& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Transcript

00:04

Let's use the standard belt to define the required pulleys.

00:08

Calculate the proper location of an idler based on the belt length and insert a portion of the detailed belt in a drawing.

00:16

Not all standardized components are as convenient as bearings or fasteners that come in uniform sizes.

00:23

Objects like belts come in specific length, but you have to be able to make them fit in your design.

00:31

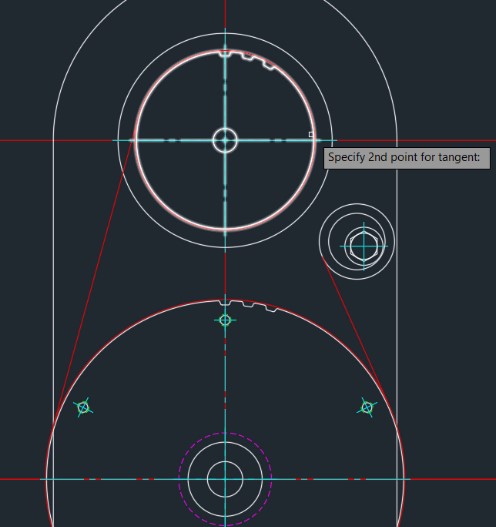

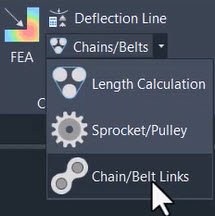

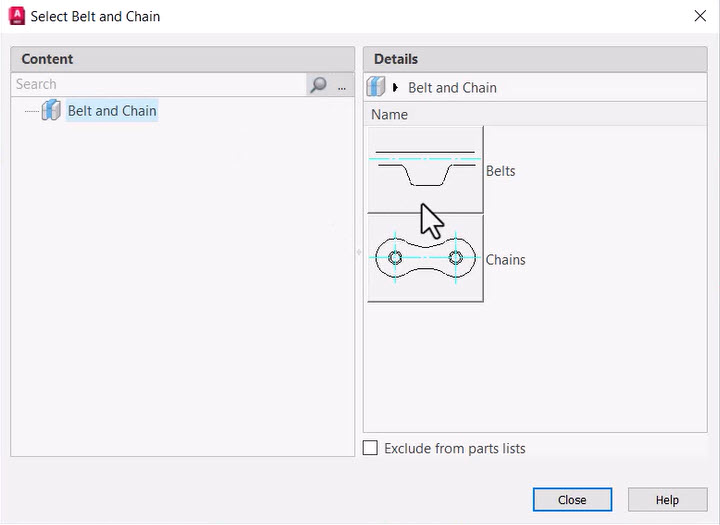

With the chain and belt tools, an AutoCAD Mechanical,

00:35

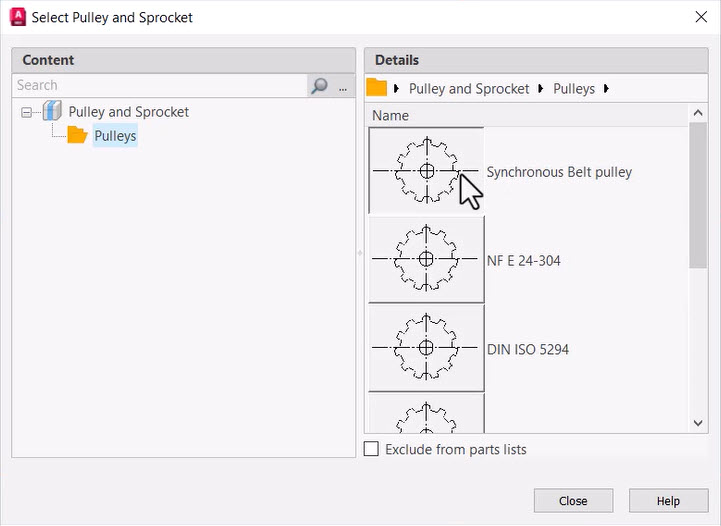

we can place sprockets for chains or pulleys for belts that have their geometry defined by the type of chain or belt that will be applied.

