& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Transcript

00:03

A prerequisite for network model calibration is that overall flow balances—

00:08

—demands, leakage, and transfers—

00:12

—are in reasonable agreement for both the model and the real-world network for the specified time period.

00:19

To determine the performance of the current network,

00:21

and to validate that a calibration exercise needs to take place,

00:26

you need to compare the simulated pressure and flows with observed values.

00:31

The simulated values are from the results of a normal hydraulic simulation,

00:36

and the observed values are provided by a live data configuration.

00:41

You can then compare the live and predicted results using either graphs or grid reports.

00:48

Observed vs Predicted Reports allow you to compare summary flow, pressure,

00:54

or reservoir depth for all network objects of an appropriate type in the model that are linked to live data.

01:01

Simulation Graphs allow you to produce graphs of the comparison between observed

01:06

and predicted data for all the selected objects of appropriate type that are linked to live data.

01:12

For this exercise, you will produce an observed versus predicted report.

01:17

Begin by running a normal hydraulic simulation.

01:21

Create a new Run Group object.

01:23

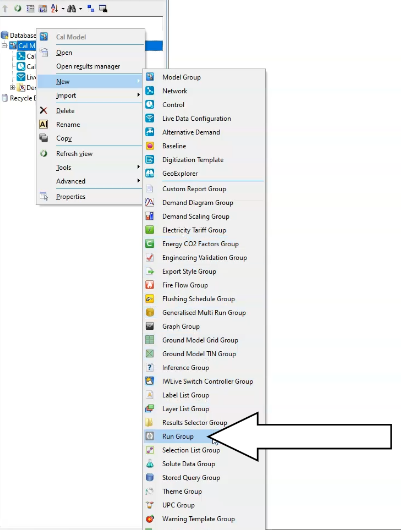

In the Model Group, right-click the Calibration Model model group and select New > Run Group.

01:32

Then, right-click the new run group and select New > Run from the flyout.

01:39

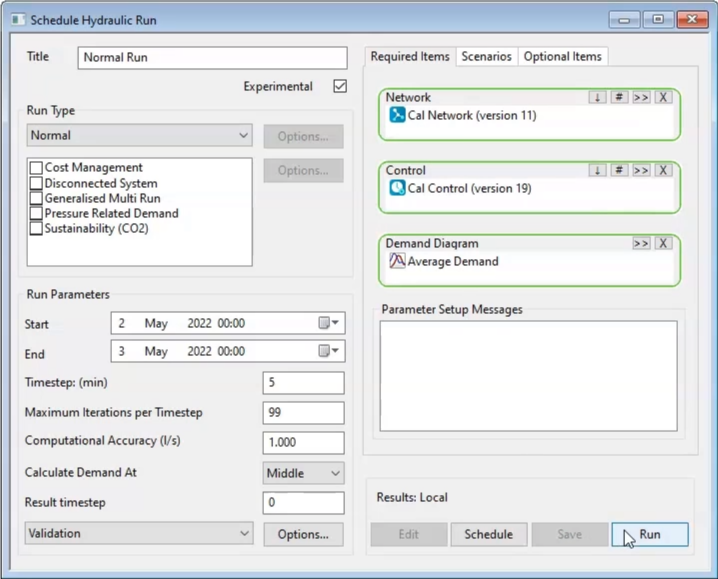

The Schedule Hydraulic Run dialog opens.

01:43

In the Title field, type a name for the run.

01:46

In this example, “Normal Run” is entered.

01:50

Check the box next to Experimental.

01:53

Then, from the Model Group, drag and drop the Calibration network into the Network panel in the dialog.

02:01

The Control and Demand Diagram panels populate as well.

02:05

Click Save, and then Run.

02:08

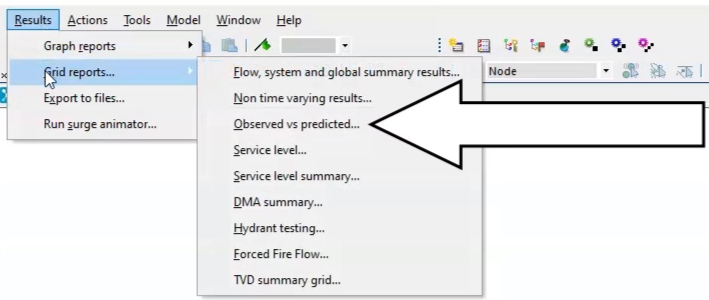

Next, to produce the observed versus simulated grid,

02:12

double click on the Cal Control simulation results, then expand the Results menu and select Grid reports,

02:21

and then from the flyout, select Observed vs predicted.

02:26

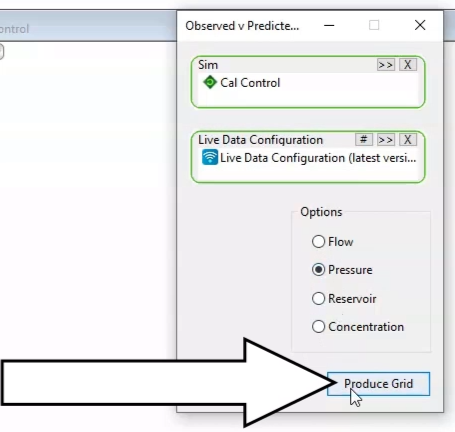

The Grid Report (Observed vs Predicted) dialog box appears.

