Everybody’s talking about the digital factory. But how do you even get started building one?

A digital factory is a factory where everything is digitized, collaboration is prioritized, and paper-based processes are eliminated. Whether you’re starting a digital factory from scratch or reconfiguring an existing operation, here are three considerations to take into account.

1. Start with a plan and design collaboratively

Like any new project or design, you need to create a plan. First, start with a deep analysis of workflows and the correlating station and equipment locations that can maximize productivity. Simulating the movements of people, machines, and materials can help reveal new efficiencies to eliminate bottlenecks and speed time to market.

With the plan in place, a manufacturing framework begins to emerge for the design phase. This is a truly collaborative step in the process. Engineers and operators need to help define and plan the physical space. Any stakeholders in the factory should share their insights for optimization. It’s also a prime opportunity to think about how automation can help.

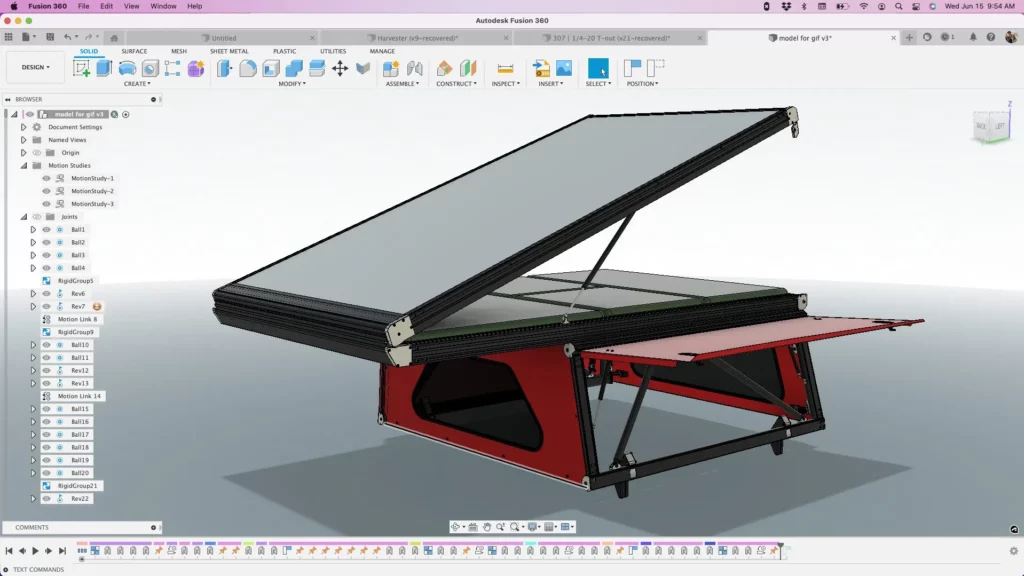

Go Fast Campers

Take Go Fast Campers and how they have embraced automation for the design and manufacturing of their innovative truck-top campers as an example. In a few short years, they have grown from a few employees to more than 70 and moved to a larger manufacturing facility where robotics play a central role. One person runs five automated machining cells, and they can change parts in under five minutes.

“Without the robots, we wouldn’t be able to do it,” says Wiley Davis, founder and CEO, Go Fast Campers in a recent Fusion 360 blog article. “We’d have so many people standing at machines all day putting parts in and out of machines. These campers would cost twice as much, and it wouldn’t be a viable product at that point.”

“With Fusion 360 for our production process and CAM, we essentially have the entire robot system modeled in there,” he continues. “When we program a new part in Fusion 360, it’s all systematized around a template. You can program a part, and no one has to re-indicate or set up a machine differently. You just program the part machine and the job and run it.”

2. Make data the priority

Data is the fundamental backbone of a digital factory. The more data manufacturers have, the more agile they can be. Accessible data on the cloud leads to better organization, which creates a stronger, more resilient company.

For a digital factory, the software used is crucial. With Autodesk Fusion 360 and Autodesk Fusion Operations, you’re able to put data to work for you. Shared data between people, processes, and machines provide a symbiotic relationship that spurs better products, faster time to market, more sustainable results, decreased downtime, and increased efficiencies from the top floor to the shop floor.

Romar Engineering

Romar Engineering is a leading manufacturer for micro-molding and silicone injection molding projects in Australia. They recently embarked on their own digital transformation to streamline and enhance collaboration.

“When it comes to Fusion 360, it’s the whole concept of the ability to share models, create assemblies in one file, see all the component dependencies, doing all your motion studies, and figuring out interfaces in one place,” says Steve Milanoski, head of advanced manufacturing, Romar Engineering in a recent Fusion 360 blog article.

3. Prepare for a culture shift

Change isn’t always easy, especially when it comes down to familiar processes and software. But a digital transformation will enhance everyone’s roles — not hinder it. It can take some time and convincing.

Milanoski shared more of his experience. “Adoption isn’t a technical problem, it’s a cultural problem,” he says. “Get it in people’s hands and incentivize them to learn it.”

“Give employees the space to learn Fusion 360 themselves,” he continues. “Don’t just drop it in their lap and say, ‘This is what we’re using.’ Let them be part of the selection process and the pushing process. Have them try to break the software. Challenge them to make Fusion 360 do things that other software can’t.”