& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

Professional CAD/CAM tools built on Inventor and AutoCAD

Transcript

00:04

To best understand how InfoSurge Pro performs a surge analysis,

00:08

it is a good idea to experiment with a simple single-pipe model.

00:12

This can help you understand the various concepts and common procedures involved in running simulations and examining the results.

00:20

To begin, double-click the desired project .aprx file to open ArcGIS Pro.

00:26

Once the project starts, click the InfoWater Pro tab to open the InfoWater Pro ribbon.

00:32

In the Project panel, click Initialize.

00:36

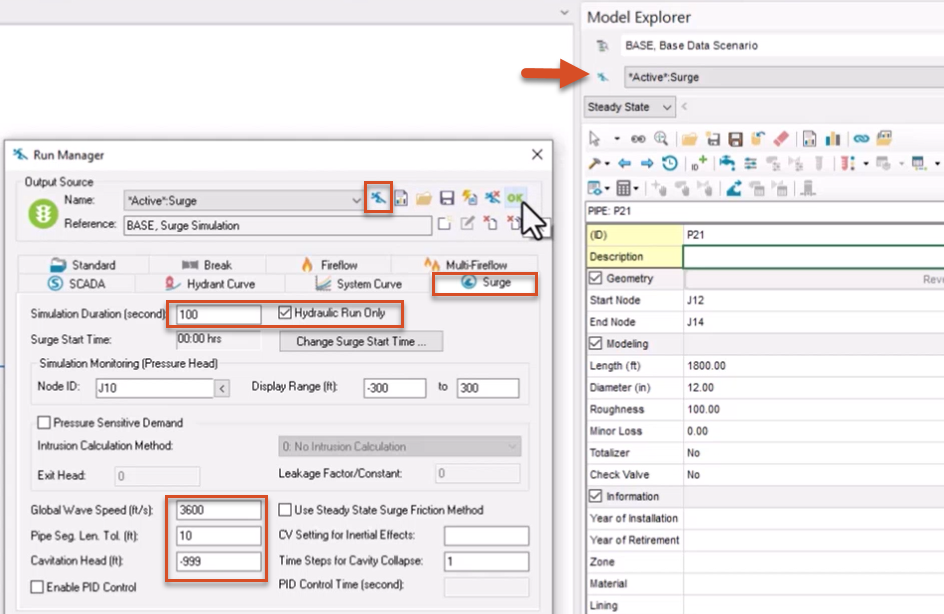

From the Model Explorer, click the Run Manager button to open the Run Manager dialog.

00:41

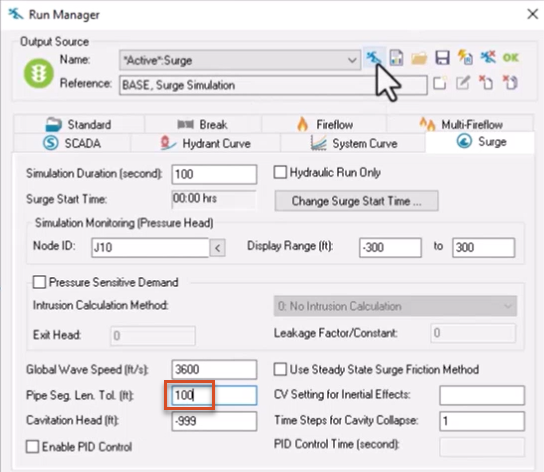

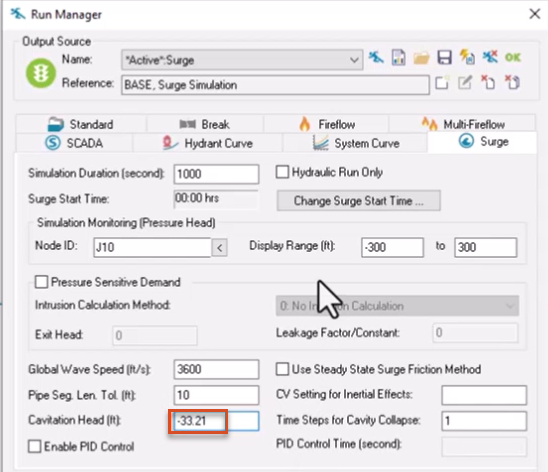

From the Surge tab: Set the Global Wave Speed to 3600 feet per second.

00:47

Set the Pipe Segment Length Tolerance to 10 feet.