00:48

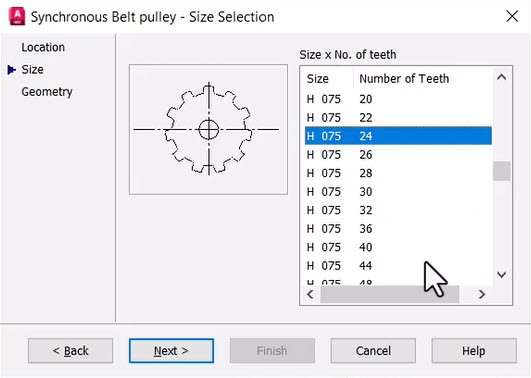

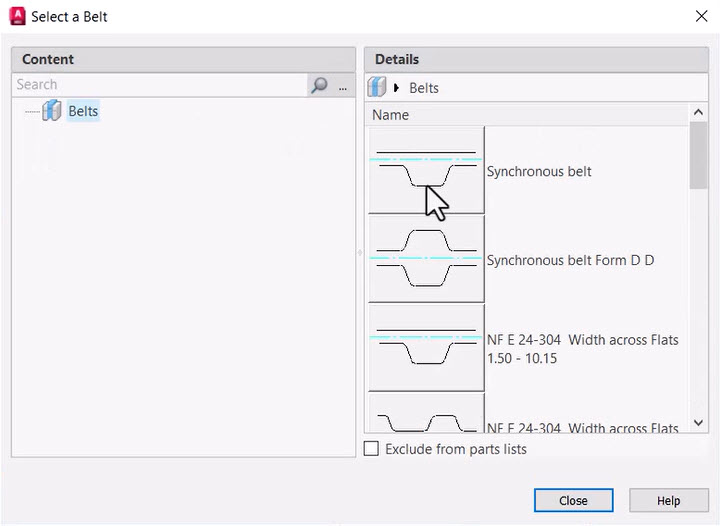

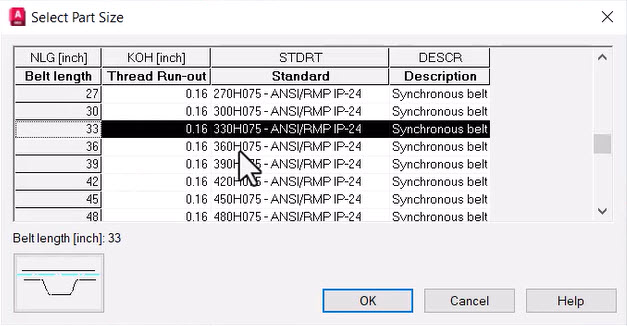

As you would expect from AutoCAD mechanical, there are a broad variety of standards available to you.

00:54

You'll need to select the standard and the number of teeth that you need.

00:58

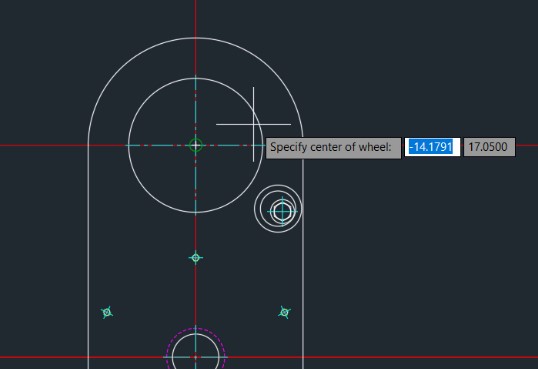

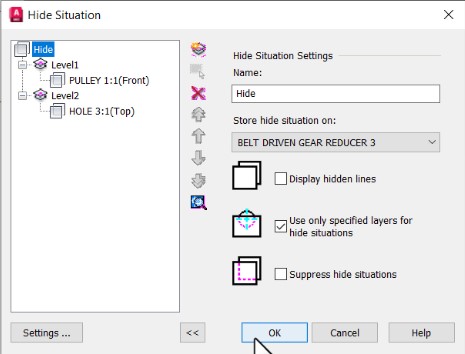

Placing it into the drawing, you'll be offered an opportunity to hide any objects or create hidden lines,

