& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

Professional CAD/CAM tools built on Inventor and AutoCAD

Transcript

00:03

InfoSurge Pro allows you to create hydraulic transients by providing a curve which will alter pump and valve operations,

00:11

as well as junction demand changes.

00:13

You can then compare the simulation results from different operational conditions.

00:18

In this example, transients are created from pump shutdown events using the Pump Speed Change option.

00:25

To begin, double-click the desired project .aprx file to open ArcGIS Pro.

00:32

Once the project starts, click the InfoWater Pro tab to open the InfoWater Pro ribbon.

00:38

In the Project panel, click Initialize.

00:41

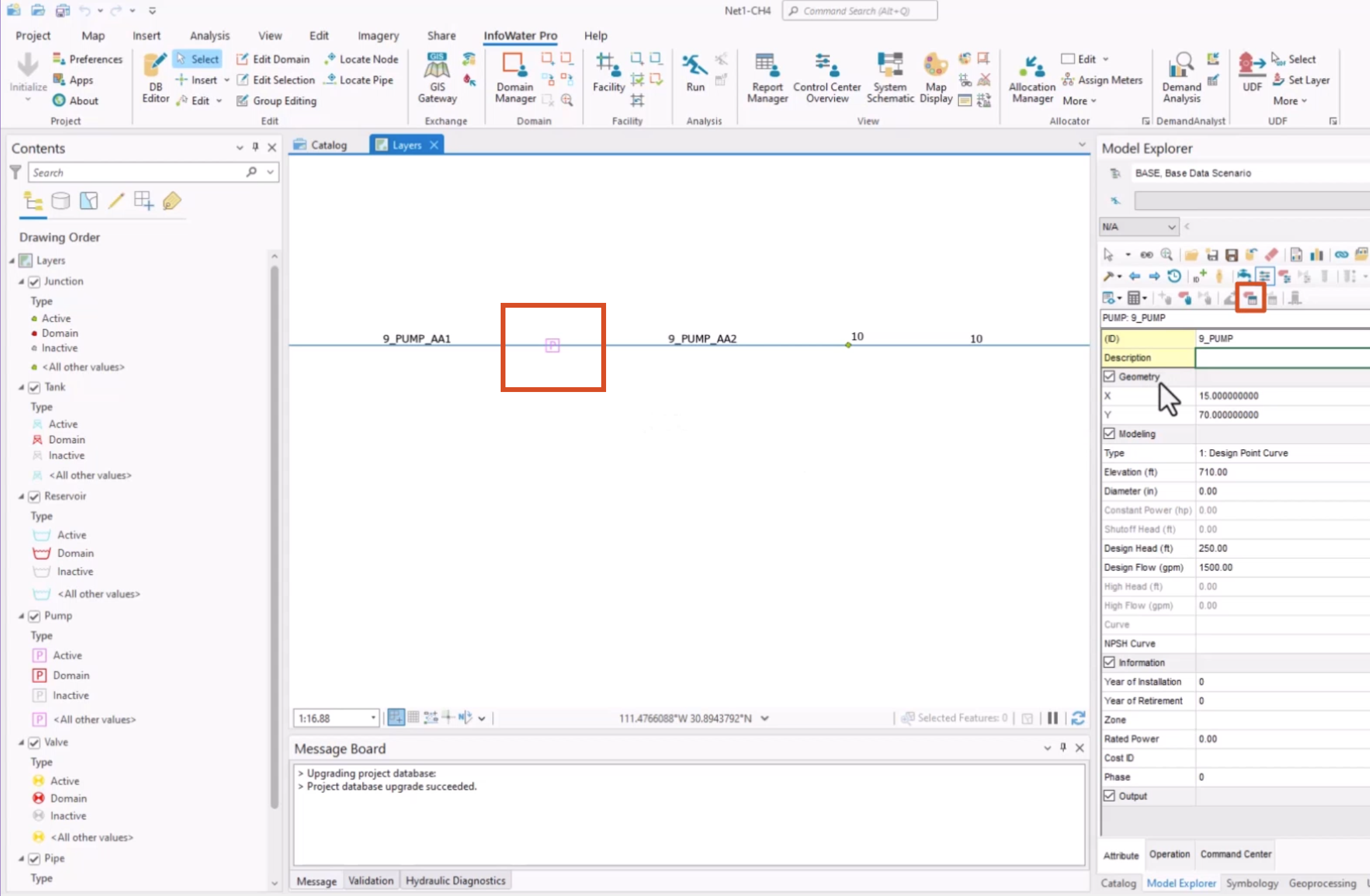

Next, with the Select tool active, zoom to and select the pump with the ID 9_PUMP.

00:48

From the Model Explorer, click the Pump Surge Data button.

