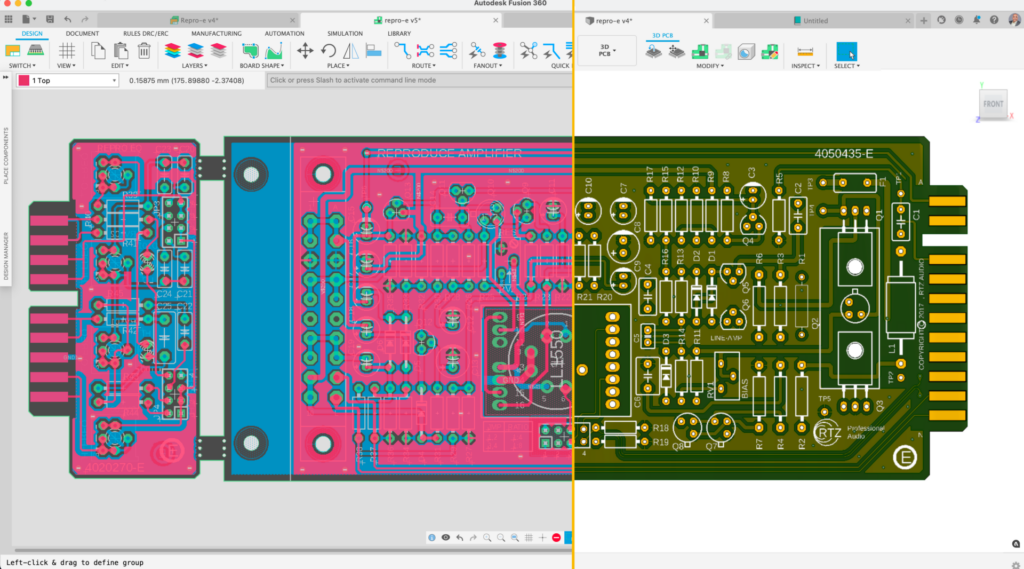

Fusion 360 includes a dedicated electronics workspace that caters to the needs of electronics engineers working on projects of any size. The Fusion 360 electronics workspace offers an extensive suite of tools and resources tailored for PCB design and provides a seamless transition from 2D circuit board layout to a functional PCB 3D model.

Here are 18 things you should know about Fusion 360 electronics. Even if you’re already using the workspace, you may learn something new.

1. Fusion 360 makes cross-disciplinary team collaboration easy

Before we dig into electronics-specific features, it’s important to understand collaboration tools in Fusion 360. As a whole, Fusion 360 is equipped with sophisticated collaboration functionalities instrumental in cross-disciplinary team engagement. It integrates electronics design tools with mechanical design, simulation, and manufacturing capabilities, thus providing a fluid, consolidated, and efficient design process.

Teams can share design files, leave comments within designs, and provide in-context feedback in real-time. This creates a conducive atmosphere for effective communication, ensuring the design process remains synchronized and enhances the confidence that products will meet desired specifications.

Digging even deeper into collaboration, Fusion 360 provides seamless integration between mechanical computer-aided design (MCAD) and electronic computer-aided design (ECAD) tools. This integration allows engineers to design PCBs within the context of the entire product, ensuring better collaboration and optimized product development. Changes in one domain are automatically reflected in the other, ensuring a synchronized design process. Learn more about how Fusion 360 makes electronics to mechanical workflows easy with seamless ECAD/MCAD integration.

2. You can import existing EAGLE designs into Fusion 360

Fusion 360 can assimilate design and library files created using Autodesk EAGLE. We have strategically incorporated the expansion of our import capabilities into our development roadmap to include files from a broader range of applications. Learn more about migrating from EAGLE to Fusion 360 electronics here.

3. Fusion 360 keeps Schematic and PCBs Synchronized

Fusion 360 offers a seamless design experience by maintaining a real-time link between the schematic design and the PCB layout. Any changes you make to the schematic are instantly reflected in the PCB layout, ensuring consistency and preventing conflicts. This synchronized workflow enables designers to work more efficiently, reduces the chances of errors, and significantly speeds up the design process.

4. Fusion 360 supports integration with Electronics Design Automation (EDA) tools

Fusion 360 offers an advanced level of integration with leading EDA tools, enabling electronics engineers to utilize their preferred EDA software within the sophisticated environment offered by Fusion 360. This harmonious integration establishes a fluid workflow, bridging schematic design and PCB layout in EDA tools to mechanical design and simulation. The result is a consolidated, efficient electronics design process.

5. Fusion 360 can perform Design Rule Checking (DRC) for PCB layouts

Fusion 360 includes real-time PCB layout Design Rule Checking (DRC) functionality. This feature empowers electronics engineers by facilitating the definition and enforcement of design principles during the design process and not as a post-process task. Ensuring designs adhere to manufacturing constraints and specifications, such as layer stack up with material assignment, clearances, and much more. The DRC utility within Fusion 360 aids in detecting potential issues within PCB layouts, thus guaranteeing the production of high-quality, manufacturable designs.

6. Fusion 360 can assist in integrating SPICE simulation for electronics design

Fusion 360 electronics schematic workspace SPICE simulation capabilities facilitate validating the expected performance of the electronic circuit. By integrating SPICE simulation, you can simulate any valid SPICE circuit, ensuring that your schematic design results align. This feature enables you to assess and verify the electronic designs’ functionality.