01:05

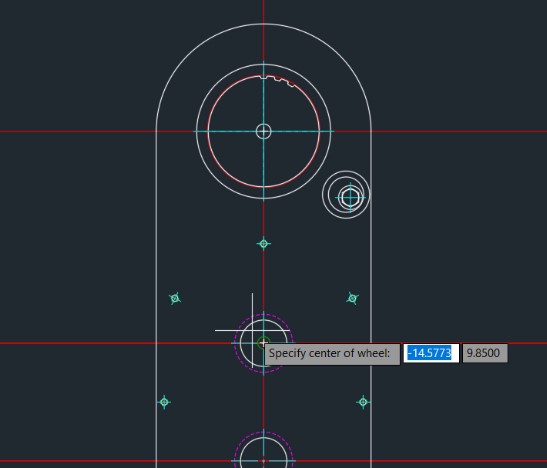

then we'll place the other sprocket.

01:08

Right now, of course, we're not exactly sure about how the spacing will work with the number of teeth that we need for this belt.

01:15

You can also do a function for calculating the number of teeth based on the sprocket spacing you need.

01:28

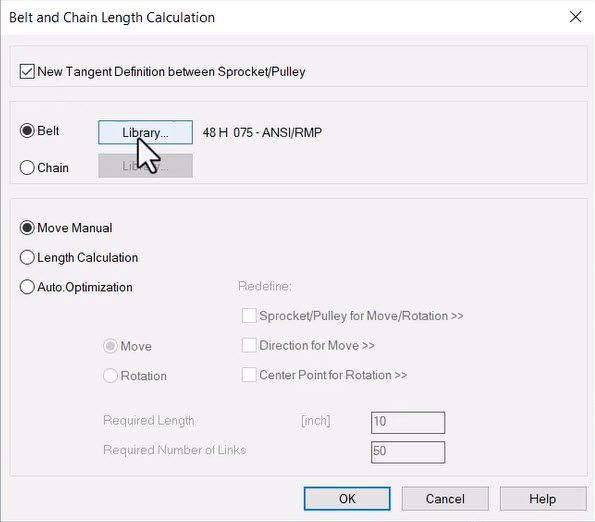

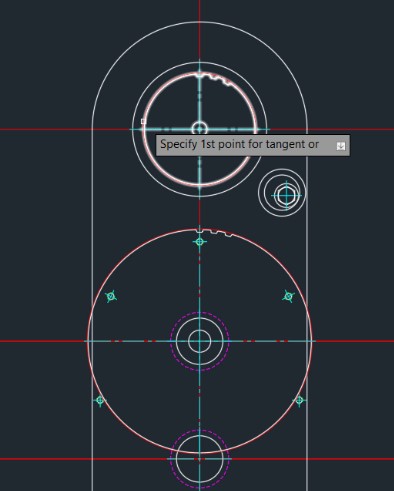

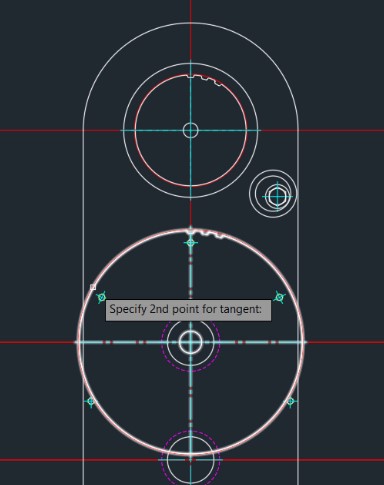

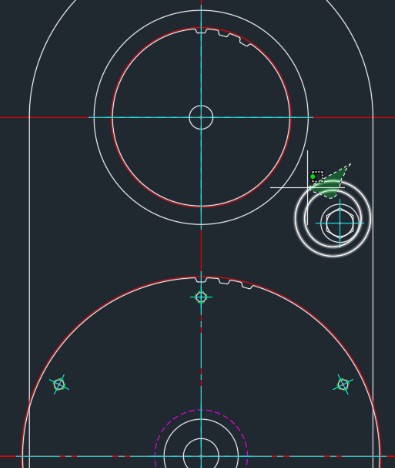

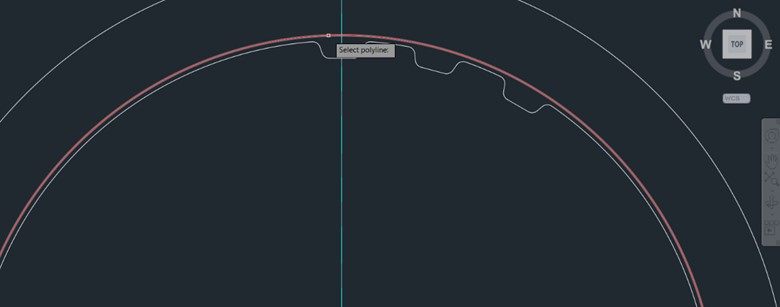