00:53

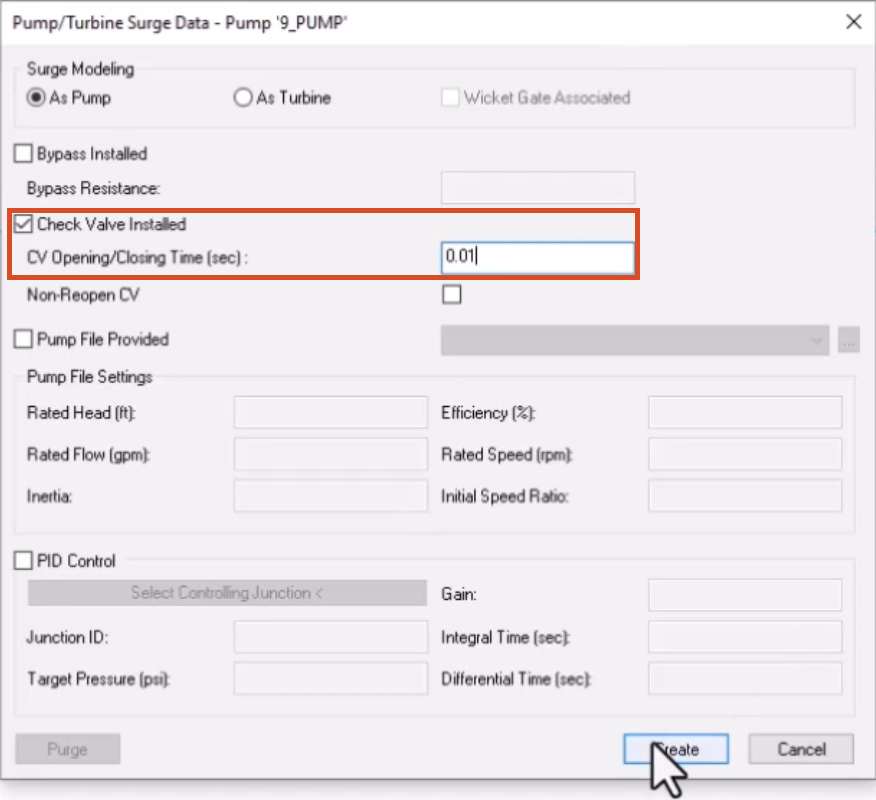

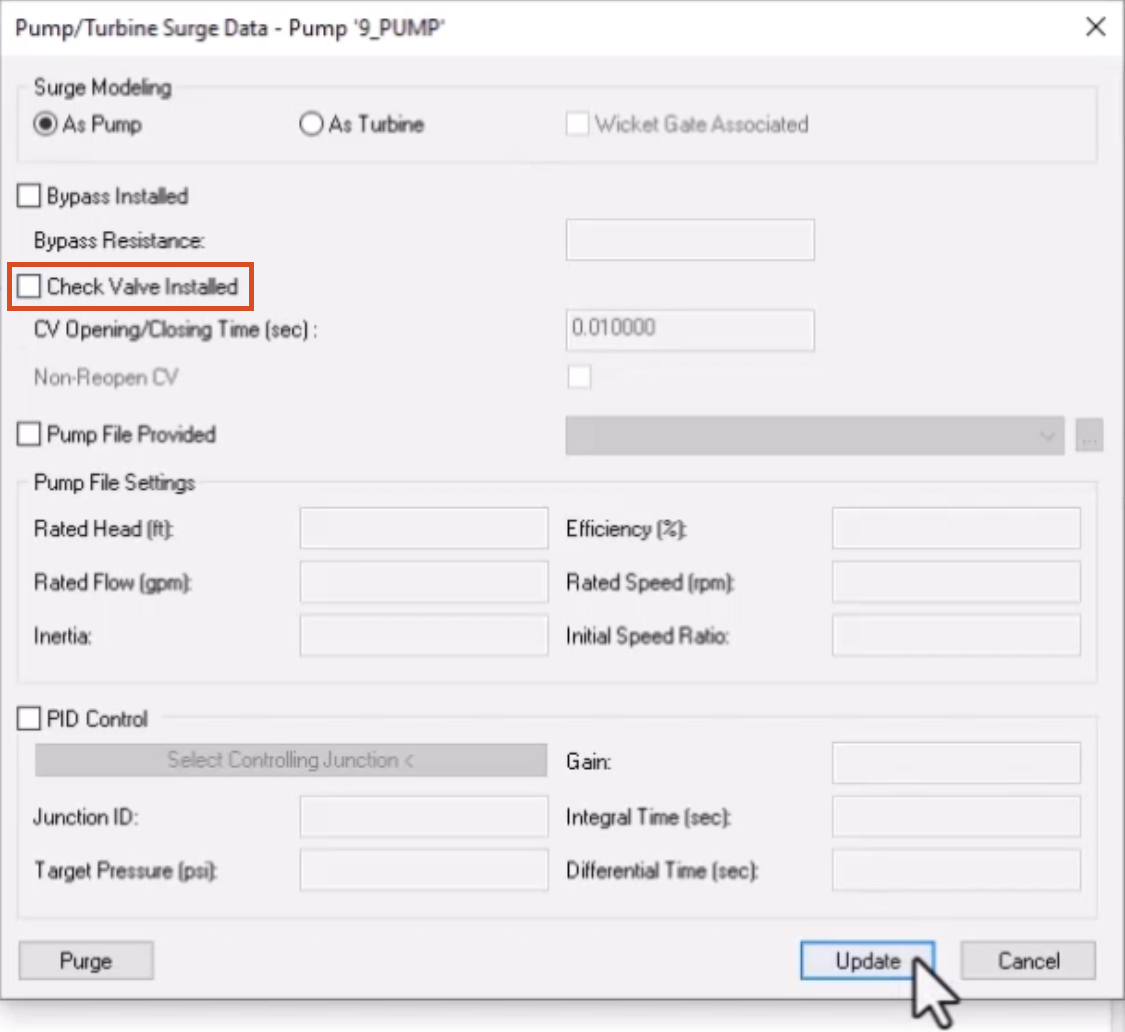

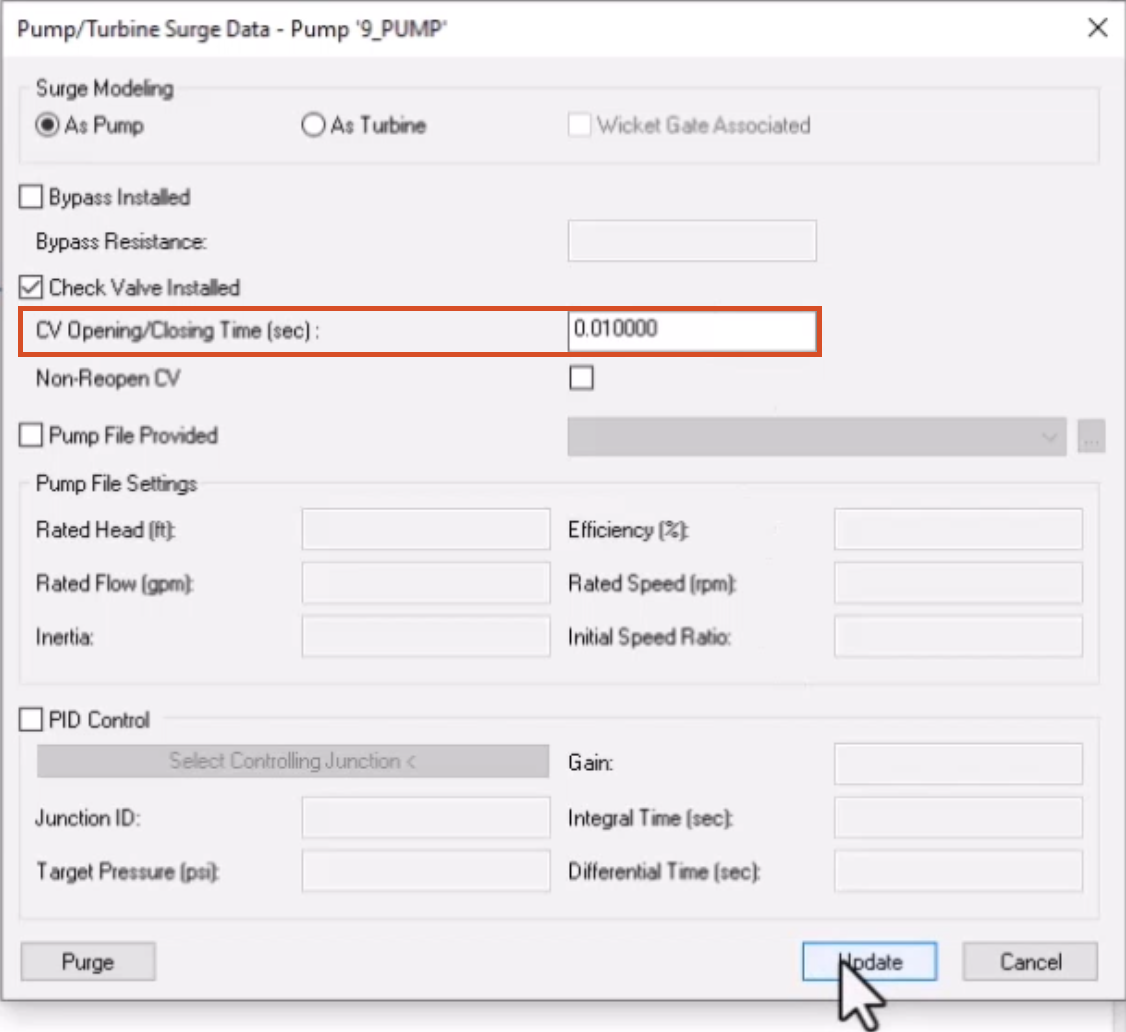

The Pump Surge Data dialog box is used to specify how the selected pump and its associated properties will be modeled.

01:01

First, make sure a check valve is modelled for the surge analysis by enabling the Check Valve Installed option.

01:08

This will prevent flow reversal through the pump.

01:12

Enter a check valve (CV) opening and closing time of 0.01 seconds.

01:19

Then, click Create to save the settings and close the dialog.

01:24

Changes in pump operating speeds produce transients.

01:28

Time-dependent speed ratios can be applied to pumps as a speed curve.