00:52

Set the Cavitation Head to -999 feet.

00:56

Cavitation head is the head at which fluid will cavitate.

01:00

Note that this is a hypothetical value, as it is typically around -33 feet.

01:06

Set the Simulation Duration to 100 seconds.

01:09

Then, enable the Hydraulic Run Only option.

01:13

Click the Run button to run a hydraulic simulation, and then OK to close the Run Manager dialog.

01:20

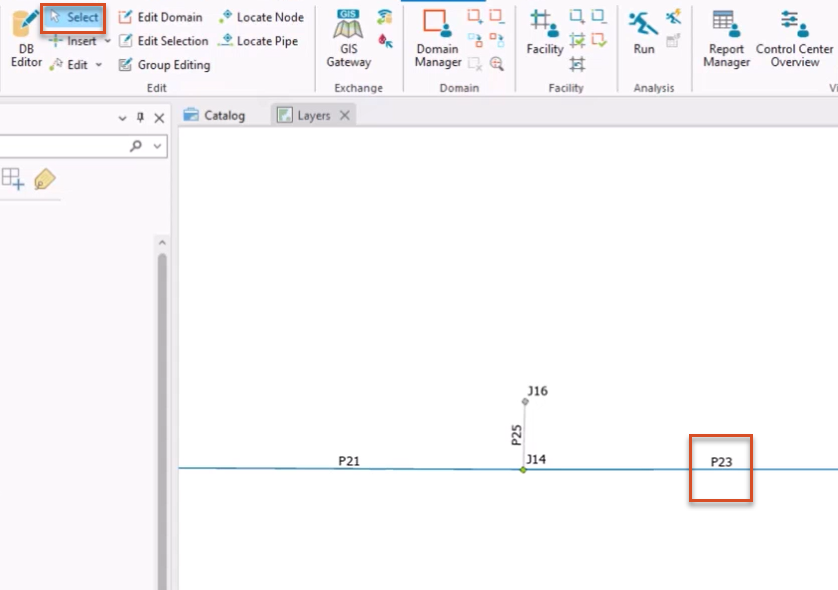

With the Select tool active, select the pipe with the ID P23.

01:26

In the Model Explorer, scroll down to view the hydraulic results for the steady state simulation.

01:32

Note that in this example, the Pipe Flow is 2663.98 gallons per minute,

01:39

with a Velocity of 7.56 feet per second.

01:43

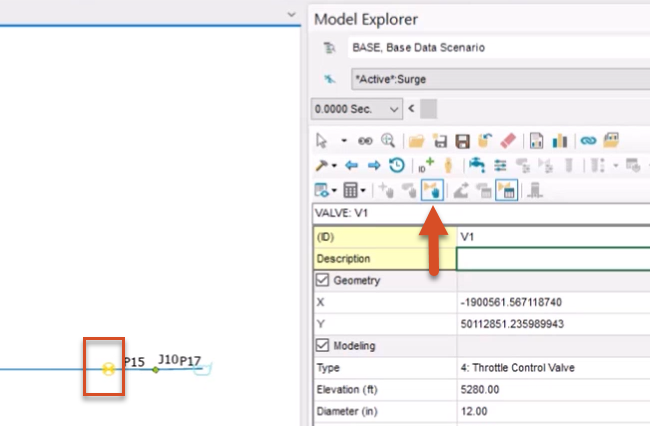

Now, from the map, select valve V1 to view its hydraulic results.

01:47

Note that the Upstream Hydraulic Pressure is 3.86 psi.

01:52

You can use these results to calculate the approximate surge pressure

01:57

immediately upstream of Valve V1 using the Joukowski equation.

02:01

This equation multiplies the change in velocity by the pipe wave speed.

02:06

This number is then divided by gravity and results in the change in hydraulic head,

02:10

which uses feet for its units.

02:13

The final calculation would be converting this head value to pressure by dividing by 2.31.

02:19

For this example, the simulation calculates results as a steady state, so you would use the velocity 7.56 feet per second.

02:29

The selected pipe does not have a wave speed, so the global wave speed of 3600 feet per second would be used.

02:36

To maintain the correct units for these calculations,

02:39

gravity would be 32.2 feet per second squared.

02:44

Using these numbers, the final calculation for the potential surge pressure would be 365 psi.

02:51

Valve V1 is a surge Active Valve (AV), assigned a stem change curve that closes the valve within ten seconds.