02:31

From the Model Group, drag and drop the Normal Run simulation into the Sim panel,

02:38

and then drag and drop the live data configuration into the Live Data Configuration panel.

02:45

Under Options, enable Pressure, and then click Produce Grid.

02:51

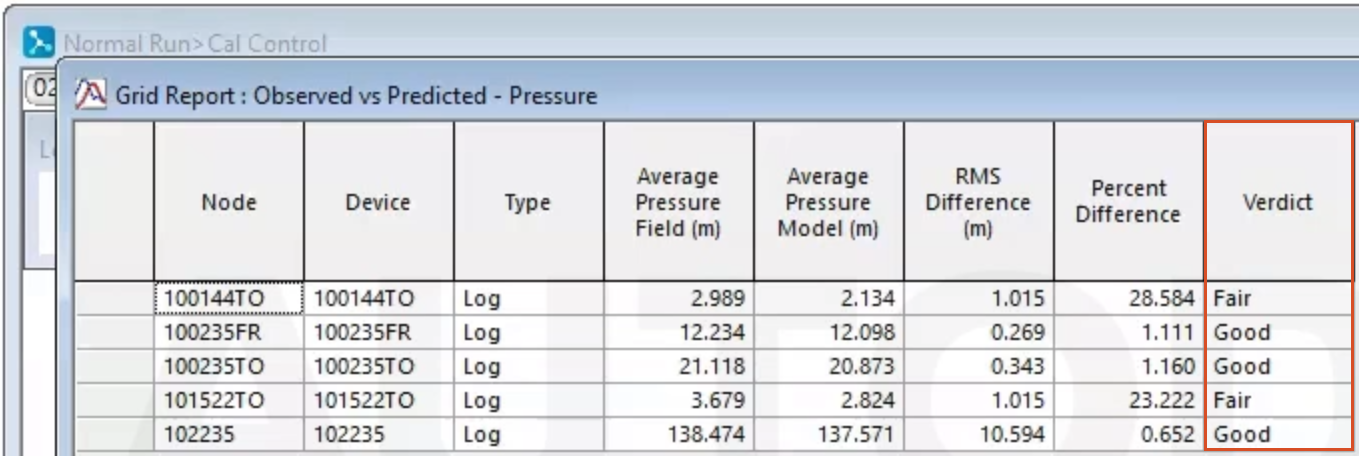

A table appears, providing some values and a verdict for each point in the network that has a live data pressure feed associated with it.

03:00

In this example, you can see that three points have a fair verdict;

03:05

therefore, running the automatic calibration module may improve the performance.

00:03

A prerequisite for network model calibration is that overall flow balances—

00:08

—demands, leakage, and transfers—

00:12

—are in reasonable agreement for both the model and the real-world network for the specified time period.

00:19

To determine the performance of the current network,

00:21

and to validate that a calibration exercise needs to take place,

00:26

you need to compare the simulated pressure and flows with observed values.

00:31

The simulated values are from the results of a normal hydraulic simulation,

00:36

and the observed values are provided by a live data configuration.

00:41

You can then compare the live and predicted results using either graphs or grid reports.

00:48

Observed vs Predicted Reports allow you to compare summary flow, pressure,

00:54

or reservoir depth for all network objects of an appropriate type in the model that are linked to live data.

01:01

Simulation Graphs allow you to produce graphs of the comparison between observed

01:06

and predicted data for all the selected objects of appropriate type that are linked to live data.

01:12

For this exercise, you will produce an observed versus predicted report.

01:17

Begin by running a normal hydraulic simulation.

01:21

Create a new Run Group object.

01:23

In the Model Group, right-click the Calibration Model model group and select New > Run Group.

01:32

Then, right-click the new run group and select New > Run from the flyout.

01:39

The Schedule Hydraulic Run dialog opens.

01:43

In the Title field, type a name for the run.

01:46

In this example, “Normal Run” is entered.

01:50

Check the box next to Experimental.

01:53

Then, from the Model Group, drag and drop the Calibration network into the Network panel in the dialog.

02:01

The Control and Demand Diagram panels populate as well.

02:05

Click Save, and then Run.

02:08

Next, to produce the observed versus simulated grid,

02:12

double click on the Cal Control simulation results, then expand the Results menu and select Grid reports,

02:21

and then from the flyout, select Observed vs predicted.

02:26

The Grid Report (Observed vs Predicted) dialog box appears.

02:31

From the Model Group, drag and drop the Normal Run simulation into the Sim panel,

02:38

and then drag and drop the live data configuration into the Live Data Configuration panel.

02:45

Under Options, enable Pressure, and then click Produce Grid.

02:51

A table appears, providing some values and a verdict for each point in the network that has a live data pressure feed associated with it.

03:00

In this example, you can see that three points have a fair verdict;

03:05

therefore, running the automatic calibration module may improve the performance.

A prerequisite for network model calibration is that overall flow balances—demands, leakage, and transfers—are in reasonable agreement for both the model and the real-world network for the specified time period.

To determine the performance of the current network, and to validate that a calibration exercise needs to take place, compare the simulated pressure and flows with observed values:

Compare the live and predicted results using either graphs or grid reports:

To produce an observed versus predicted report:

Note: The Control and Demand Diagram panels populate as well.

To produce the observed versus simulated grid:

A table appears. Two points have a Fair verdict:

Therefore, running the automatic calibration module may improve the performance.