01:33

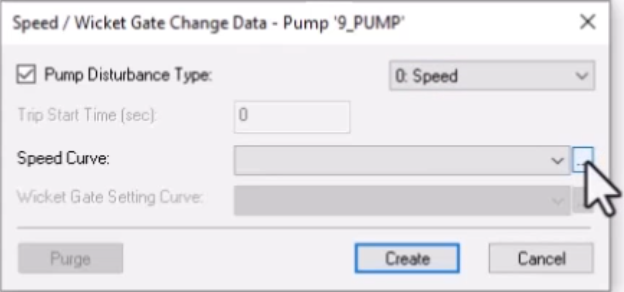

To do so, from the Model Explorer, click the Pump Operation Change button.

01:38

In the Pump Operation Change dialog, select the Pump Disturbance Type option,

01:43

and then set the disturbance speed to “0: Speed”.

01:47

The curve selected will dictate the pump speed over time.

01:51

Next to the Speed Curve drop-down, click the Browse (...) button.

01:55

This opens the Curve dialog.

01:57

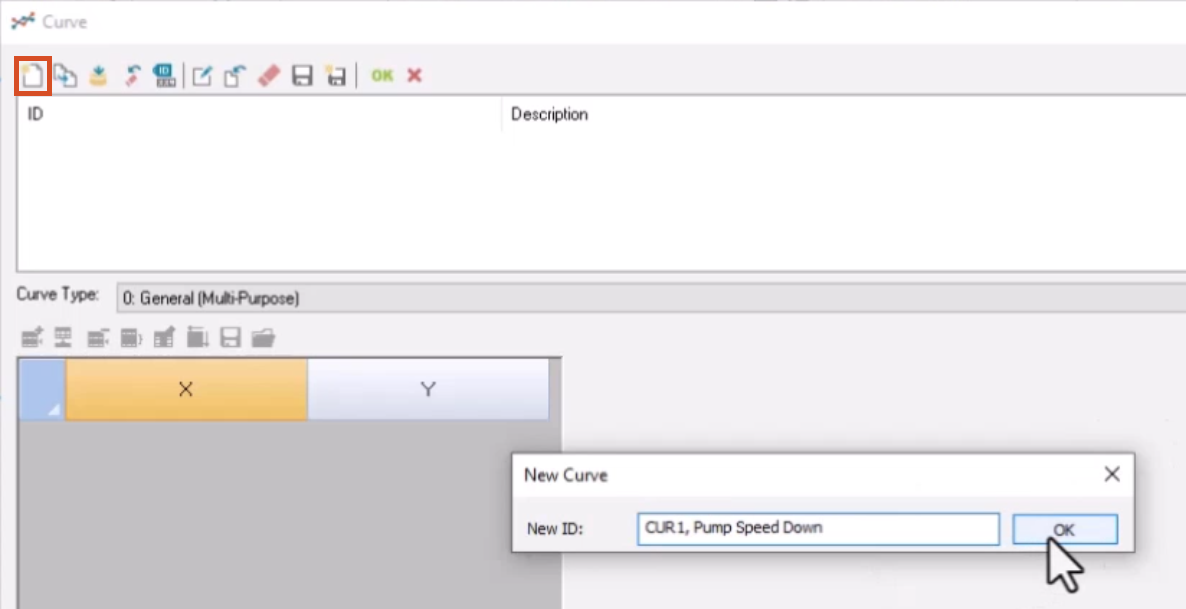

The model does not currently have a speed curve to use, so one must be created.

02:02

Click the New icon, and you are prompted to name the new curve ID.

02:06

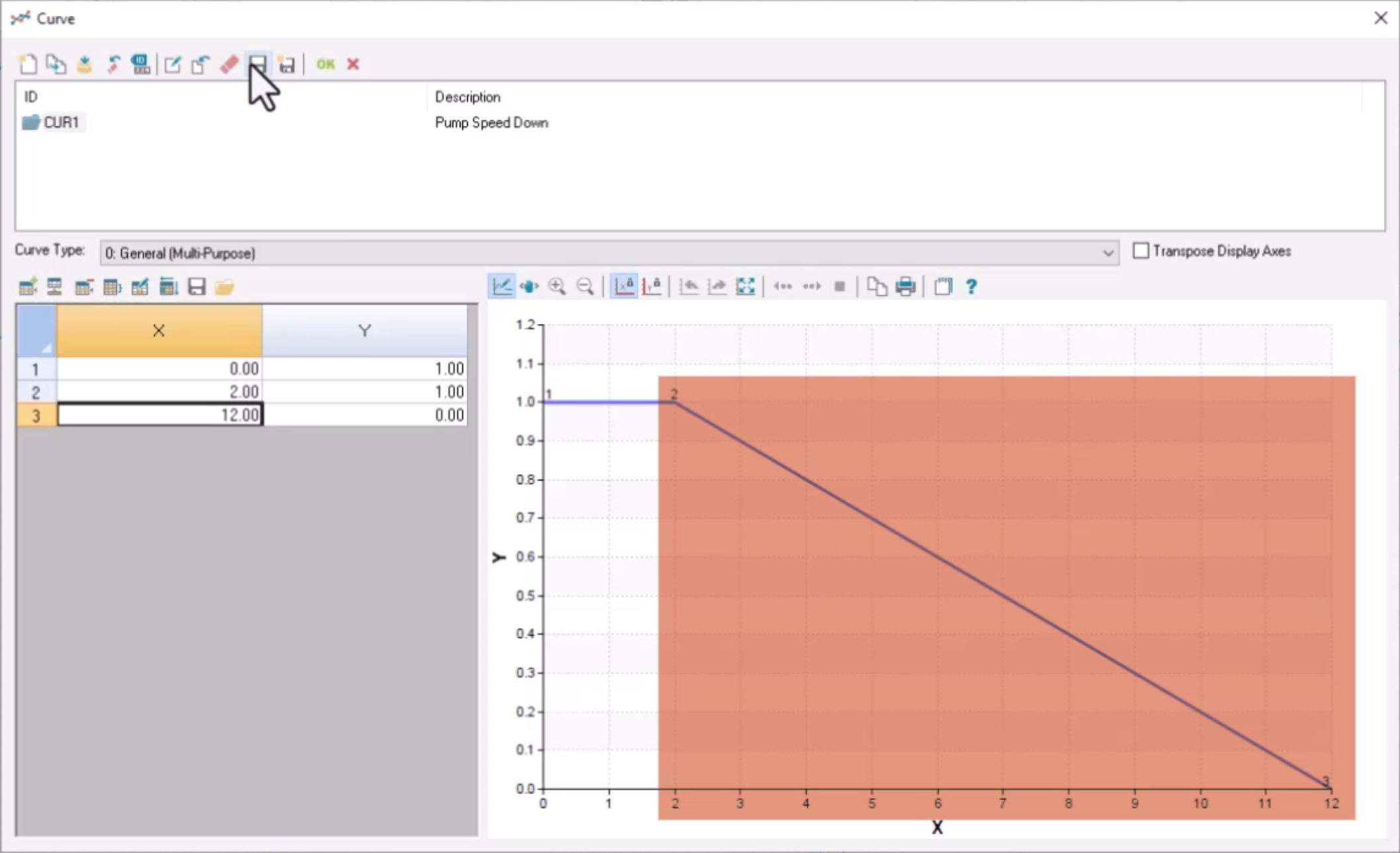

Enter the name “CUR 1, Pump Speed Down”, and then click OK.