02:59

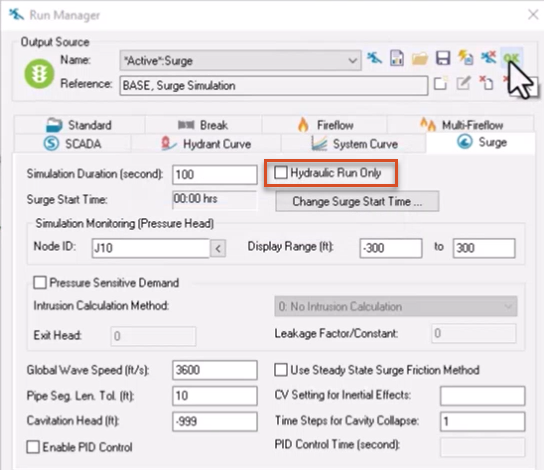

To view the upstream pressure profile of the valve, reopen the Run Manager dialog and uncheck the Hydraulic Run Only option.

03:06

Run another surge analysis, and then click OK when it completes.

03:12

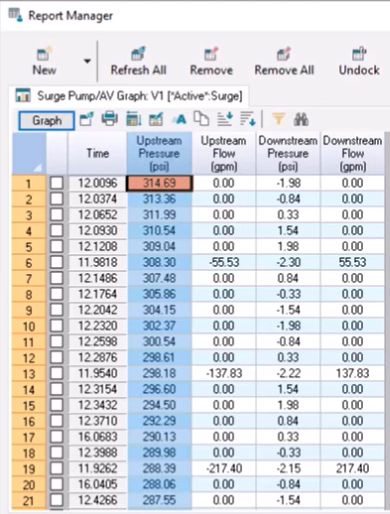

From the ribbon, View panel, click Report Manager.

03:18

In the Report Manager dialog, click New.

03:22

Select *Active*:Surge as the Available Output Source.

03:26

From the Graph Report tab, pick Surge Pump/AV Graph, and then click Open.

03:32

Now, select valve V1 to view its upstream pressure profile.

03:37

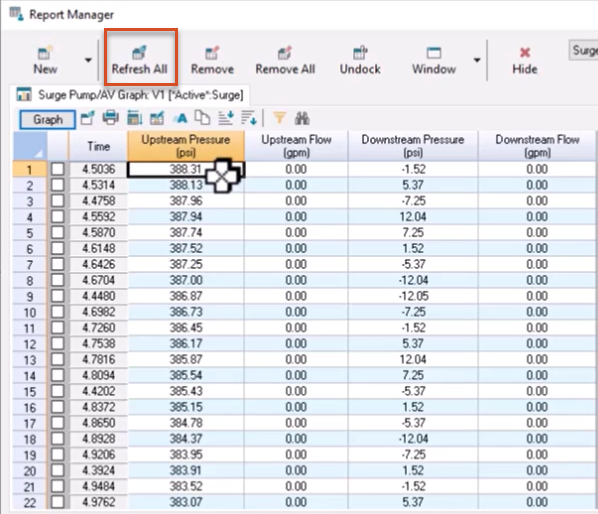

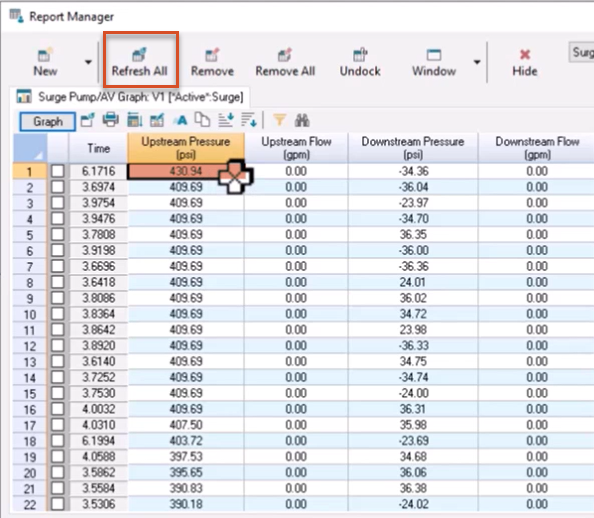

You can also click Report, right-click the Upstream Pressure (psi) header,

03:43

and then pick Sort Descending to bring the largest value to the top row.

03:48

In this example, the maximum surge pressure upstream peaks at 314.69 psi.

03:55

Click Hide to close the dialog.

