& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

Professional CAD/CAM tools built on Inventor and AutoCAD

Transcript

00:04

Once you have set up your hydraulic model,

00:06

you can run a steady state simulation and review the hydraulic status report.

00:12

The run manager is used as the entry point

00:14

for modifying the options in settings for a simulation

00:17

running and troubleshooting a simulation

00:20

and managing the output sources

00:24

to begin.

00:25

Double click the desired project dot APR X file to open

00:29

Agis Pro.

00:31

Once the project starts,

00:32

click the info water pro tab to open the info water pro ribbon

00:38

in the project panel, click initialize

00:42

in the model explorer operation tab expand simulation report

00:47

and then double click base base simulation report.

00:54

The simulation report allows you to create and customize the simulation,

00:58

run text report

01:01

in the simulation report dialog box select full for the hydraulic status

01:06

so that the status report will also include

01:09

information from each trial of each hydraulic analysis.

01:14

Also enable the generate network summary table

01:17

to create the report and generate warning messages

01:20

options so that you can see any error

01:23

or warning messages that occur during a simulation

01:27

click. OK.

01:30

Switch to the attribute tab in the model explorer

01:34

enable refresh output to automatically refresh

01:36

your output data after every simulation run

01:40

next open the run manager

01:43

in the standard tab set the report options to base base simulation

01:48

report to set the scope and content of the simulation report.

01:54

The simulation options determine the simulation parameters

01:58

for this exercise. Keep this set to base base simulation option

02:04

for the time setting.

02:05

Choose ss steady state analysis,

02:08

which is a time step that has already been configured for this simulation.

02:14

Then click run to run the simulation.

02:18

Notice the stoplight icon,

02:21

the green light indicates a successful simulation.

02:24

If this were yellow,

02:26

then it would have meant that the simulation received only partial results.

02:30

Then you would need to fix any warnings that appear in the log report.

02:35

Red would indicate a failed simulation

02:38

and gray would indicate that the simulation did not produce any output

02:43

results are available for any simulation that finishes with a green or yellow light

02:50

to open the text report in the toolbar, click report,

02:54

an html file opens in your web browser,

02:58

look through the report to see the analysis results of your simulation.

03:03

You can find answers to specific questions such as how many pipes are in the model.

03:08

In this case, there are 847

03:12

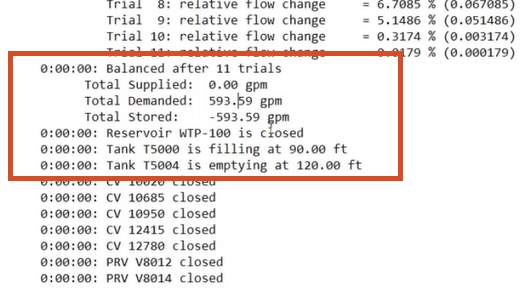

scroll down to see that it took 11 trials for the model to balance.

03:17

And below that,

03:18

you can see the system totals for supply demand and storage.

03:24

The total system demand is 593.59 gallons per minute.

03:30

If the supply reads as zero as it does here,

03:34

you can determine where the water came from.

03:37

In this example, it was coming from one of the tanks. T 5004, which was emptying

03:44

when you are finished, you can close the text report and click ok,

03:48

to exit the run manager.

Video transcript

00:04

Once you have set up your hydraulic model,

00:06

you can run a steady state simulation and review the hydraulic status report.

00:12

The run manager is used as the entry point

00:14

for modifying the options in settings for a simulation

00:17

running and troubleshooting a simulation

00:20

and managing the output sources

00:24

to begin.

00:25

Double click the desired project dot APR X file to open

00:29

Agis Pro.

00:31

Once the project starts,

00:32

click the info water pro tab to open the info water pro ribbon

00:38

in the project panel, click initialize

00:42

in the model explorer operation tab expand simulation report

00:47

and then double click base base simulation report.

00:54

The simulation report allows you to create and customize the simulation,

00:58

run text report

01:01

in the simulation report dialog box select full for the hydraulic status

01:06

so that the status report will also include

01:09

information from each trial of each hydraulic analysis.

01:14

Also enable the generate network summary table

01:17

to create the report and generate warning messages

01:20

options so that you can see any error

01:23

or warning messages that occur during a simulation

01:27

click. OK.

01:30

Switch to the attribute tab in the model explorer

01:34

enable refresh output to automatically refresh

01:36

your output data after every simulation run

01:40

next open the run manager

01:43

in the standard tab set the report options to base base simulation

01:48

report to set the scope and content of the simulation report.

01:54

The simulation options determine the simulation parameters

01:58

for this exercise. Keep this set to base base simulation option

02:04

for the time setting.

02:05

Choose ss steady state analysis,

02:08

which is a time step that has already been configured for this simulation.

02:14

Then click run to run the simulation.

02:18

Notice the stoplight icon,

02:21

the green light indicates a successful simulation.

02:24

If this were yellow,

02:26

then it would have meant that the simulation received only partial results.

02:30

Then you would need to fix any warnings that appear in the log report.

02:35

Red would indicate a failed simulation

02:38

and gray would indicate that the simulation did not produce any output

02:43

results are available for any simulation that finishes with a green or yellow light

02:50

to open the text report in the toolbar, click report,

02:54

an html file opens in your web browser,

02:58

look through the report to see the analysis results of your simulation.

03:03

You can find answers to specific questions such as how many pipes are in the model.

03:08

In this case, there are 847

03:12

scroll down to see that it took 11 trials for the model to balance.

03:17

And below that,

03:18

you can see the system totals for supply demand and storage.

03:24

The total system demand is 593.59 gallons per minute.

03:30

If the supply reads as zero as it does here,

03:34

you can determine where the water came from.

03:37

In this example, it was coming from one of the tanks. T 5004, which was emptying

03:44

when you are finished, you can close the text report and click ok,

03:48

to exit the run manager.

Once you have set up your hydraulic model, you can run a steady state simulation and review the hydraulic status report. The Run Manager is used as the entry point for modifying the options and settings for a simulation, running and troubleshooting a simulation, and managing the output sources.

The simulation report allows you to create and customize the simulation run text report.

The green light indicates a successful simulation. If this were yellow, then it would have meant that the simulation received only partial results, and you would need to fix any warnings that appear in the log report. Red would indicate a failed simulation, and gray would indicate that the simulation did not produce any output. Results are available for any simulation that finishes with a green or yellow light.

Scroll down to see that it took 11 trials for the model to balance. And below that, you can see the system totals for supply, demand, and storage. The total system demand is 593.59 gallons per minute. If the supply reads as zero as it does here, you can determine where the water came from. In this example, it was coming from one of the tanks, T5004, which was emptying.

How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | Legal | © 2025 Autodesk Inc. All rights reserved

Sign in to start learning

Sign in for unlimited free access to all learning content.Save your progress

Take assessments

Receive personalized recommendations