02:12

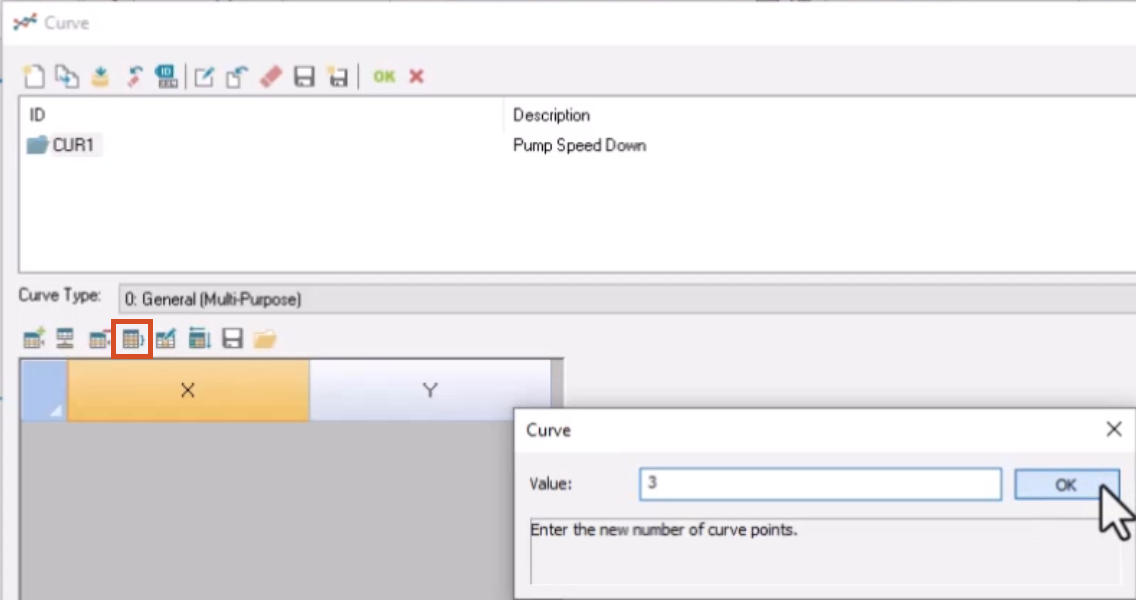

With the Curve dialog still open, click the Set Rows button.

02:16

In the Value field, enter “3”, and then click OK.

02:21

The X/Y table updates to have three rows and two columns.

02:26

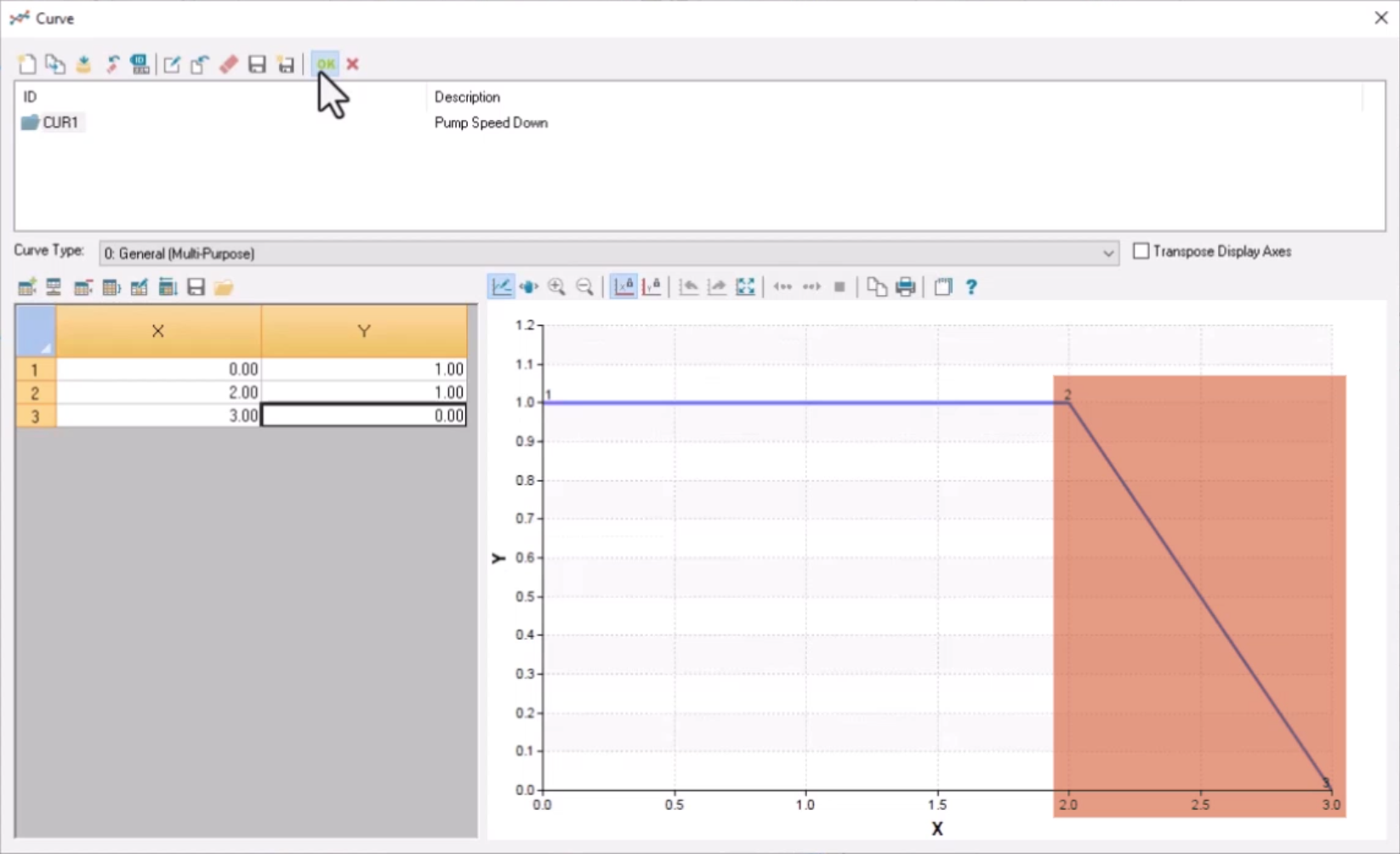

You can now enter values into the table to create a pump curve, which updates automatically in line graph form.

02:33

Note that the X-axis is operation time in seconds,

02:36

and the Y-axis represents pump speed ratio.

02:40

Enter the following values by assigning each X-axis value in numerical order,

02:45

followed by the values in the Y-axis column.

02:49

In the X column, enter: 0.00 in row 1

03:01

In the Y column, enter:

03:12

Note that the curve indicates that after two seconds, the pump will drop from full speed (1 for 100% speed)

03:19

to off (0 for 0% speed) within the next one second.

03:24

Click OK to close the Curve dialog.

03:27

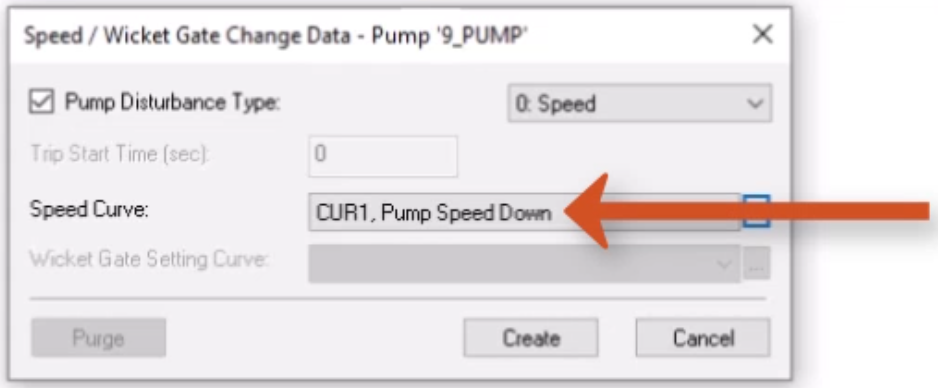

In the Speed/Wicket Gate Change Data dialog, make sure the Speed Curve drop-down is set to the name of the new curve you just created.