Once the pulleys are in place, AutoCAD mechanical makes it easy to define the path of the belt.

01:34

For this drawing, we have the two pulleys, but we also have an idler that's put in place.

01:47

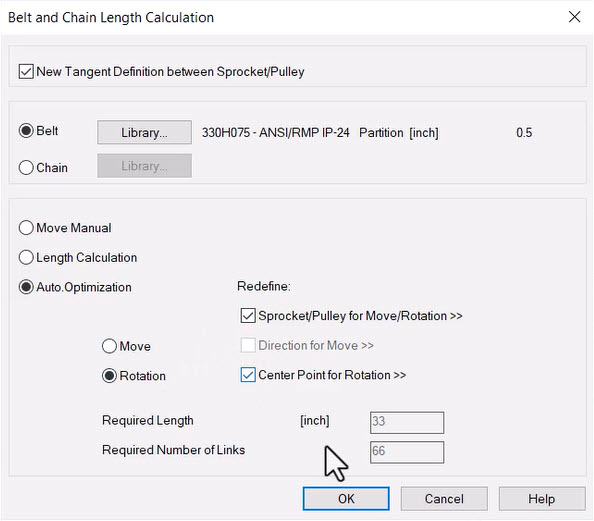

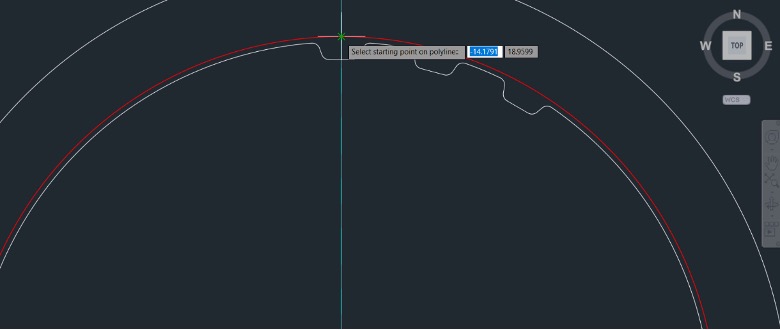

Selecting the belt with the number of teeth and the length that we need,

01:52

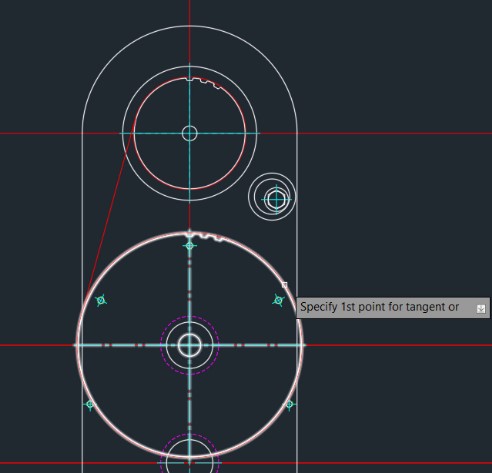

We'll tell it to automatically calculate how the idler needs to be positioned for this belt to fit in the design.