03:57

Now, change the closure time of valve V1 to see how it impacts results.

04:04

Select valve V1 again, and then from the Model Explorer, click the AV (TCV) Operation Change button.

04:11

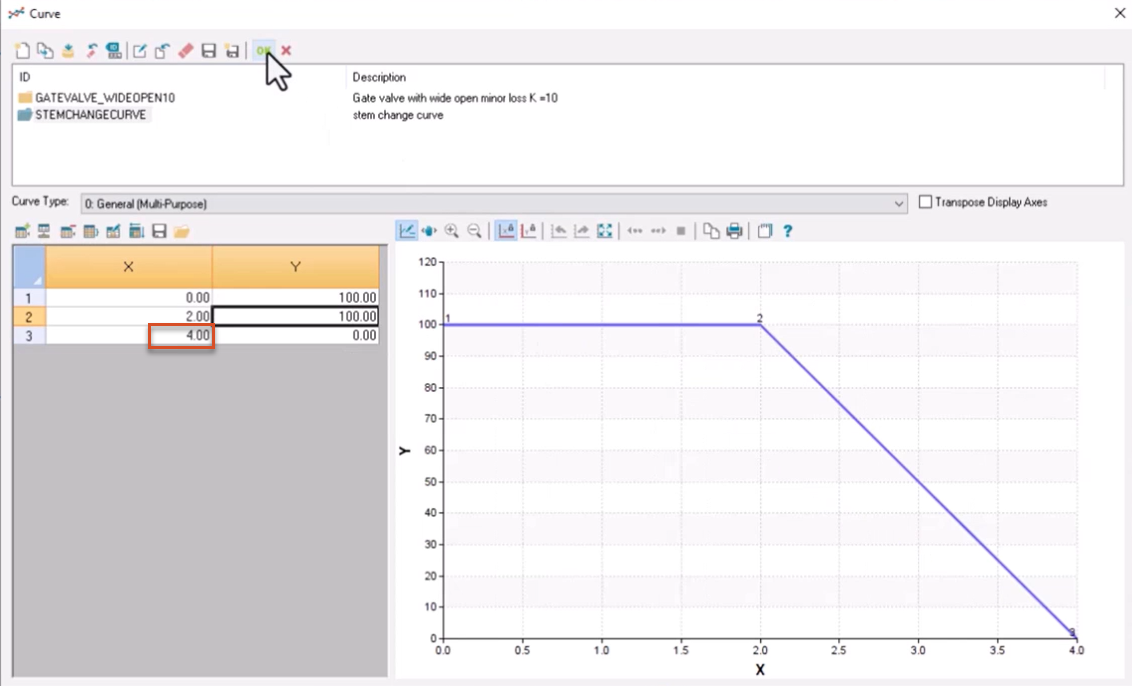

In the dialog that opens, next to the Stem Change Curve drop-down,

04:14

click the Browse button to open the Curve dialog.

04:18

With STEMCHANGECURVE selected, in the curve table, adjust the value in the third row of the X column to 4.

04:25

This changes the valve time from ten seconds to two seconds.

04:28

Click OK to save the changes and close the dialog.

04:33

In the AV (TCV) Operation Change Data dialog, click Update.

04:38

Now, open the Run Manager again, run another analysis, and then click OK when it is complete.

04:46

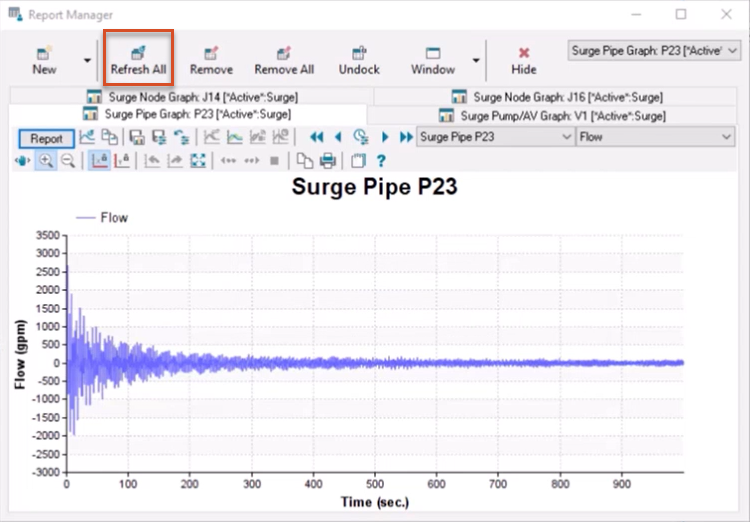

Reopen the Report Manager and click Refresh All to update the results.

