Fusion 360 provides integrated CAD/CAM that allows users to quickly set up jobs and perform efficient 2.5 and 3-axis milling operations.

In today’s fast-paced work environment, time is a rare commodity, and a designer’s software must be up to the challenge. Autodesk’s Fusion 360 is more than prepared for any project requiring 2.5 and 3-axis milling. Engineers can use computer-aided design (CAD) tools to quickly organize projects from work holding and coordinate the system.

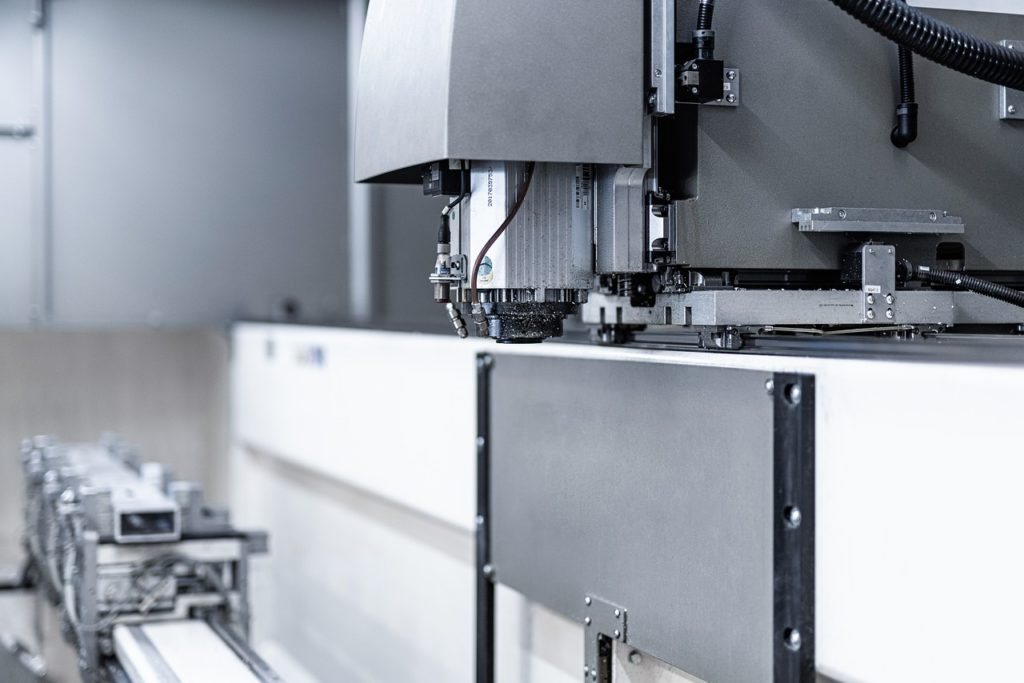

2.5-Axis Machining

When it comes to machining, 2.5-axis milling refers to the surface that is considered the projection of a plane into a third dimension. Of course, the object is three-dimensional, but there are no overhanging elements on the surface mentioned above. These surfaces are represented on the contour map, which identifies an object’s depth, height, and thickness from every angle.

Traditionally, 2.5-axis milling machines could mill on all three axes; however, the cutting operation could only be executed on two of the axes at a time. This was due in no small part to software and hardware limitations, like the lack of a true Z-axis.

3-Axis Machining

Three-axis machining is a natural progression from 2.5-axis machining with the incorporation of a true Z-axis. 3-axis machining is still commonly used across the manufacturing industry today. CAD and CAM software are essential for any computer numerical control (CNC) machine — the more axes involved, the more complicated it is to program milling instructions. This is where Fusion 360 has the advantage.

Fusion 360 and Machining

The integrated, cloud-based Fusion 360 platform provides various tools for engineers and designers in any manufacturing setting. Fusion 360 has a variety of extensions that you can purchase to unlock more advanced capabilities. Extensions are a flexible and financially feasible option for extending Fusion 360 capabilities.

The Fusion 360 Machining Extension, for example, contains features like additional controls for tool orientation, part alignment, hole recognition, and much more.

Fusion 360 Machining Applications

When it comes to 2.5 and 3-axis machining, Fusion 360 allows designers to rough parts efficiently with adaptive clearing — a proprietary algorithm that maintains a constant load on the tool with a constant engagement angle — enabling deeper, faster, and evenly distributed cuts along the whole flute length. Fusion 360 also provides a complete 2D and 3D suite that allows finishing operations as needed.

Intuitive controls across all operations eliminate complex menus and create a comfortable user interface. Fusion 360 is built on a 64-bit, multi-core engine, which enables smooth multitasking performance. Power users can benefit from Fusion 360, as it supports REST machining, form tools, intelligent parameters, and an unlimited number of machining templates.

In addition, Fusion 360 also includes a dynamic stock simulation to verify tool paths before posting them, generates setup sheets, and communicates effectively with machine operators to reduce the chance of setup errors. You can also add the Machining Extension for multi-axis capabilities for increased complexity.

Download Fusion 360 today to experience an integrated high-performance, cloud-based CAD, CAM, and CAE solution.