7. Fusion 360 electronics includes an Autorouter

Fusion 360 electronics includes an Autorouter, a powerful tool that automates routing complex electronic circuits following your DRC manufacturing preferences. You can select a particular signal(s) or the entire board to be Autorouted. The level of effort set will determine the number of results you can choose from when completed.

8. Fusion 360 has Differential Pair Routing

Differential Pair Routing is a technique developed to protect key signals in your design from common-mode noise. Fusion 360 includes Differential Pair routing for traces that require the same length. By invoking the Meander command, you can fine-tune the length of your Differential Pair.

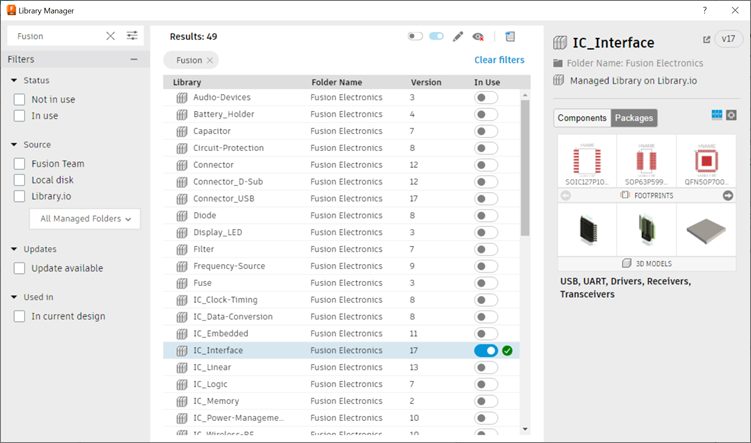

9. Fusion 360 has an electronic library component editor

Fusion 360 has a comprehensive set of libraries developed by our team and partners to meet various design needs. Should you find the necessity to create custom parts, the Library Editor within Fusion 360 is reliable and user-friendly. It includes IPC-compliant calculators that can build your footprint with 3D models in moments; you only need to transfer the details from the asset specification sheet to the calculator template.

10. You can export your PCB manufacturing files from Fusion 360

Fusion 360 includes a few options for exporting manufacturing files from your PCB, including industry-standard formats like Gerber and ODB++.

11. Fusion 360 supports Design Variant

Fusion 360’s Schematic editor allows you to create and manage design variants. This feature provides the flexibility to repurpose a schematic for different PCB variants without creating a new one from scratch. You can easily define and switch between various component values and part numbers or even enable and disable components per the requirements of different product variants.

12. The Fusion 360 Signal Integrity extension unlocks simulation

Fusion 360’s Signal Integrity extension offers simulation capabilities. It lets you visually identify signal impedance issues through a color-coded overlay on the 2D PCB design. Moreover, this extension also provides detailed data regarding signal length, transmitter-to-receiver time, inductance, resistance, capacitance, delay, and more.

13. You can define power planes in Fusion 360

Fusion 360 Electronics supports Polygon Copper pouring. Polygon copper pours on a PCB are crucial as they efficiently manage power distribution, thermal dissipation, and ground connections, thereby enhancing the overall performance and reliability of the electronic device. The polygon’s shape can be defined manually or by selecting the PCB outline. The polygon will automatically connect to assets with the same name as the polygon if it doesn’t violate the DRC constraints.

14. Fusion 360 supports Push and Shove Routing

Fusion 360’s Push and Shove capabilities offer a more advanced and interactive approach to PCB signal routing. This tool moves existing traces and vias to make space for new ones, enhancing the efficiency of the routing process. Furthermore, this feature also extends to the placement of new components. When a new part is added to the layout, Fusion 360 will attempt to adjust the existing traces and vias to accommodate the component.

15. You can route multiple signals simultaneously in Fusion 360

Fusion 360 offers many options for handling multiple signal routing. The fully manual capability gives you complete control over the path of the signals, offering maximum customization. Then there is the automatic routing feature, where Fusion 360 takes over and routes the selected traces independently. Lastly, there’s an interactive option where Fusion 360 tries to route the group based on a predefined path, balances automation, and manual control.

16. Fusion 360 offers a Quick Route toolset

Quick Route in Fusion 360 is a comprehensive toolset that drastically improves routing efficiency on a PCB. It offers multiple options catering to unique needs and preferences. For instance, one can use Quick Route interactively during manual routing. While manually routing, you can press ‘Enter’ and Fusion 360 will follow the defined design constraints, navigate around obstacles, and automatically complete the route. Additional options of Quick Route allow you to select and route individual signals and much more.

17. You can perform temperature simulations on your PCB

Fusion 360 offers a temperature cooling simulation capability for PCBs through the cooling extension. With the extension enabled, you can conduct cooling solutions to identify heating issues within their designs. You can effectively assess how their PCBs will respond under various cooling scenarios, including using cooling tools like fans.

18. You can manually route your signal on your PCB

Fusion 360 allows you to route your signals on your PCB manually. The software offers three routing modes for a tailored PCB designing experience.

- Full Manual mode gives you absolute control over your routing, including the power to override Design Rule Check (DRC) violations.

- The Walk Around mode ensures adherence to manufacturing constraints and automatically navigates around obstacles.

- Lastly, the Push and Shove mode routes your signals while moving existing traces and vias out of the way, still respecting the manufacturing constraints. This wide range of options ensures an efficient and effective routing process.

Ready to get started with Fusion 360 electronics?