04:51

Note that with the decrease in closure time, the maximum upstream pressure increased to 388.31 psi.

04:59

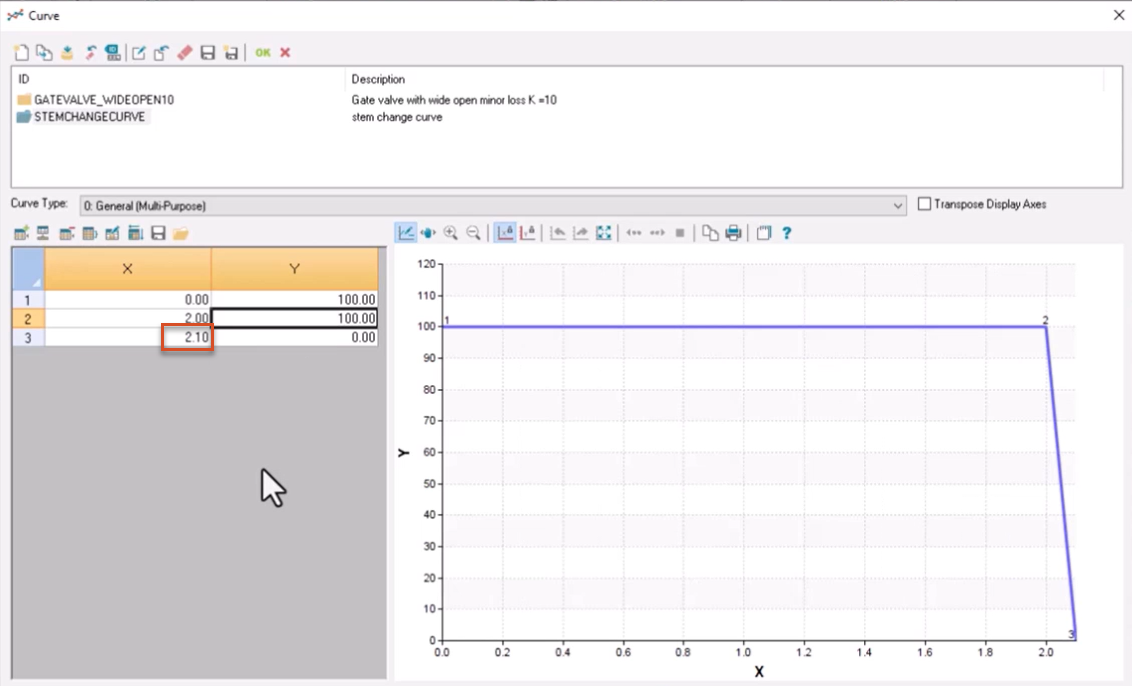

Repeat the process of changing the valve closure time, adjusting it to 2.10.

05:06

This changes the closure time from two seconds to 0.1 seconds.

05:12

Run another surge analysis and view the results in the Report Manager.

05:17

In this example, the maximum upstream pressure increased again to 430.94 psi.

05:25

Click Hide to close the dialog.

05:28

Try making various other changes to the network and perform additional runs to see how they impact results.

05:36

To simulate the effect of changing the pipe segment length tolerance:

05:40

For valve V1, in the Run Manager dialog, Surge tab, set the Pipe Segment Length Tolerance to 100 feet,

05:48

and then change it to 1 foot, performing two separate runs.

05:52

View the results in the Report Manager, noting the changes in maximum upstream pressure and the time each run takes to complete.

06:02

Generally, the larger the pipe segment length tolerance value, the longer the run takes to complete.

06:09

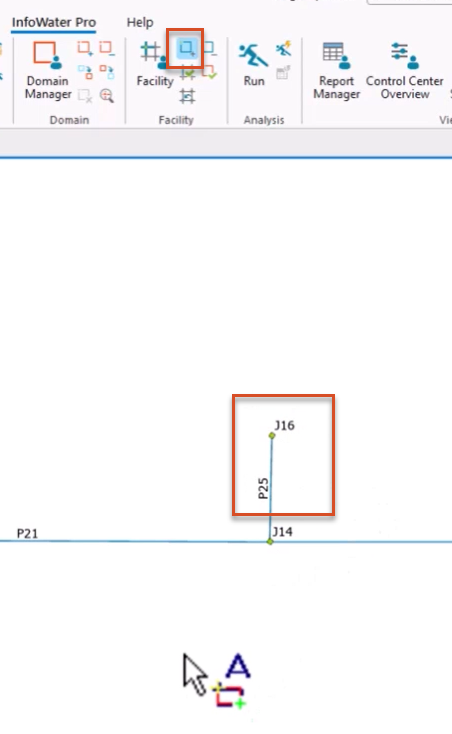

To simulate a dead end wave reflection: From the ribbon, Facility tab, click Activate Facility.