03:35

Then, click Create to close the dialog and save the settings.

03:40

You are now ready to run both steady-state and surge simulations.

03:45

From the Model Explorer, click the Run Manager button,

03:48

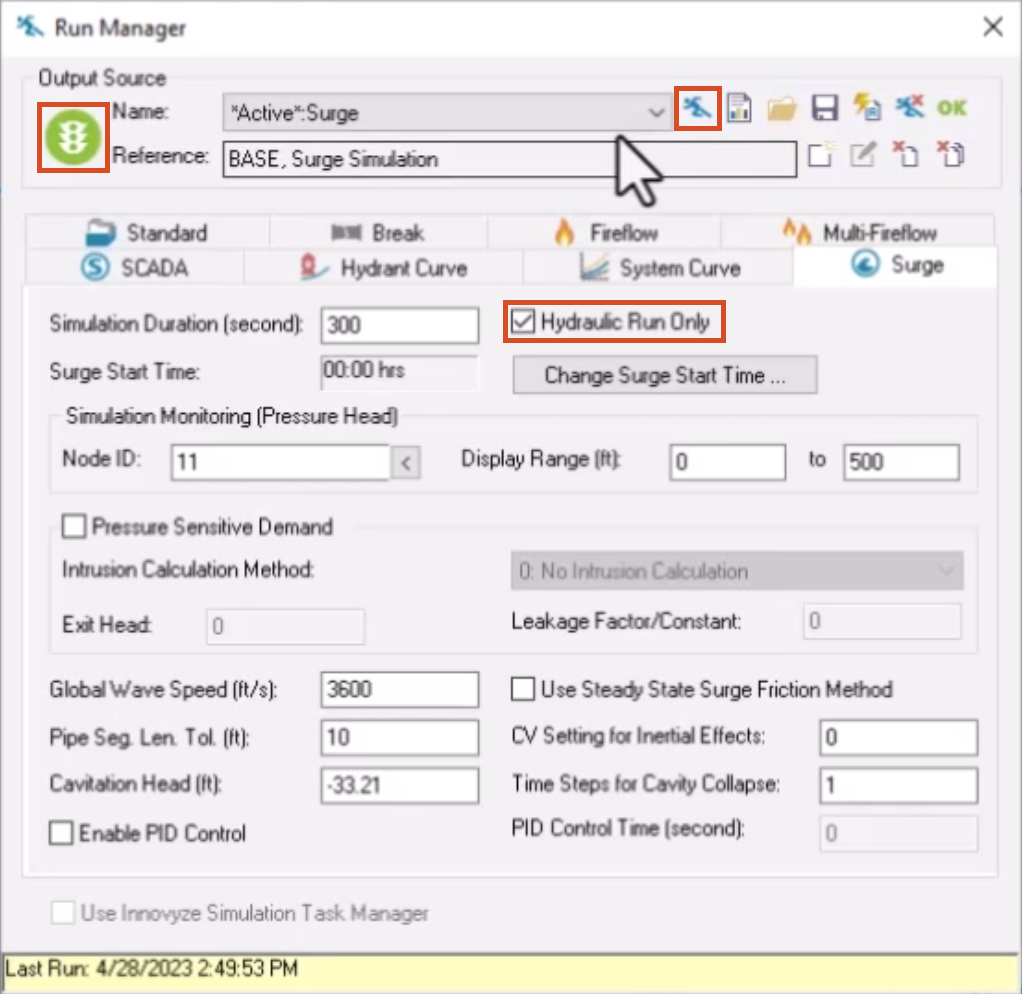

and then, in the Run Manager, open the Surge tab.

03:52

Enable the Hydraulic Run Only option, and then click Run to run the model with a hydraulic simulation.

03:59

Upon successful completion, under Output Source,

04:02

a green light icon appears, and you are ready to run a surge analysis.

04:07

Deselect the Hydraulic Run Only option, and then click Run again to perform a surge analysis.

04:14

Click OK to close the Run Manager.

04:17

If you are prompted about switching to the most recent run output data, select Yes.

04:23

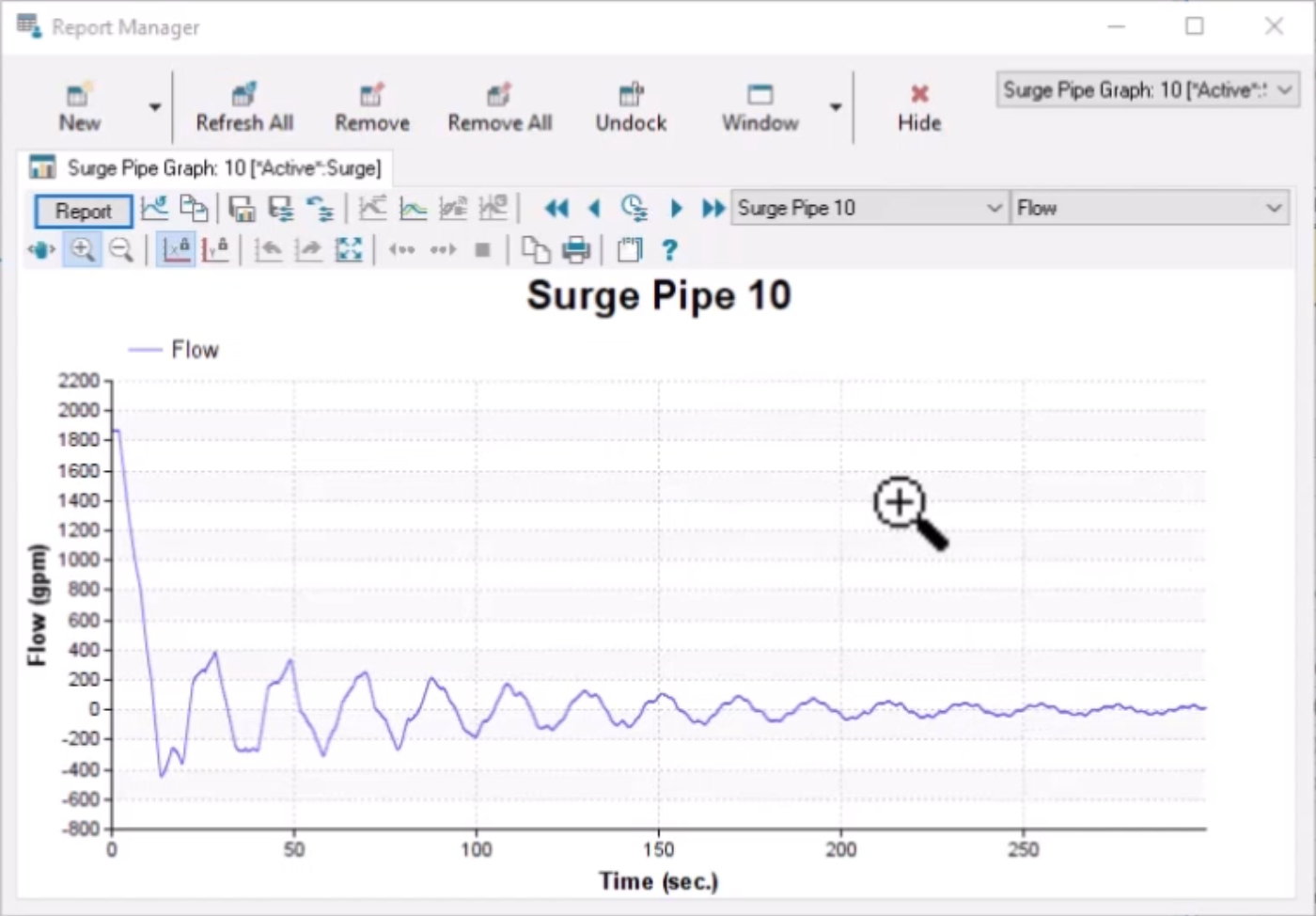

Results from the simulation can be viewed in graph or tabular format.