02:16

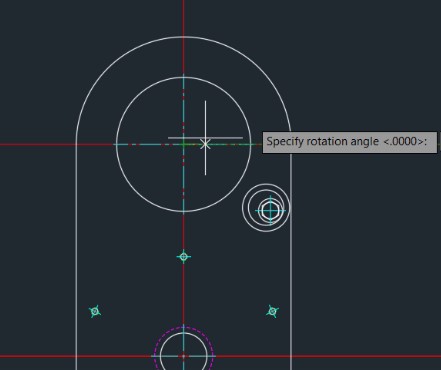

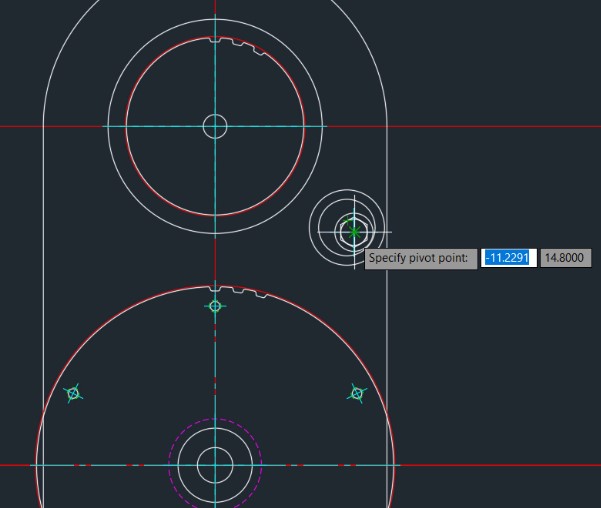

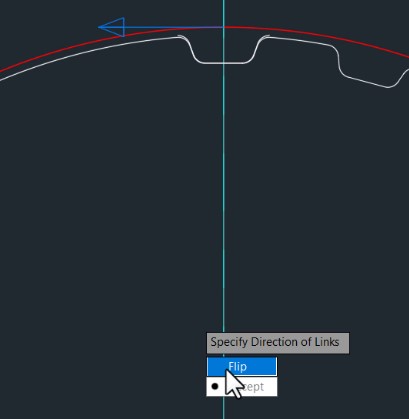

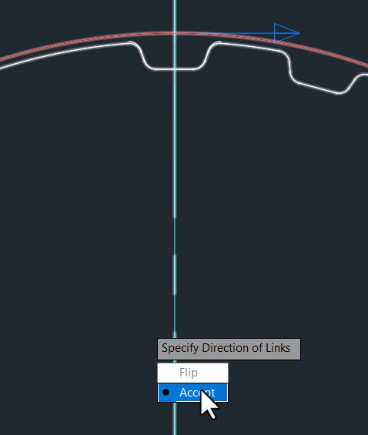

After the path has been established,

02:18

you can set the objects that need to be rotated and the center point and it will adjust the idler to fit a belt size that you can purchase.