06:18

With the tool active, on the map, click and drag to select pipe P25 and junction J16.

06:26

From the Edit panel, enable the Select tool.

06:31

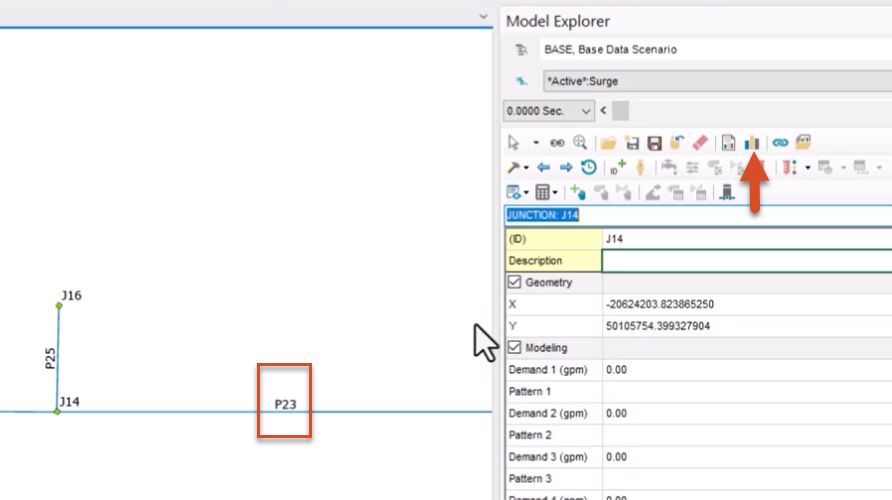

Reopen the Run Manager, change the Pipe Segment Length Tolerance to 100 feet, and then enable Hydraulic Run Only.

06:39

Perform another run, and then pick junctions J16 and J14 in turn to view their results in the Model Explorer.

06:49

Observe that both junctions have a static pressure of 23.59 psi.

06:57

Open the Run Manager once again, disable the Hydraulic Run Only option, and run the simulation one more time.

07:06

Close the Run Manager, and view the Report Manager results for J14 and J16,

07:13

noting their maximum pressures.

07:16

In this example, the pressure at J16 is higher than it is for J14.

07:20

Because J16 is a “dead end,” the transient wave is reflected here at twice the pressure head of the original wave.

07:28

To simulate how friction impacts pipe flow over time:

07:33

Select pipe P23.

07:36

Then, from the Model Explorer, click Graph to view its flow profile.

07:41

Note that flow decreases as time progresses.

07:44

In the Run Manager, Surge tab, change the Simulation Duration to 1000 seconds.

07:52

Rerun the surge analysis, and then refresh the results in the Report Manager.

07:59

Note that by viewing results over a greater time,

08:03

you can observe that the pipe flow eventually approaches a steady state.

08:07

To simulate a cavitation event:

08:11

From the Run Manager, Surge tab, adjust the Cavitation Head to -33.21 feet.

08:18

Run another surge analysis and then, in the Report Manager, review the refreshed results for valve V1 .

08:27

Note that the surge pressure does not approach 0 over time.

08:32

This is because the cavitation head changed from -999 to -33.21 feet, the head at which cavitation typically occurs.

Video transcript

00:04

To best understand how InfoSurge Pro performs a surge analysis,

00:08

it is a good idea to experiment with a simple single-pipe model.

00:12

This can help you understand the various concepts and common procedures involved in running simulations and examining the results.

00:20

To begin, double-click the desired project .aprx file to open ArcGIS Pro.

00:26

Once the project starts, click the InfoWater Pro tab to open the InfoWater Pro ribbon.

00:32

In the Project panel, click Initialize.

00:36

From the Model Explorer, click the Run Manager button to open the Run Manager dialog.

00:41

From the Surge tab: Set the Global Wave Speed to 3600 feet per second.