04:28

For this example, you will view the effect of the surge simulation on flow through a pipe downstream of the pump experiencing

04:35

the shutdown event.

04:37

From the ribbon, InfoWater Pro tab, View panel, click Report Manager.

04:42

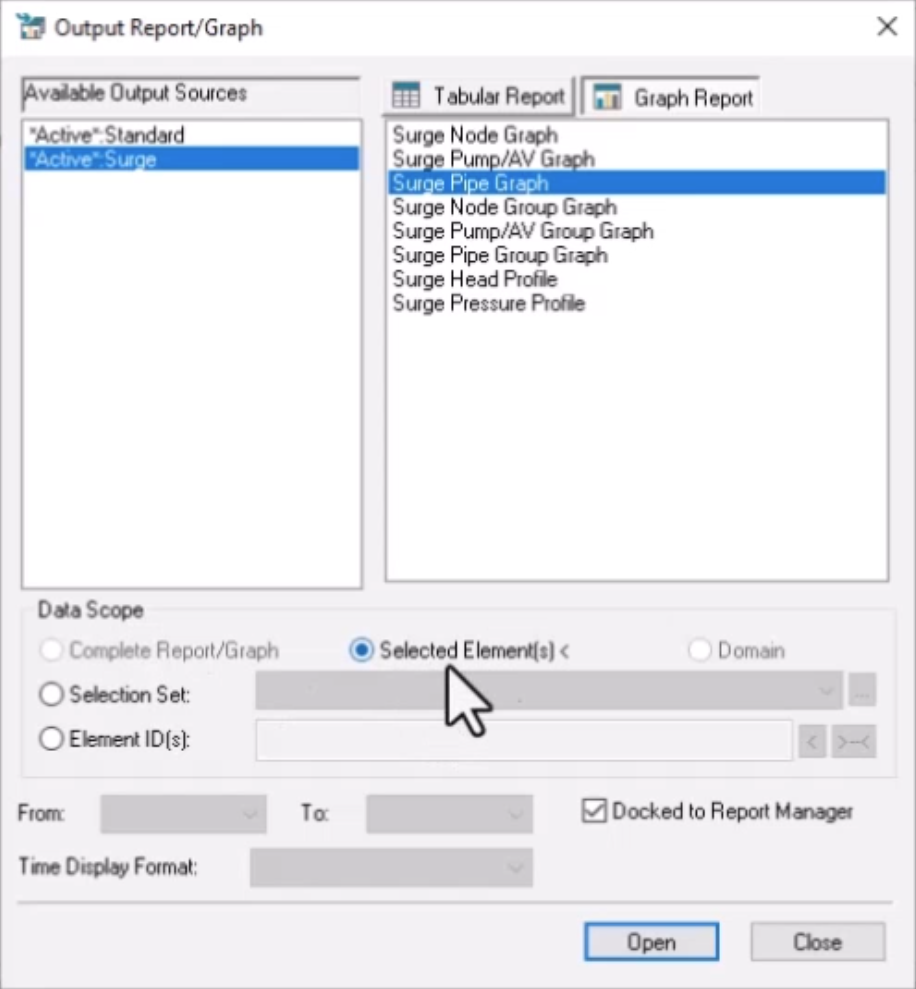

In the Report Manager dialog, click the New button to open the Output Report/Graph dialog.

04:49

Under Available Output Sources, select *Active*.Surge.

04:53

Then, open the Graph Report tab and select Surge Pipe Graph.

04:58

Note that in the Data Scope group box, the default option Selected Element(s) is enabled.

05:04

Click Open.

05:06

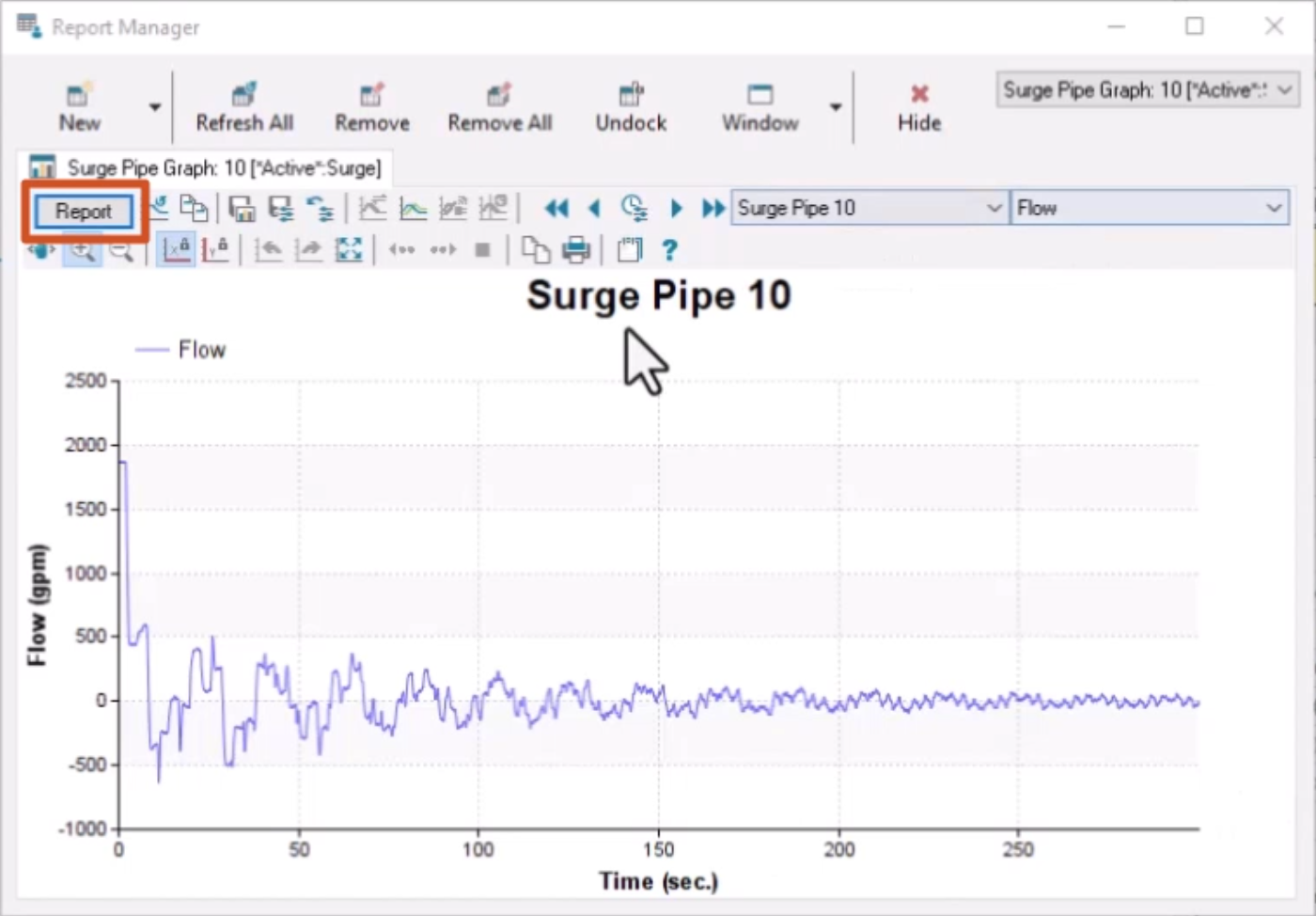

On the map, select Pipe 10 to view its flow, which indicates a typical pump shutdown response.