02:31

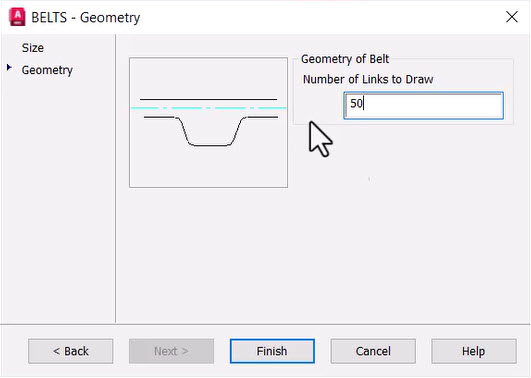

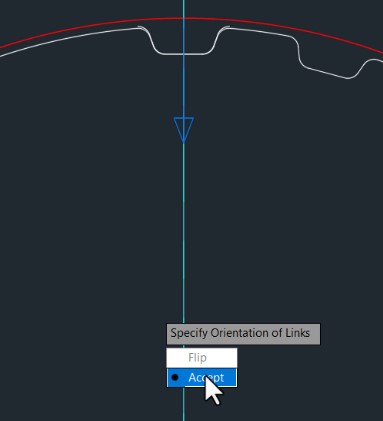

And returning more to the craft of drafting,

02:33

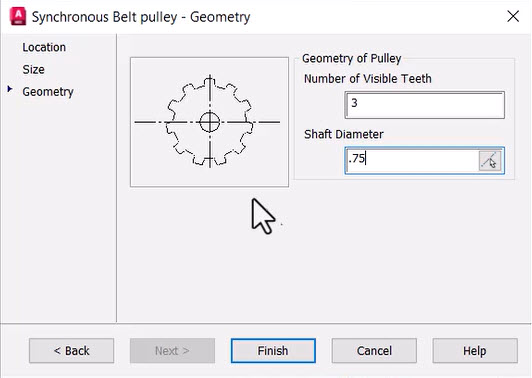

we want to make it easier for people to understand what type of object is in the drawing.

02:42

Selecting a position to start and establishing a number of teeth you want to add to the belt, it will go ahead and draw this in.

02:49

Skipping the process of having to create any sort of block for the belt and using an array tool to try and go around this complex curvature.

03:05

AutoCAD Mechanical does a phenomenal job of combining the convenience of being able to leverage standards,

03:10

and the drafting tools you need to present these objects in a way that people can easily understand.

00:04

Let's use the standard belt to define the required pulleys.

00:08

Calculate the proper location of an idler based on the belt length and insert a portion of the detailed belt in a drawing.

00:16

Not all standardized components are as convenient as bearings or fasteners that come in uniform sizes.

00:23

Objects like belts come in specific length, but you have to be able to make them fit in your design.

00:31

With the chain and belt tools, an AutoCAD Mechanical,

00:35

we can place sprockets for chains or pulleys for belts that have their geometry defined by the type of chain or belt that will be applied.

00:48

As you would expect from AutoCAD mechanical, there are a broad variety of standards available to you.

00:54

You'll need to select the standard and the number of teeth that you need.

00:58

Placing it into the drawing, you'll be offered an opportunity to hide any objects or create hidden lines,

01:05

then we'll place the other sprocket.

01:08

Right now, of course, we're not exactly sure about how the spacing will work with the number of teeth that we need for this belt.

01:15

You can also do a function for calculating the number of teeth based on the sprocket spacing you need.

01:28

Once the pulleys are in place, AutoCAD mechanical makes it easy to define the path of the belt.

01:34

For this drawing, we have the two pulleys, but we also have an idler that's put in place.

01:47

Selecting the belt with the number of teeth and the length that we need,

01:52

We'll tell it to automatically calculate how the idler needs to be positioned for this belt to fit in the design.

02:16

After the path has been established,

02:18

you can set the objects that need to be rotated and the center point and it will adjust the idler to fit a belt size that you can purchase.

02:31

And returning more to the craft of drafting,

02:33

we want to make it easier for people to understand what type of object is in the drawing.

02:42

Selecting a position to start and establishing a number of teeth you want to add to the belt, it will go ahead and draw this in.

02:49

Skipping the process of having to create any sort of block for the belt and using an array tool to try and go around this complex curvature.

03:05

AutoCAD Mechanical does a phenomenal job of combining the convenience of being able to leverage standards,

03:10

and the drafting tools you need to present these objects in a way that people can easily understand.