00:47

Set the Pipe Segment Length Tolerance to 10 feet.

00:52

Set the Cavitation Head to -999 feet.

00:56

Cavitation head is the head at which fluid will cavitate.

01:00

Note that this is a hypothetical value, as it is typically around -33 feet.

01:06

Set the Simulation Duration to 100 seconds.

01:09

Then, enable the Hydraulic Run Only option.

01:13

Click the Run button to run a hydraulic simulation, and then OK to close the Run Manager dialog.

01:20

With the Select tool active, select the pipe with the ID P23.

01:26

In the Model Explorer, scroll down to view the hydraulic results for the steady state simulation.

01:32

Note that in this example, the Pipe Flow is 2663.98 gallons per minute,

01:39

with a Velocity of 7.56 feet per second.

01:43

Now, from the map, select valve V1 to view its hydraulic results.

01:47

Note that the Upstream Hydraulic Pressure is 3.86 psi.

01:52

You can use these results to calculate the approximate surge pressure

01:57

immediately upstream of Valve V1 using the Joukowski equation.

02:01

This equation multiplies the change in velocity by the pipe wave speed.

02:06

This number is then divided by gravity and results in the change in hydraulic head,

02:10

which uses feet for its units.

02:13

The final calculation would be converting this head value to pressure by dividing by 2.31.

02:19

For this example, the simulation calculates results as a steady state, so you would use the velocity 7.56 feet per second.

02:29

The selected pipe does not have a wave speed, so the global wave speed of 3600 feet per second would be used.

02:36

To maintain the correct units for these calculations,

02:39

gravity would be 32.2 feet per second squared.

02:44

Using these numbers, the final calculation for the potential surge pressure would be 365 psi.

02:51

Valve V1 is a surge Active Valve (AV), assigned a stem change curve that closes the valve within ten seconds.

02:59

To view the upstream pressure profile of the valve, reopen the Run Manager dialog and uncheck the Hydraulic Run Only option.

03:06

Run another surge analysis, and then click OK when it completes.

03:12

From the ribbon, View panel, click Report Manager.

03:18

In the Report Manager dialog, click New.

03:22

Select *Active*:Surge as the Available Output Source.

03:26

From the Graph Report tab, pick Surge Pump/AV Graph, and then click Open.

03:32

Now, select valve V1 to view its upstream pressure profile.

03:37

You can also click Report, right-click the Upstream Pressure (psi) header,

03:43

and then pick Sort Descending to bring the largest value to the top row.

03:48

In this example, the maximum surge pressure upstream peaks at 314.69 psi.

03:55

Click Hide to close the dialog.

03:57

Now, change the closure time of valve V1 to see how it impacts results.

04:04

Select valve V1 again, and then from the Model Explorer, click the AV (TCV) Operation Change button.

04:11

In the dialog that opens, next to the Stem Change Curve drop-down,

04:14

click the Browse button to open the Curve dialog.

04:18

With STEMCHANGECURVE selected, in the curve table, adjust the value in the third row of the X column to 4.

04:25

This changes the valve time from ten seconds to two seconds.

04:28

Click OK to save the changes and close the dialog.

04:33

In the AV (TCV) Operation Change Data dialog, click Update.

04:38

Now, open the Run Manager again, run another analysis, and then click OK when it is complete.

04:46

Reopen the Report Manager and click Refresh All to update the results.

04:51

Note that with the decrease in closure time, the maximum upstream pressure increased to 388.31 psi.

04:59

Repeat the process of changing the valve closure time, adjusting it to 2.10.

05:06

This changes the closure time from two seconds to 0.1 seconds.

05:12

Run another surge analysis and view the results in the Report Manager.

05:17

In this example, the maximum upstream pressure increased again to 430.94 psi.

05:25

Click Hide to close the dialog.

05:28

Try making various other changes to the network and perform additional runs to see how they impact results.

05:36

To simulate the effect of changing the pipe segment length tolerance:

05:40

For valve V1, in the Run Manager dialog, Surge tab, set the Pipe Segment Length Tolerance to 100 feet,

05:48

and then change it to 1 foot, performing two separate runs.

05:52

View the results in the Report Manager, noting the changes in maximum upstream pressure and the time each run takes to complete.

06:02

Generally, the larger the pipe segment length tolerance value, the longer the run takes to complete.

06:09

To simulate a dead end wave reflection: From the ribbon, Facility tab, click Activate Facility.