05:12

Review the graph and, if needed, click Report to see data for the entire run in a table format.

05:20

Close out of the Report Manager once you are done reviewing.

05:24

The previous results can be compared to a new simulation that is run without a check valve

05:28

to better understand the effects of modelling a check valve in your system.

05:33

Select pump 9_PUMP.

05:36

Click the Pump Surge Data button to open the Pump/Turbine Surge Data dialog.

05:41

Disable the Check Valve Installed option, and then click Update.

05:46

Next, reopen the Run Manager.

05:49

Click the Run button to run a surge analysis.

05:53

Then, click OK to close the dialog.

05:57

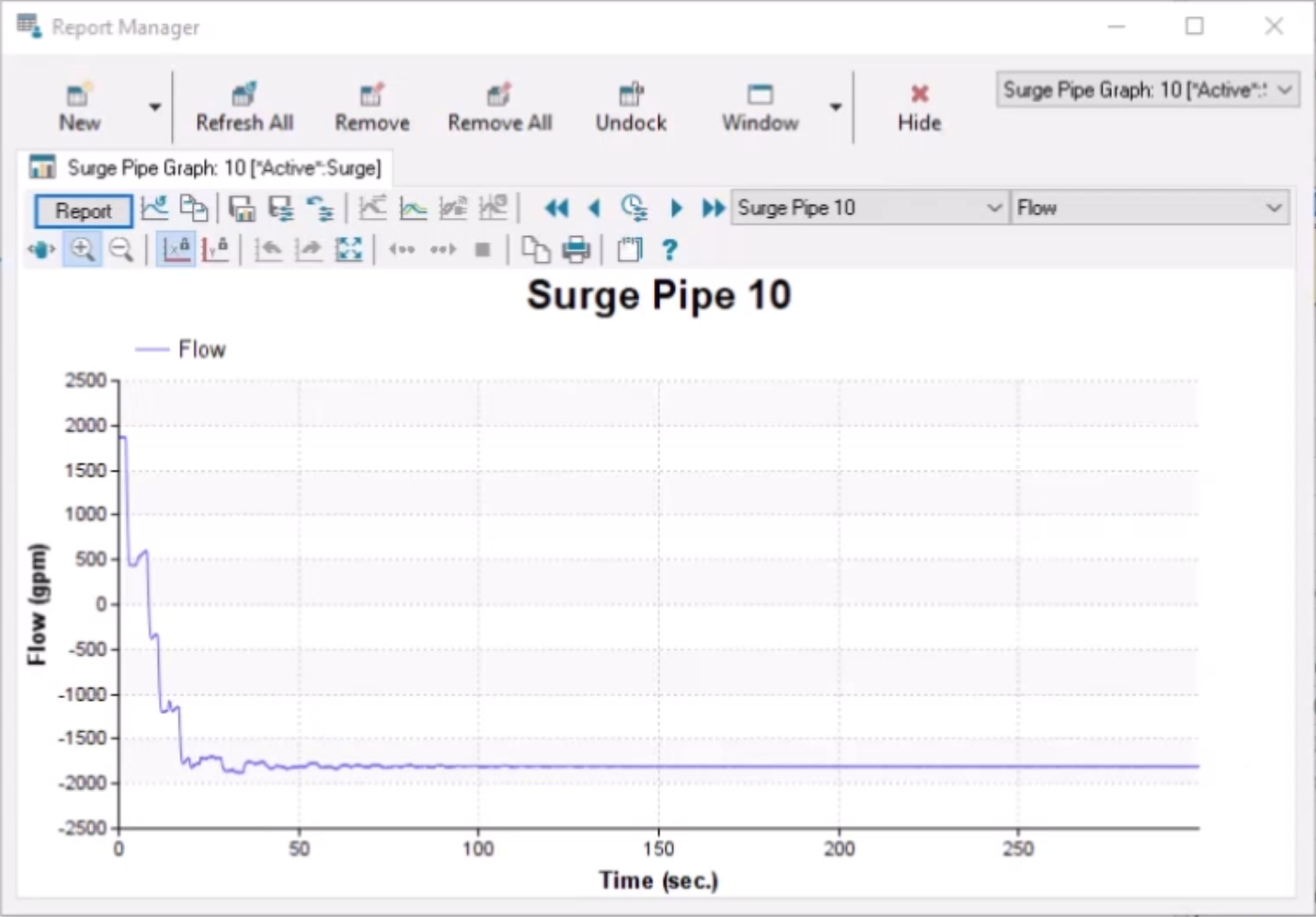

Reopen the Report Manager and click Refresh All.

06:01

This refreshes the output for pipe 10 for the latest run.

06:05

You can now review the results using the Report Manager.

06:08

Notice the difference in flow from the previous run as a result of removing the check valve.

06:14

Without the check valve to prevent reverse flow, additional flow can go through the pipe.

06:19

When you finish reviewing the results, Close the Report Manager.

06:23

Shorter shutdown times are going to create greater surge events,

06:27

whereas a slower shutdown will produce less of a transient event.

06:32

For the next step, you use a longer pump speed change operation time

06:36

to increase the pump shutdown time and minimize the impact of the surge event.

06:41

From the map, select pump 9_PUMP.

06:45

Click the Pump Surge Data button, and then in the Pump Surge Data dialog,

06:49

enable the Check Valve Installed option.

06:52

Note that the software should remember the previously entered CV closing time,

06:56

so leave it set to 0.01 seconds.

07:00

Then, click Update.

07:02

From the Model Explorer, click the Pump Operation Change button to open the Speed/Wicket Gate Change Data dialog.

07:09

Then, click Browse (...) to reopen the Curve dialog.

07:13

Make sure the CUR1 curve ID is selected.

07:17

Then, in the X-column, set the value in row 3 to 12.00.

07:22

This greatly extends the pump speed downtime from one second to ten seconds.

07:28

Click Save to save the changes, and then OK to close the dialog.

07:33

In the remaining dialog, click Update to update the changes and close the window.

07:38

Reopen the Run Manager and select Run to begin a surge analysis.

07:43

Reopen the Report Manager and click Refresh All to refresh the output for pipe 10 for the latest run and view the results.

07:51

Notice the surge event is greatly reduced.

07:54

This process could be repeated with different shutdown times to identify how slow pump shutdown would need to be

08:00

to avoid a surge event.

Video transcript

00:03

InfoSurge Pro allows you to create hydraulic transients by providing a curve which will alter pump and valve operations,

00:11

as well as junction demand changes.

00:13

You can then compare the simulation results from different operational conditions.

00:18

In this example, transients are created from pump shutdown events using the Pump Speed Change option.

00:25

To begin, double-click the desired project .aprx file to open ArcGIS Pro.

00:32

Once the project starts, click the InfoWater Pro tab to open the InfoWater Pro ribbon.

00:38

In the Project panel, click Initialize.

00:41

Next, with the Select tool active, zoom to and select the pump with the ID 9_PUMP.

00:48

From the Model Explorer, click the Pump Surge Data button.

00:53

The Pump Surge Data dialog box is used to specify how the selected pump and its associated properties will be modeled.

01:01

First, make sure a check valve is modelled for the surge analysis by enabling the Check Valve Installed option.

01:08

This will prevent flow reversal through the pump.

01:12

Enter a check valve (CV) opening and closing time of 0.01 seconds.

