified files into our data management system

03:50

for other colleagues to be able to consume them.

Video transcript

00:04

Now let's have a look at layouts.

00:06

A factory layout is basically the container of all your factory related spatial representation.

00:12

They allow you to place assets but also references of the building context.

00:15

For example, you can use one or more existing DWGs in form of an underlay as a reference for positioning.

00:22

Larger layouts or if multiple users need to work on the same layout and parallel for instance,

00:27

can be broken up into so called sub-layouts.

00:30

Inventor's any CAD functionality can be used to reference building context coming

00:34

for example in the form of a Revit project file,

00:37

the layout with all their content is also the file

00:39

that you would synchronize by directionally between the involved tools.

00:43

Let's see how that looks in action.

00:46

Here we are looking at the master layout of a digital factory model created via factory design utilities.

00:52

It consists of different production lines and office space as well as some reference DWG underlays.

00:57

We would merely like to modify the setup of one of the production lines,

01:01

so we opened its sub-layout in order to do so.

01:10

the first changes we would like to apply in birds eye view for convenience,

01:13

so we trigger the synchronization to AutoCAD via the dedicated command in the ribbon panel.

01:18

The layout gets opened automatically with an AutoCAD

01:21

and updated appropriately reflect the same state as we saw inside of inventor.

01:27

Now, we can begin with our modifications.

01:29

We would like to add a conveyor system from one machine through the whole production area.

01:33

Let's say the customer requested this to reduce time spent by factory workers to move the product to packaging.

01:39

We therefore access our asset library on the right hand panel and brought for the correct conveyor.

01:44

In this case we also leverage some built in automation in form of our configured as chain asset.

01:50

As we drop polyline representing the middle of the route Our conveyor should run along

01:54

and trigger its conversion to an asset chain via the ribbon command.

01:58

Instances of the asset are placed fully automatically connected to each other

02:02

and visually represented within the layout.

02:06

After confirming that the positioning and dimensions are correct.

02:10

After population, we can then synchronize it back to inventor in order to review our updates in 3D space.

02:27

The 3D geometric representation is fetched from the factory assets file and populated within the 3D context as well.

02:34

Within Inventor.

02:35

First the 2D representation is updated and then the layer is populated with the associated 3D models.

02:41

You can see the different instances of the conveyors also being added in the model browser.

02:45

To keep things organized,

02:46

we assign them to the correct layer and simply move them to the dedicated folder that we created prior

02:51

or have setup within the layout template.

02:55

Now we unfortunately forgot to also add the receiving packing machine when we were in AutoCAD,

03:00

but not to worry as mentioned the same drag and drop mechanism to place assets is available inside inventor.

03:05

Again we browse to the library and start the placement by double clicking on the desired piece of equipment.

03:11

Note that as we move the preview of your assets to review,

03:14

the connectors that are available to connect to start reacting to each other,

03:18

making it easy to correctly align our packing machine.

03:21

Once placed,

03:23

we can exit out of the placement mode via right click done and tidy up the model browser again.

03:31

To close the loop with the rest of the team,

03:32

we save the changes and will get a notification within our Master layout

03:38

that there have been some updates to one of the sub-layouts.

03:41

Upon refreshing, we will see all the updates also reflected in the full digital factory

03:46

and we are ready for checking it in the modified files into our data management system

03:50

for other colleagues to be able to consume them.

Note: This exercise uses the Packing Machine asset created in the Create Factory Utilities Design Assets exercise from the previous unit. If you have not already done so, you will need to complete that exercise first.

How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2025 Autodesk Inc. All rights reserved

Sign in to start learning

Sign in for unlimited free access to all learning content.Save your progress

Take assessments

Receive personalized recommendations

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.