06:18

With the tool active, on the map, click and drag to select pipe P25 and junction J16.

06:26

From the Edit panel, enable the Select tool.

06:31

Reopen the Run Manager, change the Pipe Segment Length Tolerance to 100 feet, and then enable Hydraulic Run Only.

06:39

Perform another run, and then pick junctions J16 and J14 in turn to view their results in the Model Explorer.

06:49

Observe that both junctions have a static pressure of 23.59 psi.

06:57

Open the Run Manager once again, disable the Hydraulic Run Only option, and run the simulation one more time.

07:06

Close the Run Manager, and view the Report Manager results for J14 and J16,

07:13

noting their maximum pressures.

07:16

In this example, the pressure at J16 is higher than it is for J14.

07:20

Because J16 is a “dead end,” the transient wave is reflected here at twice the pressure head of the original wave.

07:28

To simulate how friction impacts pipe flow over time:

07:33

Select pipe P23.

07:36

Then, from the Model Explorer, click Graph to view its flow profile.

07:41

Note that flow decreases as time progresses.

07:44

In the Run Manager, Surge tab, change the Simulation Duration to 1000 seconds.

07:52

Rerun the surge analysis, and then refresh the results in the Report Manager.

07:59

Note that by viewing results over a greater time,

08:03

you can observe that the pipe flow eventually approaches a steady state.

08:07

To simulate a cavitation event:

08:11

From the Run Manager, Surge tab, adjust the Cavitation Head to -33.21 feet.

08:18

Run another surge analysis and then, in the Report Manager, review the refreshed results for valve V1 .

08:27

Note that the surge pressure does not approach 0 over time.

08:32

This is because the cavitation head changed from -999 to -33.21 feet, the head at which cavitation typically occurs.

To best understand how InfoSurge Pro performs a surge analysis, it is a good idea to experiment with a simple single-pipe model. This facilitates identification of the various concepts and common procedures involved in running simulations and examining the results.

Cavitation head is the head at which fluid will cavitate. Note that this is a hypothetical value, as it is typically around -33 feet.

In this example, the Pipe Flow is 2663.98 gallons per minute, with a Velocity of 7.56 feet per second.

Note that the Upstream Hydraulic Pressure is 3.86 psi.

This equation multiplies the change in velocity by the pipe wave speed, and then divides this number by gravity, resulting in the change in hydraulic head, in feet. The final calculation, to convert this head value to pressure, is to divide by 2.31.

For this example, the simulation calculates results as a steady state, so the velocity 7.56 feet per second is used. The selected pipe does not have a wave speed, so the global wave speed of 3600 feet per second is used. To maintain the correct units for these calculations, gravity is 32.2 feet per second squared. Using these numbers, the final calculation for the potential surge pressure is 365 psi.

Valve V1 is a surge Active Valve (AV), assigned a stem change curve that closes the valve within 10 seconds. To view the upstream pressure profile of the valve:

In this example, the maximum surge pressure upstream peaks at 314.69 psi.

Now, change the closure time of valve V1 to see how it impacts results.

This decreases the valve time from 10 seconds to 2 seconds.

With the decrease in closure time, the maximum upstream pressure increased to 388.31 psi.

In this example, the maximum upstream pressure increased again to 430.94 psi.

Try making various other changes to the network and perform additional runs to see how they impact results.

To simulate the effect of changing the pipe segment length tolerance:

Generally, the larger the pipe segment length tolerance value, the longer the run takes to complete.

To simulate a dead end wave reflection:

Observe that both junctions have a static pressure of 23.59 psi.

In this example, the pressure at J16 is higher than it is for J14. Because J16 is a “dead end,” the transient wave is reflected here at twice the pressure head of the original wave.

To simulate how friction impacts pipe flow over time:

Note that by viewing results over a greater time, the pipe flow eventually approaches a steady state.

To simulate a cavitation event:

Note that the surge pressure does not approach 0 over time. This is because the cavitation head changed from -999 to -33.21 feet, the head at which cavitation typically occurs.

How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2025 Autodesk Inc. All rights reserved

Sign in to start learning

Sign in for unlimited free access to all learning content.Save your progress

Take assessments

Receive personalized recommendations

May we collect and use your data?

Learn more about the Third Party Services we use and our Privacy Statement.May we collect and use your data to tailor your experience?

Explore the benefits of a customized experience by managing your privacy settings for this site or visit our Privacy Statement to learn more about your options.