01:19

Then, click Create to save the settings and close the dialog.

01:24

Changes in pump operating speeds produce transients.

01:28

Time-dependent speed ratios can be applied to pumps as a speed curve.

01:33

To do so, from the Model Explorer, click the Pump Operation Change button.

01:38

In the Pump Operation Change dialog, select the Pump Disturbance Type option,

01:43

and then set the disturbance speed to “0: Speed”.

01:47

The curve selected will dictate the pump speed over time.

01:51

Next to the Speed Curve drop-down, click the Browse (...) button.

01:55

This opens the Curve dialog.

01:57

The model does not currently have a speed curve to use, so one must be created.

02:02

Click the New icon, and you are prompted to name the new curve ID.

02:06

Enter the name “CUR 1, Pump Speed Down”, and then click OK.

02:12

With the Curve dialog still open, click the Set Rows button.

02:16

In the Value field, enter “3”, and then click OK.

02:21

The X/Y table updates to have three rows and two columns.

02:26

You can now enter values into the table to create a pump curve, which updates automatically in line graph form.

02:33

Note that the X-axis is operation time in seconds,

02:36

and the Y-axis represents pump speed ratio.

02:40

Enter the following values by assigning each X-axis value in numerical order,

02:45

followed by the values in the Y-axis column.

02:49

In the X column, enter: 0.00 in row 1

03:01

In the Y column, enter:

03:12

Note that the curve indicates that after two seconds, the pump will drop from full speed (1 for 100% speed)

03:19

to off (0 for 0% speed) within the next one second.

03:24

Click OK to close the Curve dialog.

03:27

In the Speed/Wicket Gate Change Data dialog, make sure the Speed Curve drop-down is set to the name of the new curve you just created.

03:35

Then, click Create to close the dialog and save the settings.

03:40

You are now ready to run both steady-state and surge simulations.

03:45

From the Model Explorer, click the Run Manager button,

03:48

and then, in the Run Manager, open the Surge tab.

03:52

Enable the Hydraulic Run Only option, and then click Run to run the model with a hydraulic simulation.

03:59

Upon successful completion, under Output Source,

04:02

a green light icon appears, and you are ready to run a surge analysis.

04:07

Deselect the Hydraulic Run Only option, and then click Run again to perform a surge analysis.

04:14

Click OK to close the Run Manager.

04:17

If you are prompted about switching to the most recent run output data, select Yes.

04:23

Results from the simulation can be viewed in graph or tabular format.

04:28

For this example, you will view the effect of the surge simulation on flow through a pipe downstream of the pump experiencing

04:35

the shutdown event.

04:37

From the ribbon, InfoWater Pro tab, View panel, click Report Manager.

04:42

In the Report Manager dialog, click the New button to open the Output Report/Graph dialog.

04:49

Under Available Output Sources, select *Active*.Surge.

04:53

Then, open the Graph Report tab and select Surge Pipe Graph.

04:58

Note that in the Data Scope group box, the default option Selected Element(s) is enabled.

05:04

Click Open.

05:06

On the map, select Pipe 10 to view its flow, which indicates a typical pump shutdown response.

05:12

Review the graph and, if needed, click Report to see data for the entire run in a table format.

05:20

Close out of the Report Manager once you are done reviewing.

05:24

The previous results can be compared to a new simulation that is run without a check valve

05:28

to better understand the effects of modelling a check valve in your system.

05:33

Select pump 9_PUMP.

05:36

Click the Pump Surge Data button to open the Pump/Turbine Surge Data dialog.

05:41

Disable the Check Valve Installed option, and then click Update.

05:46

Next, reopen the Run Manager.

05:49

Click the Run button to run a surge analysis.

05:53

Then, click OK to close the dialog.

05:57

Reopen the Report Manager and click Refresh All.

06:01

This refreshes the output for pipe 10 for the latest run.

06:05

You can now review the results using the Report Manager.

06:08

Notice the difference in flow from the previous run as a result of removing the check valve.

06:14

Without the check valve to prevent reverse flow, additional flow can go through the pipe.

06:19

When you finish reviewing the results, Close the Report Manager.

06:23

Shorter shutdown times are going to create greater surge events,

06:27

whereas a slower shutdown will produce less of a transient event.

06:32

For the next step, you use a longer pump speed change operation time

06:36

to increase the pump shutdown time and minimize the impact of the surge event.

06:41

From the map, select pump 9_PUMP.

06:45

Click the Pump Surge Data button, and then in the Pump Surge Data dialog,

06:49

enable the Check Valve Installed option.

06:52

Note that the software should remember the previously entered CV closing time,

06:56

so leave it set to 0.01 seconds.

07:00

Then, click Update.

07:02

From the Model Explorer, click the Pump Operation Change button to open the Speed/Wicket Gate Change Data dialog.

07:09

Then, click Browse (...) to reopen the Curve dialog.

07:13

Make sure the CUR1 curve ID is selected.

07:17

Then, in the X-column, set the value in row 3 to 12.00.

07:22

This greatly extends the pump speed downtime from one second to ten seconds.

07:28

Click Save to save the changes, and then OK to close the dialog.

07:33

In the remaining dialog, click Update to update the changes and close the window.

07:38

Reopen the Run Manager and select Run to begin a surge analysis.

07:43

Reopen the Report Manager and click Refresh All to refresh the output for pipe 10 for the latest run and view the results.

07:51

Notice the surge event is greatly reduced.

07:54

This process could be repeated with different shutdown times to identify how slow pump shutdown would need to be

08:00

to avoid a surge event.

InfoSurge Pro allows hydraulic transients to be created by providing a curve that alters pump and valve operations, as well as junction demand changes. Then, the simulation results from different operational conditions can be compared. In this example, transients are created from pump shutdown events using the Pump Speed Change option.

The Pump Surge Data dialog box is used to specify how the selected pump is modeled. To prevent flow reversal through the pump:

Changes in pump operating speeds produce transients. Time-dependent speed ratios can be applied to pumps as a speed curve.

The selected curve dictates the pump speed over time.

The model does not currently have a speed curve to use, so one must be created. To create the speed curve:

The X/Y table updates with three rows and two columns for entering values to create a pump curve, which updates automatically in line graph form.

In the table, enter the following values in the X-axis column (operation time in seconds):

Enter the following pump speed ratio values in the Y-axis column:

The curve indicates that after two seconds, the pump will drop from full speed (1 for 100% speed) to off (0 for 0% speed) within the next one second.

Now, both steady-state and surge simulations can be run. To run the model with a hydraulic simulation:

Upon successful completion, under Output Source, a green light icon appears.

Now, a surge analysis can be run:

Results from the simulation can be viewed in graph or tabular format. This example views the effect of the surge simulation on flow through a pipe downstream of the pump experiencing the shutdown event.

Note that in the Data Scope group box, the default option Selected Element(s) is enabled.

Next, compare these results to a new simulation run without a check valve, to better understand the effects of modeling a check valve in a system.

Notice the difference in flow from the previous run. Without the check valve to prevent reverse flow, additional flow can go through the pipe.

While shorter shutdown times create greater surge events, a slower shutdown produces less of a transient event.

To use a longer pump speed change operation time to increase the pump shutdown time and minimize the impact of the surge event:

This greatly extends the pump speed downtime from 1 second to 10 seconds.

To refresh the output for pipe 10 and view the results:

Notice that the surge event is greatly reduced.

This process could be repeated with different shutdown times to identify how slow the pump shutdown would need to be to avoid a surge event.

How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2025 Autodesk Inc. All rights reserved

Sign in to start learning

Sign in for unlimited free access to all learning content.Save your progress

Take assessments

Receive personalized recommendations

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.